DH Robotics Technology AG-95 User manual

Product Manual

(AG-95)

Shenzhen DH Robotics Technology Co., Ltd.

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

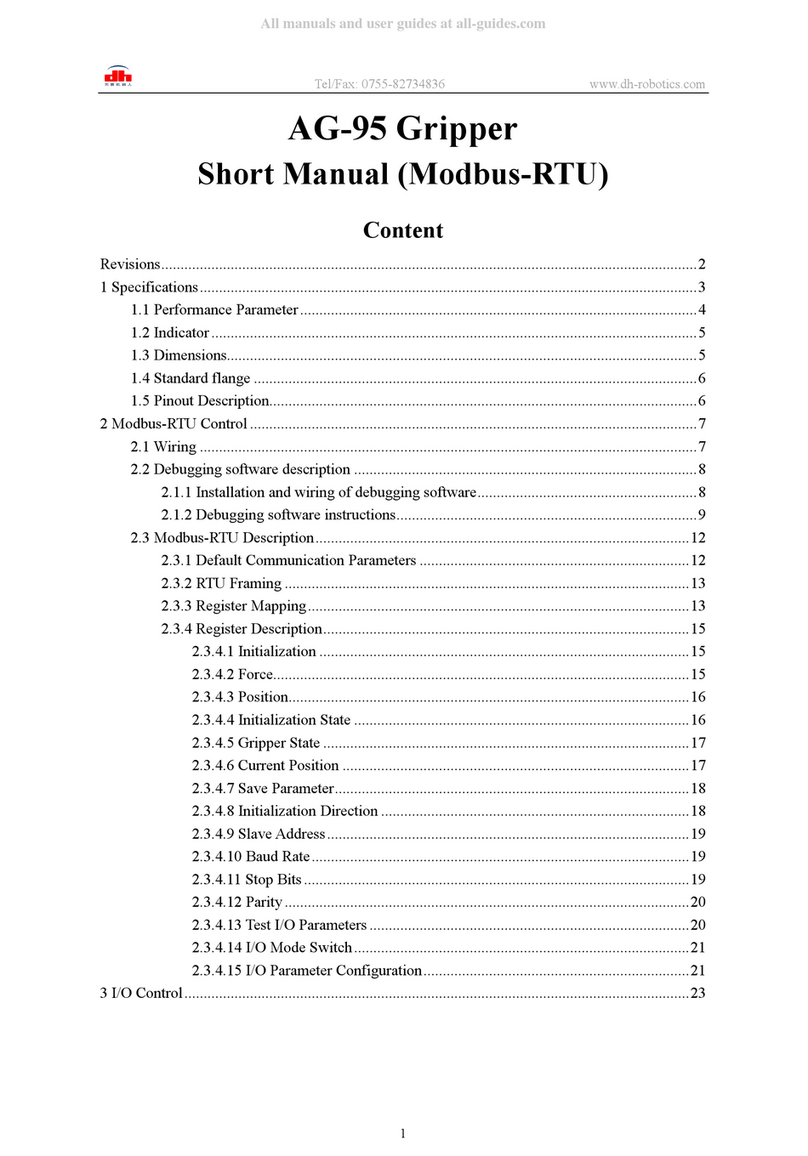

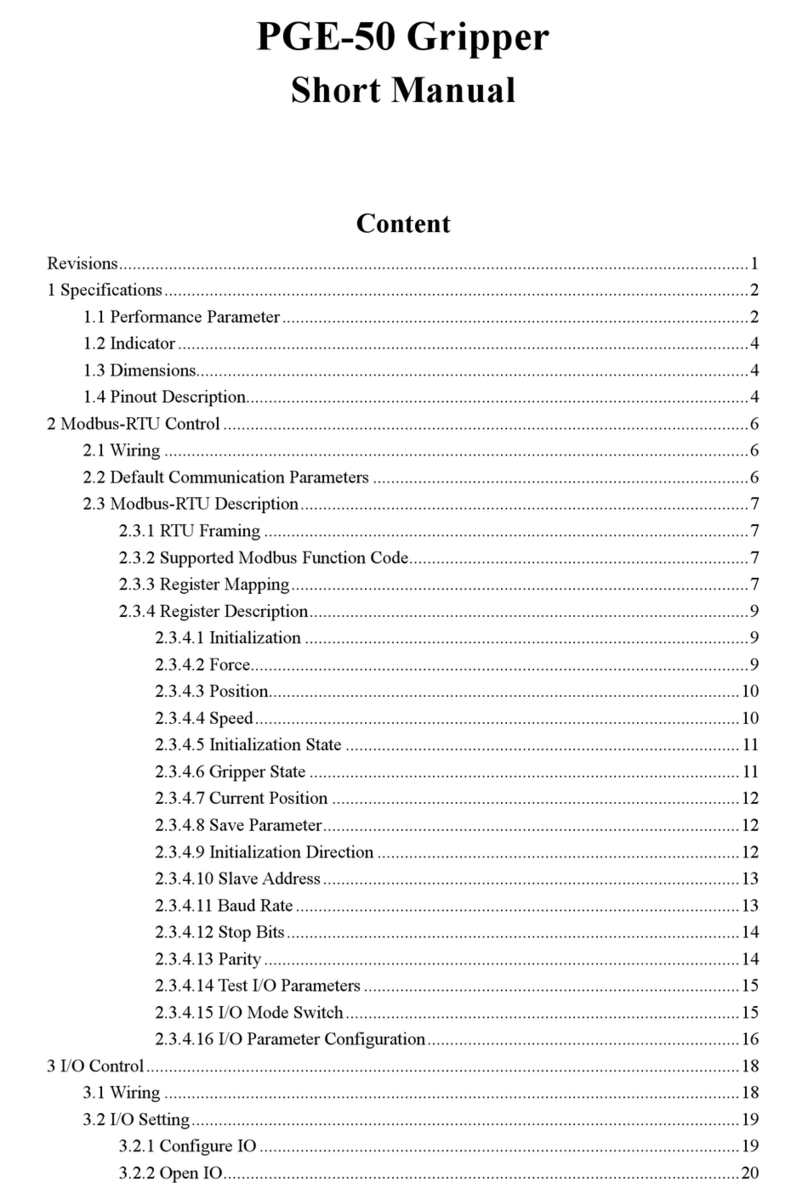

Content

1 Specifications.................................................................................................................................1

2 Connection methods.......................................................................................................................3

3 Connect and control .......................................................................................................................5

3.1 Introduction.........................................................................................................................5

3.2 Communication logic..........................................................................................................5

3.3 Protocol format ...................................................................................................................6

3.4 Command Overview ...........................................................................................................7

3.5 Detailed command ..............................................................................................................7

3.5.1 Initialization .............................................................................................................7

3.5.2 Force.........................................................................................................................8

3.5.3 Position.....................................................................................................................8

3.5.4 Feedback ..................................................................................................................9

3.5.5 I/O Mode..................................................................................................................9

3.5.6 CAN ID..................................................................................................................11

3.5.7 Firmware Version...................................................................................................12

3.5.8 CAN Baud Rate......................................................................................................12

3.5.9 Object Droped........................................................................................................13

4 Protocol Converter .......................................................................................................................14

4.1 Working Mode Selection...................................................................................................14

4.2 Parameter Configuration Mode.........................................................................................15

4.3 USB Mode ........................................................................................................................15

4.4 TCP Client Mode ..............................................................................................................16

4.5 TCP Server Mode..............................................................................................................17

4.6 RS485 Mode .....................................................................................................................18

4.7 I/O Mode...........................................................................................................................19

4.7 CAN2.0A Mode ................................................................................................................21

