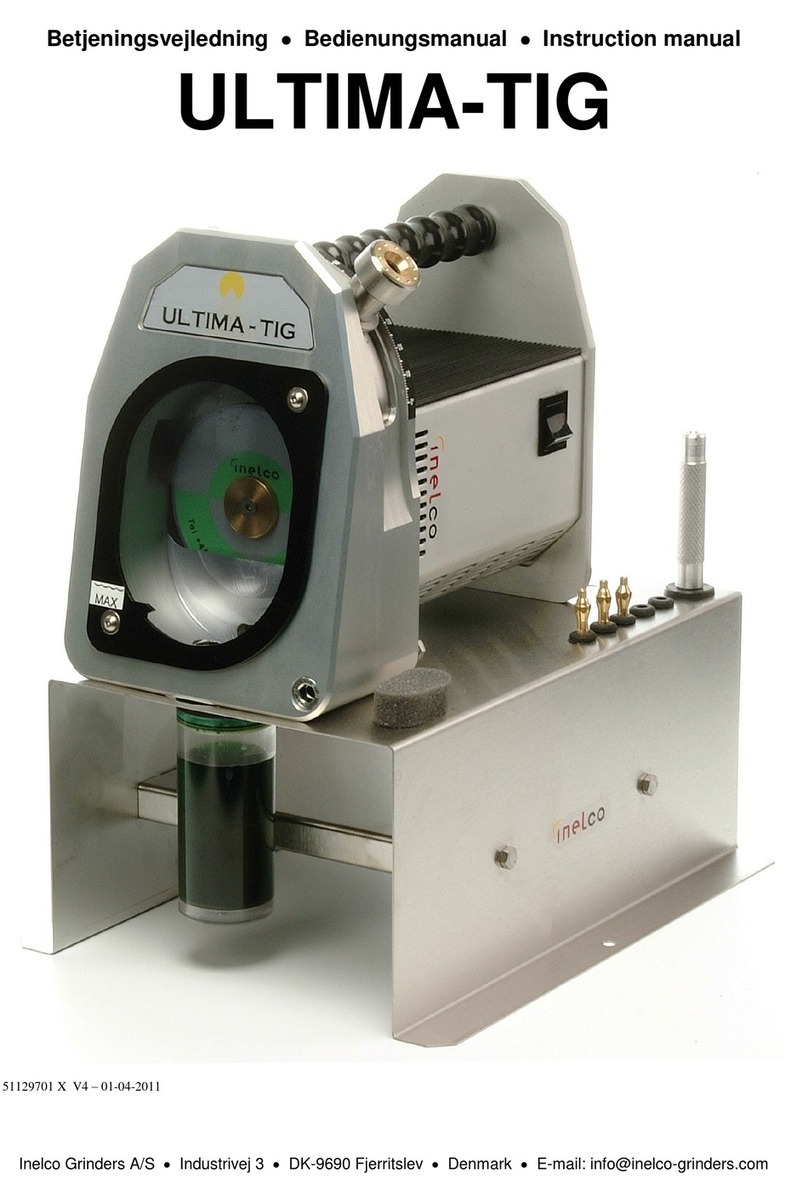

Inelco ULTIMA-TIG User manual

Operators Manual

ULTIMA

ULTIMAULTIMA

ULTIMA-

--

-TIG

TIGTIG

TIG

51129701 X V1 (4381) 2003-06-16

Welding Automation Pty Ltd. http://www.WeldingAutomation.com.au E-mail: [email protected]

ULTIMA-TIG

INSTRUCTION MANUAL

EU statement of compliance

Manufacturer: INELCO GRINDERS A/S

Handvaerkervej 6

D-9690 Fjerritslev

Denmark

Telephone: +45 98 21 15 55

Fax: +45 98 21 35 95

SE/VAT No.: DK 13269890

E-Mail: [email protected]

hereby declare that

Machine: ULTIMA-TIG

Type: UT 03 / 04

Serial No.:

Year of production: 2012

is produced in accordance with the provisions of the Commission’s Directive

of 14 th June1989 on harmonisation of national legislation’s on machinery

(98/37/EF), l ow-voltage di rective 73/23/EF ( 1973) chang ed thr ough directive

93/68/EF (1993) and EM C-directive 89/336 with particular U LTIMA-TIG i s

developed and produced according to following international norms:

EN 61029

EN 61000-6-4

EN 61000-6-2

The CE-mark was used first time in 2003.

