Industrial Fiber Optics 45-545A User manual

Digital Laser

Power Meter

User’s Guide

In d u s t r I a l FI b e r Op t I c s

Model Numbers:

45-545A

*

Copyright © 2009

by Industrial Fiber Optics, Inc.

Revision D

Printed in the United States of America

* * *

All rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in any form or by any means

(electronic, mechanical, photocopying, recording, or otherwise)

without prior written permission from Industrial Fiber Optics.

* * * * *

– i –

INTRODUCTION

This manual provides information about the Digital Laser Power Meter

(45-545A) that formerly was manufactured by Metrologic, Inc. It contains all the

information needed to assemble and set up the Digital Laser Power Meter, even

if you are a novice to optical technology. Please read the manual carefully before

operating the Digital Laser Power Meter.

As soon as you receive this Digital Laser Power Meter inspect it and the

shipping container for damage. If any damage is found, immediately refer to the

section of this manual entitled Shipment Damage Claims.

Industrial Fiber Optics makes every effort to incorporate state-of-the-art tech-

nology, highest quality and dependability in its products. We constantly explore

new ideas and products to best serve the rapidly expanding needs of industry

and education. We encourage comments that you may have about our products,

and we welcome the opportunity to discuss new ideas that may better serve

your needs. For more information about our company and products refer to http//

www.i-beroptics.com on the Worldwide Web.

Thank you for selecting this Industrial Fiber Optics product. We hope it

meets your expectations and provides many hours of productive activity.

Sincerely,

The Industrial Fiber Optics Team

– ii –

– iii –

TABLE OF CONTENTS

Introduction……………………….................…….....…………..…… i

GENERAL…………................….............................……..…...…….. 1

SAFETY & OPERATING PRECAUTIONS…..........................……. 2

LASER CLASSIFICATIONS............................................................ 3

THE DIGITAL LASER POWER METER.......................................... 4

BATTERY INSTALLATION.............................................................. 5

MEASURING: STANDARD MODE................................................. 6

MEASURING: PEAK/HOLD MODE................................................ 7

MEASURING: RATIOMETRIC MODE............................................. 8

OUTPUT........................................................................................... 9

RECALIBRATION............................................................................ 9

SPECIFICATIONS............................................................................ 10

TROUBLESHOOTING..................................................................... 10

WARRANTY..................................................................................... 12

SHIPMENT DAMAGE CLAIMS....................................................... 13

– 1 –

GENERAL

The Digital Laser Power Meter, Model 45-545A, provides accuracy required for research

applications and for CDRH compliance measurements. It employs an LCD with large 12

mm (.47”) - high numerals. This unit operates in three modes: standard, peak/hold and

percentage ratiometer. In standard and peak/hold mode, the meter’s four ranges have full

scale readings for 19.99 µW, 199.9 µW, 1.999 mW and 19.99 mW.

Calibration is within 5 percent of full scale for 633 nm of He-Ne (helium neon) or 635 nm

of red laser light. For monochromatic light or other wavelengths within the range of 500

to 950 nm, a built-in radiometric filter corrects to within 20 percent of standard. The chart

shown in Figure 1 gives the nominal response at each wavelength.

An analog signal, available from a BNC output terminal, may be used to drive strip chart

recorders, oscilloscopes, and other devices. Signals up to 100 kHz can be detected and

amplified. The analog output ranges from 0 to +2 Volts.

The meter’s detector cell may be exposed to bright light without damage because circuitry

within the amplifier protects the instrument from an overload up to 20 mW.

The detector, a silicon photo sensor with 1 cm2active area, has a 7 mm diameter aperture

and 30 degree acceptance angle. The detector is mounted in a 25.4 mm diameter cell on a

0.5 m retractable, shielded cable.

