– 11 –

POLARIZATION

All waves possess one of two different types of motion. Sound waves are compressional

motion(likecompressing,thenreleasingaspring).Lightwaves,however,aretransverse.

Tovisualizetransversewaves,imagineholdingoneendofa10-foot-longropeinonehand.

The other end of the rope is fastened to a wall, and you are pulling it tight, so it extends

inahorizontalline.Nowmovethathandup/down,right/leftandcircularinrandom

patterns.Withthesemotionsyouarecreatingavisualmodelofatransverselightwave.

Energy,orlight,beginsatyourhandandendsupatthewall.Allenergyorwavesthatyou

createdintheropeareunpolarizedbecausethereisnodenedpatternormotion.Sunlight

is unpolarized, as is light from most light sources except lasers.

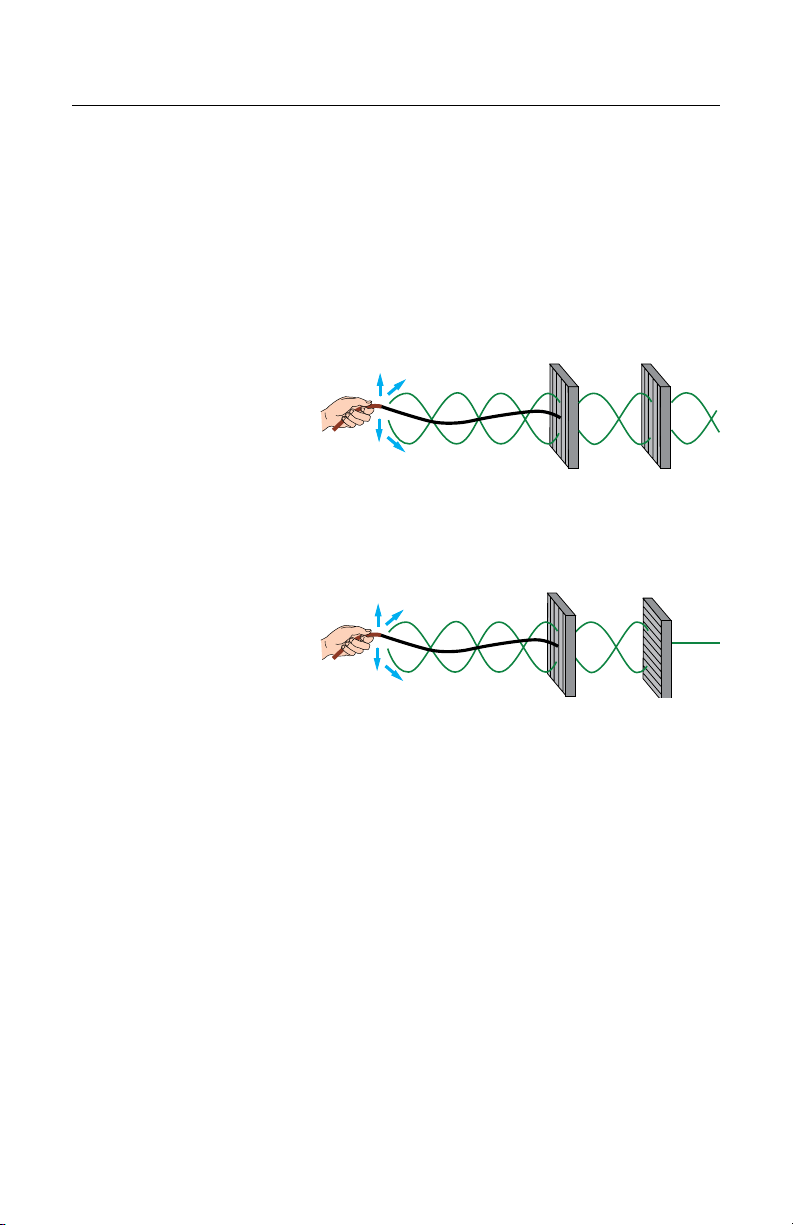

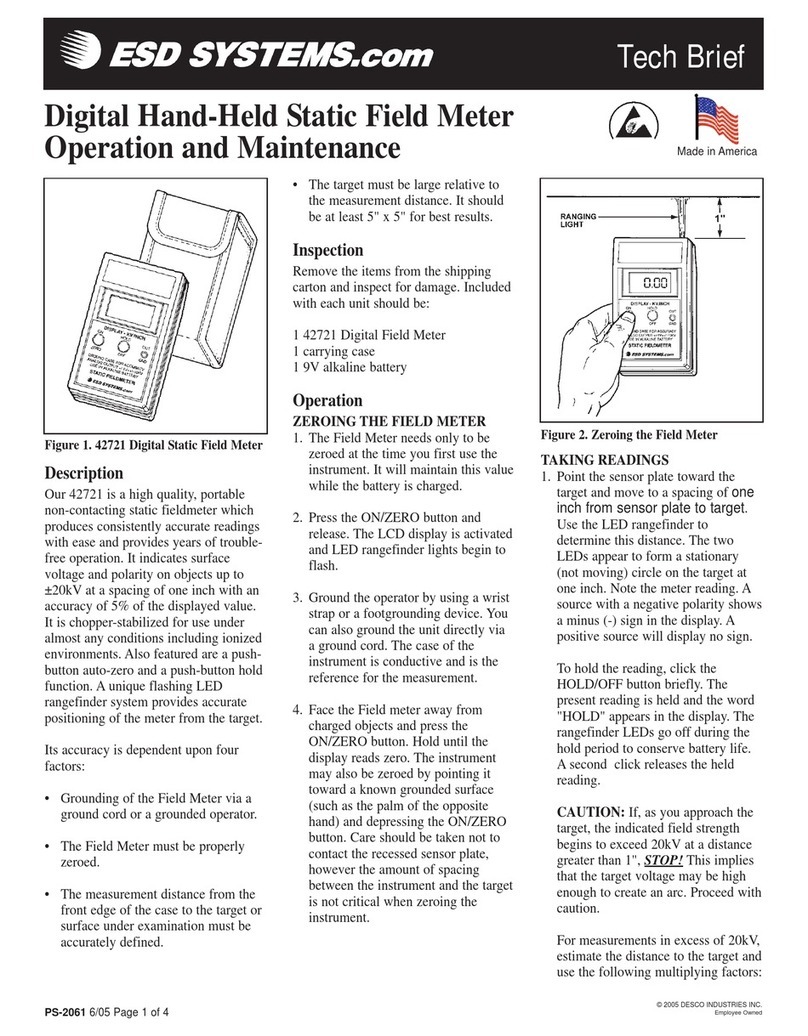

Conversely, a linearly polarized

wave travels in a known and

nonvarying pattern, as if you

weretomovetheropeonlyup/

down. Unpolarized waves can

belteredintopolarizedwavesifweusespecialmaterialswithslotsorgratingsinthem.

Imagine the rope passing through a grating with only vertical slots, as shown above. The

slot prevents sideways motion, but freely allows the vertical components of vibration

to pass.

