iNeXT Robo-CIRCLE User manual

1

The rst programmable robot kit for everyone

Step by step from starting to the intelligent robot with sensors.

Fun with learning the programmable

robotic kit. Includes building the robot

platform and learning the programming

by Logo language with iconic and text-

based software.

Fun with learning the programmable

Fun with learning the programmable

robotic kit. Includes building the robot

robotic kit. Includes building the robot

platform and learning the programming

platform and learning the programming

by Logo language with iconic and text-

by Logo language with iconic and text-

Fun with learning the programmable

Fun with learning the programmable

robotic kit. Includes building the robot

robotic kit. Includes building the robot

platform and learning the programming

platform and learning the programming

by Logo language with iconic and text-

by Logo language with iconic and text-

Refl ect sensor Light sensor Switch sensor LED Light

2

System requirements

Hardware

Software

CX-4 cable

JST3AA-8 cable

You will need either a PC or laptop computer to

run the Robo-CIRCLE software. Getting started with

Robo-CIRCLE is easiest if your PC or laptop has the

followingfeatures:

• Harddisk space 15MB

• 800 x 600 Resolution Color Monitor. 1024 x 768

recommended.

• A serial or USB port (requires USB to serial port

converter for USB port - optional)

•

A CD-ROM drive, World Wide Web access, or both.

•

Install Windows ME or newer operating system.

Windows XP Service-pack2 recommended. Also

supports Window Vista and Windows 7.

COM port interfacing cable between controller board with computer

3-wire cable for interfacing the sensor and application module

Female DB-9 connector

Computer’s side

4-pin modular plug

Microcontroller’s side

pin 2 - RxD (Serial data receiver pin)

pin 3 -

TxD (Serial data transmitter pin)

pin 4 - DTR (Data terminal ready)

pin 5 - GND (Ground)

Conductor side

+5V

RS-232 serial port may be called

COM port. Normally installed

at the back of computer. It

provides 9-pin male D-type

connector (called DB-9 male

connector).

RS-232 serial port may be called

COM port

Cable information :

Ground Signal wire 8-inch

3

Getting started with the

Computer has only USB port

Notebook computer

Desktop computer

connect with ZX-LED

or Relay driver circuits

connect with Infrared

re ectors, Light sensors

connect with Switch/

Touch sensors

The brain of Robot,

contains Logo inter-

preter rmware

Stop program

Forward

Simple DC motors DC

motor gearboxes

Turn ON or OFF the supply

voltage to all circuit

i-BOX III supports

simple Alcaline

batteries and

Rechargeable

batteries.Use 4

“AA”(not included).

Backward

Run program

USB<>COM port

UCON-232S

CX-4 cable

CX-4 cable

Optional

USB interface

Digital output

Analog input

Digital input

Microcontroller RUN/STOP switch

First step with

(1) Flip the i-BOX around and open the battery cover to place

4 “AA” batteries into the battery holder. Please ensure that the

polarity of the placement of your batteries are correct in order for

the i-BOX to function.

(2) Turn on POWER switch. The Red LED light will blink a few times

followed by a Beeping sound from its speaker.

Motor direction indicator

Motor output

POWER switch

AA size Battery

Install batteries

Serial (COM) port interface

[1] Turn on

[2] LED on

[3] Beep!

4

Software installation

(1) Insert Robo-CIRCLE CD-ROM into your drive. Double-click on i-BOX III V133

setup.exe. You will see the Installation Welcome page. Click on the “NEXT”

button to Continue installation.

(2) If do not need to change any specications, click on the “NEXT” button

continue.

(3) Installation is started. i-BOX Utility window is appeared. Yuo can use it for search-

ing the available COM port for interfacing with i-BOX controller board automatically.

(4) Run the program by clicking on the Start > Programs > i-BOX III LogoBlocks

or Criket Logo.

Click Start button

5

How does the i-BOX interface with

my computer

Direct serial connection to COM port of your computer with the CX-4 cable.

Connect USB port using the UCON-232S USB to Serial converter device.