4.4 Installation and Use of Debugging Software ....................................................................22

4.4.1 Overview................................................................................................................22

4.4.2 Software Installation ..............................................................................................22

4.4.3 User Interface.........................................................................................................25

4.4.4 Gripper Connection and Initialization....................................................................25

4.4.4.1 Composition and Introduction.....................................................................25

4.4.4.2 Connection Mode and Port Setting .............................................................26

4.4.4.3 Communication Control and Status Display ...............................................27

4.4.5 Gripper Control......................................................................................................28

4.4.6 Parameter Setting Zone..........................................................................................29

4.4.6.1 Composition and Introduction.....................................................................29

4.4.6.2 Gripper Parameter Setting...........................................................................30

4.4.7 Gripper Setting Instructions ...................................................................................31

4.4.7.1 Setting of Activated Feedback of Initialization...........................................31

4.4.7.2 Gripper ID Setting.......................................................................................31

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

4.4.7.3 Setting of Gripper CAN Baud Rate.............................................................32

4.4.7.4 Setting of Relevant Parameters of I/O Mode ..............................................32

4.4.8 Parameter Setting of Protocol Converter ...............................................................33

5. Robot Plugin ...............................................................................................................................35

5.1 UR Robot Plugin...............................................................................................................35

5.1.1 Installation (UR + CB Series) ................................................................................35

5.1.2 Robot Setup (UR+ CB series) ................................................................................37

5.1.3 Operating Instructions (UR + CB Series) ..............................................................39

5.1.4 Installation (UR+ e Series).....................................................................................43

5.1.5 Robot Setup (UR+ e Series)...................................................................................45

5.1.6 Operating Instructions (UR+ e Series)...................................................................46

5.1.7 Script Commands (Universal for UR+ CB Series and e Series) ............................47

5.2 Hanwha Robot Plugin .......................................................................................................48

5.2.1 Installation..............................................................................................................48

5.2.2 Robot Setup............................................................................................................50

5.2.3 Operating Instructions............................................................................................51