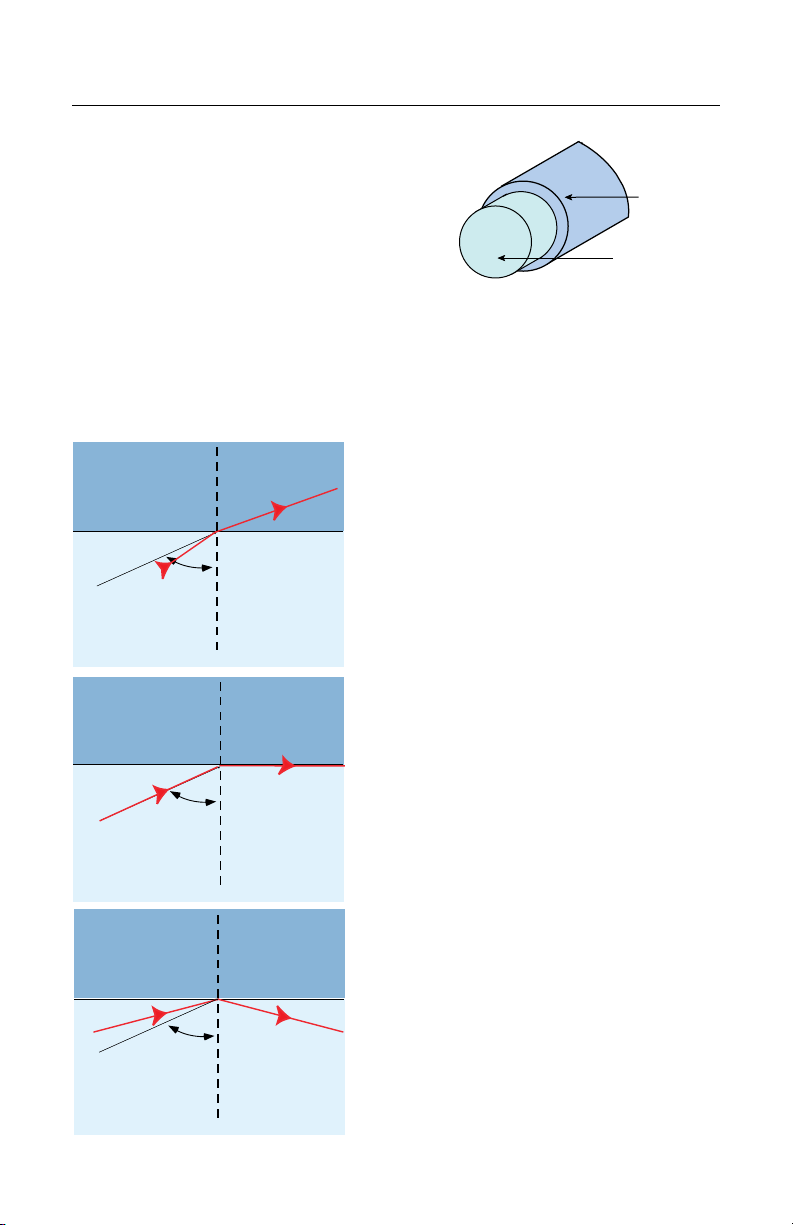

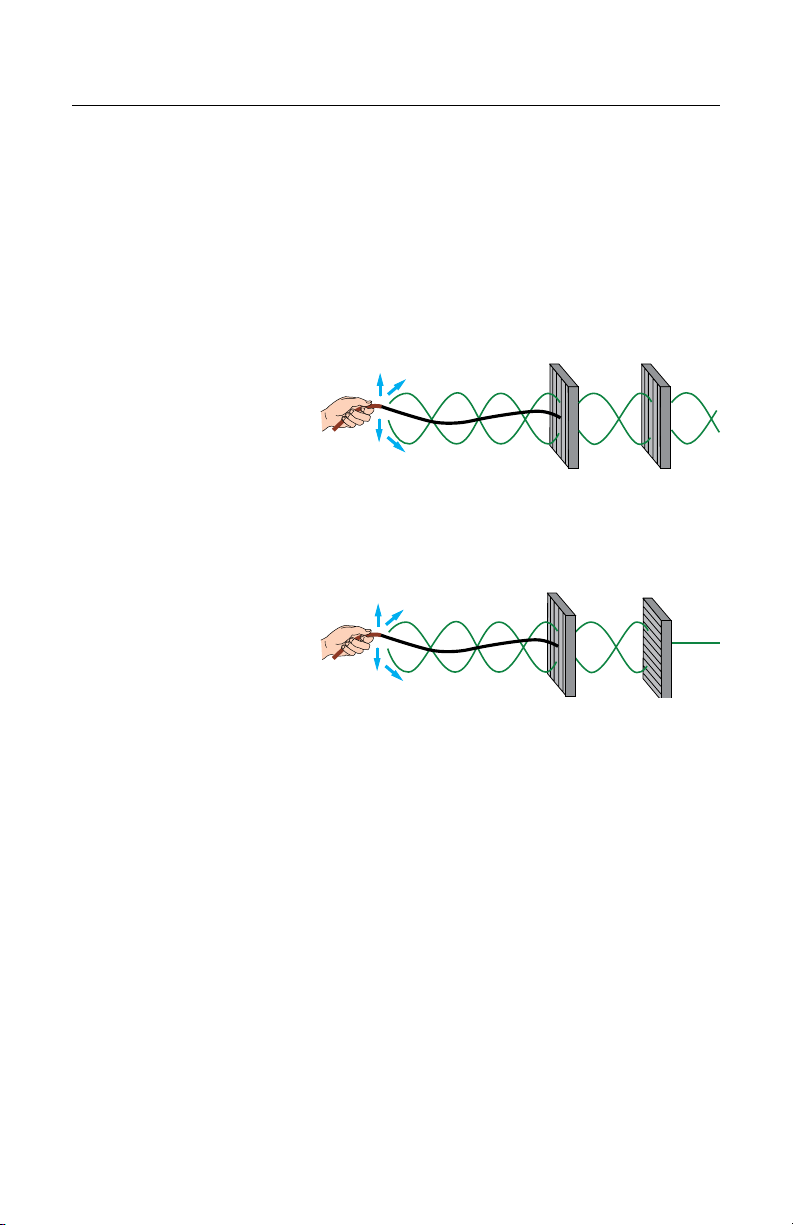

Placing a second vertical grating

behind, and aligned with, the

rstwillstillallowthevibrations

to pass through both sets of slots

freely. However, if we turn the

secondgratingtoahorizontalposition,noneoftheverticallight/wavesexitingtherst

grating will pass through or be transmitted by the second grating.

