In-situ PXD-261 User manual

Instruction Sheet

Page 1 of 4

Calibration Documentation

Documents provided with the transducer describe In-Situ’s calibra-

tion process and list the transducer’s calibration coefficients (Linear-

ity, Scale, and Offset), which are also printed on the backshell dust cap.

Installation

Installation requires four steps, which may be performed in any

convenient order:

• Attach the cable

• Connect the cable to the data logger

• Install the transducer in the water

• Program the data logger to identify the transducer

Attach the Cable

1Remove the protective caps from the backshell and the Quick-

Connect connector on the cable.

2Slide back the sleeve of the Quick-Connect connector.

3Align the tab in the transducer backshell with the slot inside the

cable connector.

4Slide the two parts together and press tightly. They should slip

together easily, without forcing.

5Tighten the locking sleeve hand-tight.

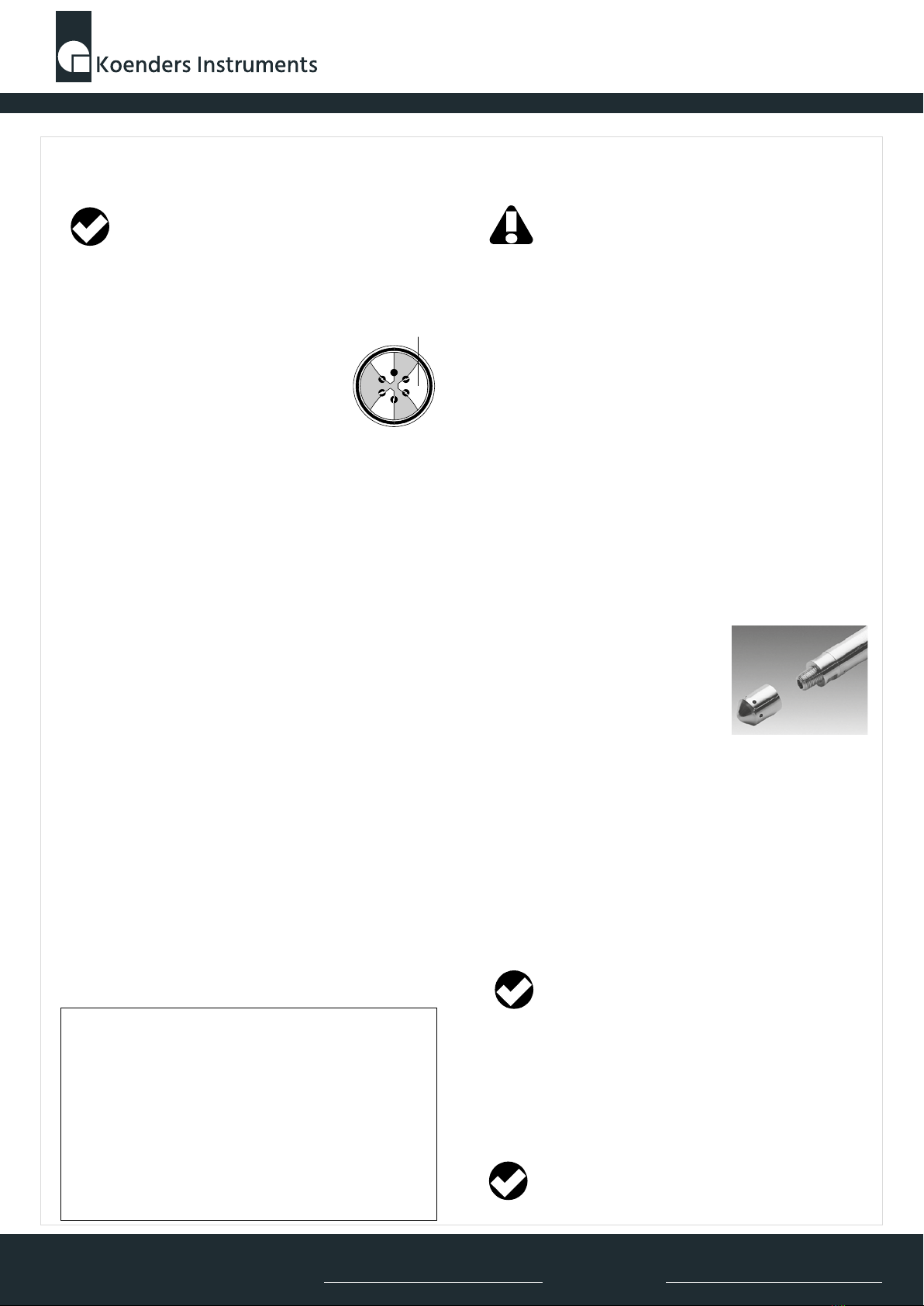

Pressure Transducers: PXD-261 & PXD-461

The only removable parts of the transducer are the nose cone

and cable. Do not take the body apart, as this may severely

damage the transducer and will void the warranty.

