1

1. Introduction

•Small, light-weight and compact

•IGBT output bridge for high speed switching and low power consumption

•Motor speed control - 8 preset speed values

•Logic inputs for remote control

•Preset drive parameters - factory drive adjustment under special customer conditions

•FRECON TELECONTROL: remote control and indication unit

•External RFI input filter

2. General characteristics

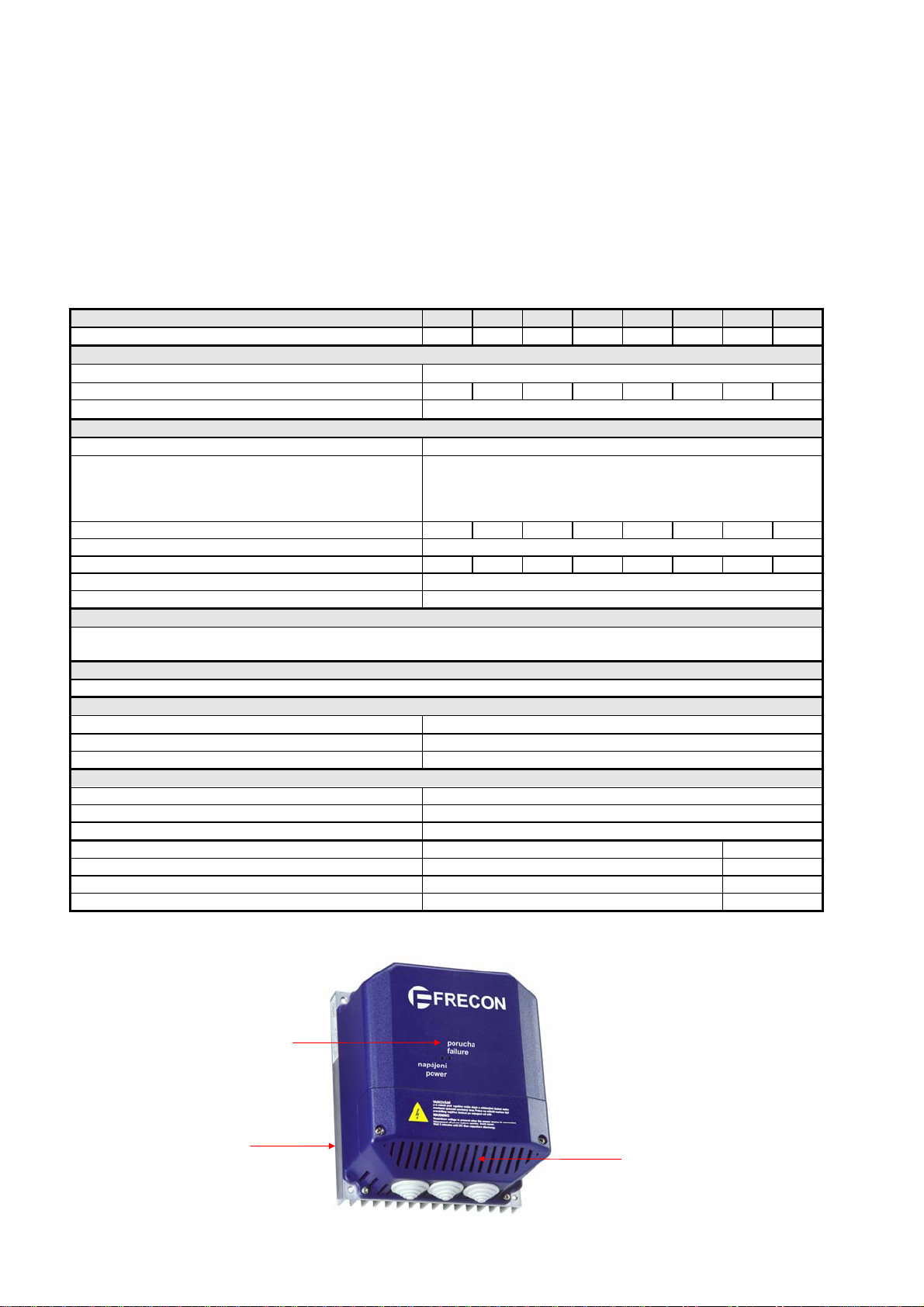

Type: FID-L: 18 37 55 75 110 150 220 250

Nominal motor rating (kW) 0,18 0,37 0,55 0,75 1,1 1,5 2,2 2,5

Input:

Voltage 1x 230V ±10%

Nominal motor rating (kW) 2,6 4,4 6,1 7,0 9,6 12,2 17,5 20,0

Frequency 47 ÷63 Hz

Output:

