Inelco AutoGrind Digital User manual

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 1/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

for Ultima-Tig and for Ultima-Tig-Cut

USER MANUAL

EN

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 2/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

EU statement of compliance

Manufacturer: INELCO GRINDERS A/S

Industrivej 3

9690 Fjerritslev

Danmark

Tel. + 45 96 50 62 33

Fax. + 45 96 50 62 32

SE Nr. : DK 32652964

Hereby declare that

the machine: AutoGrind Digital

is produced in accordance with the provisions of the Commission’s Directive

on harmonization of national legislation’s on machinery 2006/42/EU, low-voltage

directive 2006/95/EU and EMC-directive 2004/108/EU.

AutoGrind is developed and produced according to following international

norms:

EN 61029

EN 61000-6-4

EN 61000-6-2

Responsible: Name: Anders Thy

Date : 27.06.2018

Signature: _____________

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 3/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

Contents:

1. General description .............................................................................................. 4

2. What is included................................................................................................... 4

3. Mounting on the Ultima-Tig/Ultima-Tig-Cut........................................................ 5

4. Setting the grinding angle .................................................................................... 5

5. Connecting AutoGrind and the grinder................................................................ 5

6. Inserting the electrode holder in the AutoGrind.................................................. 6

7. The automatic grinding program.......................................................................... 6

8. Adjustment of the grinding time .......................................................................... 7

9. Important when using AutoGrind on the Ultima-Tig-Cut..................................... 7

10. Maintenance......................................................................................................... 8

11. Technical data....................................................................................................... 8

12. Spareparts overview item no. 75550005 ............................................................. 8

-Important safety instructions

oAutoGrind can ONLY be used with Ultima-Tig and Ultima-Tig-Cut grinders. It CANNOT be used

with other grinders.

oOnly Ultima-Tig and Ultima-Tig-Cut shall be connected to the power outlet (female socket) on the

control box. Any other equipment shall not under any circumstance be connected to the control

box.

oOnly Ultima-Tig and Ultima-Tig-Cut with the same voltage and frequency as the power supply

should be connected to the power outlet (female socket) on the control box. The control box is

NOT a transformer!

-Video

oHere you can see a video showing unboxing, installing and grinding with the AutoGrind. The video

cannot replace this Manual.

-Disposal

Do not dispose electrical equipment in your ordinary waste disposal, but use the following guidelines:

oThe control box shall be disposed as electronic equipment.

oThe grinding module has to be dismantled, and the motor and cable shall be disposed as

electronic equipment, and the rest as metal waste.

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 4/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

