Incite Fire ASD 532 User manual

ASD 532

Aspirating Smoke Detector

Operating Manual

2/ 88 ASD532 Operating Manual

Imprint

3 / 121

Imprint

Notice

This documentation, T

140 421, is valid only for the product described in Section 1.

This documentation is subject to change or withdrawal

without prior notice. The statements made in this docu-

mentation are valid until such time as the statements are revised by a new edition of the documentation

(T

number with new index). The user of this document is responsible for staying up to date with it

s current status

through the editor/publisher. We accept no responsibility for claims against any incorrect statements in this

document that were unknown to the publisher at the time of publication. Handwritten changes and additions are

not valid. This doc

umentation is protected by copyright.

Foreign language documentation as listed in this document is always released or changed at the same time as

the German edition. If there are inconsistencies between the foreign language documentation and the German

doc

umentation, the German documentation is binding.

Some words in this documentation are highlighted in

blue. These terms and designations are the same in all lan-

guages and are not translated.

Users are encouraged to contact the editor/publisher if there are statements which are unintelligible, misleading,

incorrect or contain errors.

© Securiton AG, Alpenstrasse 20, 3052 Zollikofen, Switzerland

Document T 140 421 is available in the following languages: German T 140 421 de

English T 140 421 en

French T 140 421 fr

Italian T 140 421 it

Spanish T 140 421 es

Portuguese T 140 421 pt

Swedish T 140 421 sv

Current edition: First edition 15.10.2015 Bmi/ksa

Notice

Validity for production version and firmware version

The following documentation is applicable only to the

ASD 532 aspirating smoke detector with the following pro-

duction version and firmware version:

Production version Firmware version

from 151015 from 01.00.08

ASD532 Operating Manual

Imprint

4 / 121

Other documents

Data sheet ASD 532

T 140 422

de / en / fr / it / es / pt / sv

Material for the sampling pipe

T 131 194

Multilingual (ED / FI)

Commissioning protocol

T 140 423

Multilingual (EDFI)

Data sheets

XLM 35

T 140 088

de / en / fr / it / es / pt / sv

RIM 36

T 140 364

de / en / fr / it / es / pt / sv

SIM 35

T 140 011

de / en / fr / it / es / pt / sv

SMM 535

T 140 010

de / en / fr / it / es / pt / sv

Aspirating Fan Unit AFU 32 mounting instructions

T 140 426

Multilingual (EDFI)

ASD532 Operating Manual

Safety information

5 / 121

Safety information

Provided the product is deployed by trained and qualified persons in accordance with this documentation T 140 421 and the

danger, safety and general information notices in this technical description are observed, there is no danger to persons or

property under normal conditions and when used properly.

National and state-specific laws, regulations and directives must be observed and adhered to in all cases.

Below are the designations, descriptions and symbols of danger, safety and general information notices as found in this docu-

ment.

Danger

If the Danger notice is not properly observed, the product and any other system parts may present a hazard for

persons and property, or the product and other system parts may be damaged to the extent that malfunctioning

results in

danger to persons and property.

•

Description of which dangers may occur;

•

Measures and preventative actions;

•

How dangers can be averted;

•Any other safety-related information.

Warning

The product may be damaged if the warning information is not heeded.

•

Description of which damage can occur;

•

Measures and preventative actions;

•

How dangers can be averted;

•Any other safety-related information.

Notice

The product may malfunction if this notice is not observed.

•

Description of the notice and which malfunctions can be expected;

•

Measures and preventative actions;

•Any other safety-related information.

Environmental protection / recycling

Neither the product nor its components present a hazard to the environment provided they are handled properly.

•

Description of which parts have environmental protection issues;

•

Description of how devices and their parts have to be disposed of in an environmentally-friendly way;

•Description of the recycling possibilities.

Batteries

It is not permitted to dispose of batteries in the domestic rubbish. As the end user you are legally obliged to return

used batteries. Used batteries can be returned to the seller or taken to a designated recycling centre (e.g. a

community collection point or dealer) at no cost. You may

also send them back to the seller by post. The seller

will refund the postage when you return your old batteries.

