In-situ Con TROLL PRO DC-L User manual

Installation Manual

Con TROLL®PRO Installation Manual

Information subject to change without notice. In-Situ, In-Situ logo, Baro Merge, BaroTROLL, HERMIT, HydroVu™, iSitu, Pocket-Situ, RDO,

RuggedCable, RuggedReader, SmarTROLL™, TROLL, VuSitu, and Win-Situ are trademarks or registered trademarks of In-Situ Inc.©2009-

2013. All rights reserved. This product may be covered by patents identified at www.in-situ.com/patents

0085660 | 2018-08-23

2

Copyright © 2009-2013 by In-Situ All rights reserved.

This document contains proprietary information which is protected by copyright. No part of this document may be

photocopied, reproduced, or translated to another language without the prior written consent of In-Situ

Mailing and Shipping

Address: Phone: 970-498-1500 (international & domestic)

In-Situ

221 East Lincoln Avenue

Fort Collins, CO 80524

U.S.A.

Fax: 970-498-1598

Internet: www.in-situ.com

Support: 800-446-7488 (U.S.A. & Canada)

In-Situ makes no warranty of any kind with regard to this material, including, but not limited to, its fitness for a particular

application. In-Situ will not be liable for errors contained herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material.

In no event shall In-Situ Inc. be liable for any claim for direct, incidental, or consequential damages arising out of, or in

connection with, the sale, manufacture, delivery, or use of any product.

In-Situ and the In-Situ logo, Win-Situ, TROLL, Baro Merge, BaroTROLL, HERMIT, HydroVu™, iSitu, Pocket-Situ, RDO,

RuggedCable, RuggedReader, SmarTROLL™, TROLL, VuSitu™, and Win-Situ are trademarks or registered trademarks of

In-Situ Inc. Microsoft and Windows are registered trademarks of Microsoft Corporation. Pentium is a registered trademark of

Intel. Tefzel and Delrin are registered trademarks of E. I. DuPont de Nemours and Company. Viton is a registered trademark

of DuPont Dow Elastomers. Kellems is a registered trademark of Hubbell Inc. Alconox is a registered trademark of Alconox

Company. Lime-A-Way is a registered trademark of Reckitt Benckiser. Android is a trademark of Google Inc. iPod and

iPhone are trademarks of Apple Inc., registered in the U.S. and other countries. The Bluetooth word mark and logos are

registered trademarks owned by the Bluetooth SIG, Inc. and any use of such marks by In-Situ Inc. is under license. NIST is a

registered trademark of the National Institute of Standards and Technology, U.S.A. Other brand names and trademarks are

property of their respective owners.

The presence of the Waste Electrical and Electronic Equipment (WEEE)

marking on the product indicates that the device is not to be disposed via

the municipal waste collection system of any member state of the European

Union.

For products under the requirement of WEEE directive, please contact your

distributor or local In-Situ office for the proper decontamination

information and take back program, which will facilitate the proper

collection, treatment, recovery, recycling, and safe disposal of the device.

0085660 | 2018-08-23

3

Table of Contents

1 Safety 5

Hazard Symbols that Appear in the Manual 5

Precautionary Labels that many Appear on the Product 5

2 Overview 6

Available Models 6

Compatible Instruments 6

Box Contents 7

3 Mounting the Controller 9

Optional Mounting Kit 9

Mounting Options 10

Controller Dimensions 10

Pole Mounting 13

Wall Mounting Using Mounting Tabs 14

Wall Mounting with User-supplied Hardware 16

DIN Rail Mounting the Enclosure 17

Placing Dome Connectors and Plugs in the Enclosure 18

4 Electrical Connections 20

Power Options 20

Electro-Static Discharge (ESD) Recommendations 20

Customer-Supplied Electrical Equipment 20

Ensuring Dome Connectors are Water-Tight 20

Ensuring Good Electrical Connections 20

Relay Connections 22

Disconnecting AC Power 23

Desiccant Pack 23

5 Input/Output Connections 24

PLC Connections 24

Sensor Wiring Connections 25

Current Loop Outputs 26

Relay Connections on the I/O Board 28

Desiccant Pack 28

6 Optional Battery Box 29

Overview of Battery Box Kit 29

Additional Considerations 29

Preparing the Power Cord 29

Mount the Enclosure 29

Connect the External Battery Enclosure to the Controller Enclosure 29

Connect the Battery Terminals 30

7 Maintenance 31

Cleaning the Outside of the Enclosure 31

5

Safety

Please read this manual before unpacking or installing any part of this system.