COM port

UCON-232S

CX-4

Direct connect to working

Using the USB port, you will rst need to install the

driver provided by the USB to Serial converter device

that is optional.

(1) Back to the installation CD-ROM, open UCON-232

USB Driver folder to nd USB driverInstallerV2.xx.exe.

Double-click on this le to start installation.

(2) Plug the UCON-232S to USB port. Computer will

connect with UCON-232S automatically. Blue LED of

UCON-232S turns on to shows READY connection.

(3) Connect the CX-4 cable between UCON-232S

and i-BOX controller.

6

How to choose the COM port interfacing

Search and choose by i-BOX III Center software

Check and choose with your own

(1) Connect the CX-4 cable between i-BOX and computer’s COM port.

(2) Run the i-BOX III center from Start > i-BOX III > i-BOX III Center.

(3) i-BOX III Center software will search the COM port available of your computer and

connect with i-BOX automatically.

(4) Click on the LogoBlock or CricketLogo to start the software.

(1) Click the right button mouse on My Computer icon to choose Properties. The System

Properties window is appeared. Select Hardware > Device Manager. Choose Ports listing

(COM & LPT). Observe the number of Communication port (COMx). If using the UCON-232S

device, the port name will display USB Serial Port (COMx) instead. Remember the COM port

number to set in the software later.

(2) For LogoBlocks software, select menu Edit > Preferences.. Choose the COM port

interfaced from step (1) and click on the OK button. For Cricket Logo, you can set the COM

port interfaced at Serial port combobox on the main screen.

Choosing COM port

of LogoBlocks

Choosing COM port

of CricketLogo

Notebook computer

Desktop computer

USB<>COM port

UCON-232S CX-4 cable

CX-4 cable

7

How to develop Robo-CIRCLE

programming

Connect the download cable

to i-BOX III controller.

Robo-CIRCLE development is divided into 3 parts.

Part-1 : Prepare and construct the Robot from

chassis, motors, wheels and other mechanical parts

Part-2 : Learn about i-BOX controller and Sensors

Part-3 : Controlled program

Construct the robot.

Cricket Logo

Logo Blocks

Edit code.

Connect the download

cable to COM port.

COM port

Robot programming procedures

Construct the robot

and attach sensors

Connect the cable between

robot and computer

Create code with

LogoBlocks or CricketLogo

Download the code

Test code

Does the code run correctly ?