The meter may be powered by either 115 VAC or two 9V batteries. The meter will auto-

matically disconnect the batteries when 115 VAC is in use. A small step-down (230 VAC to

115 VAC) transformer is required if the meter will be powered by 230 VAC.

– 2 –

SAFETY & OPERATING PRECAUTIONS

Before opening the unit, unplug the AC line cord from the receptacle. NEVER open the

unit until you are certain the AC line cord is unplugged.

The following operating precautions should also be observed:

• Nevermeasuretheoutputofanylightsourceuntilitisdeterminedtobe

20 mW or less. Extremely high intensity sources can damage the silicon

photo detector.

• Alwaysbeginreadingsatthehighestrange.

Turn the meter off and unplug the line cord from the AC receptacle when not in use.

Figure 1.

normalized response (%)

– 3 –

LASER CLASSIFICATIONS

All manufacturers of lasers used in the United States must conform to regulations admin-

istered by the Center for Devices and Radiological Health (CDRH), a branch of the U.S.

Department of Health and Human Services. CDRH categorizes lasers as follows:

Class Description

IA laser or laser system, which does not present a hazard to skin or

eyes for any wavelength or exposure time. Exposure varies with

wavelength. For ultraviolet, 2 to 4 µm exposures is less than from

8 nW to 8 µW. Visible light exposure varies from 4 µW to 200 µW,

and for near-IR, the exposure is < 200 µW. Consult CDRH regula-

tions for specic information.

II Any visible laser with an output less than 1 mW of power. Warning

label requirements – yellow caution label stating maximum output

of 1 mW. Generally used as classroom lab lasers, supermarket

scanners and laser pointers

IIIa Any visible laser with an output over 1 mW of power with a maxi-

mum output of 5 mW of power. Warning label requirements – red

danger label stating maximum output of 5 mW. Also used as class-

room lab lasers, in holography, laser pointers, leveling instruments,

measuring devices and alignment equipment.

IIIb Any laser with an output over 5 mW of power with a maximum out-

put of 500 mW of power and all invisible lasers with an output up

to 400 mW. Warning label requirements – red danger label stating

maximum output. These lasers also require a key switch for opera-

tion and a 3.5-second delay when the laser is turned on. Used in

many of the same applications as the Class IIIa when more power

is required.

IV Any laser with an output over 500 mW of power. Warning label

requirements – red danger label stating maximum output. These

lasers are primarily used in industrial applications such as tooling,

machining, cutting and welding. Most medical laser applications

also require these high-powered lasers.

– 4 –

THE DIGITAL LASER POWER METER

Becoming familiar with the features of the digital laser power meter will help when operat-

ing the unit. The following illustration and list explain the pertinent parts.

Figure 2. Front view of digital power meter.

LCD Display Displays the measurement.

Zero Offset Sets zero before every application.

Range Selector Species the milliwatt (mW), microwatt (µW) scale or

sets the power meter to percentage ratiometric mode.

Cal. Calibrates the meter against the standard.

Set 100% Sets the display to 100.00 reading of a transmitted

beam before starting ratiometric measurements.

Mode Switch Species if standard (CONT: Continuous) or peak/

hold mode is in use.

BNC Output Jack Provides a 0 to +2 volt analog signal.

Detector Cell Detects measurable light.

ON/OFF Switch Turns the unit on or off.

Line Cord Plugs into a 115 VAC outlet.

– 5 –

BATTERY INSTALLATION

The meter may be powered by either 115 VAC or two 9V batteries. The meter will auto-

matically disconnect the batteries when 115 VAC is in use. A small step-down (230 VAC to

115 VAC) transformer is required if the meter will be powered by 230 VAC.

To install the batteries:

1. Make sure the AC line cord is unplugged.

2. From the corners of the front panel remove the four screws, then lift the

panel from the base.

3. Place two 9V batteries in the battery holders located on the back of the PC

board.

4. Replace the front panel and screws. Once the panel is secured to the case,

the AC line cord may be plugged into an AC outlet again.

The meter will operate for approximately 10 hours on a pair of zinc carbon batteries; on

alkaline batteries it will operate 25 hours.

