Industrial Fiber Optics IF-RL05 User manual

Semiconductor

Diode Laser

Operator’s Manual

IndustrIal FIber OptIcs

Model Number:

IF-RL05

IF-RL08

IF-RL30

*

Copyright © 2023

Previous Printings 2010, 2000, 2001, 2003, 2006

by Industrial Fiber Optics, Inc.

Revision - E

Printed in the United States of America

* * *

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in any form or by any means

(electronic, mechanical, photocopying, recording, or otherwise)

without prior written permission from Industrial Fiber Optics.

* * * * *

– i –

INTRODUCTION

This manual provides information about Industrial Fiber Optics lasers model

numbers IF-RL05-635, IF-RL08-635, IF-RL30-635 and IF-RL30-670. It contains

all the information you need to operate these lasers safely and knowledgeably,

even if you are a novice to laser technology. Please read the manual carefully

before operating the laser.

As soon as you receive this laser, inspect it and the shipping container for

damage. If any damage is found, immediately refer to the section of this manual

entitled Shipment Damage Claims.

Industrial Fiber Optics makes every effort to incorporate state-of-the-art

technology, highest quality, and dependability in its products. We constantly

explore new ideas and products to best serve the rapidly expanding needs of

industry and education. We encourage comments that you may have about our

products, and we welcome the opportunity to discuss new ideas that may better

serve your needs. For more information about our company and products refer to

www.i-beroptics.com.

Thank you for selecting this Industrial Fiber Optics product. We hope it

meets your expectations and provides many hours of productive activity.

Sincerely,

The Industrial Fiber Optics Team

– ii –

.

– iii –

TABLE OF CONTENTS

Introduction……………………….................…….....…………..…… i

GENERAL....................................................................................... 1

OPERATIONAL INFORMATION………….......…..…...……............. 3

Electrical………….................................................…..................... 3

Beam Controls............…..........................…...............…............... 6

Specications............…..........................…...............…............... 7

Models and Laser Classications………................…............….... 7

SAFETY…………................…........................….................….......... 8

LASER REGULATIONS................................................................... 9

Certication/Identication.............................................................. 9

Classications............................................................…................ 9

Aperture Labels........................................….................…............. 10

Additional References................................................................... 10

OPERATING PROCEDURES.......................................................... 11

Non-modulation or CW Operation...........................….....….......... 11

Using Laser with Microphone............................…..........….......... 12

TROUBLESHOOTING..............................................….................... 13

SERVICE AND MAINTENANCE...................................................... 14

WARRANTY..................................................….................…........... 15

SHIPMENT DAMAGE CLAIMS....................................................... 16

– iv –

LASER CLASSIFICATIONS

All manufacturers of lasers used in the United States must conform to regulations admin-

istered by the Center for Devices and Radiological Health (CDRH), a branch of the U.S.

Department of Health and Human Services. CDRH categorizes lasers as follows:

Class Description

IA laser or laser system which does not present a hazard to skin

or eyes for any wavelength or exposure time. Exposure varies

with wavelength. For ultraviolet, .2 to .4 µm exposure is less than

from .8 nW to .8 µW. Visible light exposure varies from .4 µW to

200 µW, and for near IR, the exposure is < 200 µw. Consult CDRH

regulations for specic information.

II Any visible laser with an output less than 1 mW of power. Warning

label requirements — yellow caution label stating maximum output

of 1 mW. Generally used as classroom lab lasers, supermarket

scanners and laser pointers.

IIIa Any visible laser with an output over 1 mW of power with a

maximum output of 5 mW of power. Warning label requirements

— red danger label stating maximum output of 5 mW. Also used

as classroom lab lasers, in holography, laser pointers, leveling

instruments, measuring devices and alignment equipment.

IIIb Any laser with an output over 5 mW of power with a maximum

output of 500 mW of power and all invisible lasers with an output

up to 400 mW. Warning label requirements — red danger label

stating maximum output. These lasers also require a key switch

for operation and a 3.5-second delay when the laser is turned

on. Used in many of the same applications as the Class IIIa when

more power is required.