1. General description

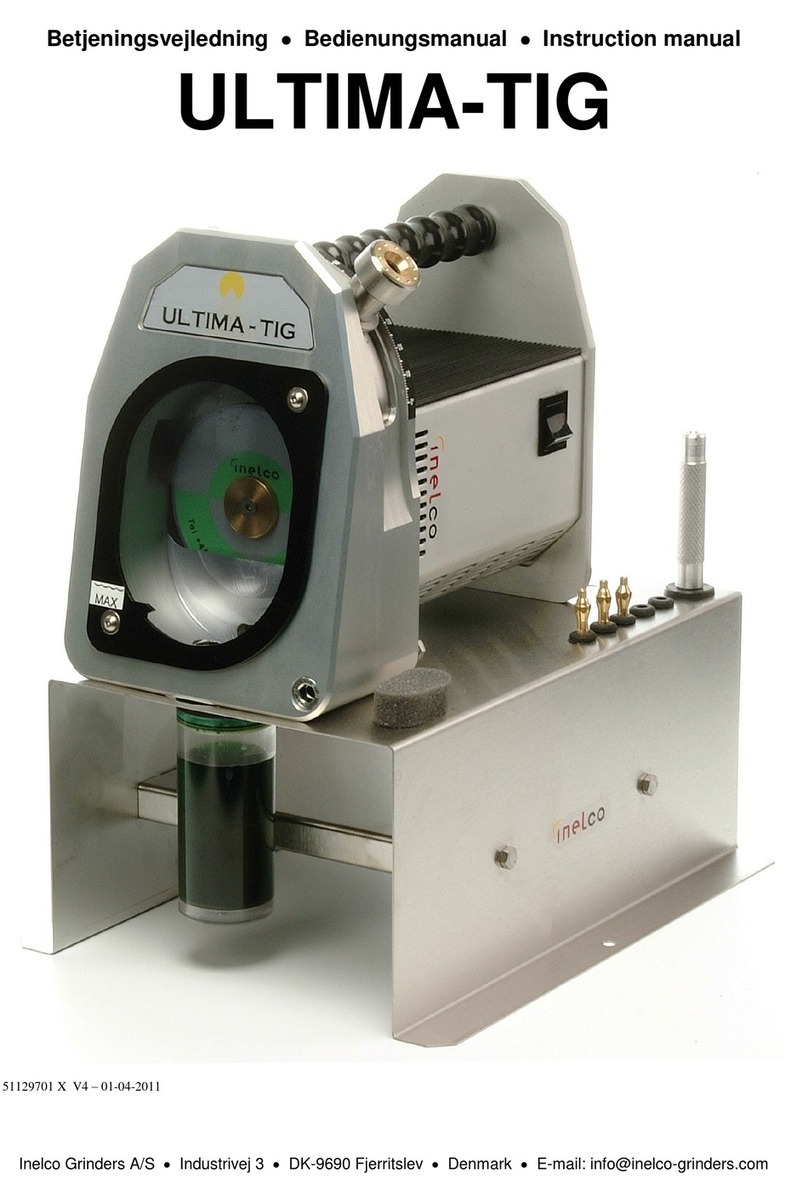

AutoGrind is engineered to be used with the Ultima-Tig and Ultima-Tig-Cut for automatic grinding of

Tungsten electrodes. The AutoGrind ensures a unified and fast grinding of the Tungsten electrodes.

2. What is included

AutoGrind consists of the following parts:

Pos.: Description:

1. Grinding module incl. connection cable and plug for the control box (Item No. 75550005)

2. Control box (Item No. 75550006)

3. Mains cable (female IEC plug, male plug depending on country)(Part no. see next page*)

4. Cable to connect the control box and the Ultima-Tig/-Cut grinder (Part No. see next page**)

5. Electrode holder for AutoGrind (Item No. 75550020)

6. O-ring ø13x1.5 (Item No. 44470213)

7. Stretching screw (Item No. 44550022) for mounting on Ultima-Tig/-Cut

8. Drain ring (Item No. 44550018)

9. Pipe fitting (Item No. 44492510)

10. Tightening screw with drain (Item No. 75550019)

11. Drain bottle set (Item No. 75550030)

12. Bottle holder (Item no. 44491215)

13. M6x14 hexagon screw (Item.No. 40310620)

14. Hexagon key 3 mm (Item No. 44510435)

1

2

3

4

5

7

8

9

10

11

12

Drain Assembly

6

13

13

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 5/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

*List of cables pos. 3 **List of cables pos. 4

Male plug type Part. No. Female plug type Part. No.

EU 230V-50Hz 74250014 EU 230V-50Hz 74300014

UK 110V-50Hz 74250015 UK 110V-50Hz 74300015

UK 220V-50Hz 74250016 UK 220V-50Hz 74300016

US 120V-60Hz /switch 75550015 US 120V-60Hz 74300017

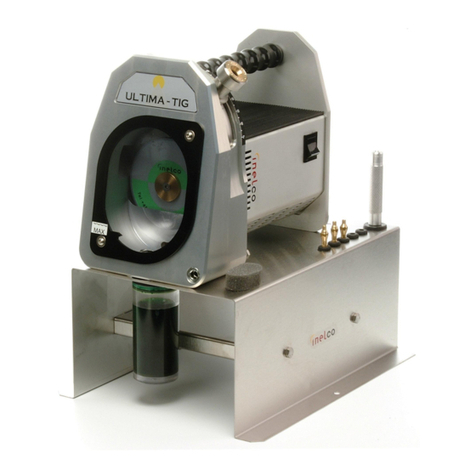

3. Mounting on the Ultima-Tig/Ultima-Tig-Cut

The original tightening screw and the stretching screw on the Ultima-Tig/-Cut

must be removed, which can only be done when the angle adjustment is in 90°

position. Otherwise it will fall down inside the grinding chamber.

The included stretching screw (Item No. 44550022) must be mounted in the angle

adjustment unit, using a little bit of white grease on the thread, and firmly

tightened with a 14 mm wrench. The included tightening screw (Item No.

75550019) is mounted loosely on the stretching screw. Then the desired grinding

angle is chosen and the tightening screw is tightened firmly by hand.

The AutoGrind grinding module can now be mounted on the tightening screw,

and secured by tightening the hexagon screw (x). Tool is included.

We recommend to position the grinding module, so that the cable from the

grinding module is hanging down to the right as shown on the front page picture

of this manual.

4. Setting the grinding angle

By turning the grinding module counter clockwise, the angle adjustment is loosened and the angle can be

adjusted. By turning the grinding module clockwise, the angle adjustment is tightened again.

5. Connecting AutoGrind and the grinder

The cable from the grinding module is connected to the control box.

