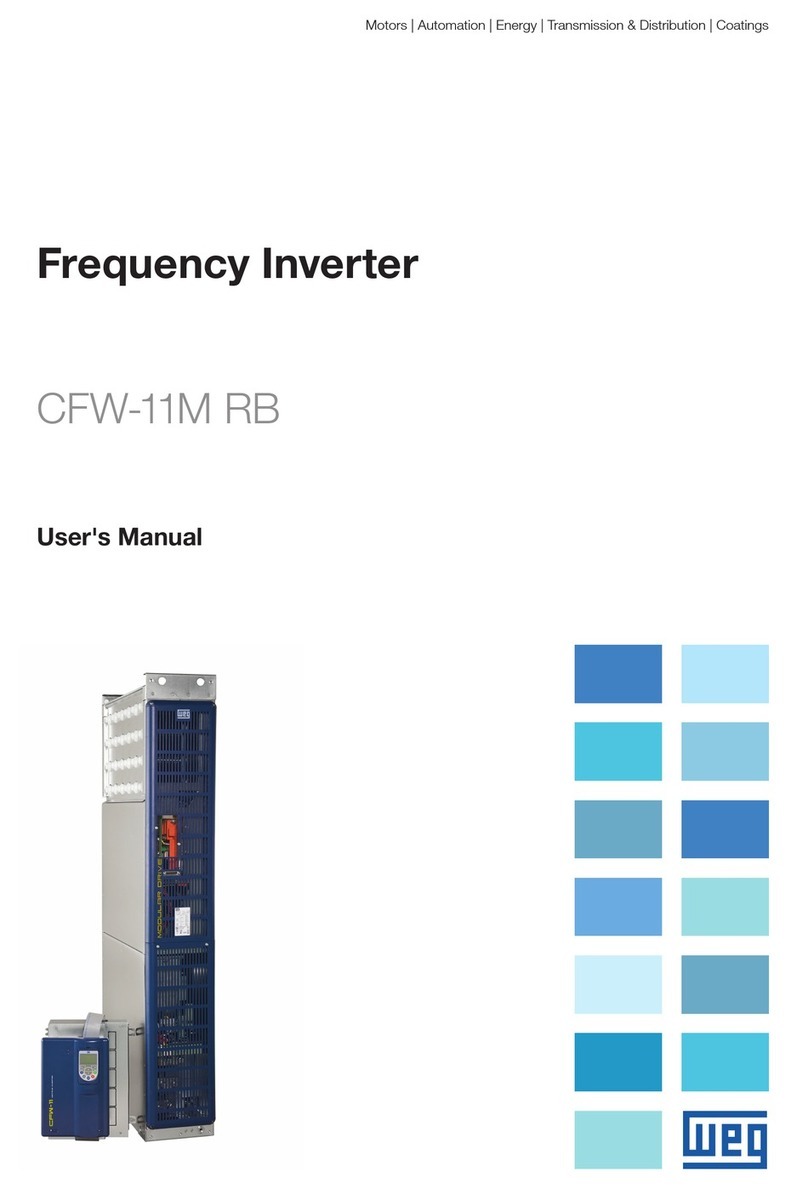

Inel GM35LER-10/09 User manual

DC drive GM35LER-10/09 (N-10LER) with overload detection,

integrated radio and battery charged by solar panel.

Drive with integrated battery, recharged by energy from a solar

panel. The drive is designed for wireless control of guards. In order

for the motor to work correctly with the roller shutter, it is necessary

to use hanger-locks on the winding tube and stoppers in the bottom

bar. The stoppers should be placed as close to the guides as possible

to improve comfort. A sill mustbe fitted to the window and the length

of the guard must match the length of the guides.

Before installing the drive, connect it to the charger and

charge the battery for 6 hours.