ASD532 Operating Manual

6 / 121 ASD532 Operating Manual

Document history

7 / 121

Document history

First edition Date 15.10.2015

ASD532 Operating Manual

8/ 121 ASD532 Operating Manual

Contents

9 / 121

Contents

_________________________________________________________________________________________

1General 13

1.1 Purpose 13

1.2 Uses and applications 14

1.3 Abbreviations, symbols and terms 14

1.4 Product identification 16

1.5 Smoke sensors used 17

1.6 Hardware / firmware 17

_________________________________________________________________________________________

2Function 18

2.1 General operating principle 18

2.2 Electrical functional principle 19

2.2.1 Power supply 19

2.2.2 Fan control 20

2.2.3 Microcontroller 20

2.2.4 Programming / operation 21

2.2.5 Displays 22

2.2.6 Relay 22

2.2.7 Outputs 23

2.2.8 Inputs 23

2.2.9 Interfaces 23

2.2.10 Airflow monitoring 24

2.2.11 Smoke sensor monitoring 24

2.2.12 Alarm release 25

2.2.12.1 Alarm 2 25

2.2.12.2 Alarm cascading 25

2.2.12.3 Isolating the smoke sensor 25

2.2.13 Autolearning 26

2.2.14 Day/night control & weekday control 27

2.2.15 Fault triggering 27

2.2.16 Event memory 27

2.2.17 Data logging on the SD memory card 28

2.2.18 Reset types 29

2.2.18.1 State reset 29

2.2.18.2 Hardware reset 29

2.2.18.3 Initial reset 29

2.2.19 ASD network 29

_________________________________________________________________________________________

3Design 30

3.1 Mechanical 30

3.2 Electrical 32

3.3 Hardware / firmware 34

3.4 List of materials / components 35

3.5 Packaging 35

ASD532 Operating Manual

Contents

10 / 121

_________________________________________________________________________________________

4Planning 36

4.1 General aspects of planning 36

4.1.1 Standards, regulations, guidelines, approvals 36

4.2 Area of application 36

4.2.1 System limits 37

4.3 Planning aids 37

4.3.1 Planning with “ASD PipeFlow” calculation 37

4.3.2 Planning without “ASD PipeFlow” calculation 38

4.4 Space surveillance 38

4.4.1 Space surveillance applications 38

4.4.2 Principles of space surveillance 39

4.4.3 Types of sampling pipe layouts for space surveillance 40

4.4.4 System limits for space surveillance without “ASD PipeFlow” calculation 41

4.4.4.1 Normative system limits for space surveillance without “ASD PipeFlow” calculation 41

4.4.4.2 Non-normative system limits for space surveillance without “ASD PipeFlow” calculation 41

4.4.4.3 System limits for planing without “ASD PipeFlow” calculation 42

4.4.4.4 Non-normative system limits table for planning without “ASD PipeFlow” calculation 43

4.4.4.5 Sampling holes for planning without “ASD PipeFlow” calculation 44

4.4.4.6 Maintenance sampling hole 45

4.5 Equipment monitoring 45

4.5.1 Equipment monitoring applications 45

4.5.2 Principles of equipment monitoring 46

4.5.3 Examples of sampling pipe layouts for equipment monitoring 46

4.5.4 System limits for equipment monitoring without ASD PipeFlow calculation 47

4.5.4.1 Alarm thresholds for equipment monitoring using sampling fixtures without ASD PipeFlow calculation 47

4.5.5 Sampling fixtures and sampling holes in equipment monitoring 48

4.6 Air recirculation 48

4.7 Settings 49

4.8 Electrical installation 50

4.8.1Installation cable requirements 50

4.8.2 Determining the conductor cross-section 51

4.9 Restrictions 52

4.10 Environmental influences 53

_________________________________________________________________________________________

5Mounting 54

5.1 Mounting guidelines 54

5.2 Dimensioned drawing / drilling plan for the detector housing 54

5.3 Material for the sampling pipe 55

5.4 Mounting the detector housing 56

5.4.1 Opening and closing the detector housing 57

5.4.2 Mounting positions for the detector housing 58

5.4.3 Removing the air outlet pipe plug 59

5.4.4 Turning the labelling strip 59

5.5 Mounting the sampling pipe 60

5.5.1 General 60

5.5.2 Mounting with PVC tubes and fittings 60

5.5.3 Mounting with ABS tubes and fittings 60

5.5.4 Mounting with metal pipes and fittings 61

5.5.5 Linear expansion 61

5.5.6 Mounting the sampling pipe 62

5.5.7 Mounting for equipment monitoring 63

5.5.7.1 Screw-free fastening of the sampling pipe 63