Voltage is continuously monitored by the meter’s circuitry. In the upper left hand corner of

the LCD display, the message “Lo Batt” or a left pointed arrow will appear when the batter-

ies are below 7V, or when the meter is operating from an AC outlet supplying less than 85

VAC.

– 6 –

MEASURING: STANDARD MODE

In standard mode (CONT: Continuous), the meter will display the power of the measured

laser light as long as the detector cell aperture is illuminated by the laser beam. In peak/

hold mode, the meter will display the maximum power of the measured laser light until

RESET is chosen.

Before performing the following procedures, make sure the meter is on, the mode switch is

in the CONT (Continuous) position, and the range selector is in the 20 mW position. Also,

before starting measurements, position the photocell and its cord.

During each session, avoid touching or moving the detector cell and its cord while taking

measurements because any movement of the detector cell or cord may cause an inaccurate

measurement. This becomes especially important as the range of the meter becomes lower

(more sensitive).

1. Position the detector cell (or optically block the detector cell) so a minimal

amount of ambient light is getting into the cell, then rotate the zero offset

knob to obtain a zero reading. (Reduce the amount of ambient light get-

ting into the cell to no more than .5% of the chosen range to obtain a zero

reading.)

2. Illuminate the detector cell aperture with the laser beam. If the reading is

less than 199 (ignore the decimal point), rotate the range selector counter-

clockwise to a successively lower scale while obtaining a zero reading each

time by repeating Step 1.

3. To measure the power of laser light, illuminate the detector cell aperture

once again with the laser beam.

Note: If the input exceeds the capability of any range, the meter will indicate “1”

and the numerals in decimal places will not appear.

– 7 –

MEASURING: PEAK/HOLD MODE

1. Repeat Step 1 of Standard Mode.

2. Flip the mode switch toward the middle position.

3. Flip and release the mode switch toward the RESET position one to

three times with ½ - 1 sec intervals until a zero reading on the display is

obtained (0 ± 5 of last digit).

4. To measure the power of laser light, illuminate the detector cell aperture

with the laser beam for no less than 10 ms. If the reading is less than 199

(ignore the decimal point), flip the mode switch toward the CONT (Con-

tinuous) position. Rotate the range selector counter-clockwise to the next

lower range and repeat Steps 1, 2, 3 and 4 until the reading is more than

199.

5. The display will show the peak power sampled for approximately 1.25 sec-

onds after the reset switch is released or the laser illuminates the detector.

The BNC output will hold the peak power detected at any time after the

reset switch is released.