Hazard Symbols that Appear in the Manual

Danger—Indicates a hazardous situation, which, if not avoided, will result in death or serious injury.

Note—Indicates a situation that is not related to potential injury.

Les Symboles D'advertissement Figurant Dans Le Guide

Danger—indique une situation dangereuse, qui, si elle n'est pas évitée, pourra provoquer la mort ou des blessures

sérieuses.

Note—indique une situation qui n'est pas susceptible de provoquer de blessure.

Precautionary Labels that many Appear on the Product

Important—When noted on the instrument, this symbol references the user to the manual.

Electrical Shock—When noted on the instrument, this symbol indicates a risk of electrical shock.

Protective Earth Ground—When noted on the instrument, this symbol indicates the location of protective earth ground.

Consignes De Precaution Dans Le Boitier

Important—Quand cette consigne s'affiche sur l'appareil, elle renvoie au guide

d'utilisateur.

Electrical Shock—Quand cette consigne s'affiche sur l'appareil, elle signale la

possibilité de choc électrique.

Protective Earth Ground—Quand cette consigne s'affiche sur l'appareil, elle indique l'emplacement de la prise de terre.

6

Overview

All Con TROLL PRO models contain the following items.

lNEMA 4X rated

lRobust keypad and display window

lEasy-to-use controller software

For a complete list of controller specifications See "Specifications" on page 32

Available Models

The Con TROLL PRO is available in three models.

lModel DC-L, a battery- or solar-powered controller with logging abilities. This model requires a 9-36 VDC ( ) 0.2 A

max supply as the primary power source. It is suited for remote applications and can trigger low-voltage relays.

lModel AC, a 100–240 VAC (~), 0.15 A, 50–60 Hz-powered controller capable of displaying and transmitting data.

This model is suited for applications with access to line power that do not require logging abilities. This model can

trigger low- and high-voltage relays.

lModel AC-L, 100–240 VAC (~), 0.15 A, 50–60 Hz-powered controller capable of logging, displaying, and

transmitting data. This model is suited for applications with access to line power that require logging abilities. This

model can trigger low- and high-voltage relays.

Compatible Instruments

The Con TROLL Pro is compatible with these instruments:

lAll Level TROLLS (400, 500, 700, 700H)

lRugged TROLL 200

lAqua TROLL 100, 200, and 400

lRDO Pro-X

lRDO Titan

7

Box Contents

Remove the controller from the shipping box. The shipping box should contain the following items.

lController (1)

lController plugs (5)

lDome connectors (3)

lO-rings (6)

lLarge lock nuts (6)

lSealed desiccant pack (1) that will be placed in the installed controller.

lOpened desiccant pack (1) that protected the instrument during shipping. Discard after opening the controller.

After verifying that the contents of the box are complete, place the controller back in the box for

transport to the installation site.

Figure 2.1 Internal view of DC model

8

Figure 2.2 Internal view of AC model

9

Mounting the Controller

Danger—Only properly trained and qualified personnel should install the controller described in this manual. This

instrument should be installed for use in non-hazardous locations only.

Danger—L'installation de l'appareil “controller” décrite dans le guide d'utilisateur doit impérativement être réalisée par

des personnes qualifiées. L'installation de cet appareil est seulement prescrite pour des emplacements sans risques.

Optional Mounting Kit

The mounting kit contains the following items.

lTwo stainless mounting brackets

lTwo 1.5—3.5 in. diameter hose clamps

lOne package containing mounting tabs (4), nuts (4), and screws (4)

lDIN rail mounting brackets

The nuts and screws supplied with the mounting tabs are suitable for use with the mounting brackets.

Figure 3.1 Con TROLL PRO mounting kit

10

Mounting Options

Controller Dimensions

Figure 3.2 shows the controller dimensions with the lid closed.