The included short cable is connecting the grinder with the control box, so

that the mail IEC plug is plugged in the control box and the female plug is

connected to the male plug from the mains cable on the grinder

X

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 6/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

The included long power cable is connecting the control box to the main power.

IMPORTANT: Only Ultima-Tig and Ultima-Tig-Cut, that is suitable for the voltage and frequency, as the

control box is connected to, shall be connected to the control box.

If the on/off switch on the Ultima-Tig/-Cut grinder is set to ”on”, the grinder is not running, but will start

and stop by activating the on/off button on the side of the AutoGrind module. The control box

automatically supplies the power to the grinder, when the grinding module is turned on. Therefore the

on/off switch on the grinder needs to be ”on”. Otherwise the control box cannot start and stop the

grinder automatically.

6. Inserting the electrode holder in the AutoGrind

The Electrode is inserted into the electrode holder and securely fastened.

Set the stick-out on the Ultima-Tig/-Cut, as described in step #6 in the

operations manual.

When the electrode holder is inserted in to the AutoGrind module, the

locking pin (black knob) needs to be pressed down to lock the drive unit

and prevent it from rotating.

The electrode holder should be rotated with a light pressure until the

electrode holder locks into the drive unit, you will feel a slight click as the

electrode holder is in position. Next push the electrode holder in and

rotate counter-clockwise until the bayonet lock is holding the electrode

holder in place.

Important: The locking pin must not be held down, when the AutoGrind is started or pressed down

during grinding. This will destroy the inner parts of the module!

7. The automatic grinding program

The control box is programmed to run through the following grinding

process that starts when the on/off button is activated:

i. Ultima-Tig/-Cut grinder is activated and starts to rotate the grinding

disc.

ii. 2 sec. later the AutoGrind module starts to rotate the electrode

holder slowly in 3 sec. This moves the electrode holder towards the

grinding disc, and the grinding of the electrode starts.

iii. The AutoGrind module is then rotating faster for 15 sec. (the grinding time). The grinding time can

be adjusted as necessary (see step #8)

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 7/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

iv. Next, the AutoGrind module slows down for 3 sec. This finishes the grinding, and gives the

electrode tip a fine and consistent surface.

v. The AutoGrind module now shifts rotational direction for 2½ sec. to move the electrode holder

back to the start position. At the same time the grinder is stopped, and the grinding is finished.

The electrode holder can now be turned clockwise and pulled out of the bayonet lock and the grinding

module.

If the on/off button on the grinding module is activated during the grinding process, the program jumps

to #v and the grinder stops.

8. Setting the grinding time

When the controlbox is plugged in to the power source, the

display will show “Ed” (Edition) and the edition number of

the software “1.0” or higher, followed by the preset grinding

time (standard 15 sec.)

The grinding time (see section #7, iii) can be adjusted from 1 to 99 sec. The adjustment is done by

pressing the “+” and “-“ buttons on the front of the controlbox. Each push changes the grinding time with

1 sec.

Any change of the grinding time is only saved in the controlbox after the AutoGrind has completed a

grinding cycle. The grinding time is not saved if the grinding cycle is interrupted.

Display the number of grindings

If the on/off button is pressed while the controlbox is connected to the power source, then

the display will show “8.8” followed by “- -“ and the number of grindings the controlbox has

carried out. The number of grindings is shown two digits at a time. The highest number it

can show is 999.999.

If the power is disponnected for 5 sec. the

controlbox returns to the grinding program.

9. Important when using the AutoGrind on Ultima-Tig-Cut

If the AutoGrind is being used with the Ultima-Tig-Cut, it is necessary to

adjust the electrode guide on the Ultima-Tig-Cut, app. 2mm outwards,

because the electrode holder for the AutoGrind is different than the

standard electrode holder. Otherwise there is a risk that the cutting disc

will cut through the electrode clamp and damage it.

INELCO GRINDERS A/S AutoGrind

Inelco Grinders A/S, Industrivej 3, DK-9690 Fjerritslev, Denmark 8/8

E-mail: info@inelco-grinders.com , www.inelco-grinders.com

10. Maintenance

The AutoGrind module and control box are maintenance free, but needs to be kept dry and clean.

The rotating part in the AutoGrind module is running in two bearings. If dirt and moisture is getting in to

the bearings, they will not last so long, and it will affect the grinding result.

When the two bearings are worn out, they need to be changed, please contact the distributor where you

purchased the AutoGrind or contact Inelco Grinders.

11. Technical data

The control box is universal and can be plugged in to all one phase power supplies from 100 V to 240 V for

both 50 Hz and 60 Hz.