In-Situ’s PXD-261 and PXD-461 are fully submersible pressure

transducers for monitoring pressure or water level. They can be used

with In-Situ’s HERMIT®data loggers to collect fast, accurate time-

drawdown data from pump and slug tests. Small diameter permits

access to 1" wells. Removable nosecone and NPT threading allows

use in piping or conduit. Quick-Connect cable is easy to install, and

long cable lengths do not compromise accuracy.

Your transducer was carefully inspected before shipping and is ready

to operate out of the box. Check for any physical damage during

shipment. Notify In-Situ and file a claim with the carrier if there is

any such damage. If your transducer didn’t come as ordered, please

contact In-Situ immediately.

Operating Principle

A pressure transducer senses changes in pressure, measured in

pounds per square inch (PSI), exerted by a column of water or other

fluid above an internal strain gauge. This is translated electronically

to a 4-20 mA signal sent to a data logger. Software calibration coeffi-

cients unique to each transducer enable the logger to convert the 4-

20 mA output to meaningful results in the desired units.

PSIA and PSIG

PSIA stands for “pounds per square inch absolute,” measured with

respect to zero pressure. PSIA transducers measure all pressure forces

detected by the strain gauge, including atmospheric pressure.

PSIG stands for “pounds per square inch gauge,” measured with

respect to atmospheric pressure. PSIG transducers thus exclude the

atmospheric pressure component.

This difference may be represented by a simple equation:

Pgauge = Pabs - Patmos

Don’t discard the caps. Set them aside for later use to

protect the contacts when the probe and cable are not in

use, and for convenient reference to the coefficients.

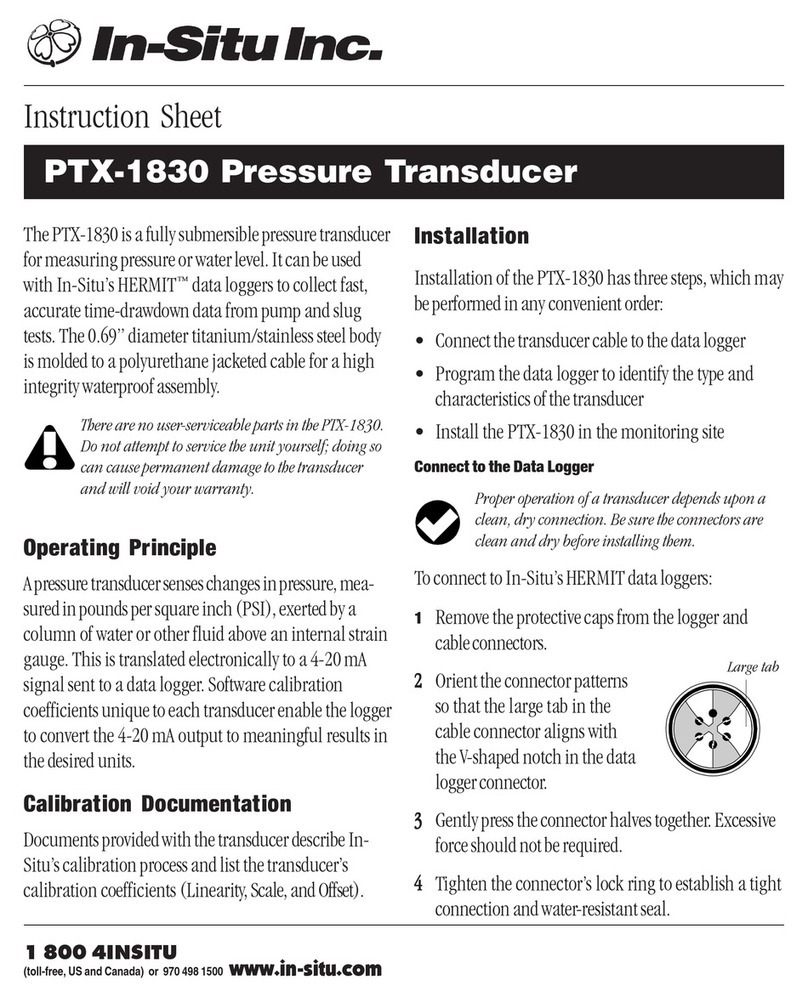

Quick-Connect

cable connector

Cable

Stainless steel nose cone,

removable for cleaning or for

installation using NPT threads Backshell

Protective dust cap lists calibration coefficients

Stainless steel body, engraved

with model & serial number

PXD Pressure Transducers

(PXD-461 shown)