Correct

Incorrect

Edit the code

Ending

8

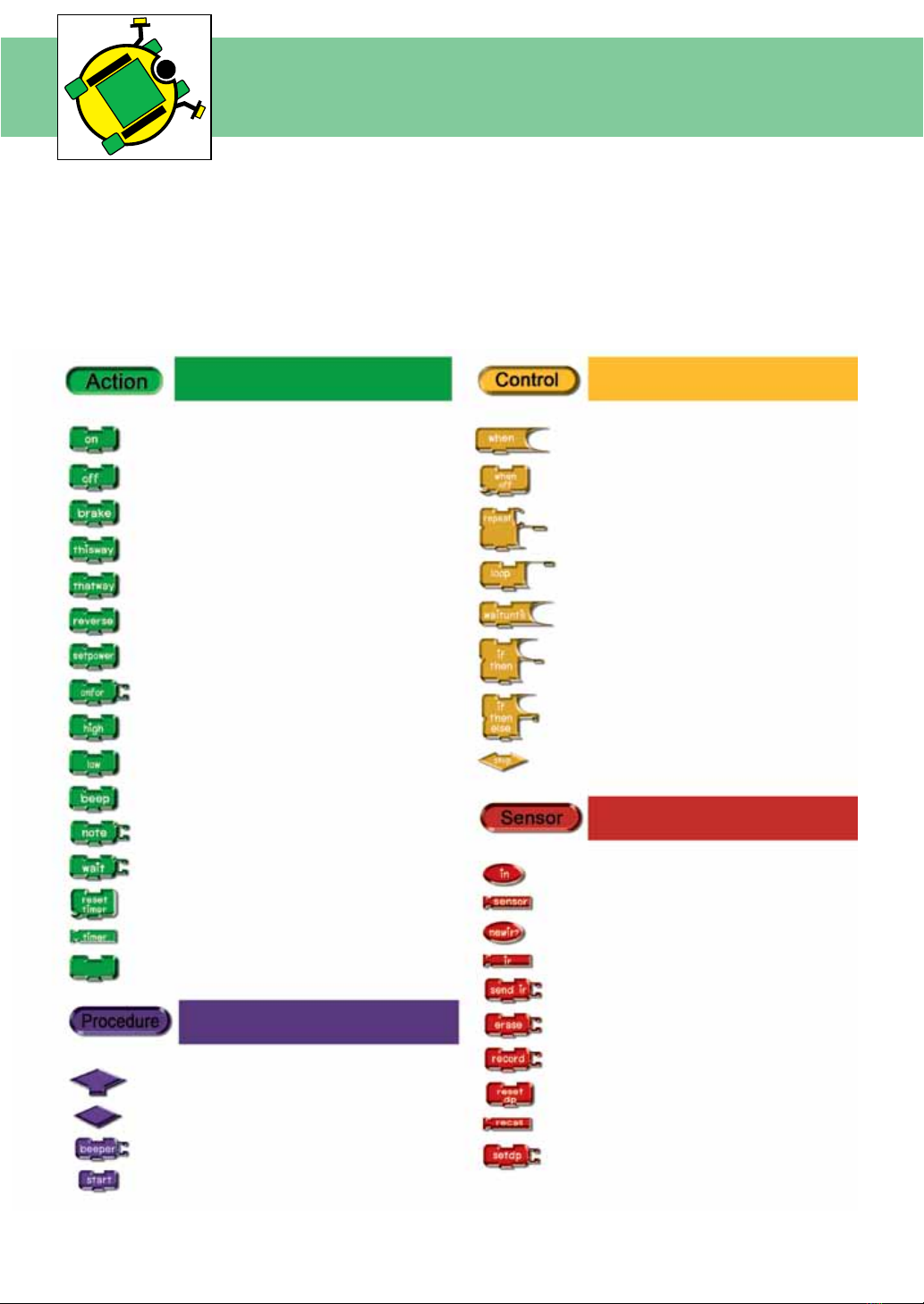

Command block

summary of LogoBlocks

LogoBlocks is a unique software that lets you create iconic programs to control the

i-BOX III controller. To create programs, you just drag blocks form the palette (on the

bottom left of the screen) and snap them together on the canvas (on the right side

of the screen). The buttons on the bottom left let you switch between palettes, each

containing a different set of commands.

Motor control, Sound

and Timer command

Condition and loops command

Procedure functions command

Sensor functions command

Drive motor Interrupt

Stop interrupt

Repeat loop

Loop operation

Wait condition

Check conditions

Check additional conditions

Stop program operation

Digital input block

Sensor block

Serial data checking

Serial data buffer

Serial data monitor

Delete data block

Record value to memory

Clear Data Pointer

Recall data from memory

Set data pointer

Stop motor

Brake motor

Forward direction

Backward direction

Reverse direction

Set power to motor

Set time of motor control

Send HIGH logic

Send LOW logic

Beep generation

Musical generation

Set delay time

Reset timer value

Read timer value

nop : No operation

Set of rules block

Procedure icon

Beep

Start sub procedure

9

Command block

summary of LogoBlocks

Number functions and arithmetic command

Declare variable

NOT : logical block operation

Adding

Subtraction

Multiplying

Divided

Modulus

Set number

Random numerical

Numerical comparison (Less than statement)

Numerical comparison (Equal statement)

Numerical comparison (More than statement)

