In-situ PTX-1830 User manual

Instruction Sheet

1 800 4INSITU

(toll-free, US and Canada) or 970 498 1500 www.in-situ.com

The PTX-1830 is a fully submersible pressure transducer

for measuring pressure or water level. It can be used

with In-Situ’s HERMIT™data loggers to collect fast,

accurate time-drawdown data from pump and slug

tests. The 0.69” diameter titanium/stainless steel body

is molded to a polyurethane jacketed cable for a high

integrity waterproof assembly.

Operating Principle

A pressure transducer senses changes in pressure, mea-

sured in pounds per square inch (PSI), exerted by a

column of water or other fluid above an internal strain

gauge. This is translated electronically to a 4-20 mA

signal sent to a data logger. Software calibration

coefficients unique to each transducer enable the logger

to convert the 4-20 mA output to meaningful results in

the desired units.

Calibration Documentation

Documents provided with the transducer describe In-

Situ’s calibration process and list the transducer’s

calibration coefficients (Linearity, Scale, and Offset).

Installation

Installation of the PTX-1830 has three steps, which may

be performed in any convenient order:

• Connect the transducer cable to the data logger

• Program the data logger to identify the type and

characteristics of the transducer

• Install the PTX-1830 in the monitoring site

Connect to the Data Logger

To connect to In-Situ’s HERMIT data loggers:

1Remove the protective caps from the logger and

cable connectors.

22

22

2 Orient the connector patterns

so that the large tab in the

cable connector aligns with

the V-shaped notch in the data

logger connector.

33

33

3 Gently press the connector halves together. Excessive

force should not be required.

44

44

4 Tighten the connector’s lock ring to establish a tight

connection and water-resistant seal.