Person responsible: Name: Anders Thy,

Date: 11th June, 2012

Signed: ____________________

INELCO A/S INSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 2/12

E-mail: info@weldingautomation.com.au

CONTENTS

General machine description ………………. ...................1

Delivered with the machine …. ………………………. .....2

Initial operation and transport …………………................3

Operational elements …………………………... ..............4

Safety procedures...........................................................5

Fastening of the electrode in the electrode holder….......6

Setting the grinding angle ...............................................7

Maintenance....................................................................8

Replacement of grinding wheel.......................................9

Field of application ………………………... ....................10

Technical specifications………………………….............11

Training …………………………..…...............................12

Spare parts list ..............................................................13

Drawing….……………………………………... ...............14

ULTIMA-TIG /Neutra grinding liquid …………………...15-30

IMPORTANT SAFETY INSTRUCTIONS

When installing and operating the machine the safety rules

enclosed should be read and strictly observed.

This instruction manual and the accompanying supplier’s

instruction for use must be accessible at all times to staff engaged

in the installation, operation and maintenance of the machine.

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 3/12

E-mail: info@weldingautomation.com.au

1. General machine description

ULTIMA-TIG is a patented grinder with a diamond wheel for wet grinding of

tungsten electrodes. This unique and patented construction gives together with the well-

known benefits of wet grinding, many advantages to obtain a perfect welding result.

The special grinding liquid in the sealed grinding chamber ensures that no

contaminated dust particles will be emitted into the surroundings. The grinding liquid

also ensures no discoloration of the tungsten electrode due to the heat, which has a

negative effect on the welding process.

A fine-grained grinding in the length-wise direction of the electrode is ensured due to

the unique construction of the tungsten electrode hol der and feeder tog ether w ith the

tangential grinding on the surface of the diamond w heel, T his is important for the

ignition capability of the tungsten electrode.

To ensure minimal griinding of the tungsten electrode (0,3-0,5 mm), a combined

electrode stick-out and locking device is located on the front of the machine. T he

grinding angle can be infinitely adjusted from 7,5 to 90 degrees (half angle) inclusive.

In the 90-degree position the tip of the electrode can be removed to the required

amount using the micrometer screw. This is of importance to the electrode’s tool life at

high welding currents.

A container for collection of toxic dust i s placed under the machi ne. This container is

easily replaced.

2. Delivered with the machine

Upon receipt please check that the following items are included in the package:

ULTIMA-TIG machine with a diamond wheel

Instruction manual and datasheet for the grinding liquid

Container with grinding liquid

Tungstenelectrode holder

Electrode clamp ø1,6mm

Electrode clamp ø2,4mm

Electrode clamp ø3,2mm

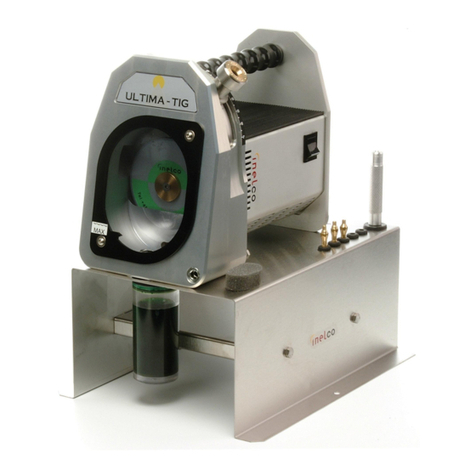

3. Initial operation and transport

Place the U LTIMA-TIG on the encl osed table and f asten the machine. Please ensure

that the table is fixed.