The grinding module has a 12V motor, that may only be connected to the control box.

12. Spare parts overview Item No. 75550005

Pos.

Item No.

Description

1

75550013

Blocking module for

AutoGrind

2

44550000

Bottom grinding module

AutoGrind

3

75550012

Axle module AutoGrind

4

75550011

Motor module for

AutoGrind

5

40310306

Allen screw M3x6

6

44550001

Top grinding module

AutoGrind

7

40310320

Allen screw M3x20

8

44550002

Motorcap

9

44550020

Bearing AutoGrind

10

17110035

On/off button AutoGrind

11

44551300

Packing box AutoGrind

12

40110511

Screw M4x12

13

44550017

Teflon disc

14

44550021

Motor Bearing

AutoGrind

15

74491429

Plug Foil Key female

16

75550010

Control cable

1

2

3

4

5

8

7

9

10

12

11

6

16

13

14

15

Table of contents

Other Inelco Grinder manuals

Popular Grinder manuals by other brands

Scheppach

Scheppach SM200L Translation of original instruction manual

Parkside

Parkside PWS 1010 - MANUEL 2 Operation and safety notes

Grizzly

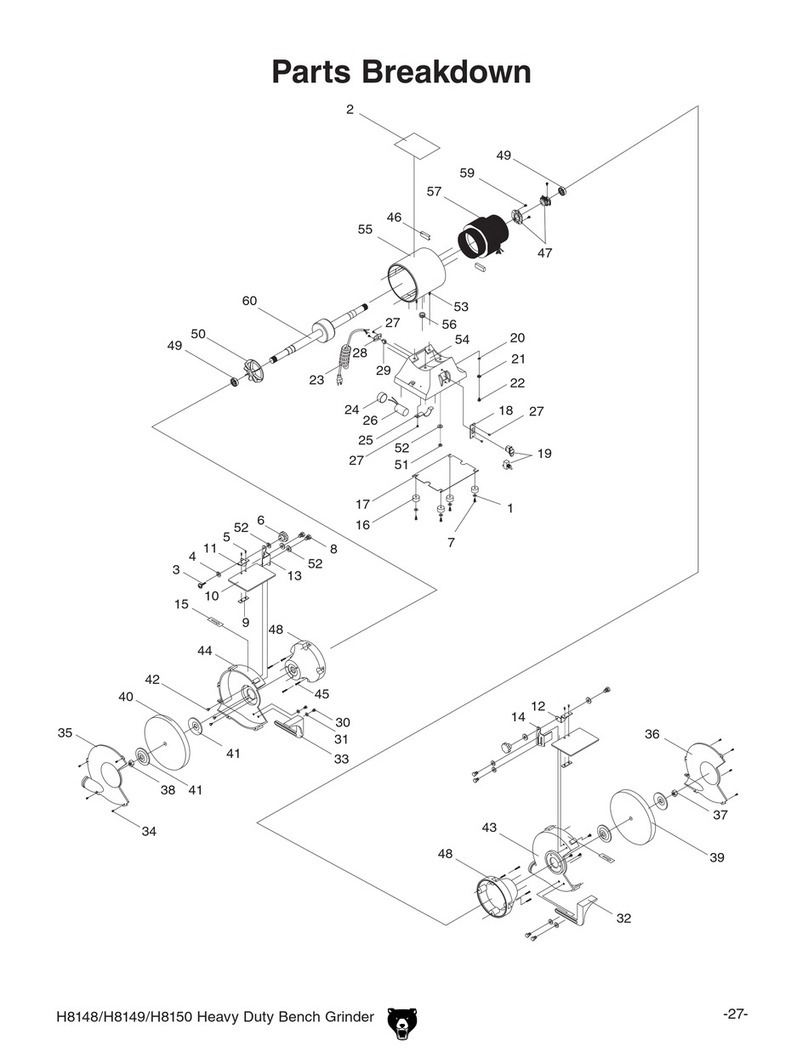

Grizzly H8150 Parts Breakdown

Cuisinart

Cuisinart SG-10 INSTRUCTION AND RECIPE BOOKLET

Neary

Neary 555 SRI Service manual

Ingersoll-Rand

Ingersoll-Rand 301 Product information

Würth

Würth EWS 7-115 BASIC Translation of the original operating instructions

Bosch

Bosch Professional GWS 750-100 E Original instructions

Makita

Makita 9558HNR instruction manual

Pentair

Pentair HYDROMATIC HPD200 Installation and service manual

BITEHARDER

BITEHARDER 12 VOLT CARBIDE GRINDER instructions

Würth

Würth EWS 8-115 Light Original operating instructions