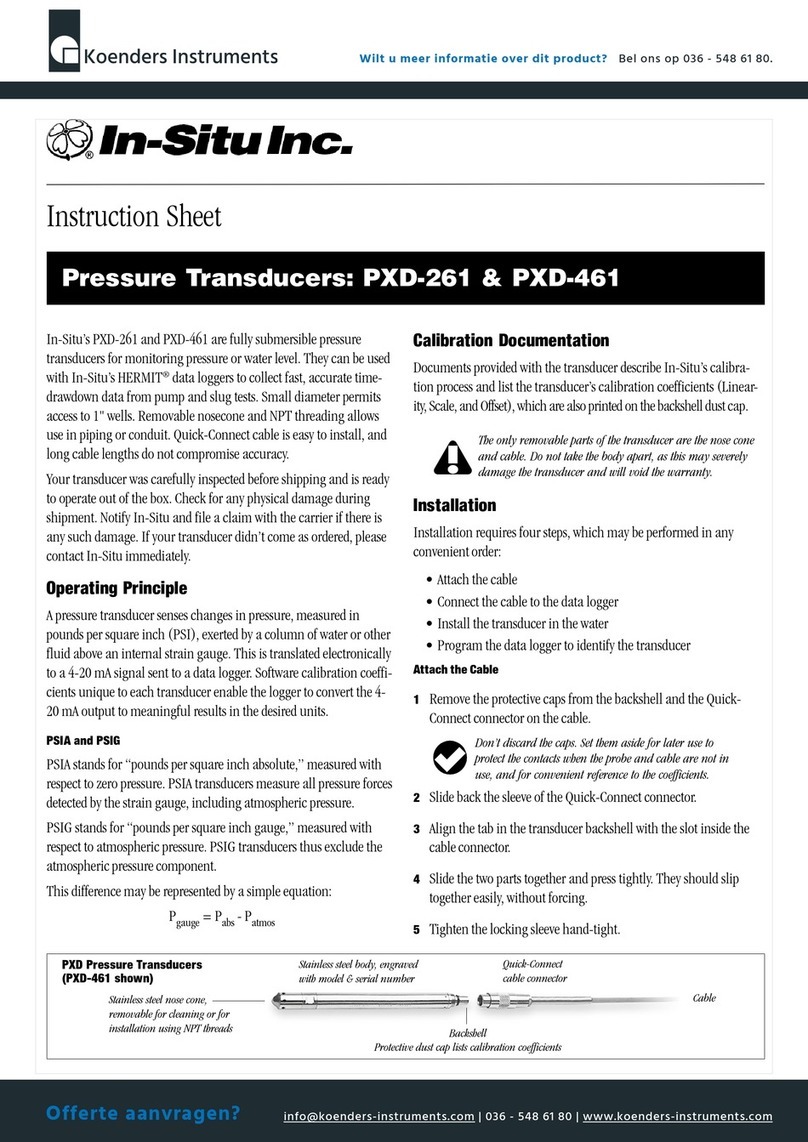

PTX-1830 Pressure Transducer

Proper operation of a transducer depends upon a

clean, dry connection. Be sure the connectors are

clean and dry before installing them.

There are no user-serviceable parts in the PTX-1830.

Do not attempt to service the unit yourself; doing so

can cause permanent damage to the transducer

and will void your warranty.

Large tab

Program the Data Logger

The process of collecting data from the PTX-1830 and

In-Situ’s data loggers is referred to as “running a test.”

This has three steps:

• Enter the transducer characteristics into the logger

• Enter the test conditions into the logger

• When the logger is programmed and the PTX-1830

is installed, the test can be started

How you carry out these steps depends on the model of

data logger you are using. For specific information,

please refer to the data logger Operator’s Manual.

Installation Guidelines

• For best results, install the PTX-1830 about an hour

prior to test setup or data collection. This will insure

that the transducer is stabilized to the water tem-

perature and allow time for the cable to stretch or relax.

• To conserve battery power, don’t put the transducer

any deeper than necessary for the test.

• To verify operation, raise and lower the transducer

and check that readings are reasonable and

showing change before starting a test.

• Be sure that the transducer is attached securely to the

wellhead or other stationary object and will not slip

during operation.

• Do not submerge a transducer more than two times

its range, or it will be permanently offset, damaged,

or destroyed.

• Don’t set a pressure transducer below the level of the

pump in a pumping well. The pressure transients

generated by the pump will cause false level

readings. Large pumps can swallow the transducer

and cause permanent damage to both the transducer

and the pump.

• The PTX-1830 will not read past its designated

range. If the range is exceeded, the value displayed

by the data logger will remain constant.

• Keep the vent tube in the cable unobstructed. Avoid

kinks in the cable. Minimum recommended bend

radius is one inch.

Using the Transducer with Other

Equipment

The transducer provides a current output that is propor-

tional to the applied pressure. This output is a 4-20 mA

change corresponding to a full-scale change in pressure.

The voltage required by the transducer is 9–30 (maxi-

mum) VDC.

Any data logger that provides the necessary voltage and

can read the 4-20 mA current output can be used with

the transducer. To insure accuracy, power should be

applied for a minimum of 50 milliseconds prior to any

reading.

The wiring of the transducer is shown below. It is a

standard 2-wire, 4-20 mA transducer.

BLK

YLW

*

**

* and red for cable > 1500 ft.

** and orange for cable > 1500 ft.

Mating connectors must be ordered separately from In-

Situ, Inc. A kit with wiring diagrams is available. Do

not use any other type of connector as this will

compromise the integrity of waterproof operation. Also,

remember that the vent tube in the cable must remain

unobstructed to assure that the transducer is insensitive

to barometric pressure changes.

Maintenance

The pressure sensor of the PTX-1830 is designed to be

insensitive to barometric pressure changes. A vent tube

incorporated into the cable assures that atmospheric

pressure is the reference pressure to the sensor dia-

phragm. For proper operation, the vent tube should not

be bent, kinked, or otherwise obstructed. Such obstruc-

tions will cause barometric pressure fluctuations to

appear in measurements, and large, varying errors will

be introduced due to thermal expansion and contrac-

tion of air within the vent tube and probe body.