The ON/OFF switch must be in the “OFF” position.

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 4/12

E-mail: info@weldingautomation.com.au

Connect the U LTIMA-TIG to the mains voltage stated on the type label. Use single-

phase power supplied with earth.

The ULTIMA-TIG must not operate without grinding liquid!!

The ULTIMA-TIG does not contain grinding liquid on delivery. Before starting the

machine grinding liquid must be applied. Take out the drain plug ( 8) and fit the

enclosed liquid container (39) to the machine. Place the filler neck on to the enclosed

container. Feed the ULTIMA-TIG with the grinding liquid through the hose (29) until the

correct liquid level has been r eached (please see mar k on the i nspection cover frame

(7)). There is sufficient liquid in the grinding chamber when the diamond wheel is seen

to pump the fluid as the machine is switched on.

For safety reasons the grinding l iquid must be drained f rom the ULTIMA-TIG into a

sealed closed container during transport.

ULTIMA-TIG can be operated in locations with surrounding temperatures ranging from

-10°C to +40°C and a relative humidity up to 50% at 40°C and 90% at 20°C.

The machine has been tested in accordance to protection class IP21.

4. Operational elements

•Current and main switch

•Carry handles

•Degree scale

•Electrode holder

•Stick-out adjustment

•Grinding fluid container 250 ml

•Micrometer screw to flatten the tip of the electrode

5. Safety procedures

•Never use the product if the grinding wheel is damaged

•Use only grinding wheels recommended by Inelco A/S

•Only use the product when all parts have been assembled

6. Fastening of the electrode in the electrode holder

Place the electrode clamp fitting the diameter of the tungsten electrode into the

electrode holder. Push the electrode through the electrode clamp and into the electrode

holder. Use y our fingers to tig hten the electrode lightly, please ensure that it may still

be able to slide in the electrode holder. The electrode must be extended approx. 2 cm

from the clamp. Then place the el ectrode and the holder into the stick-out setting(10)

placed below on the right front side until it stops and tighten the electrode with a

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 5/12

E-mail: info@weldingautomation.com.au

smooth turn of the el ectrode holder to the right. The electrode clamp has a hexagon

which fits the hole of the stick-out setting. The electrode may only be fastened so tight,

that it does not slide in the electrode clamp. If the electrode is fastened too tightly the

clamp may be damaged. A regulation screw on the back of the stick-out-setting makes

it possible to determine the length of the electrode you wish to grind. If you remove the

regulation screw, more electrode will be ground and visa versa. The manufacturer has

set the r egulation screw to grind approx. 0,3 mm in order to obtain maximum number

of grindings per electrode as possi ble. A minimum length of 30 mm of the electrode

means that you can re-grind the electrode 450 times. It is often not necessary to break

off metal dr ops on the electrode. T he metal drops do not alloy with the

electrode. They will be removed during grinding and a new tungsten surface which is

necessary for a good ignition of the electrode and a stable arc. In case a clean

tungsten sur face is not achieved the length of the stick-out can be extended. It is

necessary to adjust the stick-out as the diamond wheel is used up.

7. Setting the grinding angle

The grinding angle is set by aligning the pointer (24) on the electrode guide (22) to the

required number on the degree scale. The electrode guide is then locked in position

using the tightening screw (20). After inserting the tungsten electrode into the electrode

holder push i t into the el ectrode guide until the electrode reaches the diamond wheel.

Start the machine usi ng the ON /OFF sw itch ( 35) and WAIT FOR THE WHEEL TO

REACH FULL SPEED. Turn the electrode holder, gently pushing the electrode

against the diamond wheel. When the shoulder of the

electrode holder meets the face of the electrode guide the grinding is completed and

the electrode holder is withdrawn from the guide tube.