5.5.7.2 Transition to a flexible tube 64

5.5.8 Creating the sampling holes 65

5.5.9 Mounting the sampling hole clips and maintenance clips 65

5.5.10 Mounting the sampling funnel 65

5.5.11 Mounting sampling stubs for a ceiling bushing 66

5.5.12 Mounting the filter-box, filter unit, dirt trap box, dust retaining box, water retaining box 67

ASD532 Operating Manual

Contents

11 / 121

_________________________________________________________________________________________

6Installation 68

6.1 Regulations 68

6.2 Cable entry 68

6.3 Using the smoke sensor 69

6.4 Installing additional modules XLM 35, RIM 36, SIM 35 70

6.5 Electrical connection 70

6.5.1 Terminal assignment Main Board AMB 32 71

6.5.2 Terminal assignment for eXtended Line Module XLM 35 72

6.5.3 Terminal assignment for RIM 36 Relay Interface Module 72

6.5.4 Terminal assignment of an SIM 35 Serial Interface Module 72

6.6 Connection variants 73

6.6.1 Power supply 73

6.6.2 Reset input 73

6.6.3 Control 74

6.6.3.1 Control via voltage supply by means of auxiliary relay 74

6.6.3.2 Control via “Reset external” input 75

6.6.4 Connection to the FACP line 76

6.6.4.1 Connection to zone detection via Al / St relays 76

6.6.4.2 Connection to selective identification or addressable loop via Al / St relay 76

6.6.4.3 Connection to SecuriFire / Integral addressable loop from XLM 35 77

6.6.5 OC outputs 77

_________________________________________________________________________________________

7Commissioning 78

7.1 General 78

7.2 Programming 79

7.2.1 Configuration options 80

7.2.2 Relay allocation 82

7.3 Starting up 82

7.3.1 Commissioning with EasyConfig 82

7.3.2 Commissioning with “ASD Config” configuration software 83

7.3.3 Setting to pre-defined switch positions A11 to C31, W01 to W44 84

7.3.4 Setting and polling the date and time 85

7.3.5 Initial reset 86

7.3.6 Displaying the firmware version 86

7.3.7 Logging off additional modules XLM 35, RIM 36, SIM 35 and the SD memory card 87

7.4 Re-programming 87

7.4.1 Re-programming on the ASD 532 87

7.4.2 Re-programming with “ASD Config” configuration software 87

7.4.3 Re-programming from SecuriFire / Integral with XLM 35 87

7.5 Download new firmware to the ASD 532 88

7.5.1 FW upgrade from SD memory card 88

7.5.2 FW upgrade from PC via “ASD Config” configuration software 89

7.6 Measurements 90

7.6.1 Reading out the set configuration and airflow 91

7.7 Testing and checking 92

7.7.1 Checking the alarm release 92

7.7.2 Test triggerings 93

7.8 Commissioning protocol 93

ASD532 Operating Manual

Contents

12 / 121

_________________________________________________________________________________________

8Operation 94

8.1 Operation and display elements 94

8.2 Functional sequence of operation 95

8.3 Switch positions 96

8.4 Reset 97

8.5 Displays 97

8.5.1 Displays on the control unit 97

8.5.2 Indicators on the AMB 32 main board 98

8.5.3 SD memory card operation 98

8.5.3.1 Data logging on the SD memory card 98

8.5.4 Displaying and reading out the event memory 99

8.5.4.1 Procedure and interpretation of the event memory display 99

8.5.4.2 Event groups 100

8.5.4.3 Event codes within event groups 100

8.5.5 Operation and displays on the XLM 35 103

8.5.6 Operation and display on the SIM 35 104

8.5.7 Operation and display on the SMM 535 105

8.6 Operation from SecuriFire / Integral with XLM 35 105

_________________________________________________________________________________________

9Maintenance and service 106

9.1 General 106

9.2 Cleaning 106

9.3 Maintenance checks and function checks 107

9.4 Replacing units 109

9.4.1 Replacing the smoke sensor 109

9.4.2 Replacing the aspirating fan unit 109

9.4.3 Replacing the airflow sensor 110

9.4.4 Replacing the AMB 32 Main Board 110

9.5 Disposal 111

9.5.1 Materials used 111

_________________________________________________________________________________________

10 Faults 112

10.1 General 112

10.2 Warranty claims 112

10.3 Finding and rectifying faults 113

10.3.1 Fault states 113

_________________________________________________________________________________________

11 Options 116

11.1 sampling pipe 116

11.2 Use under extreme conditions 116