AND : logical block operation

OR : logical block operation

XOR : logical block operation

10

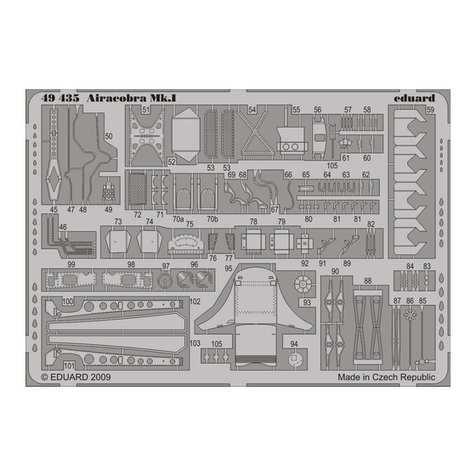

ZX-LED : The LED output board

introduction

How it work ?

Interfacing with i-BOX III

The ZX-LED is digital output device module. The LED will lit when get the logic “1”

A light emitting diode (LED) emits light when current passes through it. The color of the LED usually just tells you what

color it will glow when current passes through it. The important markings on an LED are contained in its shape.

Since an LED is a one-way current valve, you have to make sure to connect it the right way, or it won’t work as intended.

LED has 2 terminals. One is called the anode, and the other is called the cathode. On the schematic symbol, the cath-

ode is the line across the point of the triangle and part drawing. For the part drawing, note that the LED’s leads are

different lengths. The longer lead is connected to the LED’s anode, and the shorter lead is connected to its cathode.

ZX-LED includes a transistor to drive current for supporting the low source current output port of microcontroller.

It ensures the LED on when the logic “1” applied to input.

ZX-LED is output device. Must connect with P0 and P1;

the digital output port of i-BOX III controller following the

gure on left. There is 4 command blocks for controlling

the ZX-LED

Set P0 as logic “1” (+5V)

Signal connector

Transistor current

amplier for driving LED

ZX-LED schematic diagram

8mm. LED

Set P1 as logic “1” (+5V)

Set P0 as logic “0” (0V)

Set P1 as logic “0” (0V)