It is only necessary to press the electrode holder lightly against the diamond

wheel, as the weight of the electrode holder gives sufficient pressure by it self.

Do not remove the electrode holder from the machine until the wheel stops.

Remove the electrode from the electrode holder by placing the electrode holder into the

stick-out setting (10) and turn it left. Remove the electrode.

8. M aintenance

The ULTIMA-TIG should always be filled with sufficient grinding liquid to ensure

optimum collection of all grinding dust as well as adequate cooling of the grinding

process. The correct liquid level is between the minimum mark and 3mm above.

Please check the liquid level frequently and top up the level

of liquid as necessary. Only the original ULTIMA-TIG grinding liquid ensures the

optimum lifetime of the diamond wheel.

Heavily polluted (ie:FULL)grinding liquid or receivers containing grinding dust must

be deposited according to national regulations. Remember, Thoriated Tungsten is

mildly radioactive! (In most countries, burying in landfill is acceptable.)

After each10-15 hrs grinding (say 2500-3500points), the grinding chamber should be rinsed

thoroughly for grinding residue and dust. Tap off the grinding liquid through the hose(29)

and retain it in a deposit bottle for re-use. Liquid tank(39) is removed. Remove screws(21A),

inspection cover frame(7) and plastic inspection cover(6), and wash out the grinding

chamber with water. Leave the grinding residues safe in the liquid tank!

Then replace inspection cover frame(7),the liquid tank (39) and refill grinding

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 6/12

E-mail: info@weldingautomation.com.au

liquid to appropriate level. Please ensure that the person cleaning the ULTIMA-TIG

wears the appropriate safety gear e.g.

rubber gloves and protection glasses. Mains cabl es should be inspected at regular

intervals, and should only be replaced by a qualified electrician.

Contact Welding Automation for further information.

9. Replacement of the grinding wheel

Please follow the procedure below when disassembling the machine:

The power to the ULTIMA-TIG must be turned off – pull the plug

The g rinding l iquid i s tapped off, scr ews ( 21A), pl astic inspection cov er ( 6) and

cover frame (7) are removed. The wheel (4) wheel is now accessable.

Remove the grinding chamber as shown on Page 8A

Unlock the left-hand threaded centre screw. Remove the retaining disc ( 26).

Remove the old wheel and reassemble with a new one (4).

10. Field of application

The grinder is only to be used for grinding of tungsten electrodes.

11. Technical specifications

NEUTRA grinder patent application No. 9500123.

Current class: (single-phase alternating current) 1x110V or 1x220-240V AC

Protection isolated without protection cable 10-16A UMEC 97/66/68-CEE (7) VII

12. Training

No special education is required to operate the U LTIMA-TIG. However, persons who

are to operate the ULTIMA-TIG machine should read the instruction manual

thoroughly beforehand and to have received basic training in use of the machine.