11.3 Use of detector boxes 116

11.4 ASD network 117

11.4.1 ASD networking via RS485 interface from SIM 35 117

11.4.2 ASD networking via Ethernet interface from AMB 32 118

_________________________________________________________________________________________

12 Article numbers and spare parts 119

12.1 Detector housings and accessories 119

12.2 Sampling pipe and accessories 119

_________________________________________________________________________________________

13 Technical data 120

_________________________________________________________________________________________

14 List of figures 121

ASD532 Operating Manual

General

13 / 121

1 General

1.1 Purpose

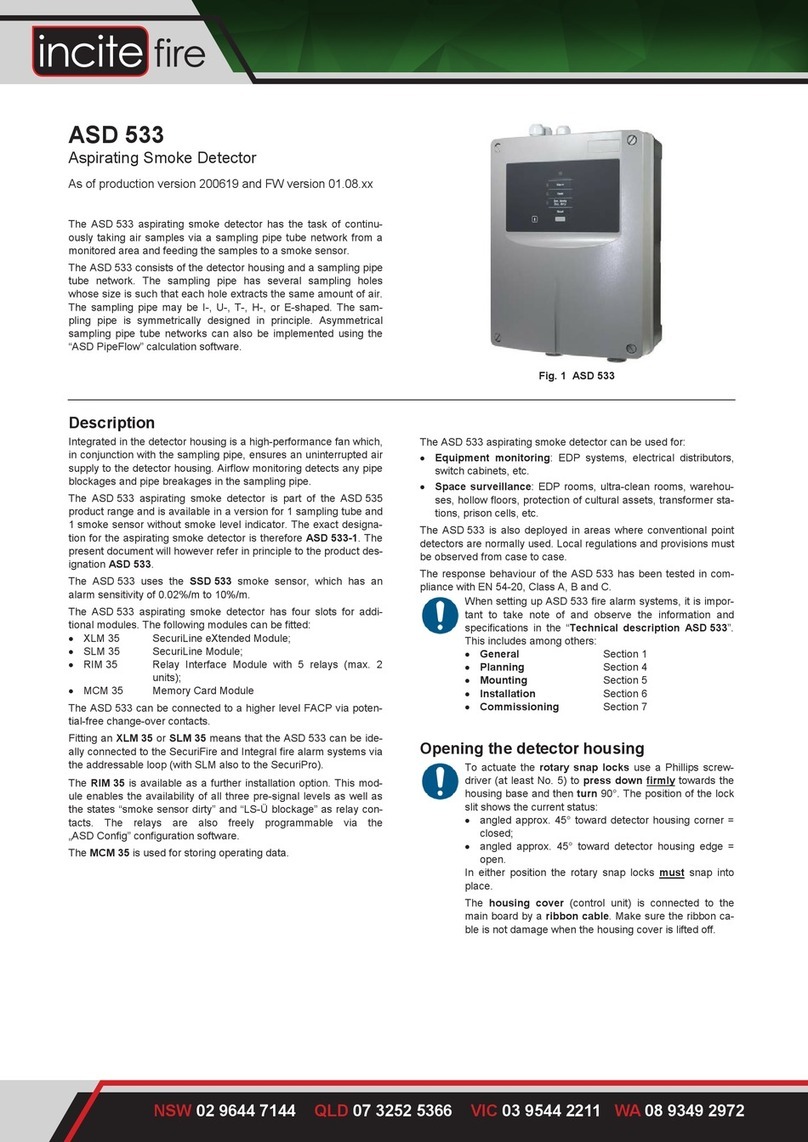

The ASD 532 aspirating smoke detector has the task of continuously taking air samples via a sampling pipe tube network from

a monitored area and feeding the samples to a smoke sensor. Thanks to this detection method and the product’s excellent

properties under severe ambient conditions, the ASD 532 aspirating smoke detector is used wherever problems are to be ex-

pected owing to poorly accessible monitored areas or latent disturbance variables during operation such that optimal protec-

tion can no longer be guaranteed with conventional point detectors.

The SSD 532 smoke sensor is used in the ASD 532. It is available in the three following versions and sensitivity ranges:

•SSD 532-1 Alarm sensitivity range 0.5%/m to 10%/m

•SSD 532-2 Alarm sensitivity range 0.1 %/m to 10%/m

•SSD 532-3 Alarm sensitivity range 0.02%/m to 10%/m.

The ASD 532 aspirating smoke detector has two slots for additional modules. The following modules can be fitted:

•XLM 35 eXtended Line Module

•RIM 36 Relay Interface Module with 5 relays;

•SIM 35 Serial Interface Module.

With the installation of a eXtended Line Module XLM 35 the ASD 532 aspirating smoke detector can be ideally connected to

the fire alarm systems SecuriFire (SecuriLine eXtended) and Integral (X-Line) via the addressable loop. Control operations and

changes to the ASD device configuration can be carried out directly from the FACP (in preparation). For this purpose the

FACP user software “SecuriFire Studio” and “Integral Application Center” are used to start the “ASD Config” configuration

software for access to the ASDs; the configuration software is then used to make changes to the ASD 532.

A further installation option is the RIM 36 relay interface module. This module enables the availability of all three pre-signal

levels as well as the states “smoke sensor dirty” and “LS-Ü pipe blockage” as relay contacts. The relays are also freely pro-

grammable via the “ASD Config” configuration software.

The SIM 35 Serial Interface Module is for networking multiple ASD 532 aspirating smoke detectors via RS485 bus. Using the

“ASD Config” configuration software, all ASD 532 units present in the network can be visualised and operated from a PC. The

master module in the ASD network is the SMM 535, by means of which a PC is connected.

Notice

The normative alarm transmission of the

ASD 532

to the superordinate centre does not take place via the ASD

network. For that purpose the

“Alarm” / “Fault”

relays in the ASD or the SecuriFire / Integral addressable loop are

to be used from the XLM 35.

The present technical description contains all information essential for trouble-free operation. For obvious reasons only those

details specific to individual countries and companies or special applications can be discussed if they are of general interest.

ASD532 Operating Manual

General

14 / 121

1.2 Uses and applications

Thanks to the detection method, air sampling by means of a sampling pipe tube network and the good properties of the prod-

uct under extreme ambient conditions, the ASD 532 aspirating smoke detector is used wherever problems can be expected

owing to poorly accessible areas to be monitored or latent disturbance variables during operation such that optimal protection

cannot be guaranteed with conventional point detectors. This includes:

•Space surveillance:

EDP rooms, ultra-clean rooms, warehouses, hollow floors, protection of cultural assets, transformer stations, prison cells,

etc.