Wilt u meer informatie over dit product? Bel ons op 036 - 548 61 80.

Page 2 of 4

Connect to the Data Logger

To connect to In-Situ’s HERMIT data loggers:

1Remove the protective caps from the logger and cable connectors.

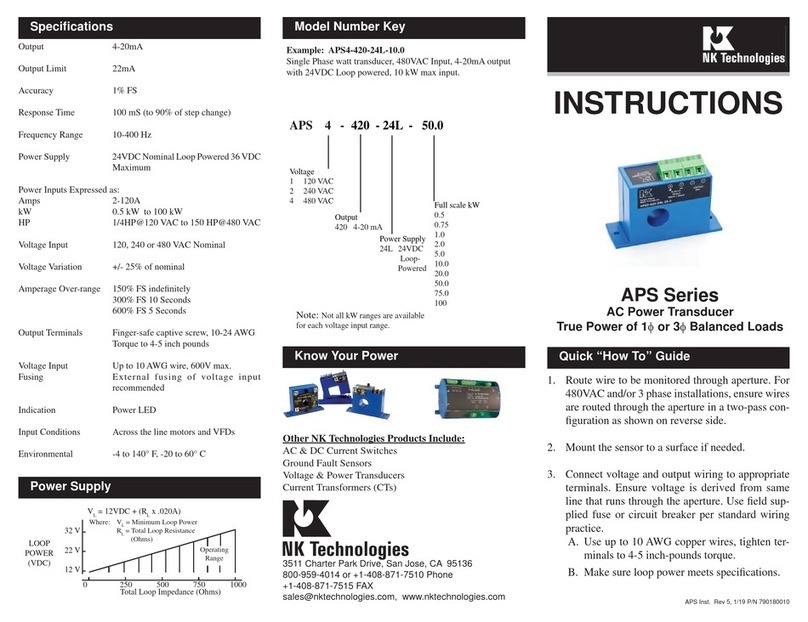

2Orient the connector patterns so that the large tab

in the cable connector aligns with the V-shaped

notch in the data logger connector.

3Gently press the connector halves together.

Excessive force should not be required.

4Tighten the connector’s lock ring to establish a tight connection

and water-resistant seal.

Program the Data Logger

The process of collecting data from the PXD series transducers and

In-Situ’s HERMIT data loggers is referred to as “running a test.” This

has three steps:

• Enter the transducer characteristics into the data logger

• Enter the test conditions into the data logger

• When the logger is programmed and the transducer is in place,

the test can be started

How you carry out these steps depends on the model of data logger

you are using. For specific information, please refer to the data logger

Operator’s Manual.

Installation Guidelines

• For best results, install the transducer about an hour prior to test

setup or data collection. This will insure that the transducer is

stabilized to the water temperature and allow time for the cable to

stretch or relax.

• To conserve battery power, don’t put the transducer any deeper

than necessary for the test.

• The transducer will not read past its designated range. If the range

is exceeded, the displayed value will remain constant.

• To verify operation, raise and lower the transducer and check that

readings are reasonable and showing change before collecting

data.

• Be sure that the transducer is attached securely to the wellhead or

other stationary object and will not slip during operation.

• Don’t set a pressure transducer below the level of the pump in a

pumping well. The pressure transients generated by the pump will

cause false level readings. Large pumps can swallow the trans-

ducer and cause permanent damage to both the transducer and

the pump.

• Keep the vent tube in the cable unobstructed. Avoid kinks in the

cable. Minimum recommended bend radius is one inch.

Piping Installations

With the nosecone removed, the transducer

can be installed in any ¼” NPT threaded

pipe to monitor flow. Always remove the

cable before screwing the transducer body

into the NPT.