5.2.4 Script Commands...................................................................................................53

5.3 Aubo Robot Plugin............................................................................................................54

5.3.1Installation...............................................................................................................54

5.3.2 Robot Setup............................................................................................................55

5.3.3 Operating Instructions............................................................................................56

5.3.4 Script Commands...................................................................................................58

6 Maintenance.................................................................................................................................59

6.1 Daily Cleaning ..................................................................................................................59

6.2 Fingertip Replacement ......................................................................................................59

6.3 Periodic Inspection and Maintenance ...............................................................................60

6.4 Part Numbers.....................................................................................................................61

7 Common Faults and Troubleshooting ..........................................................................................62

7.1 Meanings of Gripper Indicators ........................................................................................62

7.2 Common Faults and Solutions ..........................................................................................62

8 Certificates ...................................................................................................................................65

9 Warranty and Statement ...............................................................................................................68

10 Contact us...................................................................................................................................69

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

1

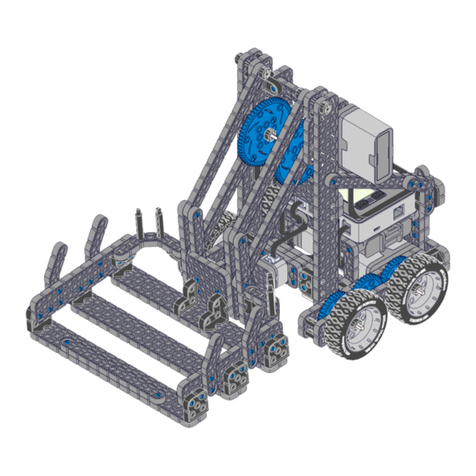

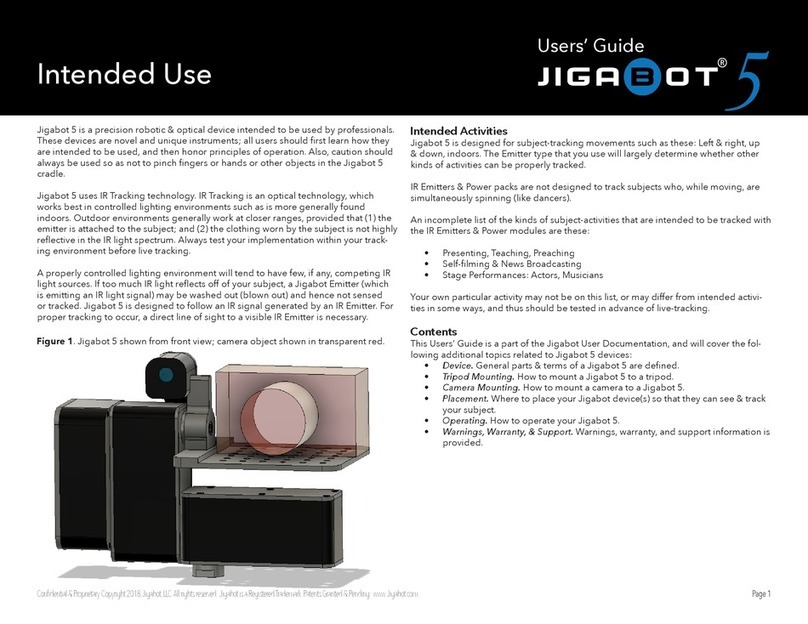

1 Product overview

The electric gripper of AG-95 has two joints, which are respectively composed of multiple link

mechanisms and one spring, as shown in Figure 1.1. The gripper can engage up to 5 contact points

of contact with an object (two on each of the phalanges plus the palm). The fingers are under-

actuated, indicating they have fewer motors than the total number of joints. This design allows the

fingers to automatically adapt to the shape of the object they grip and it also simplifies the control

method. It has the following characteristics:

Controllable force position: the gripper can program and adjust the clamping position,

clamping force value .

Multiple communication modes: support CAN2.0A, USB2.0, TCP / IP, RS485, IO,

EtherCAT (optional).

Clamping judgment: the combination of force control and position control is adopted in the

clamping process.

Clamping feedback: the status of the gripper can be read by programming, and can also be

judged according to the indicator light of the gripper.

Various clamping methods: the clamping angle of gripper can be modified adaptively. Then

it can produce three kinds of clamping methods: centering clamping, parallel clamping and

vertical clamping, which can achieve the most appropriate clamping position and angle for the

clamping objects.

Fingertips can be customized: fingertips can be replaced according to real-time situation,

which is suitable for precision machining, parts assembly and other fields.

Fig 1.1 AG-95 Gripper appearance

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

2

1.1 Specifications

The specific parameters of AG-95 electric gripper are listed in Table 1.1.