•Equipment monitoring:

EDP systems, electrical distributors, switch cabinets, etc.

The ASD 532 can also be deployed in areas where normally conventional point detectors are used. Local regulations and pro-

visions must be observed from case to case.

The response behaviour of the ASD 532 has been tested in compliance with EN 54-20, Class A, B and C.

When control-unit-specific alarm transmitters, line monitoring elements etc. are used, the ASD 532 can be connected via its

potential-free change-over contacts to all common fire alarm systems virtually without restrictions.

1.3 Abbreviations, symbols and terms

The following abbreviations, symbols and terms are used in the Technical Description T 140 421. The abbreviations for tube

material and accessories are listed in a separate document: T 131 194 (see also Sec. 5.3).

µC

=

Microcontroller / microprocessor

ABS

=

Acrylonitrile-butadiene styrene (plastic)

AFS 32

=

Air Flow Sensor

AFU 32

=

Aspirating Fan Unit

Al

=

Alarm

AMB 32

=

ASD main board

ASD

=

Aspirating Smoke Detector

ASD Config

=

configuration software for the ASD 532

ASD PipeFlow

=

Calculation software for the sampling pipe, “ASD PipeFlow” as of Version 2.3

CE

=

Communauté Européenne (European Community)

DA

=

Detection area

Default

=

Preset values / settings

DET

=

Detector

DIN

=

Deutsche Industrie Norm (German industry standard)

DZ

=

Detection zone

EasyConfig

=

Commissioning process without the “ASD Config” configuration software

EDP

=

Electronic data processing

EEC

=

European Economic Community

EEPROM

=

Memory component for system data and ASD configuration

EMC

=

Electromagnetic compatibility

EN 54

=

European standards for fire alarm systems (Germany = DIN, Switzerland = SN, Austria = Ö-Norm)

Ex-zone

=

Area subject to explosion hazards

FACP

=

Fire alarm control panel

FAS

=

Fire alarm system

Fault

=

Fault

Flash PROM

=

Memory component for firmware

Flush mounting /

surface mounting

= Flush mounted / surface mounted

FW

=

Firmware

GND

=

Supply ground (minus (-) pole)

ASD532 Operating Manual

General

15 / 121

Continuation:

H-Al

=

Main alarm

HF

=

High frequency

HW

=

Hardware

IEC

=

International Electrotechnical Commission

Initial reset

=

First start-up on commissioning

IPS 35

=

Insect Protection Screen

LED

=

Light-emitting diode (indicator)

LS

=

Airflow

LS-Ü

=

Airflow monitoring

Manufacturer

=

Securiton

OC

=

Open collector output

OEM

=

Original Equipment Manufacturer (reseller)

PA

=

Polyamide (plastic)

PC

=

Personal computer

PC

=

Polycarbonate (plastic)

PE

=

Polyethylene (plastic)

Pin

=

Terminal pin

PMR 81

=

Semi-conductor relay

Port

=

Input or output component

PVC

=

Polyvinyl chloride (plastic)

RAM

=

Memory component

RIM 36

=

Relay interface module

RoHS

=

Restriction of Certain Hazardous Substances (eco-friendly manufacturing processes)

SecuriFire

=

FAS system

SecuriLine

=

Fire detector addressable loop

SIM 35

=

Serial Interface Board

SMM 535

=

Serial Master Module

SSD 532

=

Smoke sensor

St

=

Fault

St-LS

=

Airflow fault

SW

=

Software

Te.

=

Terminal

UMS 35

=

Universal Module Support

Update /Release

=

Renewal / update of the firmware

V-Al

=

Pre-alarm

VDC

=

Direct current voltage

VdS

=

Verband der Schadenversicherer (Association of Indemnity Insurers, Germany)

VKF

=

Vereinigung Kantonaler Feuerversicherungen (Cantonal Fire Insurance Union, Switzerland)

VS

=

Pre-signal

Watchdog

=

Monitoring of the microcontroller

XLM 35

=

eXtended Line Module

ASD532 Operating Manual

General

16 / 121

1.4 Product identification

For identification purposes, the ASD 532 and its units have rating plates or identification plates.

The following product identifications apply:

Rating plate on the ASD 532 and identification on the packaging

Additional conformity marks may be affixed to a second rating plate or to an extended area of the rating plate (wider plate).

Identification on the packaging of the mounted printed circuit boards

Notice

The

rating plates, type designations and/or identifications on devices and printed circuit boards must not be re-

moved, written over or defaced in any way.

Many products, such as accessories and mounting materials, are identified only with a sticker showing the article number. The

manufacturer identifies these parts by article number.

3052 Zollikofen / Switzerland

11-2000003-01-01.