Figure 3.3 shows the dimensions of the controller box with the lid open. It indicates where holes should be drilled for wall or

panel mounting without using the supplied mounting tabs.

Figure 3.4 shows the depth dimensions of the controller. When installing on a wall or panel, make sure to allow adequate

space for opening the enclosure door or making electrical connections.

Figure 3.2 Controller dimensions with lid closed

11

Figure 3.3 Controller dimensions with lid open

12

Figure 3.4 Side view dimensional drawings

13

Pole Mounting

1. Remove the 4 nuts and 4 screws from the mounting kit.

2. With the enclosure open, drop 1 nut into each drilled corner of the box.

3. Use a screwdriver to push the nut down and set it in place.

Figure 3.5 Placing the nut in the enclosure

4. Place the 2 brackets on the back of the enclosure so that the flanges on the brackets will point toward the ground.

5. Attach the mounting brackets to the enclosure using 2 screws for each bracket. Make sure that the screws

properly thread into the nuts that you seated in steps 2 and 3.

6. Place 2 hose clamps over the mounting pole and tighten them until they are almost secure.

7. Place the flanges from the mounting bracket into each of the hose clamps.

8. Completely tighten the hose clamps until the entire controller unit is secure on the pole.

14

Figure 3.6 Attaching the mounting brackets

Figure 3.7 Back and side view of pole-mounted controller

Wall Mounting Using Mounting Tabs

The optional mounting kit contains a set of wall mounting hardware that includes four screws, nuts, and tabs for mounting the

controller to a wall or panel. Follow the instructions included with the mounting tab hardware to attach the tabs.

15

Figure 3.8 Back view of controller with tabs

16

Wall Mounting with User-supplied Hardware

You can supply your own mounting hardware and attach the controller to a wall. Use a screw that is best suited for your wall

material.

Figure 3.9 Back view of Con TROLL PRO

17

Figure 3.10 Template for wall mounting with user-supplied hardware

DIN Rail Mounting the Enclosure

Each rail mount clip is secured to the enclosure with a supplied #6 screw.

1. With the enclosure open, drop 1 screw into each drilled corner of the box.

2. Use a long screwdriver to push the screw through the back of the enclosure.

3. Place the DIN clip on the top of the enclosure. See Figure 3.12 .

4. Use a long screwdriver to tighten the screw to the clip.

5. Repeat steps 2-4 for the remaining screw and clip.

6. Mount on a DIN rail.

18

Figure 3.11 Placing the screw in the enclosure

Figure 3.12 Securing the screw to the DIN clip

Placing Dome Connectors and Plugs in the Enclosure

When installed as directed, this product is rated IP-67 and can withstand temporary immersion in up to 1 meter of water. To

meet the IP-67 rating, the following conditions must be met.

lThe lid must be completely closed and screwed down.

lThe 6 ports must be plugged with either cord grips and cables, port plugs, or a combination of both.

lAdditionally, O-rings must be used as described below.

Attach plugs and dome connectors to the enclosure using the following steps.

1. Place a large O-ring over the threaded end of the plug or dome connector.

2. Screw the threaded end of the plug or dome connector through the bottom of the enclosure. Tighten it to “snug” and

then an turn it an additional half turn.

Do not over tighten.

3. Inside the enclosure, place the lock nut, concave-side-down, over the threaded end of the plug or dome connector

and tighten with a flat-head screwdriver and mallet. Tighten the lock nuts so that there is approximately 1 thread

showing above the nut.

4. Screw the dome nut onto the threaded connector. Tighten it to “snug” and then turn it an additional half turn.

19

Do not over tighten.

5. Thread sensor or electrical cables through the dome connectors for later wiring by a qualified electrical technician.

Tighten to approximately 15 in-lbs of torque.

Figure 3.13 Controller box hardware

Figure 3.14 Attached port plug (left) and attached dome connector (right)

20

Electrical Connections

Danger—Only properly trained and qualified personnel should install the controller described in this manual. This

instrument should be installed for use in non-hazardous locations only.