Specifications

Maximum recommended load

3*kg

Finger opening stroke

0-95mm

Gripper force

45-160N

Maximum finger opening and

closing speed

136mm/s

Supply voltage

24V DC±10%

Minimum closing time

0.7s

IP Rating

IP40

Communication protocol

TCP/IP, USB2.0, RS485, I/O,

CAN2.0A, Ethernet (optional),

Profinet (optional)

Note:* Depend on the shape of the grib object and the friction of the contact surface. The object's center

of gravity deviation can also affect the load. If you have any questions, please contact us.

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

3

2 Connection methods

The electric gripper of AG-95 use CAN for communication, which supports CAN2.0A version.

In order to communicate with other protocols, we develop protocol converter to support other

communication protocol, such as TCP/IP , USB , RS485 IO .If the system itself supports CAN , you

can also connect the gripper directly to the system without using a communication protocol

converter.

You can refer to the electrical connection diagram for communication connection of the

gripper (as shown in Figure 2.1)

Figure 2.1 The electrical connection diagram

Taking Ethernet connection as an example, we connect the protocol converter, as shown in

Figure 2.2.

Description of connection of gripper

·Use the aviation plug cable provided by our company to connect the gripper and

communication protocol converter.

·Insert the bent end of the cable into the gripper end; insert the straight end of the cable into

the converter.3

·The interfaces of Ethernet, RS485, USB, IO, can and power supply have been marked on

the side plate of protocol converter respectively. Users can connect the corresponding ports

with the controller according to the requirements.

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

4

Figure 2.2 Ethernet connection diagram

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

5

3 Connect and control

3.1 Introduction

The AG-95 adaptive Gripperuse aviation connector to connect the CAN network. It supports the

CAN protocols version 2.0A.

For environments without a CAN network, we have provided a protocol converter to transfer

other interfaces (like USB, TCP/IP, RS485, I/O) to CAN2.0A.

You can also connect it directly to the CAN network without the protocol converter.

The communication system block diagram is as follows

PC/PLC/Robot protocol

converter Gripper

USB/(TCP/IP)/RS485/(I/O) CAN2.0A

CAN2.0A CAN2.0A

solution

solutionsolution

RS485/CAN2.0A/(I/O)

Figure 3.1 The communication system

3.2 Communication logic

1. Successfully receive feedback:The gripper will return the same data after successfully

receiving the command.

2. Initialization success automatic feedback:After the initialization is successful, the

success flag will be returned automatically.

3. Initialization can be interrupted:The initialization process can be interrupted by a new

initialization command, and start a new initialization process. It is recommended to check

the relevant flags to avoid frequent interruptions.

4. Position command can be interrupted: The moving process can be interrupted by a

new positon command, and gripper will move to the new position. It is recommended to

check the relevant flags to avoid frequent interruptions.

5. Guaranteed setting successfully:The setting command (CAN ID, CAN Baud rate, I/O

Mode) will return after the setting is successful, so gripper will not return the same data

immediately.

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

6

6. Command interval:It is recommended that the send interval between the command and

the command is above 20 milliseconds.

7. Drop detection:The diameter of the object needs to be greater than 5mm.

3.3 Protocol format

(For TCP/IP, USB, RS485)

All external communication interfaces (except CAN and I/O interfaces) send commands to the

protocol converter in the following format (a total of 14 bytes).

Table 3.1 data format

Frame header

Gripper

ID

Data Segment(8 Bytes)

Frame End

Function

Re gister

Sub-Function

register

Read/Write

Reserve

Data

4 Bytes

(0xFFFEFDFC)

1 Byte

1 Byte

1 Byte

1 Byte

1 Byte

(0x00)

4 Bytes

1 Byte

(0xFB)

(For CAN2.0A)

The CAN ID is the gripper ID. The 8 bytes data is as follows:

Table 3.2 CAN data format

Function

register

Sub-Function

register

Read/Write

Reserve

Data

1 Byte

1 Byte

1 Byte

1 Byte

(0x00)

4 Bytes

The command consists of four parts: frame header, Gripper ID, data segment, and the end of the

frame. the frame header and the end of the frame are fixed。

1. Frame header:The command starts with 0xFFFEFDFC, and the protocol converter will

recognize this field to determine the start of the command.

2. Gripper ID: The Gripper ID in the command is the actual CAN ID of the gripper(The default

is 1), range : 0-255.(The “Gripper ID” in the following example is the default value of 1)

3. Data segment:It is the actual command, the data segment is also the CAN data segment,

when using the CAN interface as the communication interface, the command has 8 bytes, and there

is no need to add a frame header and end.

Function register:It is used to identify the main function of the command

Sub-Function register:It is used to identify the use function of the command

Read/Write:Only 0x00 and 0x01 are allowed,0x00 indicates that the command is a read

command, and 0x01 indicates that the command is a write command.

Reserve:unused, default is 0x00

Data:32-bits signed integer,value range: 0x00000000 – 0xFFFFFFFF,little endian mode,

For example, 1 = 01 00 00 00, -1 = FF FF FF FF.(The data has no effect during the read operation.)