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 7/12

E-mail: info@weldingautomation.com.au

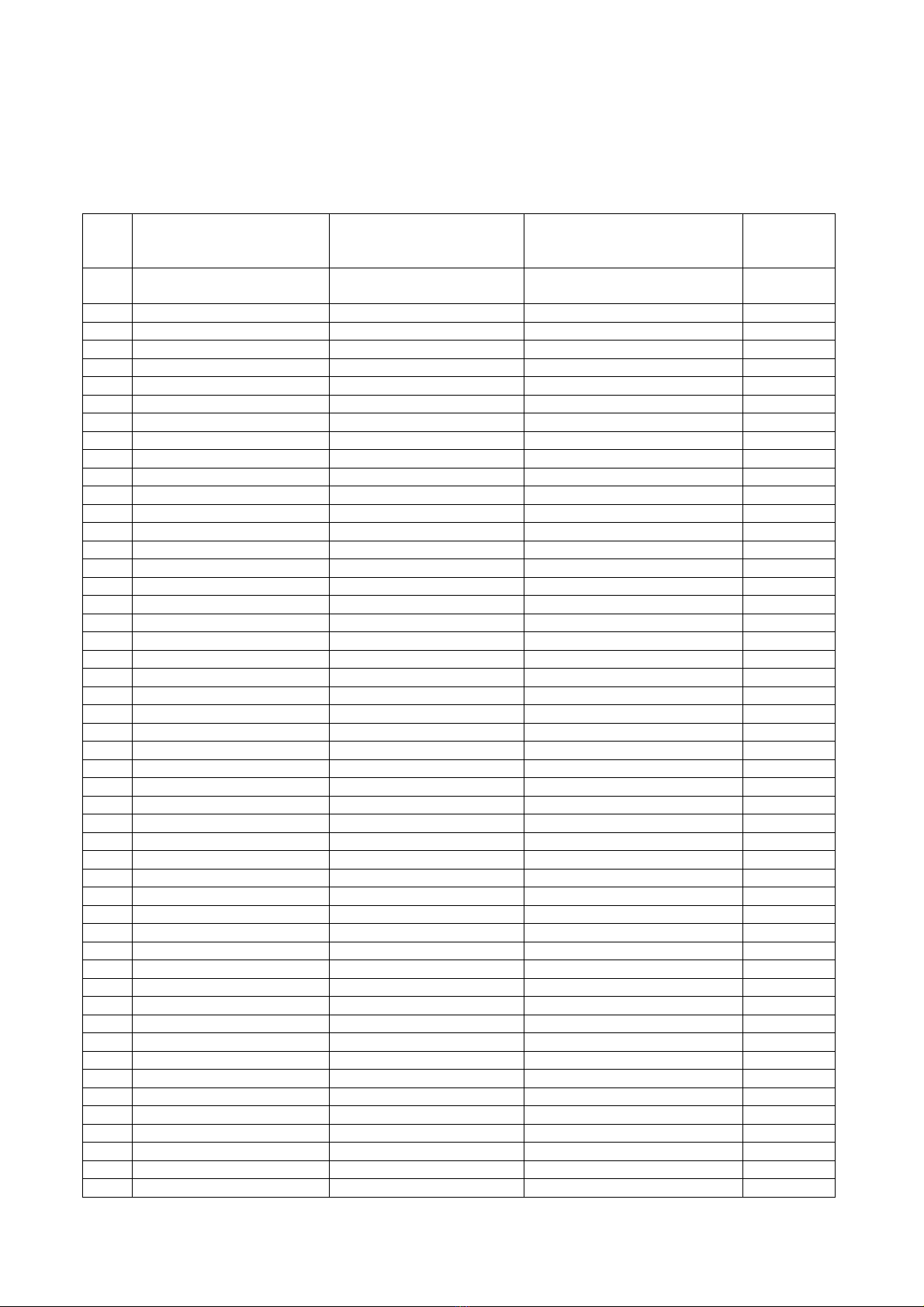

13. Reservedelsliste • Spare Parts List • Ersatzteilliste

Pos.

No.

(DK)

Betegnelse

(GB)

Description

(D)

Bezeichnung

Varenr.

Article No.

Warennr.