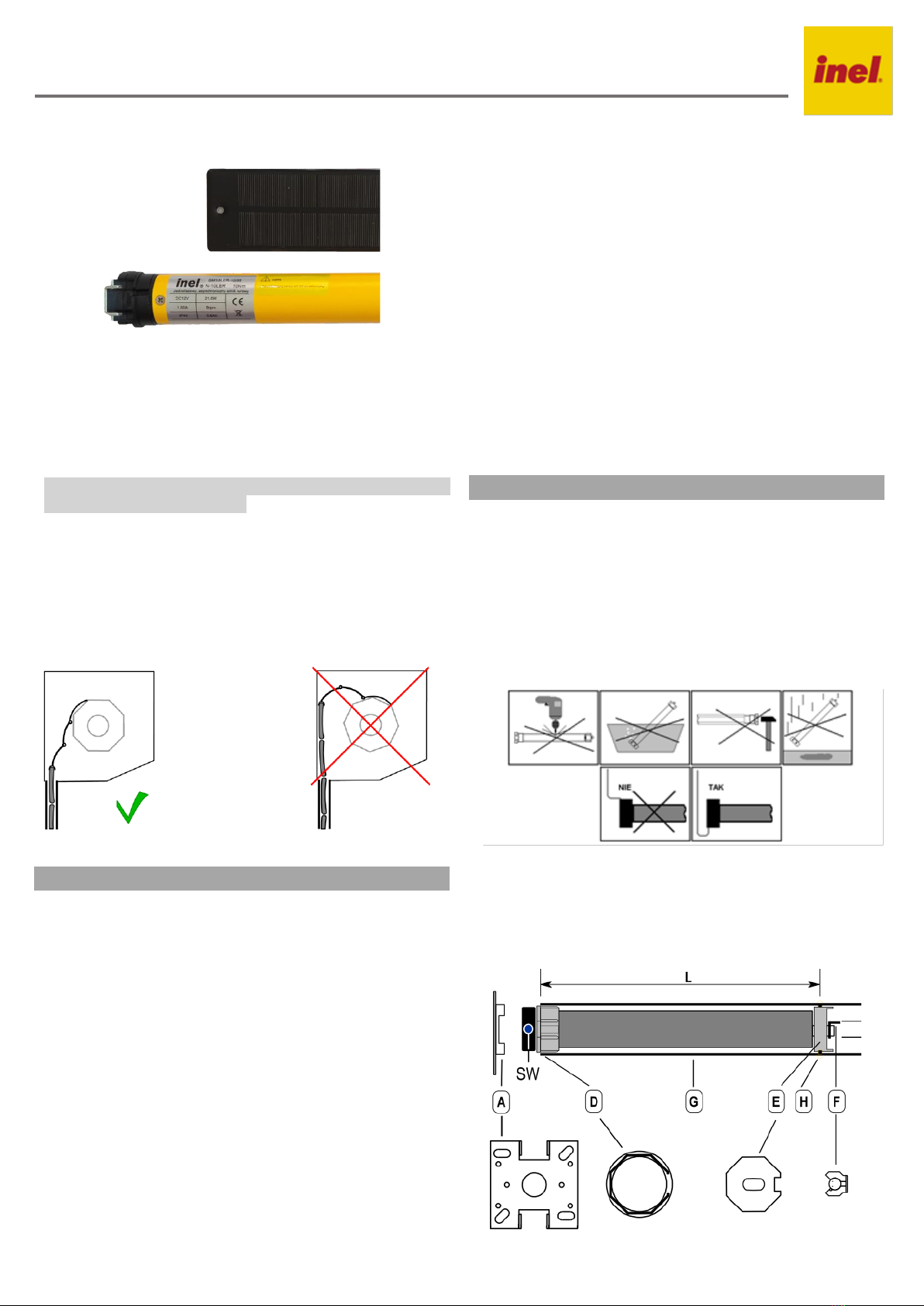

Locking hanger –assembly guidelines

The shutter height should be selected to make sure that with the shutter

closed the uppermost slat of the curtain protrudes from the guide up to

half of its height at maximum.