XXYYZZ

XX.YY.ZZSecuriton: 022.XXXXXX

Schrack: YYYYYYY

EN 54-20 Class: A, B and C

G xxxxxx

U: 14 - 30 VDC

Operating current (24 VDC):

Idle / fault:

Alarm:

Data sheet T 140 422

100 mA

115 mA

ASD 532

XXXXXXXXXX

Made in Germany

Approvals, approval mark

Manufacturer

Type designation

Response class

Operating voltage / current consumption

Document number (data sheet)

Approval number

Article number (Hekatron)

Article number (Securiton/Schrack)

Production date (day.month.year)

Production version (day/month/year)

ID number

1

SECURITON XYZ 35

4000XXX.XXXX.XXYYZZ YY/ZZ

Securiton: XXX.XXXXXX

Schrack: YYYYYYY

Approvals, approval mark

Type designation

Article number (Hekatron)

Article number (Securiton/Schrack)

Production date (month/year)

Production version (day/month/year)

Manufacturer

ASD532 Operating Manual

General

17 / 121

1.5 Smoke sensors used

Danger

Only those smoke sensors in the device approval and in the list below may be used in the

ASD 532 aspirating

smoke detector. The use of third-party detectors voids the ASD 532 approval issued by the manufacturer.

Smoke sensors of the following type can be fitted in the ASD 532 (see also Sec. 4.9 and 6.6.4):

•SSD 532-1 Alarm sensitivity range 0.5%/m to 10%/m

•SSD 532-2 Alarm sensitivity range 0.1 %/m to 10%/m

•SSD 532-3 Alarm sensitivity range 0.02 %/m to 10%/m

The response sensitivity of the concerned smoke sensor can be adjusted within the above specified range. Depending on the

application in accordance with EN 54-20, Class A, B or C, the value is specified via AMB 32 (pre-defined switch positions as

described in Sec. 4.4.4 to 4.4.4.3) or based on planning specifications using the ASD PipeFlow calculation software via the

ASD Config configuration software (see Sec. 7.2.1). The selection of the smoke sensor type with the respective range of sensi-

tivity is based on the information in Sec. 4.4.4.3 or “ASD PipeFlow”.

1.6 Hardware / firmware

The hardware is considered to comprise the complete detector housing and all the units belonging to the ASD 532 aspirating

smoke detector such as sampling pipe and mounting material.

The firmware is located on the Flash PROM in the ASD 532. An EEPROM is fitted for storing and saving system-specific pa-

rameters.

Danger

The

ASD 532 is to be operated only with the appropriate original firmware from the manufacturer.

Any unauthorised intervention in the firmware or the use of non

-

original firmware may result in malfunction and/or

in damage to the device. Furthermore, all guarantee and warranty rights with respect to the manufacturer of the

ASD 532 will become null and void as a result.

© Copyright by Securiton

All ASD 532 firmware is subject to the manufacturer’

s copyright. Any unauthorised intervention in the firmware, misuse,

copying or unauthorised trade with the firmware represents a breach of copyright and will be subject to legal proceedings.

Notice

A version change or extension of the

ASD 532

firmware does not imply a right to an upgrade or new release for

existing ASD 532 systems.

ASD532 Operating Manual

Function

18 / 121

2 Function

2.1 General operating principle

In the sampling pipe tube network, the fan generates a vacuum which results in fresh air continuously reaching the detector

housing via the sampling pipes. In this way the smoke sensor is constantly supplied with new air samples from the monitored

area. Should the smoke concentration exceed the permissible value, the ASD 532 triggers an alarm. The alarm is indicated

visually on the ASD 532 and can be transmitted via a potential-free change-over contact to a superordinate fire alarm control

panel.

The operational reliability of the aspirating smoke detector depends on the functional reliability of the smoke sensors and on

the constant air supply to the system. A fan failure, blockage of the sampling holes or pipe breakage must be communicated to

the fire alarm control panel in the form of a fault signal. This condition is satisfied by the airflow monitoring of the ASD 532.

Fig. 1General operating principle

ASD 532

Housing

Smoke sensor

chamber

Installation location

for additional module Cable entries

Monitoring area

Sampling

holes

Sampling pipe network Smoke sensor Airflow sensor

Fan

Air outlet

AMB ASD Main Board

ASD532 Operating Manual

Function

19 / 121

2.2 Electrical functional principle

Fig. 2Block diagram

2.2.1 Power supply

The operating voltage of the ASD 532 is +14 to +30 VDC. On the AMB 32 Main Board, 5 VDC of the operating voltage is di-

verted for internal voltage use.

The operating voltage is monitored on the AMB 32 for undervoltage. If the operating voltage falls below 13 VDC (+0 /

–0.3 VDC), the ASD 532 triggers an undervoltage fault.