Danger—L'installation de l'appareil “controller” décrite dans le guide d'utilisateur doit impérativement être réalisée par

des personnes qualifiées. L'installation de cet appareil est seulement prescrite pour des emplacements sans risques.

Power Options

The Con TROLL PROis available with 2 power options.

lDC-powered, which requires a 9-36 VDC supply as the primary power source. This model can trigger low-voltage

(<50 V) relays only. See "Input/Output Connections" on page 24

lAC-powered, which requires a 100-240 VAC as the primary power source. This model can trigger low-voltage

relays (<50 V) through the I/O board only (See "Input/Output Connections" on page 24), and high-voltage relays

(>50 V) through the AC board only.

Electro-Static Discharge (ESD) Recommendations

Before making wiring connections, discharge any static electricity from your body before touching circuit boards and

other internal components by touching a grounded metal object.

When making wiring connections, make sure to remain properly grounded by wearing an ESD wrist strap or similar

device.

Customer-Supplied Electrical Equipment

The end user must supply the following items.

l18-12 AWG wire for electrical connections using conduit or 100-240 VAC power supply

l24-12 AWG cable for connecting relays and PLC devices

lFor hard-wired locations using conduit, a 100-240 VAC or 9-36 VDC source with over current/disconnect protection

will be provided by the end user.

lFor cord-connected plug and socket locations, approved suitable wiring to be provided by the end user.

Ensuring Dome Connectors are Water-Tight

The dome connectors that you installed must be tightened securely after sensor cable or electrical cables are routed through

them.

These dome connectors are not meant to be weight-bearing.

For best results, ensure that the following conditions are met.

lThe cable does not slide or move after the connectors are tightened.

lSufficient cable has been threaded through the connector so that secure wiring connections can be made.

lThere is no weight or force from the water pulling on the cable.

Ensuring Good Electrical Connections

To ensure that all sensors and power sources function properly consider the following recommendations.