IV Any laser with an output over 500 mW of power. Warning label

requirements — red danger label stating maximum output. These

lasers are primarily used in industrial applications such as tooling,

machining, cutting and welding. Most medical laser applications

also require these high-powered lasers.

– 1 –

GENERAL

Industrial Fiber Optics’ family of diode lasers (whose models vary only in their power and

output wavelength) utilizes the latest technology in miniaturization electronics and laser

science — the same as used in long-distance fiber optic communication networks, CD

players and bar code scanners. The technology incorporates semiconductor laser diodes —

tiny electronic microchips that operate as lasers.

Semiconductor diode devices oer an important alternative to widely known and used

helium-neon-gas (HeNe) lasers. Diode lasers are smaller, more ecient, and oer direct

digital and analog modulation capabilities previously unavailable. Exceptional versatility

makes this semiconductor technology an essential component of modern science, physics

and industrial technology curriculums.

The Industrial Fiber Optics family of lasers oers particular educational value in its ability

to increase and reinforce learning via fascination. They also oer more options for internal

application and types of modulation inputs. With these lasers, students will readily,

enthusiastically learn about physical optics, fiber optics, light propagation, speed of light

theory and measurement, laser communications, and much more!

Table 1. Common abbreviations used in this manual.

Abbr. Long version Scientic Notation

mW milliwatts. 1 x 10-3 watts

µW microwatts 1 x 10-6 watts

nW nanowatts 1 x 10-9 watts

mm millimeters. 1 x 10-3 meters

µm micrometers 1 x 10-6 meters

nm nanometers 1 x 10-9 meters

– 2 –– 2 –

OPERATIONAL INFORMATION

Electrical

All electrical controls are located at the rear of the laser chassis. A diagram of the rear view

of the laser appears in Figure 1. Following are descriptions of each item identified in

Figure 1:

1. Power Jack (PWR)

All Industrial Fiber Optics lasers use a standard 2.1 mm DC power input jack to

provide power to the laser. (An ON/OFF switch controls power from the jack to the

electronic circuitry and lasing element.)

Power input to the laser must be applied from a low-voltage DC power source in the

range of 10 to 15 volts, such as supplied with the laser. See Item 9 in this section for

more information about the power adapter.

1

MODEL IF - RL

GAIN

AUDIO

50

INDUSTRIAL FIBER

OPTICS

SW

PWR

DIGITAL

GND

ANALOG

PILOT

MODEL IF - RL

Power adapter

(not shown)

1334.eps

GAIN

1

MODEL IF - RL

MODEL IF - RL

GAIN

GAIN

AUDIO

50

INDUSTRIAL FIBER

OPTICS

SW

PWR

DIGITALGNDANALOG

PILOT

AUDIO

50

INDUSTRIAL FIBER

OPTICS

SW

PWR

PILOT

Figure 1. Rear view of laser showing electrical inputs and controls.

– 3 –

2. Switch (SW)

A push-button switch is located immediately to the right of the 2.1 mm power jack.

It controls power from the 2.1 mm power jack to the electronic circuitry and lasing

element. When the switch is closed it will be slightly depressed, compared to the open

position, when the switch will be fully extended.

3. Pilot light (PILOT)

Just below and left of the Switch is the pilot light. It emits a green light when the

switch is on and power is applied to the electronic circuitry and lasing element

4. Gain control (GAIN)

The gain control feature of this laser makes it the most versatile educational laser

on the market. The Gain control knob is located on the left side of the front panel.

It controls the gain of an internal electrical circuit which amplifies signals from the

microphone (AUDIO) and analog (ANALOG) inputs. This feature is particularly useful

for ensuring compatibility of the laser with low-level microphone signals as well as

larger amplitude signals from cassette and CD players.