The pressure sensor diaphragm is protected by the

nosecone. This diaphragm is very sensitive and must be

protected in the event that the nosecone is removed.

If the holes in the nosecone become plugged, try a

gentle rinse with a squirt bottle, or swish the probe in a

bucket of water. If the nosecone must be removed, be

very careful with the exposed pressure diaphragm. Never

try to dig sediment away from the pressure sensor. If you

encounter any problems, contact Customer Service, as

described below.

To Obtain Repair Service (U.S. and Canada)

If you suspect that the transducer is malfunctioning

and repair is required, you can help assure efficient

servicing by following these guidelines:

1Call In-Situ Customer Service toll-free at 1-800-446-

7488. Have the model and serial number handy.

2Be prepared to describe in detail the exact nature

(symptoms) of the problem, including how the

instrument was being used and the conditions noted

at the time of the malfunction.

3If service personnel determine that service is

required, they will assign an RMA (Return Material

Authorization) number.

4Clean the probe and cable. Decontaminate thor-

oughly if it has been used in a toxic or hazardous

environment.

5Pack the transducer in its original shipping box, if

possible.

6Send the package, shipping prepaid, to

In-Situ, Inc.

Customer Service

ATTN: RMA # _(assigned no. here)_

221 E. Lincoln Ave.

Ft. Collins, CO 80524

The warranty does not cover damage during transit. In-

Situ recommends the customer insure all shipments.

Warranty repairs will be shipped back prepaid.

Please . . . call us before you return equipment,

and remember to put the RMA number on the label.

In-Situ Inc. does not warrant the transducer

against damage caused by use with devices not

provided by In-Situ.

Specifications

Wetted materials: Titanium, 316 stainless steel, acetal

Transduction

principle: Titanium-encased silicon strain gauge

bridge

Dimensions: 0.69” diameter, 7.86” long (1.75 ×20 cm)

Weight: 4 oz. (0.12 kg)

Storage temp.: -20° to 60°C (-4° to 140° F)

Compensated

temp. range: -2° to 30°C (28° to 85° F)

Input 9 to 30 VDC

Output: 4-20 mA (typical) over pressure range

Ranges: Pressure Max. Usable Depth

5 PSIG 11.5 ft. / 3.5 m water

10 PSIG 23 ft. / 7 m water

15 PSIG 35 ft. / 11 m water

20 PSIG 46 ft. / 14 m water

30 PSIG 69 ft. / 21 m water

50 PSIG 115 ft. / 35 m water

100 PSIG 231 ft. / 70 m water

150 PSIG 346 ft. / 105 m water

Overpressure

tolerance: 2x full range

Accuracy: 0.1% of range

Warning

There are no user-serviceable parts in the PTX-

1830. Do not attempt to service the unit yourself;

doing so can cause permanent damage to the

transducer and will void your warranty.

Cable

Wetted material: Polyurethane

Size: 0.25” (6.4 mm) OD nominal

Weight: 4.7 lb/100 ft. (2.1 kg/30 m)

Reels optional

Warranty Provisions

In-Situ Inc. warrants all products sold, excluding

batteries sold with such products, against defects in

materials and workmanship under normal operating

conditions. Consult the separate warranty for specific

warranties that may apply.

0012910 rev. 001 09/04

Due to continuing product development this information is subject to change without notice. In-Situ, HERMIT, and the In-Situ logo are trademarks or registered

trademarks of In-Situ Inc. Other trademarks are the property of their respective owners. Copyright © 1998, 2004 by In-Situ Inc. All rights reserved.

Outside the U.S. and Canada

Contact your international In-Situ distributor for repair

and service information.

Other In-situ Transducer manuals

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WB Series user manual

ProMinent

ProMinent Dulcometer DMT operating instructions

Camille Bauer

Camille Bauer SIRAX CH-5610 operating instructions

Veris Industries

Veris Industries PW Series installation guide

HBM

HBM TJ1-S6 installation manual

Simrad

Simrad ES120-7C - REV D Dimensions