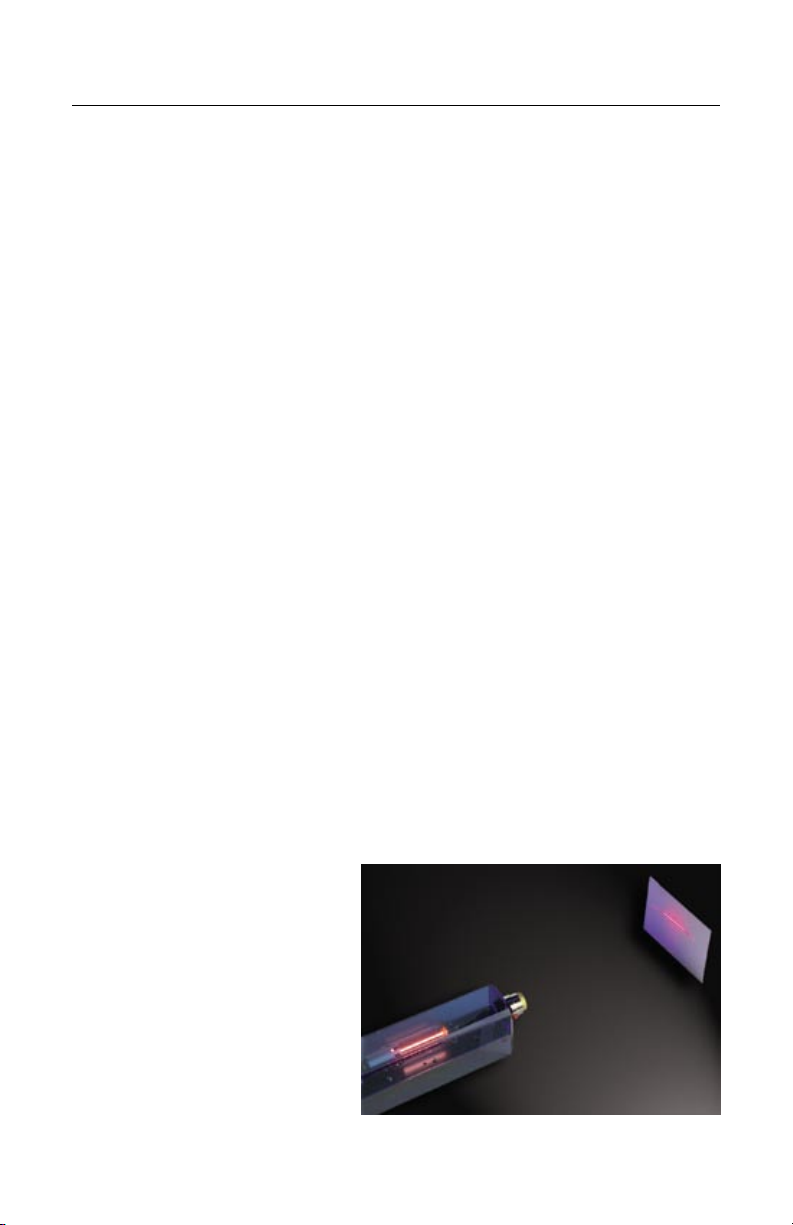

Thepolarizinglterinyouropticskitactslikethegratingsdescribedabove.Imbedded

inside the plastic are molecules that allow only light waves of a certain polarization to pass

through.Whenunpolarizedlightpassesthroughalinearpolarizinglter,itemergesas

polarizedlightvibrationsinasingleplane—althoughwithone-halftheintensity.

Unpolarizedlightcanalsoundergopolarizationbyreection.Non-metallicsurfaces

suchasasphaltroads,snoweldsandwaterreectlightwithalargeconcentrationof

vibrations(whichwecommonlycall“glare”)inaplaneparalleltothereectingsurface.

Lightreectedoffalakeispolarizedmostlyinadirectionparalleltothewater’ssurface.

Glareoftenpreventsshermenfromseeingshinthewaterbelow.Savvyanglersknow

that using special sunglasses (containing lenses with a proper polarization axis) reduces

glare,andtheycaneasilyseeshandotherunderwaterobjects.Polarizationhasawealth

ofotherapplicationsbesidesitsuseinglare-reducingsunglasses.Inindustry,polarizing

equipment is used to indicate stress in transparent plastics. Polarization also is used in the

entertainmentindustrytoproduceandshow3-Dlmsandvideotapes.