Excessive shutter height may cause faulty operation or even damage. The

hanger length and shutter height must be selected so that the hanger

presses on the first slat of the curtain downwards the guide.

1Safety instructions

1.1 Basic guidelines

The drive is handed over in a condition for safe installation and use,

provided that all instructions in the operating manual are complied with.

Conversion or changes to the drive are not permitted. Warranty repairs

may only be carried out by the manufacturer. Only original spare parts

and accessories should be used for post-warranty repairs. Safe operation

of the supplied drive is only guaranteed when used in accordance with the

manufacturer's specifications. The limits given in the technical data must

not be exceeded under any circumstances.

1.2 Supplementary safety provisions

Important safety and accident prevention regulations must be observed

when installing, commissioning and maintaining the drive. The following

provisions require special attention:

1. Fire regulations.

2. Accident prevention regulations.

1.3 General comments on hazards and safety measures

The comments listed are general guidelines when using INEL equipment

in combination with other equipment. These indications must be strictly

adhered to when installing and operating the equipment.

• Before installing the drive and setting the end positions, check the

tightening of all screw connections.

• The applicable safety and accident prevention regulations must be

observed.

• Wires and cables should be checked regularly for insulation damage

and conductor continuity.

• If the cables are found to be damaged, the damaged cables must be

replaced after the power supply has been switched off immediately.

1.4 Warning

•Do not let children play with the control devices.

•Keep remote control devices out of the reach of children.

•Watch the roller shutter moving and keep bystanders clear until it is

fully open or closed.

•Users of the roller shutter must be trained and instructed on how to

operate the roller shutter and on the dangers involved in its use. People

can be considered trained if the employer, administrator or owner has

allowed them to operate the roller shutter and instructed them on how

to use it.

2Assembly instructions

2.1 Safety rules

▪Inst Installation of the drive must only be carried out by suitably

qualified persons.

▪The weight of the roller shutter must not exceed the load capacity of

the drive as indicated in the selection table (table available at

www.inel.gda.pl).

▪The proper way of laying the cable (loop facing downwards) further

protects the drive from possible water damage.

▪Do not drill holes in the motor housing.

▪Protect the motor from contact with any fluid.

▪Avoid crushing, impact to the motor and protect the motor from falling.

Figure 1

2.2 Assembly of the drive

•Attach the mounting bracket (A) to the side of the roller shutter box,

connect the adapter (D) to the motor drive ring.

•Place the dog (E)supplied with the motor on the motor shaft and secure

it with the pin (F), then slide the entire drive into the winding tube (G).

•Connect the winding tube and the drive dog with screws or rivets (H).

Figure 2

Original instructions PL

Drive installation and operation manual, type: GM

Model: GM35LER-10/09 (N-10LER)

2.3 Electrical connections

After starting, the motor increases its speed until it reaches the optimum

speed.

Check the condition of the guard, guides and roller shutter box

before starting / programming the drive.

The roller shutter box and the guides should be free of dirt and ensure

free movement of the roller shutter guide along its entire length. Guides

that are contaminated with construction material or too tight may cause

damage to the drive and the roller shutter, which is not covered by

warranty.

3Registering the remote control

The drive is compatible with the next remote controls: PIL-01/04NS,

PIL 01/05/09/19PM, PIL-19/99PMT, PIL-01/05/09/19DL,

PIL-19/99DLT, PIL-19/99MMT, PIL-01PT.

Use remote controls from Inel's extensive range (except key fobs) to

control the drive. The remote control must be registered. Registering the

remote control involves memorizing the remote control channel in the

drive's memory.