Ultim a-TIG Wolframsliber Ultima-ITG

Wolframgrinder

Ultima-TIG Wolframschleif-

maschine 88897022

Væskebeholder 250 ml Liquid container 250ml Flüssigkeitsbehalter 250ml 75491200

1 Slibek onsol Grinding konsole Schleif-Konsole 44520000

2 Vinkelindstiller Angle adjust unit Winkeleinstellungseinheit 44520001

3 Bagplade for konsol Rear plate for konsole Rückplatte für Konsol 44520002

4 Diam antskive Grinding disc Schleif-Scheibe 44490512

5 Bøsning for skive Bush for disc Buchse für Scheibe 44520017

6 Skueglas Plastic Inspection Cover Schauglas 44490700

7 Ramme for glas Frame Glasrahmen 44490901

8 Bundpr op Drain plug Ablaßschraube 44491120

9A Bær ehåndtag Handle Tragehandgriff 44520012

9B Gummi for håndtag Rubber for handle Gummi für Handgriff 44520013

10 Bolt for Stick-out Bolt for Stick-out Bolt für Stick-out 44520024

11 Motor 230V-50/60Hz Motor Motor 17809004

12 Fjeder for stick-out Spring for stick-out Feder für Einstellschablone 44520028

13 Bagplade Rear plate Rückplatte 44520003

15 Mø belhoved Mounting screw Möbelschraube 44491711

16 Sty reprint Control PCB Steuer-Leiterplatte 71618967

17 G evindstang Thread bar Gewindestange 44520011

18 Lej ehus Bearing housing Lagergehäuse 44520029

19 Sk aft Shaft Stiel 44520020

20 Spændeskrue med anslag Tightening screw Spanschraube mit Anschlag 44520004

21A Spændskrue for skueglas Screw for inspection cover Schraube für Schauglas 40320410