Starting with the Gain Control Knob set to 1 (Gain Control Knob turned fully counter-

clockwise) the AUDIO and ANALOG signal inputs accept voltage levels up to 50 mv

RMS peak before saturating the modulation range of the laser. When you have input

signals less than 50 mv RMS peak you can use the Gain Control Knob to increase the

signal to the laser modulation. You can now take input signal levels even as low as

<1 mv and with the Gain Control Knob turned fully clockwise increase the level 50

times. This allows for maximum laser modulation for improved output detection using

a variety of laser receivers.

5. 3.5 mm jack (AUDIO)

This is an industry-standard jack, commonly described as a 3.5 mm audio type. It is

compatible with most remote microphones and, with patch-cord interconnections, to

cassette and CD players.

The minimum impedance of this input is 1 k ohms. Typically the Gain control is set

at about the 2 o’clock position when using a microphone connected to this jack. Turn

the Gain control knob fully counterclockwise when patching cassette and CD player

outputs into the 3.5 mm jack

6. Analog input (ANALOG)

This jack is an industry-standard “banana” type as are the GND and DIGITAL inputs. It

is located in the lower left portion of the control panel.

The Analog input is an alternate method of inputting signals to utilize this laser’s

analog modulation capabilities.

– 4 –

The input source and the laser must share a common ground when using the analog

banana input jack. Establish the common ground connection for the analog input

through the jack labeled “GND”, described in the next section

7. Ground Input (GND)

This is the green banana jack located in the lower center portion of the laser control

panel. The ground banana jack completes the electrical circuit when the analog and

digital banana jacks are signal inputs for modulating the laser beam intensity.

8. Digital Modulation Input (DIGITAL)

The white banana jack is the input for digital signals to the laser, to digitally modulate

the laser optical beam. Examples of utilizing the laser for such an application would be

a computer-to-printer through-the-air link, a digitally coded security system or a long-

distance remote TV control.

The digital input to this laser is

compatible with standard LSTTL

logic, powered by +5 volts. Do not

connect the input to any logic with

voltage levels greater than +5 volts, or

below ground (0 volts). Table 2 is the

truth table describing laser output in

response to digital inputs.

As with analog modulation, the digital

source and the laser must share a

common ground for you to use the

laser’s digital modulation capabilities.

To establish the common ground, use

the “GND” banana jack.

9. Power adapter (not shown)

All Industrial Fiber Optics lasers sold in the United States come complete with a power

adapter suitable for 60 Hz 110 VAC-to-VDC conversion. Most others come with 50 Hz

220 VAC-to-VDC power adapters. It is strongly recommended that the power adapter

furnished with the laser be the only supply used.

If you must use another power supply, it must be one with voltage output between

10 to 15 volts DC, and minimum current capability of 150 milliamperes. Do not use a

power supply which may generate or pass voltage spikes exceeding 36 volts.

Table 2. Laser Output versus Digital Input.

Digital Signal Laser Output

>3.4 volts High*

<0.7 volts Low**

Unconnected High*

* Output power will equal the laser power rating.

** The laser will still produce a small amount of opti-

cal power, less than 20% of high level.

– 5 –

BEAM CONTROLS

1. Optics Mount

The optics mount is a nickel-plated aluminum cylinder with internal diameter of

¾ inches and with 32 threads per inch. The threads facilitate the use of this laser in

many optical experiments using mounted lenses, polarizers and spatial filters, such as

Industrial Fiber Optics Laser Optics Kit P/N IF-535.

2. Beam Stop

TThe beam stop (also known as a beam attenuator) is required on lasers by federal

regulations. When viewed from the rear of the laser, its handle protrudes from the

right side of the optics mount. Its function is to mechanically block the laser beam

when the handle is pushed downward. When the handle is pushed upward, the beam

stop rotates and allows the laser beam to exit the lasing apparatus.

1193

AVOID EXPOSURE

LASER RADIATION EMITTED

FROM THIS APERTURE

1

2

Figure 2. Front View of Laser with Beam Stop

Blocking the Laser Beam

– 6 –

SPECIFICATIONS

Caution: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Specifications for laser model numbers IF-RL05-6351, IF-RL08-6351, IF-RL30- 6351, and

IF-RL30-6701are shown in Table 3.