To install the transducer in a pipe fitting:

1If the cable is attached, remove it. To do so, unscrew the locking

sleeve and gently pull the transducer and cable connector apart.

2Unscrew the nosecone by hand and remove it.

3Using an open end wrench (7/8" for PXD-261, 5/8” for PXD-461)

and the wrench flats on the transducer body, screw the transducer

onto any ¼" NPT threaded nipple, tee, or elbow.

4Reattach the cable.

Accuracy of the electronics may be affected by temperature fluctua-

tions. For long-term tests (several weeks), we recommend you insu-

late the transducer to ensure a thermally stable environment.

Proper operation of a transducer depends upon a clean,

dry connection. Be sure the connectors are clean and

dry before installing them.

Apply your wrench to the wrench flats, not to the spanner

holes at the back end of the transducer. Thread sealing

compound or tape may be used if necessary.

Do not submerge the PXD-261 more than two times its range.

Do not submerge the PXD-461 more than 1.5 times its range.

Overpressuring will permanently offset, damage, or destroy

the transducer.

The pressure reading is calculated by In-Situ’s HERMIT data

loggers using the quadratic formula

P = LX2+ SX + O

where P = Pressure in PSI

X = Normalized* transducer value (0-1)

L = Linearity value from probe data tag

S = Scale value from probe data tag

O = Offset value from probe data tag

*Transducer reading (in milliAmps) minus 4 divided by 16

When replacing the nose cone, first position the o-ring

(PXD-461) or wavy spring washer (PXD-261), if re-

moved, then screw on the nose cone hand-tight.

Large Tab

Wilt u meer informatie over dit product? Bel ons op 036 - 548 61 80.