– 8 –

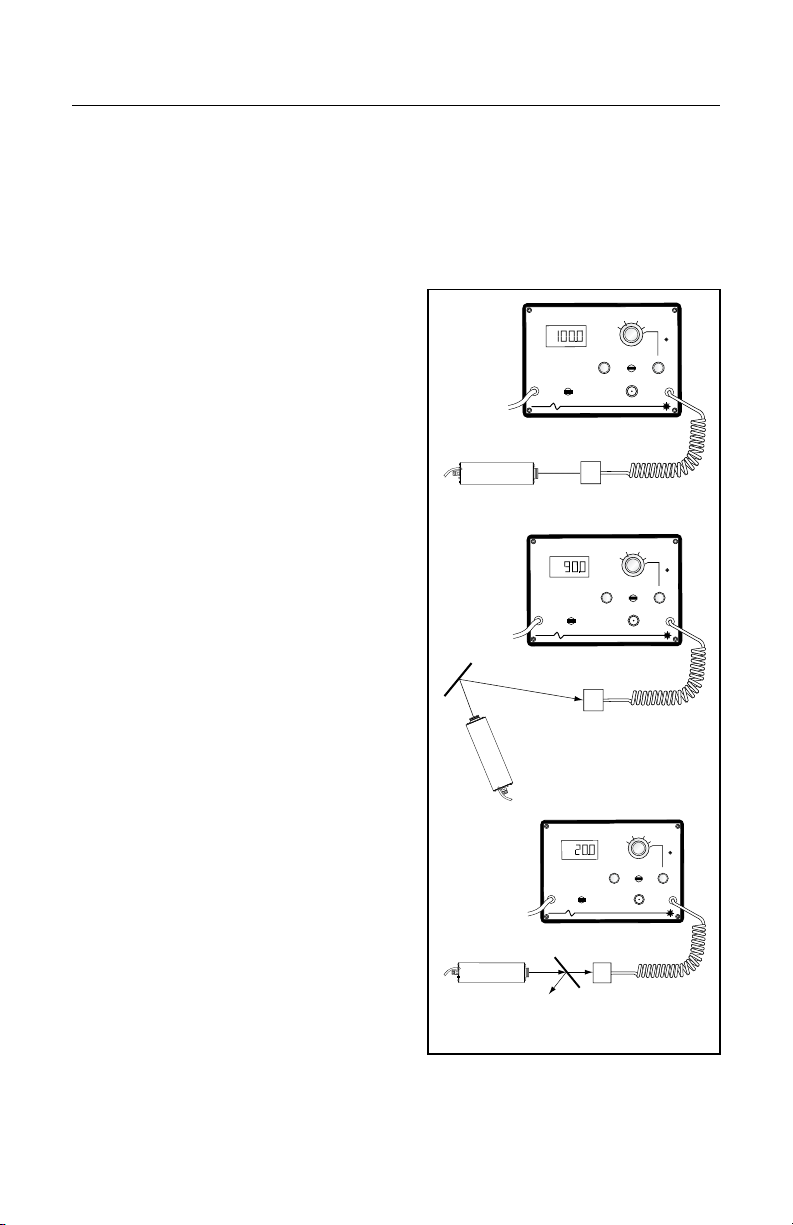

MEASURING: RATIOMETRIC MODE

The meter will perform a percentage calculation of the transmitted beam once it has been

reflected from a mirror or passed through an attenuator when the Set 100% feature has

been implemented.

Before performing the following procedure, make sure the meter is on, the mode switch is

in the CONT (Continuous) position, and the range selector is in the SET 100% position.

1. Turn the SET 100% knob clockwise

as far as it will go.

2. Position the detector cell (or optically

block the detector cell) so a minimal

amount of ambient light is getting

into the cell, then rotate the zero off-

set knob to obtain a zero reading. (To

obtain a zero reading, reduce to no

more than .5% of the chosen range

the amount of ambient light getting

into the cell.)

3. Illuminate the detector cell aperture

with the beam power previously

measured from .5 mW to 1.5 mW.

Rotate the SET 100% knob again

to obtain a 100.0 reading. Refer to

Example A in Figure 3.

4. Aim the beam onto the measured

object (mirror or attenuator) and

measure the transmitted power of

this beam. The LCD display will

show the coefficient of the transmis-

sion in percentage. Refer to Examples

B and C in Figure 3.

Laser

Beam

LASER PO W ER METER

PEAK/CONT.

INDUSTRIAL FIBER OPTICS

2mW

20mW 20mW

200µW

CAL.

CONT.

RESET

ZERO

OFFSET

OUTPUT

500

POWER

ON

OFF

SET

100%

Detector Cell

Example A

1743

Example B

Laser

Mirror

Beam

LASER PO W ER METER

PEAK/CONT.

INDUSTRIAL FIBER OPTICS

2mW

20mW 20mW

200µW

CAL.

CONT.

RESET

ZERO

OFFSET

OUTPUT

500

POWER

ON

OFF

SET

100%

Detector Cell

90.0%

1744

Example C

Laser

Attenuator

LASER POWER METER

PEAK/CONT.

INDUSTRIAL FIBER OPTICS

2mW

20mW 20mW

200µW

CAL.

CONT.