Voltage 3 x 0 ÷input voltage

Frequency 8 preset values

20,25,30,35,40,44,47,50Hz

acceleration/deceleration between

preset values - 5Hz/s

Apparent power (kVA) 0,6 1,0 1,4 1,6 2,2 2,8 4,0 4,5

Overload 150%, 30 sec

Nominal current (A) 1,4 2,4 3,0 4,0 5,5 7,0 10,0 11,3

Modulation PWM - 18kHz

V / f - characteristic square - law

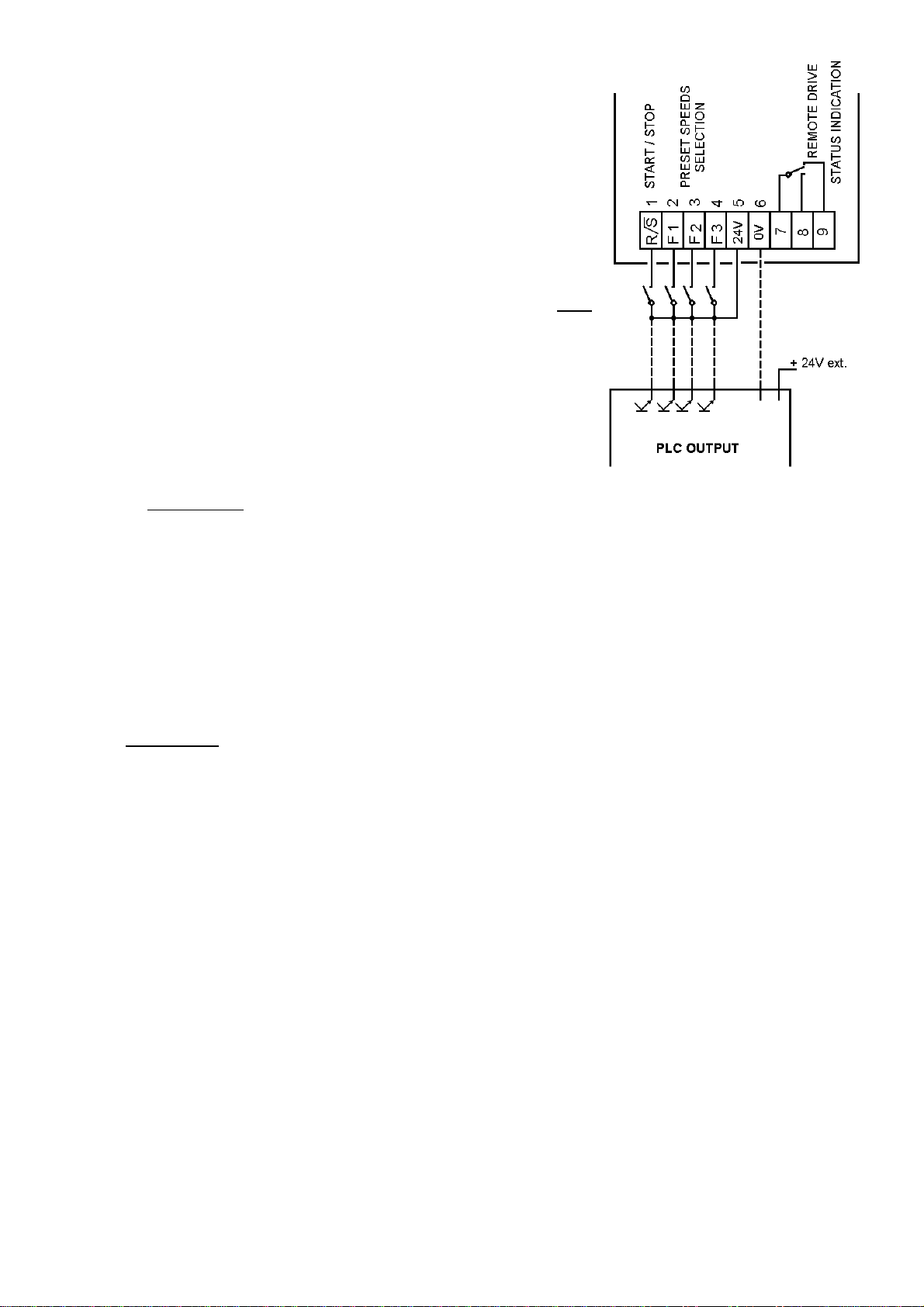

Control:

logic inputs - control switches or PLC outputs

function - START/STOP, preset speeds selection: 8 values

Protections:

low voltage, overvoltage, overcurrent, I x t, short-circuit (phase-phase, phase-earth)