Models and Laser Classications

Table 3. Laser Specications

Parameter Value Units

Operating

Input voltage 10 to 15 volts

Input current 60 to 125 milliamperes

Temperature 0 to 40 ° C

Optical

Polarization Linear

Wavelength 630 - 6751nm

Output power See label2mW

Beam diameter 3.2 mm

Beam divergence, max 2 milliradians

Electrical

Analog modulation310 to 500 kHz

Digital modulation30 to 500 kHz

Storage

Dimensions 5.6 x 7.5 x 22 cm

Weight 400 grams

Temperature -20 to 50 ° C

1 The lasing wavelength, in nanometers, is the last three numbers in the part number

located on the underside of the laser chassis.

2 Label is located on the bottom side of the laser.

3 Refer to the section on electrical controls in this manual for more information

Table 4. CDRH Classications for laser models.

Laser Model Classication Typical power levels

IF-RL05-635 CLASS II .4 to .6 mW

IF-RL08-635 CLASS II .75 to .90 mW

IF-RL30-635 CLASS IIIa 2.8 to 3.2 mW

IF-RL30-670 CLASS IIIa 2.8 to 3.2 mW

– 7 –

SAFETY

OPTICAL

All lasers addressed by this manual emit a visible beam of red light. No infrared, ultra-violet,

x-ray or other non-visible radiation is emitted from these products.

This low-power laser cannot be used to burn, cut or drill. Even so, you should use caution,

because the beam is concentrated. It could become focused to a pinpoint within the human

eye. Never look directly into the laser beam or stare at its bright reflections — just

as you should avoid staring at the sun or other very bright light sources.

Review the Rules for Laser Safety on the back cover of this booklet.

ELECTRICAL

Included with this laser is a UL-approved VAC-to-VDC adapter for VAC operation. The

adapter converts common lab/household voltage to low DC voltage suitable for laser use.

Always plug the adapter into a grounded circuit.

This laser is particularly safe because it operates at low wattage and low current levels.

However, as when using any electrical device, you must take certain safety precautions:

• Do not touch (or short-circuit) the connection point at which incoming power from

the adapter enters the laser housing, as this could damage the power supply.

• Do not open the laser housing under any circumstances, as this will expose you

to unshielded electrical connections, violating federal government regulations and

voiding the product warranty.

– 8 –

LASER REGULATIONS

The U.S. Department of Health, Education and Welfare regulates and classifies all laser

products sold in the United States. Industrial Fiber Optics lasers comply fully with laser

performance standards established by Center for Devices and Radiological Health (CDRH)

Regulation 21, parts 1040.10 and 1040.11, Code of Federal Regulations.

Specific labeling is required by Federal Regulations on all laser products. For your safety

and that of others, do not remove any of the labels.

Certication/ Identication

Laser certification and iden-

tification labeling required

by federal regulations have

been combined in a single

label located on the under-

side of the laser. A graphic

representation of that label is

shown in Figure 3. It certifies

that this laser complies with

federal regulations; identifies

the manufacturer; and lists

the model number and date of

manufacture.

Classications

All lasers described by this manual fall within the limitations of Class II and Class IIIa of

CDRH standards. All lasers covered by this manual will exhibit a label located on the top,

rear of the laser chassis as shown in Figure 7.

Class II lasers may not exceed 1 milliwatt

(1 mW) of output power, must contain a pilot

light and a beam attenuator. An example of the

“warning logotype” label used for Class II lasers

is shown in Figure 4.

No User Serviceable Parts Inside

This LASER product complies with

C.D.R.H. Regulation 21 CFR 1040.10 and 10410.11

Model Number:

Output Power:

Manufacturing Date:

Serial Number:

Manufactured by:

INDUSTRIAL FIBER OPTICS, INC.