15 14 13 12 11 10 987654321

LED1

IN

OUT

LED2

LED3

LED4

LED5

(8)(8)

2 RIM 36

nd

Fan

Connection possibilities of the additional modules

to or

1 x SIM 35 to or

2 x RIM 36 to cascaded

1 x XLM 35 :

“”“”

“”“”

“”

Option1

Option1 Option2

Option3 ,

Option2

1 2 3 4 5 6

(16)

SIM 35

(16)

L1

C1

G1

L2

C2

G2 LED2

LED1

XLM 35

Air flow

sensor

Smoke sensor

SSD 532

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

LED1

IN

OUT

LED2LED3LED4LED5

(8)(8)

1 RIM 36

st

Reset

ext.

Rel. 2

Al Rel. 1

St OC Supply

Red. InOEM

Accessories

bus

(16) (16) (8)

AMB 32

Option3Option1 Option2

BAT

Reset

OK

HW-Reset

SENSSSD

Vent

21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 54 3 2 1

Ethernet

UP

CardOK

Com

Wdog

Pwr

Al

Flt

Det.

dusty

dirty

1

2

3

4

5

6

7

8

9

10

LED1

LED2

LED3

LED4

ASD532 Operating Manual

Function

20 / 121

2.2.2 Fan control

The physical and electrical properties of a fan cause a brief power surge when it is switched on and starts up, which in turn af-

fects the conductor dimensioning and the total power consumption of the fire alarm system.

A specially designed circuit therefore ensures that the fan cannot exceed a specific maximum power consumption in its start-

up phase. When the ASD 532 is switched on, the computer-controlled fan speed starts up slowly. After the fan has been pow-

ered up, the speed is kept constant.

Any blocking of the fan is detected by evaluating the motor speed. If the specified threshold is undershot, the fan supply is

switched off and a fault is signalled.

Depending on the size of the system and/or environment, the fan can be operated at different speeds (by means of the

“ASD Config” configuration software). This is useful primarily in critical areas (long pipes) to increase the transport speed in the

sampling pipe tube network (high speed) or to reduce the noise level in cases where the noise level produced by the fan is a

disturbance (low speed). The following fan speed levels can be selected:

Level

Speed

(rpm)

Effect

I

5250

Low transport speed / low noise level

II

6900

Normal transport speed / reduced noise level

III

9300

High transport speed / normal noise level

Notice

•

The fan speed levels can be changed only with the “ASD Config” configuration software.

•

For applications and commissioning without “ASD Config” configuration software, Level II must always set.

•

If the fan speed is changed (by using the “ASD PipeFlow”

calculation software), ensure that the maximum

permissible transport time according to EN 54-20 is not exceeded.

•

After the fan speed has been changed, it is imperative

that a new initial reset is carried out (observe waiting

time of at least 2 min).

2.2.3 Microcontroller

The entire program and switching sequence is controlled by a microcontroller. The firmware is stored on a Flash PROM. Sys-

tem-specific configurations are stored in an EEPROM.

The program is monitored by the internal watchdog of the microcontroller. In the event of a failure of the microcontroller circuit,

an emergency fault is triggered. This is signalled on the device by the steady lit Fault LED. The “Fault” relay switches.