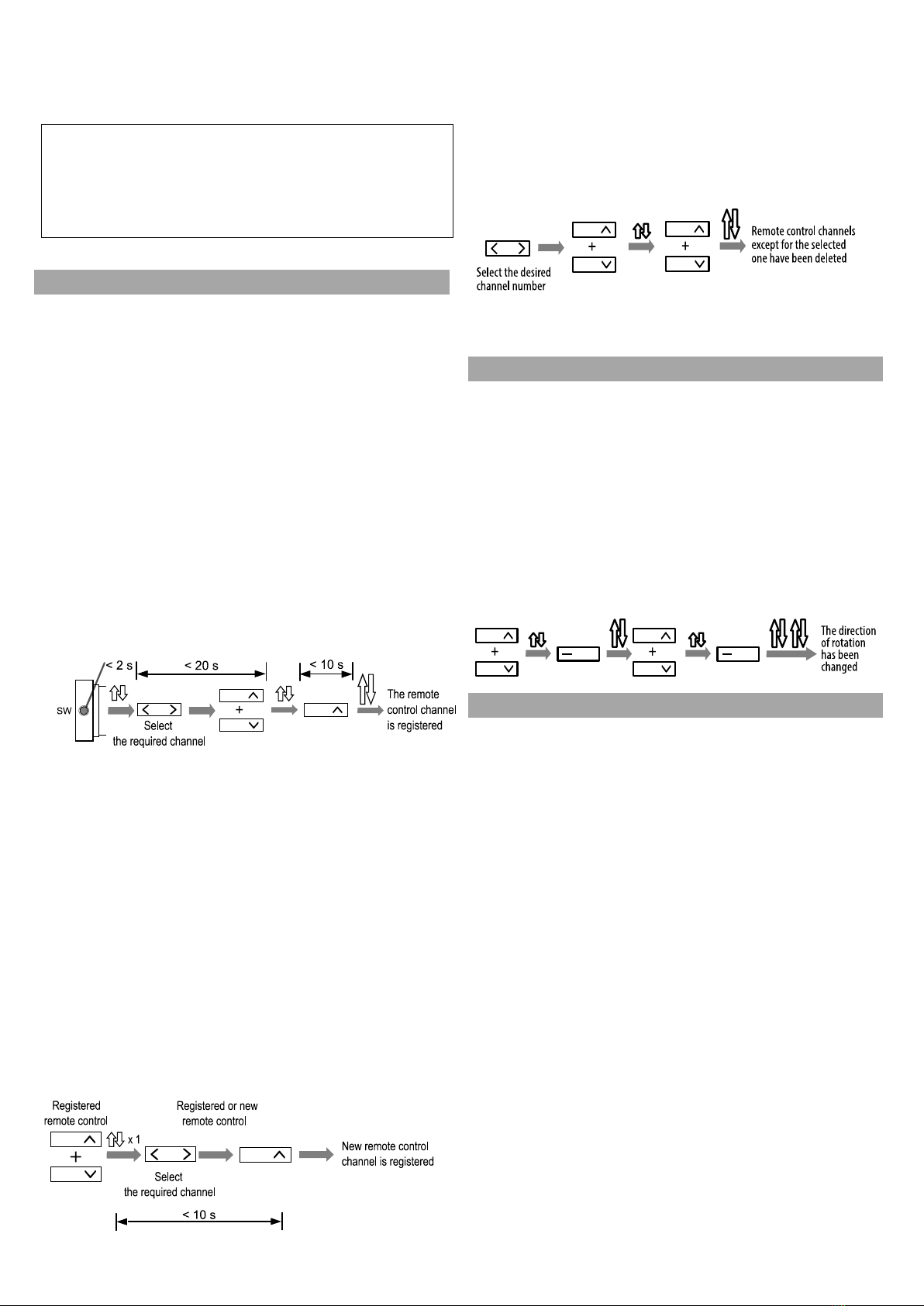

3.1 Registering the first remote control

For drives received from the manufacturer or if the remote control is lost,

the remote control must be registered using the following procedure:

•briefly press (< 2 seconds) the SW button on the drive head

–the drive makes a short up-down movement

•within 20 seconds select the desired channel on the remote control

and press the ∧and ∨keys simultaneously - the drive will make a

short up-down movement

The 20 second limit applies to all operations with simultaneous

pressing of the ∧and ∨keys.