1725 West 1st Street

Tempe, AZ 85281-7622

1188.eps

Figure 3. Laser certication

and identication label.

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

PEAK POWER 1 mW

WAVELENGTH 600 - 700 nm

Class II Laser Product

1189.eps

Figure 4. Warning logotype label

for Class II lasers.

– 9 –

Class IIIa lasers have an output power limitation

between 1 and 5 milliwatts, and require a pilot

light and a beam attenuator. The “warning

logotype” label required for this classification of

laser is shown in Figure 5.

Aperture Labels

Federal regulations also require that the laser

emission aperture/port be labeled. A graphic

representation of that label is shown in Figure

6. Location of this label is shown in Figure 2.

Additional References

For more information about lasers and laser

standards, contact your local U.S. Department

of Health and Human Services, or write to the

agency’s headquarters at 1390 Piccard Dr.,

Rockville, MD 20850.

For U.S. guidelines on laser classifications and health standards, refer to the American

National Standards Institute (ANSI) specifications governing lasers and laser safety. The

guidelines are published by the Laser Institute of America, 12424 Research Parkway,

Suite 130, Orlando, FL 32826.

LASER RADIATION

DO NOT STARE INTO BEAM

PEAK POWER 5 mW

WAVELENGTH 600 - 700 nm

Class IIIa Laser Product

DANGER

1190.eps

AVOID EXPOSURE

LASER RADIATION EMITTED

FROM THIS APERTURE

1191.eps

Figure 5. Warning logotype label

for Class IIIa lasers

Figure 6. Beam aperture label.

1209.eps

LASER RADIATION

DO NOT STARE INTO BEAM

PEAK POWER 5 mW

WAVELENGTH 600 - 700 nm

Class IIIa Laser Product

DANGER

Figure 7. Top view of laser showing the location of the

“warning logotype” label for a Class IIIa laser.

– 10 –

OPERATING PROCEDURES

Non-modulation Or CW Operation

1. Review the laser safety steps on the back cover of this manual.

2. Point the laser toward a wall or other dull non-reflecting surface.

3. Push the beam stop’s handle downward to its closed position.

4. Make sure the laser’s ON/OFF switch (SW) is in its OFF position.

(The push button should be in its extended position.)

5. Plug the 110* VAC-to-DC power adapter (provided with the laser)

into an AC wall outlet.

Important: If you must use a power adapter other than the one supplied with this laser,

check the section entitled Operational Information in this manual to ensure

the power adapter’s voltage and current levels are within recommended

specifications

6. Plug the cord from the power adapter into the power jack (PWR) located

on the rear of the laser.

7. Depress the ON/OFF switch (SW) on the control panel of the laser until

it clicks into the ON position. (The switch should be slightly depressed.)

8. The pilot light (green LED) just to the left and below the ON/OFF switch

should now be lit, showing that the laser is on.

9. Push the beam stop’s handle upward, to its open position.

10. Observe the red beam striking the wall, or other surface, in the direction

which the laser is pointed.

* 220 VAC for most customers outside of North America

– 11 –

Using Laser With Microphone

We will outline the steps for using a microphone with your Industrial Fiber Optics diode

laser. Because we don’t know what receiver you will use to convert the optical signal on

the laser beam to sound, please refer to that receiver’s instruction manual as directed in

the procedure below.

1. Complete Steps 1 through 10 on page 10.

2. Push the beam stop to its closed position, and make sure the laser’s ON/

OFF switch is OFF. (The button should be extended and the pilot light no

longer illuminated.)

3. Plug the 3.5 mm plug on the end of the microphone cord into the

3.5 mm audio jack.

4. Point the laser toward a wall or other non-reflecting dull surface.

5. Set up your laser receiver, referring to its manual for operating proce-

dures.

6. Press the ON/OFF switch (SW) on the control panel of the laser. The

laser now should be on, as indicated by the pilot light.

7. Rotate the beam stop’s handle upward, to its open position.

8. Target the laser beam on the light detector found on the laser receiver.

9. Position the receiver or laser as needed, so the laser light beam strikes the

center of the receiver detector.