Page 3 of 4

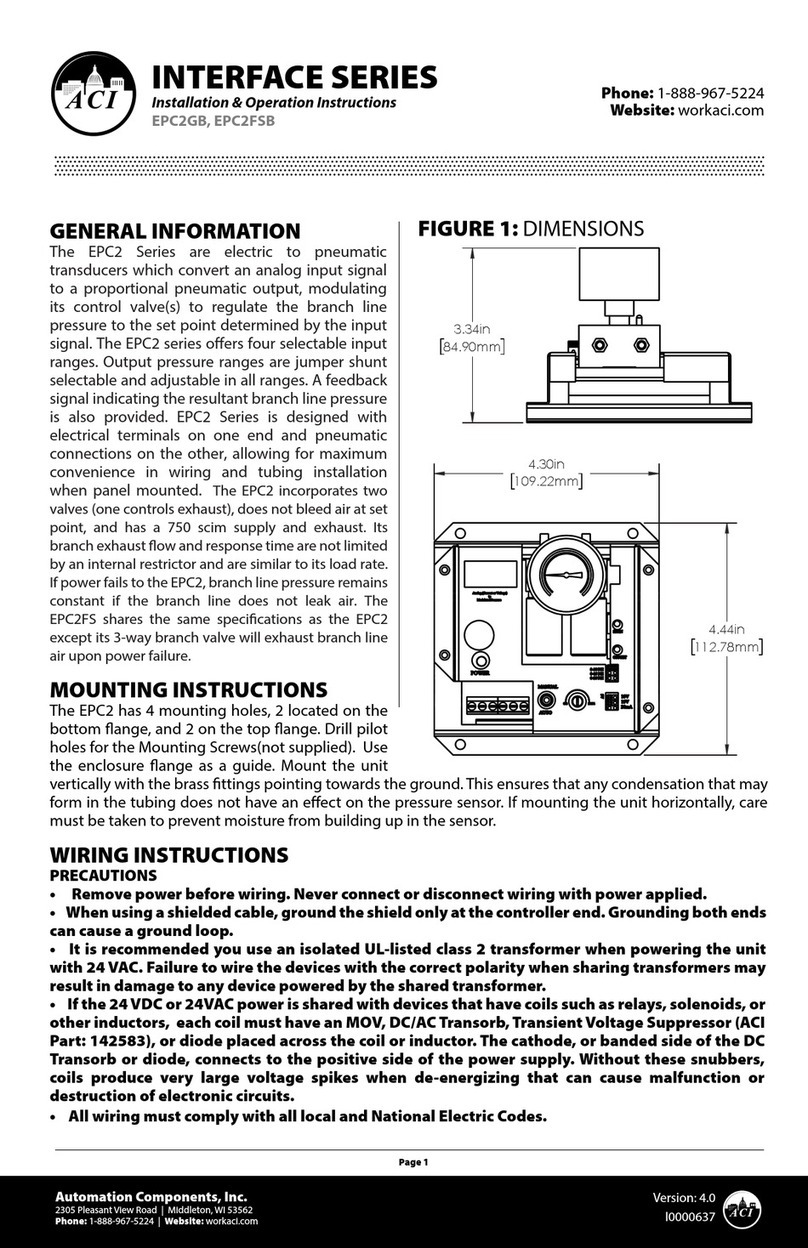

Using the Transducer with Other Equipment

The transducer provides a current output that is proportional to the

applied pressure. This output is a 4-20 mA change corresponding to a

full-scale change in pressure. The voltage required by the transducer

is 11.6–40 (maximum) VDC.

Any data logger that provides the necessary voltage and can read the

4-20 mA current output can be used with the transducer. To insure

accuracy, power should be applied for a minimum of 50 milliseconds

prior to any reading.

Transducer wiring is shown in the table below by cable type.

Mating connectors must be ordered separately from In-Situ, Inc. A kit

with wiring diagrams is available. Do not use any other type of

connector as this will compromise the integrity of waterproof opera-

tion. Also, remember that the vent tube in the cable must remain

unobstructed to assure that the transducer is insensitive to barometric

pressure changes.

Maintenance

Filter

A small mesh filter protects the pressure sensor from dirt and other

foreign objects. It is held in the end of the NPT threads by a small star

washer and can be seen when the nosecone is removed. The filter

appears opaque when clean. If it becomes clogged with silt, try

flushing it gently with a couple of squeezes from a water bottle. If this

doesn’t do the trick, contact Customer Service.

Nose Cone

If the holes in the nose cone become plugged, take the nose cone off

and clean the holes with a swab or brush. To replace the nose cone

on the PXD-261, first put the wavy spring washer over the threads,

then screw on the nose cone hand-tight.

Cable

The transducer’s Quick-Connect cable connector permits easy cable

removal when changing to a different cable, installing the transducer

in a pipe fitting, or storing the probe. Cable is available in standard

and custom lengths of vented polyurethane or FEP*, or non-vented

HDPE.

Take care to protect the cable from the sharp edges of well casings.

All cables are internally sealed to protect the transducer in the event

that the cable is cut. Don’t attempt to repair, splice, or seal any cuts

without first consulting In-Situ Technical Support personnel.

Vent Tube (Vented Cable)

PSIG pressure sensors are designed to be insensitive to barometric

pressure changes. A vent tube in the cable assures that atmospheric

pressure is the reference pressure to the sensor diaphragm. For

proper operation the vent tube should not be bent, kinked, or

blocked. Such obstructions will cause barometric pressure fluctua-

tions to appear in measurements, and may also introduce large,

varying errors due to thermal expansion and contraction of air

within the vent tube and probe body.

Calibration

Accuracy can be adversely affected by improper care and handling,

exceeding operating pressure and temperature limits, physical

damage or abuse. Annual recalibration is recommended.

Contact In-Situ Customer Service for information on recalibration.

Warranty Provisions

In-Situ Inc. warrants the PXD-261 and PXD-461 for one year from date of

purchase by the end user against defects in materials and workmanship

under normal operating conditions. To exercise this warranty contact Techni-

cal Support at the phone or e-mail address below for a return material

authorization (RMA) and instructions. Complete warranty provisions are

posted on our website at www.In-Situ.com.

In-Situ Inc. does not warrant the transducer against dam-

age caused by use with devices not provided by In-Situ.

Source Double Return Double

Cable Source (+) Return (–) Ground Connector (+) Connector (–)

4-conductor Yellow Brown Shield Yellow & Orange Brown & Red

Non-vented (Pin 6) (Pin 5) (Pin 4)

6-conductor Poly Brown Black Shield Black & White Brown & Red

Vented (RuggedCable™) (Pin 6) (Pin 5) (Pin 4)

6-conductor FEP Yellow Black Shield Yellow & Orange Black & Brown

Vented (RuggedCable™) (Pin 6) (Pin 5) (Pin 4)

Wilt u meer informatie over dit product? Bel ons op 036 - 548 61 80.