•press the key ∧the next 10 seconds –the drive will confirm

the channel registration by making a long up-down confirmation

movement

NOTE: The procedure will erase all previously registered channels

from the drive memory. This allows the registration of a remote

control for the drive when no registered remote control is available

(new drive or case of lost / stolen remote control).

3.2 Registering another remote control / channel

When you have a previously registered remote control, further channels

of the same or another remote control must be registered without using

the SW button.

To this end:

•on the registered remote control simultaneously press the

keys ∧ and ∨–the motor makes a short up-down movement

For the next 20 seconds, the drive remains in registering mode. To

register a new channel of the same or a different remote control, proceed

as follows within that time:

•select the desired channel on the remote control

•press the key ∧ –the drive will make a long confirmatory up-down

movement

With this method, you can register any channel to any drive, but only if

you have a pre-registered remote control.

3.3 Deleting memorised channels

To delete memorised channels, proceed as follows:

•select channel on registered remote control

•press simultaneously the keys ∧ and ∨–the drive makes a short up-

down movement

•once again press simultaneously the keys ∧ and ∨–the drive will

make a long confirmatory up-down movement –all channels will be

erased except for the channel of the remote control used in the erasing

procedure.

NOTE: all remote controls and other channels of this remote

control will be deleted

.

4Change of direction of rotation

If, after pressing the key ∧the roller shutter moves upwards, the direction

of rotation of the drive is correct and you can proceed to set the end

positions.

If the direction of rotation is opposite, it should be changed as follows:

•press simultaneously the keys ∧ and ∨ on the remote control

–the drive makes a short up-down movement

•press the key (STOP) on the remote control –the drive makes a long

up-down movement

•press simultaneously the keys ∧ and ∨ on the remote control

–the drive makes a short up-down movement

•press the key (STOP) on the remote control –the drive makes 2 long

confirmatory up-down movements

NOTE: the end positions will be erased when the direction is

changed.

5Setting of end positions (EP)

Manual EP setting is not necessary, as the drive can set it automatically.

For this purpose, 3 cycles of full opening / closing of the roller shutter are

required. The drive has an overload detection function; after stopping 3

times at an obstacle (parapet, stopwatch) in the same place, it sets a zone

of increased sensitivity there. Subsequent stops in this zone will occur

with greater sensitivity –as you enter the zone, the motor slows down,

gently reaches the obstacle and stops.

After moving the drive to another window or after changing the length of

the roller shutter, it is enough to make 3 cycles of closing/opening the

roller shutter for the drive to set the new end positions

The drive starts at 100% when moving downwards, and at 50% when

moving upwards and accelerates to 100% after 2 s

The manual setting of the EP is described below.

The order in which the EPs are set is irrelevant; you can set both EPs,

only one of them or not set an EP at all.

The EPs cannot be set too close together; the drive will make a short

up-and-down movement when attempting to do so.