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

7

4. Frame End:The command starts with 0xFB and the protocol converter will recognize this

field to determine the end of the command.

example:Initialization --- FF FE FD FC 01 08 02 01 00 00 00 00 00 FB

3.4 Command Overview

Function

Function

register

Sub-Function

register

REMARK

Initialization

0x08

0x01-0x02

Initialize related commands

Force

0x05

0x02-0x03

Read/ Write opening/closing Force

Postion

0x06

0x02

Read/ Write Position

Feedback

0x0F

0x01

Read current status

IO mode

0x10

0x01-0x0B

Set/read the IO mode command.

CAN ID

0x12

0x01

Read/ Write Gripper CAN ID

Version

0x13

0x01

Read Current Gripper firmware

version

CAN

BAUDRATE

0x14

0x01

Read/ Write Gripper CAN Baud

Rate

Drop

detection

0x15

0x01/0x02

Related to the drop detection

3.5 Detailed command

3.5.1 Initialization

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x08

0x01

0x00/0x01

0x00

Integer

Read/Write Initialization

feedback

0x02

0x00/0x01

Integer

Read/Write

When the Sub-Function register value is 0x01, the function of this command is to read and

write whether feedback after finish initialization.

Example:

Set Initialization feedback:

Send :FF FE FD FC 01 08 01 01 00 00 00 00 00 FB

Receive :FF FE FD FC 01 08 01 01 00 A5 00 00 00 FB

Read whether feedback :

Send :FF FE FD FC 01 08 01 00 00 00 00 00 00 FB

Receive :FF FE FD FC 01 08 01 00 00 A5 00 00 00 FB (YES)

OR:

Receive :FF FE FD FC 01 08 01 00 00 00 00 00 00 FB (NO)

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

8

When the Sub-Function register value is 0x02, the function of this command is to initialize

gripper or read whether finish initialization.

initialization :

Send :FF FE FD FC 01 08 02 01 00 00 00 00 00 FB

Receive :FF FE FD FC 01 08 02 01 00 00 00 00 00 FB

After set Initialization feedback:

Receive :FF FE FD FC 01 08 02 00 00 00 00 00 00 FB

read whether finish initialization :

Send :FF FE FD FC 01 08 02 00 00 00 00 00 00 FB

Receive :FF FE FD FC 01 08 02 00 00 01 00 00 00 FB (Finished)

OR:

Receive :FF FE FD FC 01 08 02 00 00 00 00 00 00 FB (Not finished)

3.5.2 Force

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x05

0x02/0x03

0x00/0x01

0x00

Integer

Read/Set Opening/Closing

Force

The function of this command is to read and write the gripper Force (internal and external grip):

Data range:20-100 (14 00 00 00 – 64 00 00 00)

Example:(0x1E = 30)

Set 30% closing grip force:

Send:FF FE FD FC 01 05 02 01 00 1E 00 00 00 FB

Receive :FF FE FD FC 01 05 02 01 00 1E 00 00 00 FB

Read current closing grip force:

Send :FF FE FD FC 01 05 02 00 00 00 00 00 00 FB

Receive :FF FE FD FC 01 05 02 00 00 1E 00 00 00 FB

3.5.3 Position

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x06

0x02

0x00/0x01

0x00

Integer

Read/Write Position

The function of this command is to read and write the gripper position:

Data range: 0-100 (00 00 00 00 – 64 00 00 00)

Example: (0x3C = 60)

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

9

Set 60% position:

Send :FF FE FD FC 01 06 02 01 00 3C 00 00 00 FB

Receive :FF FE FD FC 01 06 02 01 00 3C 00 00 00 FB

Read current position:

Send:FF FE FD FC 01 06 02 00 00 00 00 00 00 FB

eceive:FF FE FD FC 01 06 02 00 00 3C 00 00 00 FB

3.5.4 Feedback

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x0F

0x01

0x00

0x00

Integer

Read current status

The function of this command is to read and write the gripper current status.

00 00 00 00 :default or moving

02 00 00 00 :Arrive positon/rotation but not catch object

03 00 00 00 :Catch the object but not arrive position/rotation

Example:

Read current status:

Send:FF FE FD FC 01 0F 01 00 00 00 00 00 00 FB

Receive default:FF FE FD FC 01 0F 01 00 00 00 00 00 00 FB OR:

Arrive positon :FF FE FD FC 01 0F 01 00 02 00 00 00 00 FB

OR:

Catch the object :FF FE FD FC 01 0F 01 00 03 00 00 00 00 FB

3.5.5 I/O Mode

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x10

0x01

0x00/0x01

0x00

Integer

Read/Write Group 1 Position 1

0x02

Read/Write Group 1 Position 2

0x03

Read/Write Group 1 Force 1

0x04

0x01

Control Group 1 grip

0x05

0x00/0x01

Read/Write Group 2 Position 1

0x06

Read/Write Group 2 Position 2

0x07

Read/Write Group 2 Force 1

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

10

0x08

0x01

Control Group 2 grip

0x09

0x00/0x01

Read/Write Enable I/O Mode

0x0A

0x00/0x01

Read/Write Group 1 Force 2

0x0B

0x00/0x01

Read/Write Group 2 Force 2

I/O mode is a simple communication mode. The status of the input pin is detected by the

protocol converter with I/O interface, and the command is sent to the gripper according to the

current pin status. There are two input pins on the protocol converter, each pin recognizes two

input states, and corresponds to four states in total.