RESET

ZERO

OFFSET

OUTPUT

500

POWER

ON

OFF

SET

100%

Detector Cell

20.0%

1745

Figure 3.

– 9 –

OUTPUT

A BNC output jack on the front panel provides a 0 to +2 volt analog signal. The voltage of

the output in millivolts is the same as the reading on the display except that decimal places

are ignored. If the display reads 0.500 mW, the output will be 500 mV.

NOTE: If the input power exceeds the capability of the range, the voltage output will

exceed +2 V.

The output has a 560 ohm impedance. The meter’s frequency response is DC to 100 kHz.

This is adequate to permit the meter to be used as a demodulator for an audio frequency

modulated laser beam.

RECALIBRATION

When exacting precision and accuracy are required, annual recalibration is recommended.

Where a deviation of a few percent is acceptable, the meter typically deviates very little

over a several-year period.

Industrial Fiber Optics offers factory recalibration at a nominal cost. Contact Industrial Fiber

Optics for current price and shipping instructions.

If field recalibration is desired, a suitable standard is available, and the meter is functioning

normally, the display and output can be recalibrated as follows:

1. Position the detector cell (or optically block the detector cell) so a minimal

amount of ambient light is getting into the cell, then rotate the zero offset

knob to obtain a zero reading. (To obtain a zero reading, reduce to no more

than .5% of the chosen range the amount of ambient light getting into the

cell.)

2. Illuminate the detector cell aperture with a source of known brightness.

With a small, flat blade screwdriver, adjust the CAL. potentiometer until

the display equals the standard.

– 10 –

SPECIFICATIONS

Size 20 x 14 x 8 cm

Weight 1 kg

Operating temperature 10 to 30 °C

Storage temperature -10 to 50 °C

Power requirement (85-125 VAC) 2 W

Battery life (two IEC 6F22 or 6LR61) 10-25 hrs

Maximum optical input power 20 mW

Display resolution 3 ½ digits

Minimum power resolution 0.01 uW

Calibration accuracy 635 nm 5%

Calibration accuracy 500 – 950 nm 20%

Minimum power for 100% ratiometric reading 0.5 mW

Peak/Hold sample time 1.25 seconds

Peak/Hold power threshold 6% of full scale

TROUBLESHOOTING

LCD Remains Blank When Turned On

• On/Offswitchisnotfully“ON”.

• NobatteriesinstalledornoACpower.

• Batteriesmaybeweak.Replacebatteries.SeesectionentitledBattery

Installation.

LCD Display Does Not Read “Zero”

• Toomuchambientlight.

• Zeroadjustmentneedstobemade.SeesectionentitledMeasuring:Stan-

dard Mode for corrective procedure.

• Batteriesmaybeweak.Replacebatteries.SeesectionentitledBattery

Installation.

– 11 –

No Change in Display Reading

• Lightsourceorlaserbeamnotstrikingthedetector’ssensitiveareainside

Detector Assembly. Reposition Detector Assembly or light source.

• Selectorswitchissetattoohighalevel.TurnSelectorswitchcounter-

clockwise one step.

• Selectorswitchissetattoolowalevel.Displaystayson“1”.TurnSelector

switch clockwise one step.

• InPeak/Holdmode.SetModeswitchtoCONTposition.

• Batteriesmaybeweak.Replacebatteries.SeesectionentitledBattery

Installation.

No Output from BNC Jack

• On/Offswitchisnotfully“ON”.

• Lightsourceorlaserbeamnotstrikingthedetector’ssensitiveareainside

Detector Assembly. Reposition Detector Assembly or light source.

• Selectorswitchissetattoohighalevel.TurnSelectorswitchcounter-

clockwise one step.

• Batteriesmaybeweak.Replacebatteries.SeesectionentitledBattery

Installation.

• Thedevice(load)attachedtothejackoutputhastoolowanimpedance.

(This output was not designed to drive an audio speaker.)