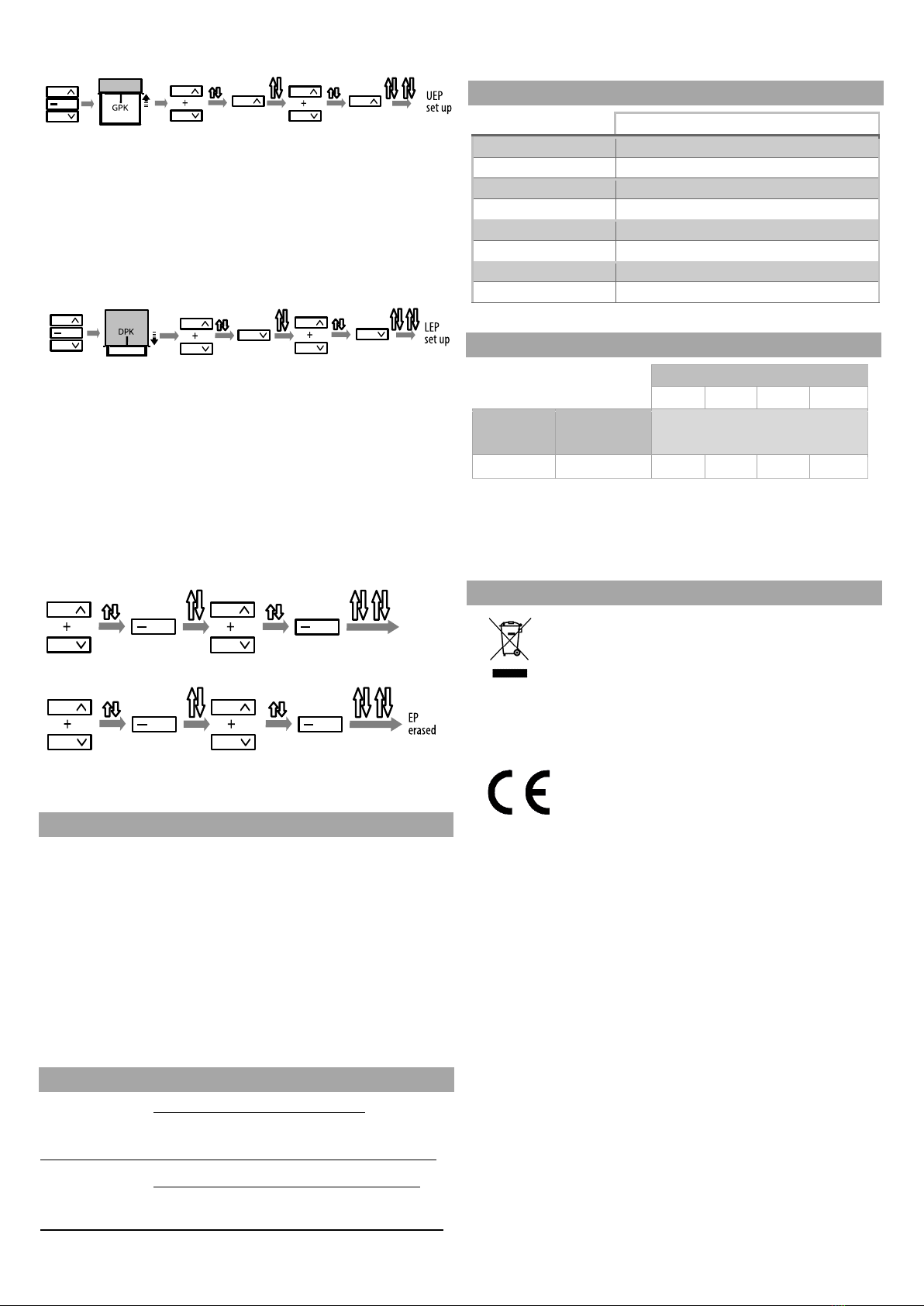

5.1 Setting the upper end position (UEP)

To set the upper end position (UEP):

•set the roller shutter to the desired UEP (with the ∧, ∨, ▬(STOP)

keys on the remote control

•press simultaneously the keys ∧ and ∨on the remote control

- the drive makes a short up-down movement

•press the key ∧ on the remote control –the drive makes a long up-down

movement

•press simultaneously the keys ∧ and ∨ on the remote control

- the drive makes a short up-down movement

•press the key ∧on the remote control –the drive makes 2 long up-down

movements –the UEP has been set

5.2 Setting the lower end position (LEP)

To set the lower end position (LEP):

•set the roller shutter to the desired LEP (with the ∧, ∨,▬(STOP) keys

on the remote control

•press simultaneously the keys ∧ and ∨ on the remote control

- the drive makes a short up-down movement

•press simultaneously the keys ∧ and ∨on the remote control

- the drive makes a short up-down movement

•press the key ∧ on the remote control –the drive makes 2 long up-down

movements –the LEP has been set

5.3 Erasing end positions (EP)

To erase end positions (EP): execute twice the procedure for reversing

the direction of rotation

•press simultaneously the keys ∧ and ∨on the remote control –the

drive makes a short up-down movement

•press the key ▬(STOP) on the remote control –the drive makes a

long up-down movement

•press simultaneously the keys ∧and ∨ on the remote control –the

drive makes a short up-down movement

•press the key (STOP) button on the remote control –the drive makes

2 long up-down movements

•repeat the above steps

ATTENTION! Pressing the SW button while the roller shutter is

moving will also delete the end positions.