ASD532 Operating Manual

Table of contents

Other Incite Fire Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

detectomat

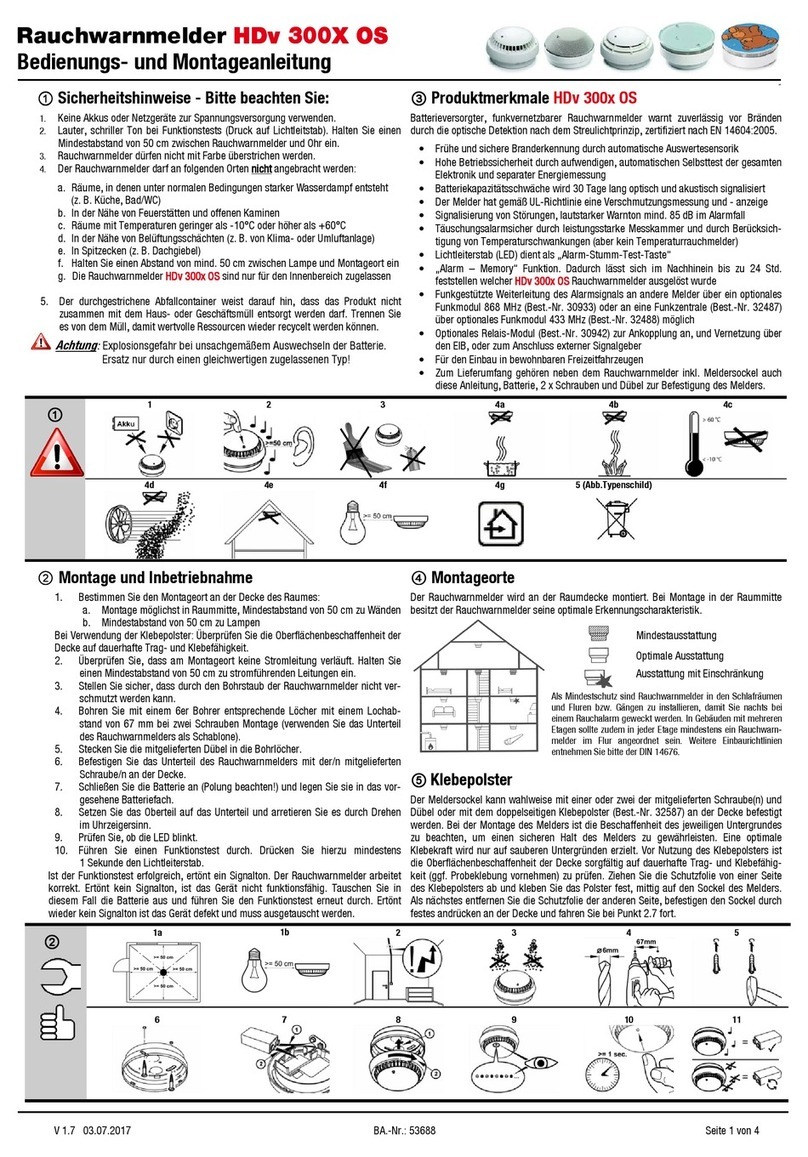

detectomat HDv 300 OS Series Operation and installation manual

UltraFire

UltraFire UBH1RF user manual

Honeywell

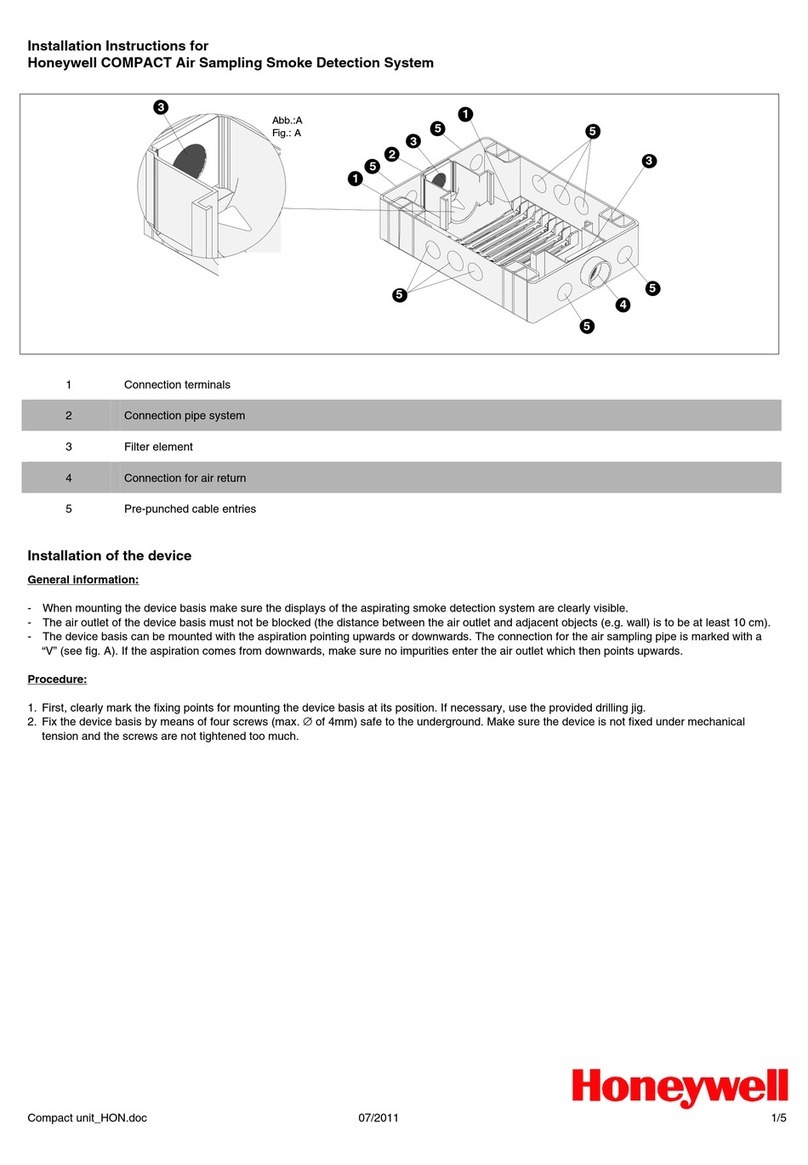

Honeywell compact asd installation instructions

Ei Electronics

Ei Electronics Ei161RC Ionisation installation instructions

BRK electronic

BRK electronic 83RN quick start guide

careium

careium i10 user guide

Notifier

Notifier SFP-400B manual

Housegard

Housegard System Link SA423WS user manual

Elektrotechnik Schabus

Elektrotechnik Schabus GX-D500P operating instructions

System Sensor

System Sensor 2351E Installation and maintenance instructions

System Sensor

System Sensor 2D51A Installation and maintenance instructions

Smoke hollow

Smoke hollow 44241G2 Assembly & operation