10. If a high-pitched squeal is produced by the laser receiver and speaker,

reduce the volume at the receiver.

11. Speak into the microphone. If you cannot hear yourself, bring the

microphone closer to your mouth and/or increase laser receiver volume.

Your laser and receiver should now be functioning as a free-space optical voice link.

You should be hearing your voice or music from the audio receiver.

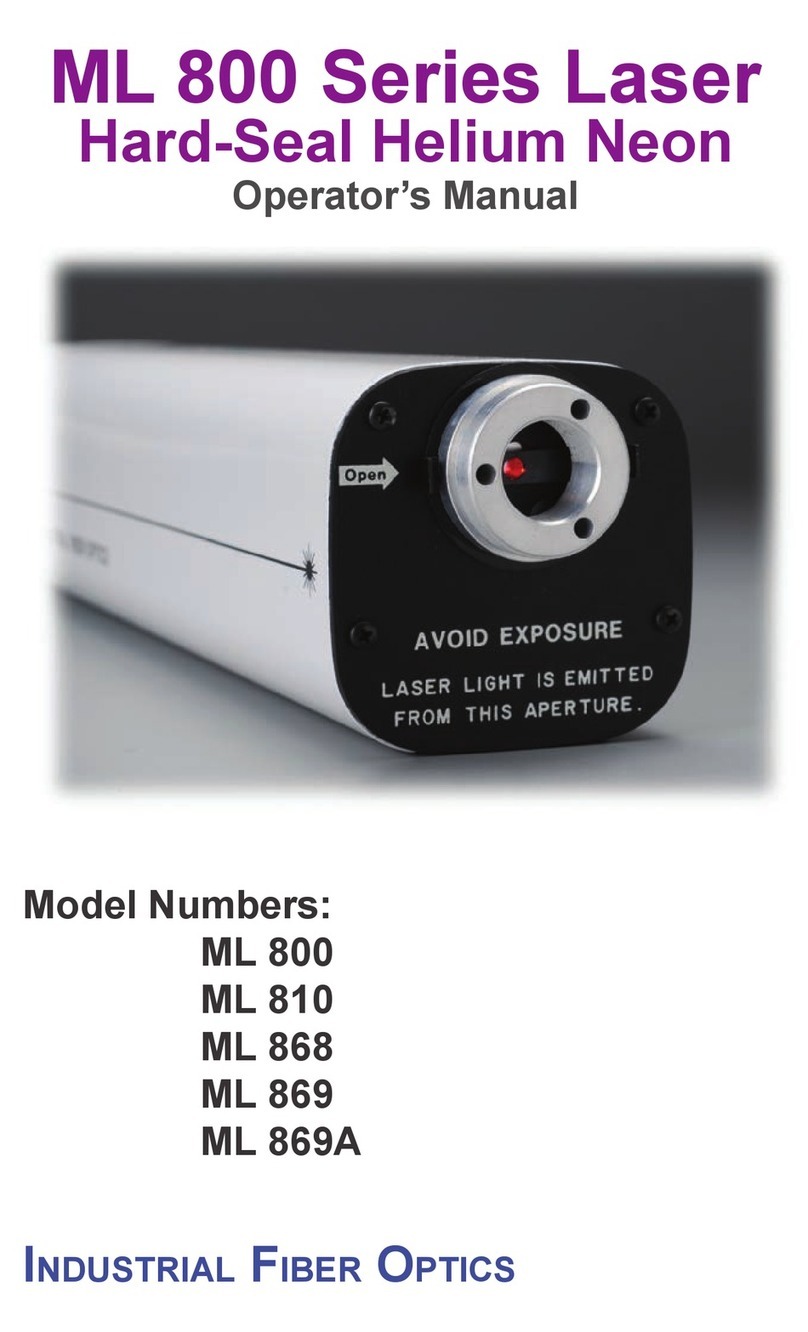

Figure 8. Class IIIa laser and laser beam aligned with an Industrial Fiber Optics’

audio laser receiver for demodulation of the laser beam’s modulated signal and

producing sound waves.