Sub-functions 0x01-0x03, 0x05-0x07, 0x0A-0x0B ,These 8 sub-functions are the write

force and the target position. For the value range, refer to the force command and position

command section above.

(Position 1 is bound to force 1, position 2 is bound to force 2)

Sub-function 0x04 and 0x08, command that the protocol converter sends in I/O mode.

Sub-function 0x09, write/read I/O mode switch status.

Example:

Enable I/O mode:

Send:FF FE FD FC 01 10 09 01 00 01 00 00 00 FB

Receive :FF FE FD FC 01 10 09 01 00 01 00 00 00 FB

Set I/O mode parameter:

Send:FF FE FD FC 01 10 01 01 00 00 00 00 00 FB (Set Group 1 Position 1 0)

Receive :FF FE FD FC 01 10 01 01 00 00 00 00 00 FB

Send :FF FE FD FC 01 10 02 01 00 5A 00 00 00 FB (Set Group 1 Position 2 90)

Receive :FF FE FD FC 01 10 02 01 00 5A 00 00 00 FB

Send :FF FE FD FC 01 10 03 01 00 5A 00 00 00 FB (Set Group 1 force 1 90)

Receive :FF FE FD FC 01 10 03 01 00 5A 00 00 00 FB

Send :FF FE FD FC 01 10 0A 01 00 3C 00 00 00 FB (Set Group 1 force 2 60)

Receive :FF FE FD FC 01 10 0A 01 00 3C 00 00 00 FB

Send :FF FE FD FC 01 10 05 01 00 1E 00 00 00 FB (Set Group 2 Position 1 30)

Receive :FF FE FD FC 01 10 05 01 00 1E 00 00 00 FB

Send :FF FE FD FC 01 10 06 01 00 3C 00 00 00 FB (Set Group 2 Position 2 60)

Receive :FF FE FD FC 01 10 06 01 00 3C 00 00 00 FB

Send :FF FE FD FC 01 10 07 01 00 3C 00 00 00 FB (Set Group 2 Force 1 60)

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

11

Receive :FF FE FD FC 01 10 07 01 00 3C 00 00 00 FB

Send :FF FE FD FC 01 10 0B 01 00 5A 00 00 00 FB (Set Group 2 Force 2 90)

Receive :FF FE FD FC 01 10 0B 01 00 5A 00 00 00 FB

I/O Control:

Send :FF FE FD FC 01 10 04 01 00 00 00 00 00 FB (gripper grip to Group 1 Position

1)

Receive :FF FE FD FC 01 10 04 01 00 00 00 00 00 FB

Send :FF FE FD FC 01 10 04 01 00 01 00 00 00 FB (gripper grip to Group 1 Position

2)

Receive :FF FE FD FC 01 10 04 01 00 01 00 00 00 FB

Send :FF FE FD FC 01 10 08 01 00 00 00 00 00 FB (gripper grip to Group 2 Position

1)

Receive :FF FE FD FC 01 10 08 01 00 00 00 00 00 FB

Send :FF FE FD FC 01 10 08 01 00 01 00 00 00 FB (gripper grip to Group 2 Position

2)

Receive :FF FE FD FC 01 10 08 01 00 01 00 00 00 FB

3.5.6 CAN ID

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x12

0x01

0x00/0x01

0x00

Integer

Read/Set Gripper CAN ID

The function of this command is to read and write the CAN ID. (default: ID = 1)

After the CAN ID has been set successfully, the gripper must be reboot.Data Range: 1-

255 (01 00 00 00 – FF 00 00 00)

When user don’t know or forget gripper CAN ID, user can use ID 0 to read or set gripper CAN

ID.

Example:

Set CAN ID to 2:

Send:FF FE FD FC 01 12 01 01 00 02 00 00 00 FB (when ID=1,set ID to 2)

Receive :FF FE FD FC 01 12 01 01 00 02 00 00 00 FB

OR: (when you don’t know current ID)

Send:FF FE FD FC 00 12 01 01 00 02 00 00 00 FB (use ID=0,set ID to 2)

Receive :FF FE FD FC 00 12 01 01 00 02 00 00 00 FB

Read CAN ID:

Send:FF FE FD FC 02 12 01 00 00 00 00 00 00 FB(when ID=2,read ID)

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

12

Receive:FF FE FD FC 02 12 01 00 00 02 00 00 00 FB

OR: (when you don’t know current ID)

Send:FF FE FD FC 00 12 01 01 00 00 00 00 00 FB (use ID=0 to read ID)

Receive:FF FE FD FC 00 12 01 01 00 02 00 00 00 FB

3.5.7 Firmware Version

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x13

0x01

0x00

0x00

0x00000000

Read gripper firmware version

The function of this command is to read gripper current firmware version.