Due to continuing product development this information is subject to change without notice. In-Situ, HERMIT, RuggedCable, and the In-Situ logo are

trademarks or registered trademarks of In-Situ Inc. Teflon and Delrin are registered trademarks of E. I. DuPont de Nemours and Company. Viton is a registered

trademark of DuPont Dow Elastomers. Other trademarks are the property of their respective owners. Copyright © 1996 – 2007 by In-Situ Inc. All rights reserved.

1 800 446 7488

(toll-free, US and Canada) or 970 498 1500 www.in-situ.com

Page 4 of 4

Specifications

Wetted materials 316 Stainless steel, Viton®

Transduction principle Integrated silicon strain gauge bridge

Voltage input 11.6 – 40 (absolute maximum) VDC

Signal current 4 – 20 mA (typical throughout pressure range)

Operating temperature 5º to 30ºC (41º to 86ºF)

Storage temperature -40º to 125ºC (-40º to 257ºF)

Min. warmup time 50 milliseconds

PXD-261

Dimensions 0.86” dia., 8.5” long (2.2 x 21.6 cm)

Weight 1 lb. (0.45 kg)

Accuracy ±0.05% of full scale at 15ºC (59ºF)

Ranges Pressure Max. Usable Depth

15 PSIG/PSIA 35 ft /11 m water

20 PSIG/PSIA 46 ft /14 m water

30 PSIG/PSIA 69 ft /21 m water

50 PSIG/PSIA 115 ft /35 m water

100 PSIG/PSIA 231 ft /70 m water

250 PSIG 577 ft /176 m water

Overpressure tolerance 2X full range

PXD-461

Dimensions 0.7” diameter, 8.5” long (1.78 x 21.6 cm)

Weight 0.5 lb (0.22 kg)

Accuracy ±0.04% of full scale at 15ºC (59ºF)

Ranges Pressure Max. Usable Depth

500 PSIA 1153 ft / 352 m water

1000 PSIA 2307 ft / 703 m water

Overpressure tolerance 1.5X full range

Cable

Wetted materials 316 Stainless steel, Viton®

Vented: FEP* or polyurethane

Non-vented: high-density polyethylene (HDPE)

Size 0.25” (6.7 mm) OD nominal

Max. length 4500 ft (1372 m)

Reels Plastic: up to 350 ft (106 m) capacity

Small Steel: up to 450 ft (137 m) capacity

Large Steel: up to 1500 ft (457 m) capacity

0010000 rev. 004 06/07

How to Contact Us

Technical Support: 800 446 7488

Toll-free 24 hours a day in the U.S. and Canada

Address: In-Situ Inc.

221 East Lincoln Ave.

Fort Collins, CO 80524 USA

Phone: 970 498 1500

Fax: 970 498 1598

Internet: www.in-situ.com

e-mail: [email protected]

To Obtain Repair Service (U.S.)

If you suspect the transducer is malfunctioning and repair is re-

quired, you can help assure efficient servicing as follows:

1Call or e-mail In-Situ Technical Support ([email protected]).

Have the product model and serial number handy.

2Be prepared to describe the problem, including how the instru-

ment was being used and the conditions noted at the time of the

malfunction.

3If Tech Support determines that service is needed, they will ask

that your company pre-approve a specified dollar amount for

repair charges. When the pre-approval is received, Tech Support

will assign an RMA (Return Material Authorization) number.

4Clean the probe and cable. Decontaminate thoroughly if it has

been used in a toxic or hazardous environment.

5Pack the transducer in its original shipping box, if possible.

6Mark the RMA number clearly on the outside of the box.

7Send the package, shipping prepaid, to

In-Situ, Inc.

ATTN: Repairs

221 East Lincoln Ave.

Fort Collins, CO 80524

The warranty does not cover damage during transit. In-Situ recom-

mends the customer insure all shipments. Warranty repairs will be

shipped back prepaid.

Outside the U.S.

Contact your international In-Situ distributor for repair and service

information.

** FEP = fluorinated ethylene propylene, the generic equivalent of DuPont Teflon®.

Wilt u meer informatie over dit product? Bel ons op 036 - 548 61 80.

This manual suits for next models

1

Other In-situ Transducer manuals

Popular Transducer manuals by other brands

Ametek

Ametek Gemco 953 Series installation manual

aci

aci ACCESS series Installation & operation instructions

FuehlerSysteme

FuehlerSysteme VMU1/A manual

OHIO SEMITRONICS

OHIO SEMITRONICS DVT Series operating instructions

Dossena

Dossena FL Series quick start guide

Airmar

Airmar M260 Owner's guide & installation instructions