21B Skive for spændskrue Dome washer for screw Scheibe für Schraube 41512304

22A Bronzeleje Udvendig Bronze bearing outward Äusser Bronzelager 44520027

22B Bronzeleje indvending Bronze bearing inward Inner Bronzelager 44520026

23 Sk rue Screw Schraube 40210525

24 Gradskalabøsning Logging scale bush Gradskaler-Buchse 44520008

25 Omløber for pen Barrel for electrode clamp Umläufer für Elektrodenzange 44520023

26 U- skive U-wheel U-scheibe 41530530

27 Klemtang Electrode clamp Elektrodenzange 4451016x

28 W olframelektrode Tungsten electrode Wolframelektrode

29 PVC-slange ø4x60 Tapping hose Ø4x60 PVC-Schlauch 44492600

30 Smørenippelhætte Grease nippel stopper Schmiernippel-Stöpsel 44492610

31 Vridbar vinkel Elbow pipe Winkelrohr 44492500

33 Tætningsring for bøsning Packing ring for bush Dichtungsring für Buchse 44520018

34 O-ring Ø12x2,5 mm O-ring Ø12x2,5mm O-ring 12x2,5 mm 44470312

35 Af bryder Switch Schalter 17110027

36 Aflastning PG9 Relief PG9 Verschraubung PG9 18480012

37 Netledning Mains cable Netzkabel 74250014

38 Låg for væskebeholder Cover for liquid tank Deckel für Flüssigkeitbehälter 44494540

39 Væs kebeholder Liquid tank Flüssigkeitbehälter 75494500

40 O-ring Ø13x1,5 mm O-ring Ø13x1,5 mm O-ring Ø13x1,5 mm 44470213

41 Bor dkonsol Desk console Tisch-Konsole 88897910

43 G radskala Degree scale Gradskala 62189220

44 Gummi membran Rubber pack (membrane) Gummi Membran 44470124

45 Afstandsstykke motor Space piece motor Abstandstück Motor 44520019

46 Afstandsskrue Str etching screw Abstandschraube 44520022

47 Etiket Ultima-TIG Label Ultima-TIG Etikett Ultima-TIG 62189222

Væskebeholder 5 ltr. Liquid container 5 ltr Flüssigkeitsbehalter 75494000

INELCO A/S I NSTRUCTION MANUAL

Inelco A/S • Haandvaerkervej 6 • DK-9690 Fjerritslev • Denmark 8/12

E-mail: inelco@inelco.com

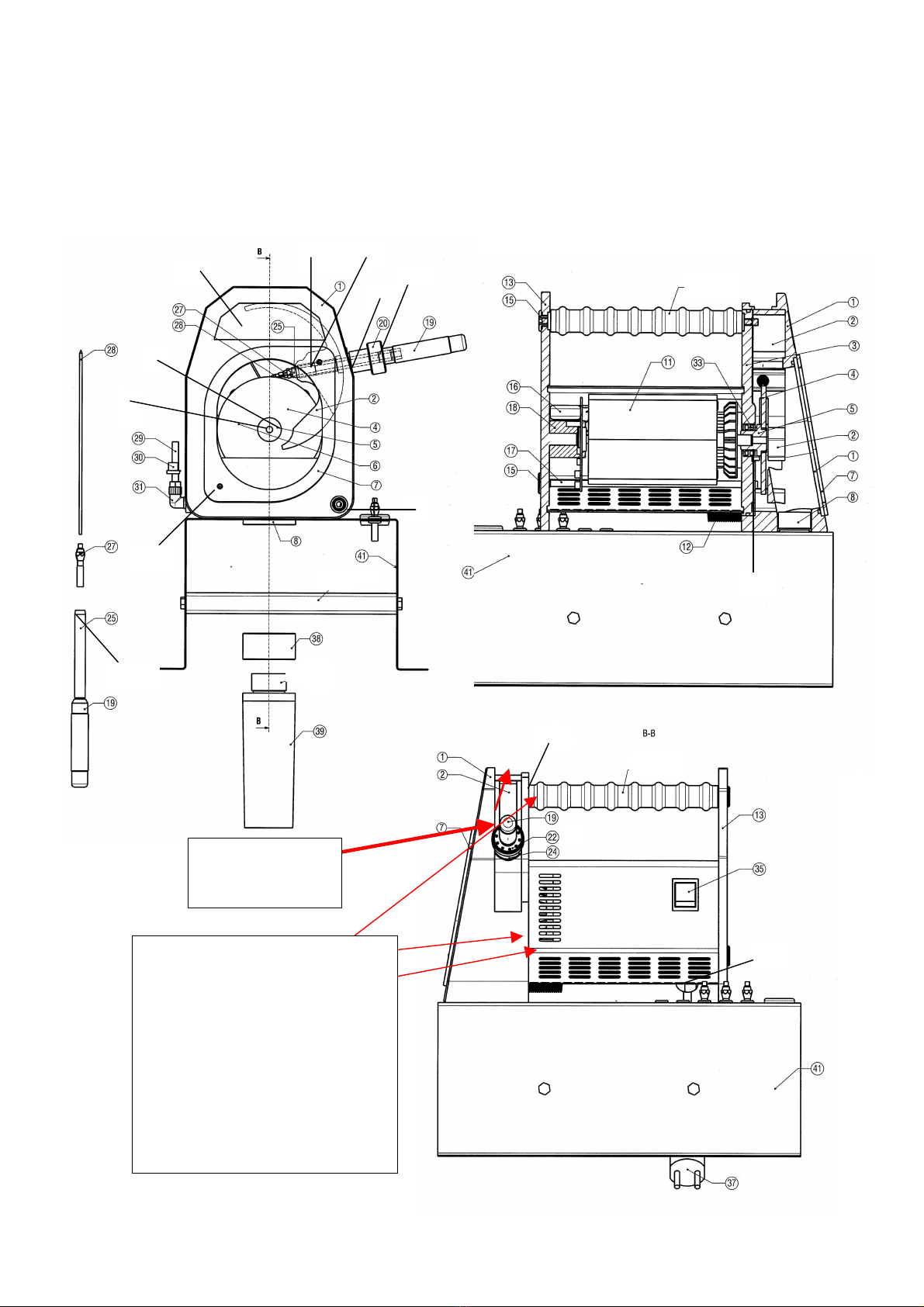

14. Drawing of Ultima-TIG

10

21A

23

26

47

21B

22B

46

44

9A+B

45

43

9A+B

36

A

Drawing Ultima-TIG – Changing of the grinding disc.

10

21A

23

26

47

21

B

22B

46

44

9A+B

45

43

9A+B

36

A

25A

1. Raise the

adjustment level

to hi

g

h

p

osition.