Example:

Read firmware version:

Send:FF FE FD FC 01 13 01 00 00 00 00 00 00 FB

Receive:FF FE FD FC 01 13 01 00 00 00 02 01 04 FB

3.5.8 CAN Baud Rate

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x14

0x01

0x00/0x01

0x00

Integer

Read/Set Gripper CAN Baud Rate

The function of this command is to read and write the CAN baud rate.

After the CAN baud rate has been set successfully, the gripper must be reboot.

Data range: 0-5 (00 00 00 00 – 05 00 00 00)

Table 3.10 Baud Rate

Index

Baud Rate

0

500Kbps

1

400Kbps

2

250Kbps

3

200Kbps

4

125Kbps

5

100Kbps

Example:

Set CAN bps to 250K :

Send:FF FE FD FC 01 14 01 01 00 02 00 00 00 FB

Receive:FF FE FD FC 01 14 01 01 00 02 00 00 00 FB

Read CAN bps(Receive 2):

Send:FF FE FD FC 01 14 01 00 00 00 00 00 00 FB

Receive:FF FE FD FC 01 14 01 00 00 02 00 00 00 FB

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

13

3.5.9 Object Droped

Function

register

Sub-Function

register

Read/Write

Reserve

Data

Function

0x15

0x01/02

0x00/0x01

0x00

Integer

Object droped feedback

Open object droped feedback function :

FF FE FD FC 01 15 01 01 00 01 00 00 00 FB

close object droped feedback function :

FF FE FD FC 01 15 01 01 00 00 00 00 00 FB

When object dropped,gripper will send automatically:

grip droped:FF FE FD FC 01 15 02 00 00 00 00 00 00 FB

stop feedback :FF FE FD FC 01 15 02 01 00 00 00 00 00 FB

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

14

4 Protocol Converter

The protocol converter (CTS-B1.0) is to convert communication protocols between the

controller and the DH’s gripper, in order to make the gripper compatible with controllers as many

as possible. In addition, the protocol converter (CTS-B1.0) has multiple working modes according

to the communication protocols to be converted. Users can select a specific communication

protocol as needed.

If you need to use the USB mode in the Windows system, please install the USB driver first

(see the debugging software installation below).

4.1 Working Mode Selection

A communication protocol is selected and set mainly through the DIP switch of the protocol

converter (CTS-B1.0). The protocol converter (CTS-B1.0) has a four-digit DIP switch (as shown in

the following figure). The switch numbers are 1, 2, 3 and 4.

The switch is “ON” in the upper status (identified by 1) and “OFF” in the lower status

(identified by 0). as shown in Figure 3.1.

Figure 3.1 Dialing diagram

If the mode number is 1, seen from the left (i.e. the bit 1), the switch status is 1, 0, 0 and 0

accordingly.

The working modes corresponding to the DIP switch statuses are as follows:

Table 1 working modes

Switch Status

(Mode Number)

Working Mode

Switch Status

(Mode Number)

Working Mode

0 0 0 0 (0)

Parameter

configuration mode

0 0 1 0 (4)

RS485 mode

1 0 0 0 (1)

USB mode

1 0 1 0 (5)

MODBUS mode of RS485

0 1 0 0 (2)

TCP client mode

0 1 1 0 (6)

IO mode

1 1 0 0 (3)

TCP server mode

1 1 1 0 (7)

CAN2.0A mode

After changing the working mode of the DIP switch, the user needs to restart the protocol

converter (CTS-B1.0) without connecting the USB cable to apply this mode.

When using the gripper, the user needs to connect the cable to the controller and then

turn on the protocol converter (CTS-B1.0). (The protocol converter (CTS-B1.0) search for the

gripper at the startup process.)

All modes have their own default parameters. The gripper can be quickly set up according to

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

15

the default parameters.

4.2 Parameter Configuration Mode

Switch Status (Mode Number)

Working Mode

0 0 0 0 (0)

Parameter configuration mode

In this mode, parameters of other modes of the protocol converter can be set by the software,

such as modifying the IP address of the protocol converter used as a TCP server.

The procedures of setting the parameter configuration mode of the protocol converter are as follows.

(Accessories needed in this mode: USB cable, DC power cable, and protocol converter)

1. Connect the 24V power supply to the protocol converter through the DC power cable.

2. Make sure that the protocol converter is turned off and the USB cable is not connected to the

computer.