This manual suits for next models

2

Table of contents

Popular Controllers manuals by other brands

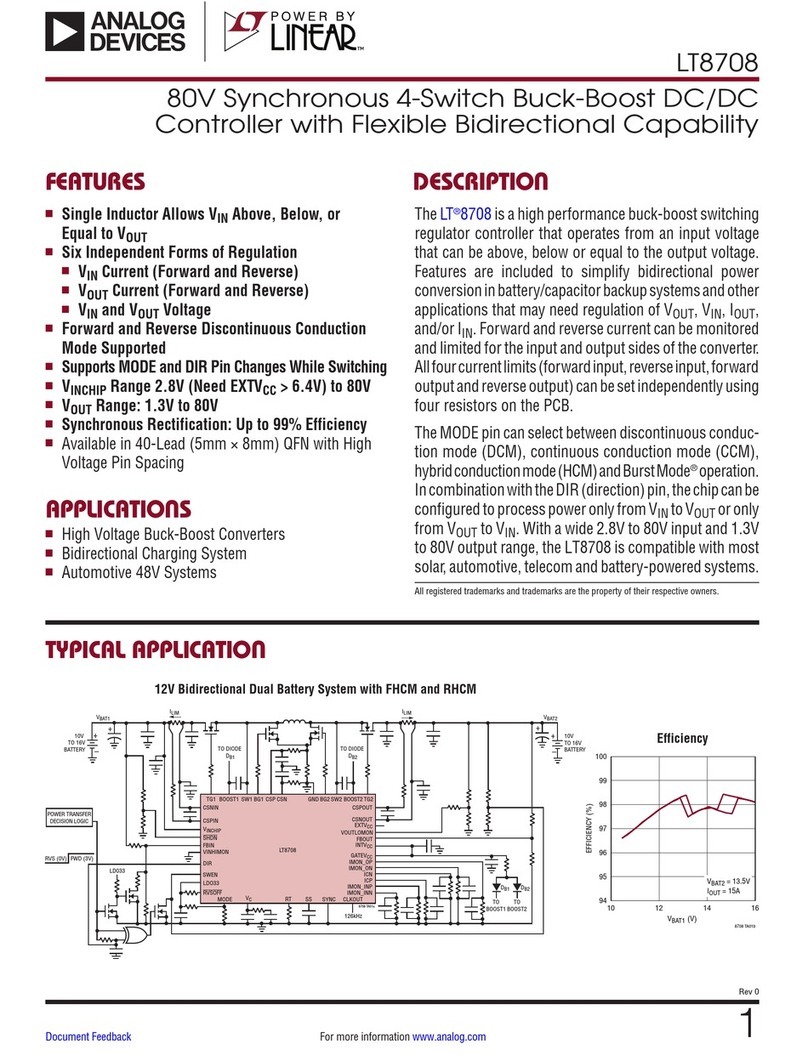

Linear Technology

Linear Technology Analog Devices LT8708 datasheet

FIBARO

FIBARO FGPB-101 instructions

KMC Controls

KMC Controls MCP-1040 Series installation guide

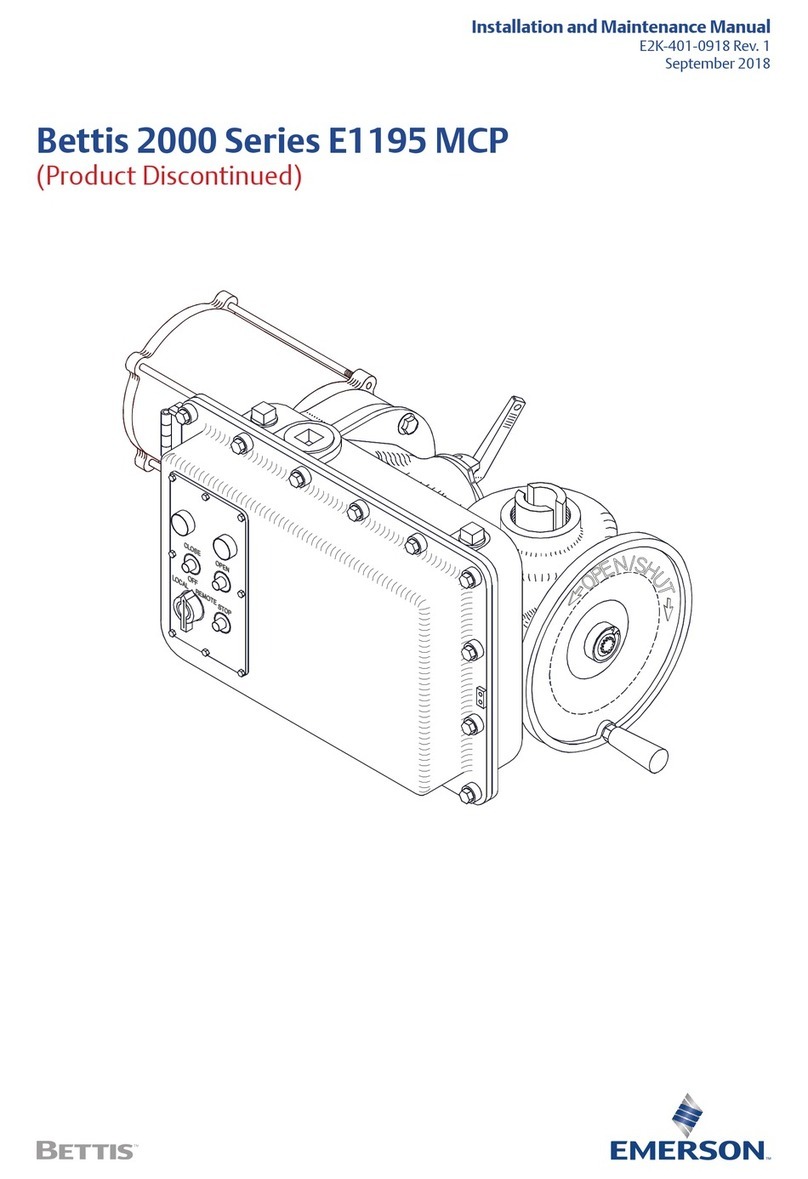

Emerson

Emerson Bettis 2000 Series Installation and maintenance manual

LOCKLY GUARD

LOCKLY GUARD INGRESS user manual

NavAtlas

NavAtlas NA2BT Installation & owner's manual