2. Loosen the 3 screws at the

back of the grinding console –

remove the console to make

access to the grinding wheel.

Hold the grinding wheel firmly

in place and fully tighten the

screw holding the

grinding wheel.

Keep this instruction sheet

with your operating manual

8A/12

INELCO A/S

Industrivej 3

DK-9690 Fjerritslev

Denmark

Tel +45 98 21 15 55

Fax+45 98 21 35 95

Welding Automation Pty Ltd

5/51 Taunton Drive

Cheltenham Vic 3192

Tel 0 86 2

Fax 03 9011 6203

………………………………………………………………………………

NEUTRA grinding liquid

Ultima TIG Grinding Liquid (concentrate)

Material Safety Data Sheet

1. Supplier

Welding Automation Pty Ltd

5/51 Taunton Drive

Cheltenham

Victoria 3192

Phone: 03 8516 2472

Fax: 03 9011 6203

2. Product Identification

Names:

Neutra Grinding Liquid EP770

Ultima TIG Grinding Liquid (concentrate)

Part Numbers;

75491301

75491300

2.1 Use

When diluted (19:1) with water, used as lubricant/coolant in NEUTRA and Ultima-TIG tungsten

grinding machines.

3.1 Appearance

Green, water-based liquid.

3.2 Odour

None detectable.

3.3. Ingredients

Alcanolamine compounds,

glycol derivatives,

preservatives,

dye and water.

3.4 Physical & chemical properties

Physical state: Liquid

Colour: Green

Odour: Faint

pH: 8,0

Boiling point: 100 ° C

Melting point: < 0° C

Density: 1,02g/ml

Solubility in water: Fully miscible.

3.5 Hazard Identification

Not classified as hazardous

Repeated or prolonged contact may lead to skin irritation.

4. First aid measures

Eyes: Immediately flood the eyes with plenty of water for at least 15 min,

holding the eye open.

Obtain medical assistance if soreness or redness persists.

Skin: Wash skin with soap and water.

Inhalation: Remove the person from exposure.

Ingestion: Wash out mouth with water. Do not induce vomiting. Obtain medical

assistance.

5. Flammability

Danger of fire: The product is unable to develop fire or explosion.

Extinguishing media: None required.

Precautions: Avoid inhalation of hazardous fumes of the fire.

6. Accidental release measures

Spillages:

Contain and absorb using earth, sand or other inert material.

Transfer into suitable container for recovery or disposal

7. Handling and storage

Handling: Avoid contact with the skin and eyes. Avoid inhalation.

Storage: Storage temperature should be controlled between 1- 40º C

8. Exposure controls & personal protection

When using the product inside the wet grinder there is no need of personal protection.

If any risk of contact with the skin, use PVC or rubber gloves.

If any risk of eye contact, use chemical goggles.

9. Stability & reactivity

The product is stable under normal conditions

10. Toxicological information

Short-term effects: Contact with the eyes will cause irritation

Long-term effects: Long-term or repeated skin contact with the concentrate may result in

inflammation of the skin.

12. Ecological information

The product is not classified as dangerous to the environment.

The product will leach into soil.

13. Disposal

Used fluid is to be disposed of according to local regulations or returned to Inelco A/S or its

distributors.

14. Transport information

The product is not classified as dangerous goods

15. Labelling

Classification : Hazard labelling is not required

R-sentences : none

S-sentences : none

16. Other information

MSDS date revised: March 2012.

Other manuals for ULTIMA-TIG

1

Table of contents

Other Inelco Grinder manuals

Popular Grinder manuals by other brands

Central Pneumatic

Central Pneumatic 52848 Operating and maintenance instructions

Powerplus

Powerplus POWXQ5104 manual

EGAmaster

EGAmaster aqua Master 79901 operating instructions

Far Tools

Far Tools SBG 150 manual

Lumberjack

Lumberjack BGS125 Safety and operating manual

Band-it

Band-it 2890SP Operating & parts manual