3. Set the red DIP switches of the protocol converter to 0000 (all four DIP switches are in the lower

position).

4. Turn on the protocol converter, and connect it to the computer via the USB cable.

5. If the setting is successful and the USB driver has been installed in the computer, the COM

device will be displayed in the COM category under Windows System Device Manager, starting

with “STMicroelectronics Virtual COM Port”.

6. If the setting fails, check whether the operation is correct.

After successfully entering the setting mode, you can configure the parameters through the host

software. For the specific configuration process, refer to the related contents of the debugging

software below.

4.3 USB Mode

Switch Status (Mode Number)

Working Mode

1 0 0 0 (1)

USB mode

In this mode, the gripper can be controlled via USB.

Set the USB mode of the protocol converter as follows,

(Accessories needed in this mode: USB cable, aviation plug cable, DC power cable, and protocol

converter)

1. Connect the protocol converter to the gripper through the aviation plug cable and the 24V power

supply through the DC power cable.

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

16

2. Make sure that the protocol converter is turned off and the USB cable is not connected.

3. Set the red DIP switches of the protocol converter to 1000 (with the DIP switch 1 in the upper

position, and the DIP switches 2, 3 and 4 in the lower position).

4. Turn on the protocol converter, and connect it with the controller via the USB cable.

5. If the setting is successful and the USB driver has been installed in the computer, the COM device

will be displayed in the COM category under Windows System Device Manager, starting with

“STMicroelectronics Virtual COM Port”. In the Linux system, the “ttyACM” device will be

displayed, and the gripper indicator will flicker in red.

6. If the setting fails, check whether the operation is correct.

After successfully entering the USB mode, the gripper can be set with the host computer or other

control devices.

The USB mode is virtualized as a serial port device on the application layer, so the protocol

converter in the USB mode can be operated by operating the serial port.

For how to control the gripper in USB mode, you can refer to the aforesaid communication

protocol or the debugging software below.

4.4 TCP Client Mode

Switch Status (Mode Number)

Working Mode

0 1 0 0 (2)

TCP client mode

In this mode, the protocol converter works as a TCP client and the controller can control the

gripper via the TCP/IP protocol.

Default parameters of the TCP client:

Default protocol converter IP: 192.168.1.30

Default protocol converter gateway: 192.168.1.1

Default remote server IP: 192.168.1.60

Default remote server port: 8888

Set the protocol converter to TCP client as follows:

(Accessories needed in this mode: network cable, aviation plug cable, DC power cable and protocol

converter)

1. Connect the protocol converter and gripper through the aviation plug cable, and the 24V power

supply to the protocol converter through the DC power cable.

2. Make sure that the protocol converter is turned off and the USB cable is not connected to the

controller.

3. Set the red DIP switches of the protocol converter to 0100 (with the DIP switch 2 in the upper

position, and the DIP switches 1, 3 and 4 in the lower position).

DH Robotics Technology Co., Ltd.

www.dh-robotics.com

17

4. Turn on the protocol converter.

5. If the setting is successful, the network port of the protocol converter will light up or flicker and

the gripper indicator will flicker in red.

6. If the setting fails, check whether the operation is correct.

After successfully entering the TCP client mode, the protocol converter will attempt to connect the

remote server. When connection is built successfully, the remote server can send commands to

control the gripper. Refer to the aforesaid communication protocol or debugging software

instructions for gripper control below.

4.5 TCP Server Mode

Switch Status (Mode Number)

Working Mode

1 1 0 0 (3)

TCP server mode

In this mode, the protocol converter works as a TCP server and the controller can control the

gripper according to the TCP/IP protocol.

Default parameters of the TCP server:

Default protocol converter IP: 192.168.1.29

Default protocol converter gateway: 192.168.1.1

Default monitoring port: 8888

Set the protocol converter to TCP server as follows.

(Parts needed in this mode: network cable, aviation plug cable, DC power cable, gripper body and

protocol converter)

1. Connect the protocol converter and gripper through the aviation plug cable. Then connect the

Recommendations for use of the TCP client mode:

1. Make sure that the server is turned on normally.

2. Ping the address of the gripper to test the connection.

3. If the computer is used as a network server, it is recommended to check whether the

firewall allows server applications to be networked.

4. If the computer is connected directly, set the IPV4 address of the wired network of

the computer to a static IP, and make sure its IP address is within the same network segment

as the gripper.

Example: IP: 192.168.1.60; subnet mask: 255.255.255.0

If the computer IP is not 192.168.1.60, set or change the remote server IP and

port according to the debugging software instructions below.

5. If the gripper is connected to a control device (e.g. computer) through a router or

switch, make sure that the IP address of the gripper matches the network segment of the

router. If they do not match each other, change the IP of the protocol converter according

to the debugging software instructions below.

Other manuals for AG-95

1

Table of contents

Other DH Robotics Technology Robotics manuals