– 12 –

TROUBLESHOOTING

No Pilot Light

• Is the laser’s ON/OFF switch in the ON position?

• Is the 110 (220) VAC-to-VDC power adapter plugged into the laser and an

appropriate wall outlet or extension cord?

• Is there power to the wall outlet?

No Laser Light Output

• Is the ON/OFF switch in the ON position?

• Is the 110 (220) VAC-to-VDC power adapter plugged into the laser and an

appropriate wall outlet or extension cord?

• Is there power to the wall outlet?

• Is the pilot light on?

• Is the mechanical beam stop in its open position?

No Modulation from Receiver

• Is the laser beam positioned properly so its beam hits the receiver detector?

• If you are using an analog or digital input banana jack, is it properly connected,

including a “ground” connection?

• Are input signals to the laser of sucient amplitude? (See microphone, analog

and digital portions in the Electrical section of this manual.)

• Slowly move the receiver detector out of the path of the laser beam while

continuously monitoring receiver operation. (This would desensitize the

receiver in case the receiver is too sensitive for this laser [saturating].)

• Check the troubleshooting section in your laser receiver manual.

Do not attempt to troubleshoot the laser beyond the steps listed above. If all your

connections are correct, and you are confident that power is being supplied to the laser and

any input devices, please return the laser for appropriate inspection/servicing to Industrial

Fiber Optics, as described in the section entitled SERVICE AND MAINTENANCE.

– 13 –

SERVICE AND MAINTENANCE

Periodic operation, maintenance and service of this laser are not required. The warranty

will be voided if entry has been made to the laser housing and/or any screws have

been removed.

In the unlikely event this laser malfunctions and you wish to have it repaired, please do

the following:

• Contact us to request an RMA number.

• Carefully pack the laser, power adapter, manual, and written description in a

stout box with sucient packing material to prevent damage in shipment.

• Ship the package with assigned RMA number to:

IndustrIal FIber OptIcs

W S

T, AZ -

USA

– 14 –

WARRANTY

Industrial Fiber Optics diode lasers are warranted against defects in materials and

workmanship for 4 years. The warranty will be voided if the laser components have been

damaged or mishandled by the buyer, including entry to the laser housing and/or removal

of screws.

Industrial Fiber Optics’ warranty liability is limited to repair or replacement of any defective

unit at the company’s facilities, and does not include attendant or consequential damages.

Repair or replacement may be made only after failure analysis at the factory. Authorized

warranty repairs are made at no charge, and are guaranteed for the balance of the

original warranty.

Industrial Fiber Optics oers to pay the return freight for warranty repair within the

continental United States by United Parcel Service. Any other delivery means must be paid

for by the customer.

The costs of return shipments for lasers no longer under warranty must be paid by the

customer. If an item is not under warranty, repairs will not be undertaken until the cost

of such repairs has been approved, in writing, by the customer. Typical repair costs start at

$65, and repairs usually take one to two weeks to complete.

When returning items for analysis and possible repair, please do the following:

In a letter, describe the problem, person to contact, phone number and return

address. Contact us to request an RMA number.

• Pack the laser, power adapter, manual and letter carefully in a strong box

with adequate packing material to prevent damage in shipment.

• Ship the package with provided RMA number to:

IndustrIal FIber OptIcs

W S

T, AZ -

This manual suits for next models

2

Table of contents

Other Industrial Fiber Optics Measuring Instrument manuals

Industrial Fiber Optics

Industrial Fiber Optics ML 800 Series User manual

Industrial Fiber Optics

Industrial Fiber Optics ML 801 User manual

Industrial Fiber Optics

Industrial Fiber Optics IF 535 Manual

Industrial Fiber Optics

Industrial Fiber Optics 45-545A User manual

Industrial Fiber Optics

Industrial Fiber Optics IF User manual