Do not attempt to troubleshoot the Laser Power Meter beyond the steps listed above. If

you believe that a problem exists within the Laser Power Meter, please either contact the

factory or return it for appropriate servicing to Industrial Fiber Optics, as described in the

section entitled Warranty.

– 12 –

WARRANTY

Industrial Fiber Optics products are warranted against defects in materials and workman-

ship for 90 days. The warranty will be voided if internal or external components have been

damaged, mishandled, or altered by the buyer.

Warranty liability is limited to repair or replacement of any defective unit at the company’s

facilities, and does not include attendant or consequential damages. Repair or replacement

can be made only after failure analysis at the factory. Authorized warranty repairs are made

at no charge, and are guaranteed for the balance of the original warranty.

Industrial Fiber Optics will pay the return freight and insurance charges for warranty repair

within the continental United States, by United Parcel Service or Parcel Post. Any other

delivery means must be paid for by the customer.

The costs of return shipments for a Laser Power Meter no longer under warranty must be

paid by the customer. If an item is not under warranty, repairs will not be undertaken until

the cost of such repairs has been prepaid by the customer. Typical repair costs range from

$15 - $75, and completion times from two to three weeks.

When returning items for analysis and possible repair, please do the following:

• Inaletter,describetheproblem,personwhomweshouldcontact,phone

number and return address.

• Packtheunitandyourlettercarefullyinastrongboxwithadequatepack-

ing material, to prevent damage in shipment.

• Shipthepackageto:

In d u s t r I a l FI b e r Op t I c s

1725 We s t 1s t st r e e t

te m p e , AZ 85281-7622

UsA

– 13 –

SHIPMENT DAMAGE CLAIMS

If damage to an Industrial Fiber Optics product should occur during shipping, it is impera-

tive that it be reported immediately, both to the carrier and the distributor or salesperson

from whom the item was purchased. DO NOT CONTACT INDUSTRIAL FIBER OPTICS.

Time is of the essence because damage claims submitted more than five days after delivery

may not be honored. If shipping damage has occurred during shipment, please do the fol-

lowing:

• Makeanoteofthecarriercompany,thenameofthecarrieremployee,the

date and the time of the delivery.

• Keepallpackingmaterial.

• Inwriting,describethenatureofdamagetotheproduct.

• Incasesofseveredamage,donotattempttousetheproduct(including

attaching it to a power source).

• Notifythecarrierimmediatelyofanydamagedproduct.

• Notifythedistributorfromwhomthepurchasewasmade.

------------------------------

12 0270

Rules for Laser Safety

•Lasers produce a very intense beam of light. Treat them with respect. Most

educational lasers have an output of less than 3 milliwatts, and will not harm the

skin.

•Never look into the laser aperture while the laser is turned on! PERMANENT

EYE DAMAGE COULD RESULT.

•Never stare into the oncoming beam. Never use magnifiers (such as binoculars or

telescopes) to look at the beam as it travels – or when it strikes a surface.

•Never point a laser at anyone’s eyes or face, no matter how far away they are.

•When using a laser in the classroom or laboratory, always use a beam stop, or

project the beam to areas, which people won’t enter or pass through.

•Never leave a laser unattended while it is turned on – and always unplug it when

it’s not actually being used.

•Remove all shiny objects from the area in which you will be working. This

includes rings, watches, metal bands, tools, and glass. Reflections from the beam

can be nearly as intense as the beam itself.

•Never disassemble or try to adjust the laser’s internal components. Electric shock

could result.

Table of contents

Other Industrial Fiber Optics Measuring Instrument manuals

Industrial Fiber Optics

Industrial Fiber Optics IF 535 Manual

Industrial Fiber Optics

Industrial Fiber Optics ML 801 User manual

Industrial Fiber Optics

Industrial Fiber Optics IF-RL05 User manual

Industrial Fiber Optics

Industrial Fiber Optics ML 800 Series User manual

Industrial Fiber Optics

Industrial Fiber Optics IF User manual