6Operating instructions

6.1 Battery

The manufacturer supplies the drive with a charged battery. Once the

drive is installed, the battery is recharged with electricity from the solar

panel.

If there is a long period between purchase and installation of the drive,

the battery should be charged using a charger (sold separately by the

manufacturer). The charger should be connected to the drive in place of

the solar panel. The time to full charge is approximately 8 hours.

If the charge level is too low, the drive stops and makes 2 short up- down

movements when attempting to start.

When the need to charge the battery with the charger occurs too

frequently, check the condition of the solar panel. If thepanel is clean and

sunlight reaches it unobstructed, the battery is probably worn down.

7Troubleshooting

Problem: Motor does not respond to commands

Reason: Battery is discharged

Solution: Charge the battery

Problem: Battery requires recharging several times a year

Reason: Battery is worn out

Solution: Replace the drive

8Technical data

GM35LER-10/9

(N-10LER).

Power supply

12 DC

Torque

10 Nm

Power

21,6 W

Rotation speed

9 obr./min.

IP rating

IP 44

Operating time

100 s

Length

655 mm

Weight

1,55 kg

9Tubular motor selection table

Roller blind length

1,5 m

2,0 m

2,5 m

3 m

Rotation

Speed

Tube

diameter

Permissible roller shutter weight

for the above heights

N-10 Nm

Φ = 40 mm

20 kg

19 kg

18 kg

17 kg

The parameters given are only estimates - they depend on numerous

factors (correct installation, co-efficient of friction of the blind,

atmospheric conditions and other).

10 Handling of waste equipment

Do not dispose of with household waste. Dispose only in

specially designated areas. Households play a key role in the

recycling of waste electrical and electronic equipment.

Waste sorting, including waste equipment and batteries,

guarantees that the equipment is not disposed of with

household waste but is handed over to a designated collection point for

the recycling of waste electrical and electronic equipment.

Przedsiębiorstwo Informatyczno-Elektroniczne INEL

Sp. z o.o., ul. Mostowa 1, 80-778 Gdańsk, as the

manufacturer of the product, hereby declares that the

drive described in this manual and used in the manner

specified herein complies with the essential

requirements of the relevant EU directives, in particular Directive

2006/42/EC and Directive 2014/53/EU.

The full text of the EU Declaration of Conformity is available at the

following internet address: www.inel.gda.pl

1paneolarnego GC8005

The solar panel is designed for the application with the GM35LE-10/09

(N-10LER) drive. The panel converts solar energy into electrical energy

used to charge battery packs located inside the drive.

1Safety tips

Do not drill holes in the solar panel.

When attaching the solar panel to the shutter box,

do not use excessive force to avoid solar panel damage.

Do not cover the panel with paint.

2Installation

2.1 Site selection

Place the panel on the shutter box cover in the area with the highest sun

exposure.