Enviromental conditions:

Ambient temperature 0 ÷400C

Ambient humidity max. 90% (non condensing)

Enclosure IP 00 or IP 20 or IP 54

Design criteria:

Safety EN 61 010-1/95

Electromagnetic compatibility-emission: EN 55 011/A1,B1; EN 50 081-1, 2 (with external RFI filter)

-immunity: EN 50 082-1, 2

Dimensions: Height (mm) 180 200

Width (mm) 153 160

Depth (mm) 97 145

Weight: (kg) 1,3 2,5

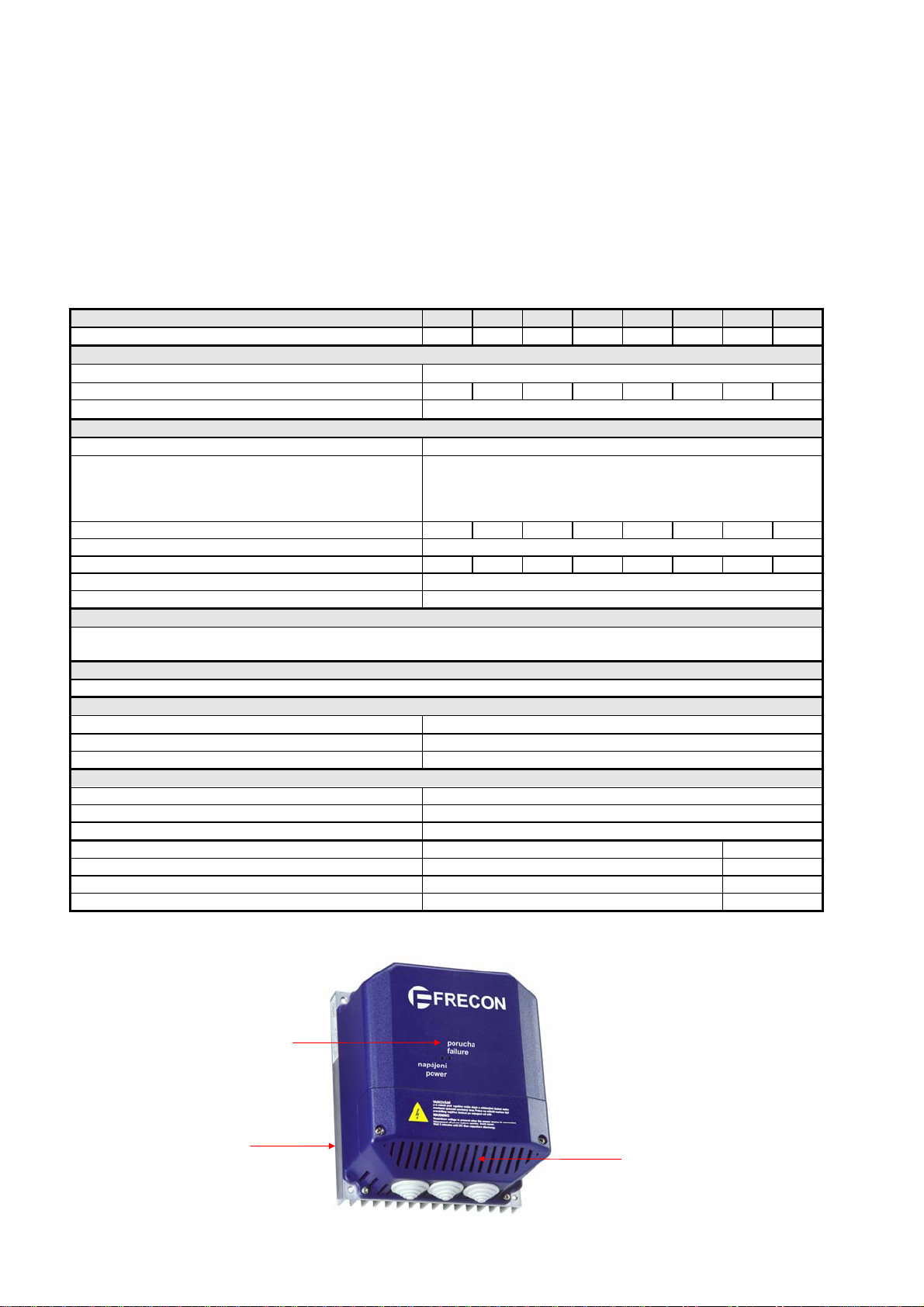

3. Description

heat sink control and power

cables lead-in

status LED indication

- power

- failure