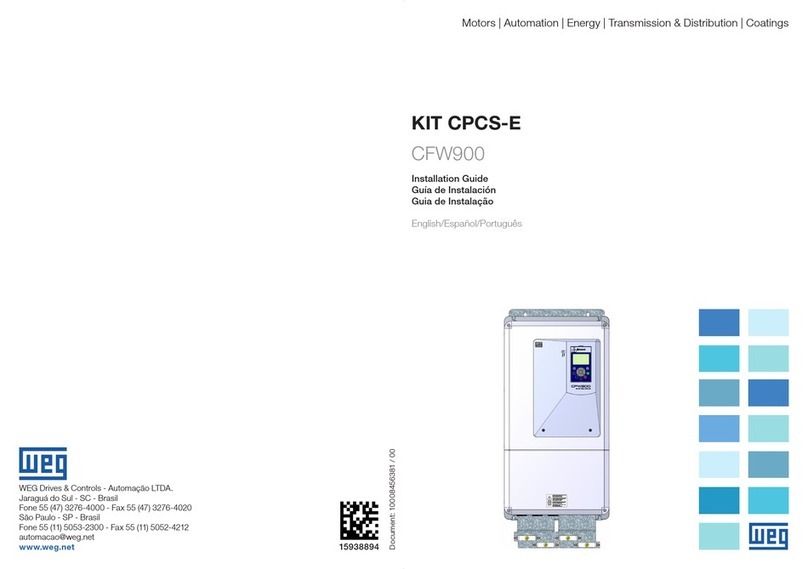

2.2 Solar panel fixing

In order to fix the solar panel properly, please follow the steps listed

below in the following sequence:

•drill two 3 mm holes in the shutter box, as shown in the figure below,

to attach the solar panel and a 15 mm hole to insert the cable, smooth

the edges of this hole.

•thread the panel cable through the hole into the box interior.

•fix the solar panel with aluminium rivets (with a diameter of 4.0mm)

or screws (max length 15mm) in both drilled holes, taking special care

2.3 Electrical connections

The connector, which is terminated by the solar panel cable, should be

connected to the socket located on the motor cable. The wires should be

attached to the side of the box so that they do not come into contact with

moving parts.

3Cleaning

Keep the solar panel clean. Use clean water and a soft cloth for cleaning.

Do not allow the panel to be covered with leaves or snow.

4Troubleshooting

Problem: Battery requires recharging several times a year

Reason: Solar panel is insufficiently illuminated

Solution: Remove obstructions, clean the panel.

Reason: Solar panel is faulty

Solution: Replace the solar panel

5Handling of waste equipment

Do not dispose of with household waste. Dispose only in

specially designated areas. Households play a key role in the

recycling of waste electrical and electronic equipment.

Waste sorting, including waste equipment and batteries,

guarantees that the equipment is not disposed of with

household waste but is handed over to a designated collection point for

the recycling of waste electrical and electronic equipment.

Przedsiębiorstwo Informatyczno-Elektroniczne INEL

Sp. z o.o., ul. Mostowa 1, 80-778 Gdańsk, as the

manufacturer of the product, hereby declares that the

drive described in this manual and used in the manner

specified herein complies with the essential

requirements of the relevant EU directives, in particular Directive

2006/42/EC and Directive 2014/53/EU.

The full text of the EU Declaration of Conformity is available at the

following internet address: www.inel.gda.pl

Przedsiębiorstwo Informatyczno-Elektroniczne INEL Sp. z o.o., ul. Mostowa 1, 80-778 Gdańsk, Poland [email protected] www.inel.gda.pl

Original Manual PL

Installation and operation manual for solar panel: 3,8W, 18V

Model: GC8005

This manual suits for next models

1

Popular DC Drive manuals by other brands

WEG

WEG CFW900 installation guide

Welcon

Welcon WEC-D048/25-FS0025-E Hardware manual

Danfoss

Danfoss VLT AutomationDrive FC 301 Programming guide

Altec Lansing

Altec Lansing HF DRIVER CROSS REFERENCE MASTER LIST Reference

HAUTAU

HAUTAU EKA 20-118 Additional instructions

Danfoss

Danfoss NEMA-3R installation instructions

Power Electronics

Power Electronics SD 500 Series manual

Parker

Parker HMR 08 Series Assembly and operating instructions

Control Techniques

Control Techniques MiniAx 60 x 5/10 manual

Danfoss

Danfoss VLT Midi Drive FC 280 installation guide

Frecon

Frecon FID-L18 Installation and user manual

Trane

Trane VarioTrane TR1 2800 Series operating instructions