11

Fun with LED

Connection diagram

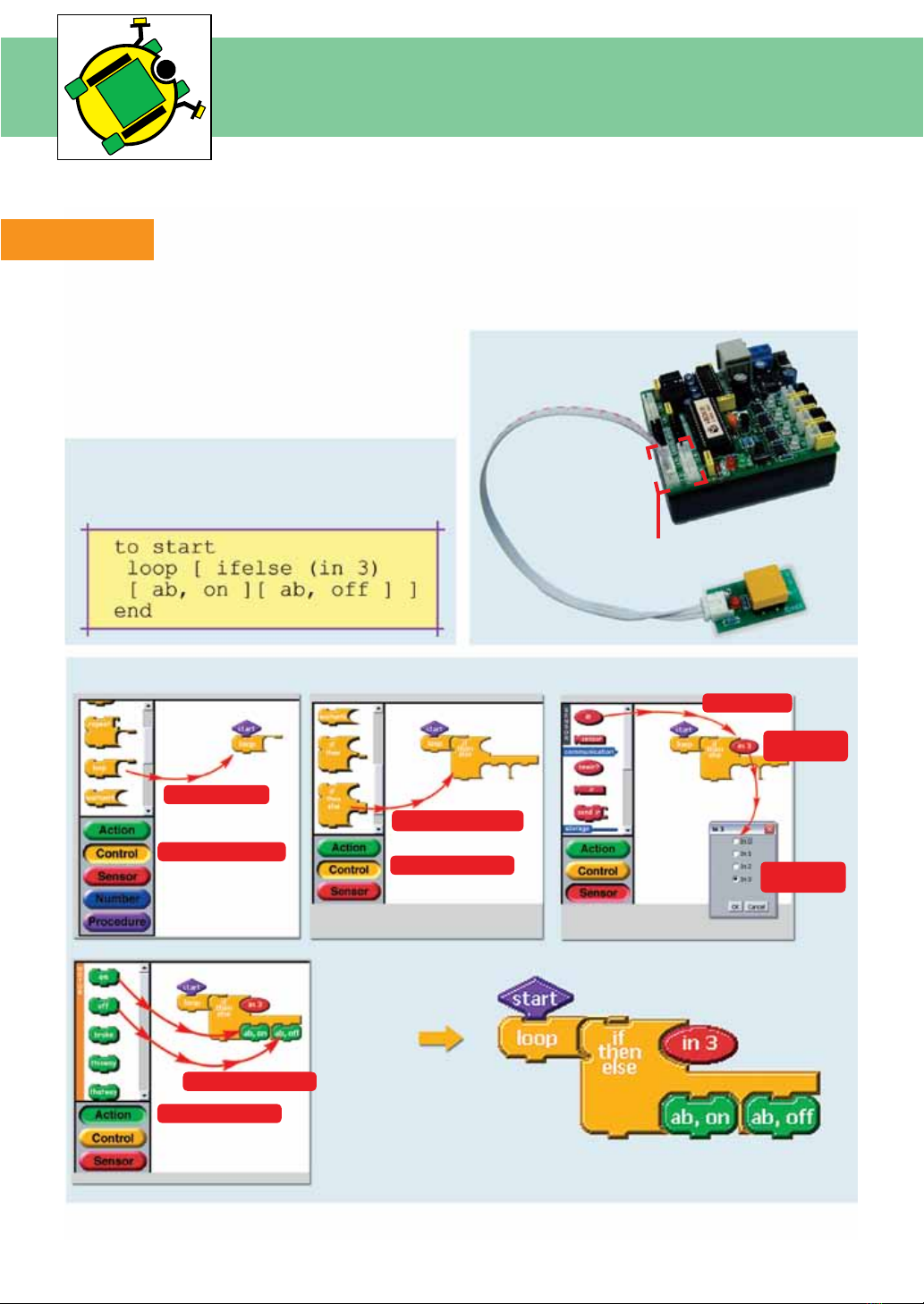

Program development procedure with Cricket Logo

Dual LED blinking Cricket Logo example code

(LED.lgo)

(1) Connect i-BOX III controller to the computer.

(2) Open the Cricket Logo software.

(3) Type in LED.log listing into the Cricket Logo editor.

(4) Type in start on into the Run this box.

(5) Turn-on power of i-BOX III.

(6) Download the code into the i-BOX III by clicking on the DOWNLOAD button.

(7) Press RUN button on the i-BOX III controller. The RUN green LED is on and ZX-LED on P0 and P1 ports are blinked.

Computer has only USB port

Notebook computer

Desktop computer

CX-4 cable

CX-4 cable

USB interface

Serial (COM) port interface

12

Fun with LED

Program development procedure with LogoBlocks

(1) Connect i-BOX III controller to the computer.

(2) Open the LogoBlocks software.

(3) Drag and drop the command blocks as follows.

(3.1) Choose

Control group

(3.8) Select blocks.

(3.9) Copy the

selected blocks.

(3.10) Paste the

copied blocks.

(3.11) Change

some value.

The nish block codes are shown in the

LED.blk block code le.

(3.2) Drag

loop block

(3.3) Choose

Action group

(3.6) Drag wait block

to connect the latest

block code

(3.7) Double-click

to change value

to 50.

(3.4) Drag high

and low block

(3.5) Double-click

to change value

(4) Turn-on power of i-BOX III.

(5) Download the code into the i-BOX III by clicking on the

DOWNLOAD button. Wait for the downloading complete.

Observe the DOWNLOAD button released.

(6) Press RUN button on the i-BOX III controller. The RUN

green LED is on and ZX-LED on P0 and P1 ports are blinked.

Dual LED blinking LogoBlocks example code

(LED.blk)

13

Introduction to Switch /Touch sensor

Basic operation of Switch

Switch operation

The Touch / Switch Sensor module consist of 3 main components, the Wire input, LED Indication light

and the Switch. It will be give 2 status as Press and Release switch.

Switch/Touch sensor give 2 results as follows :

Result is logic “1” when switch is not pressed

or released. Condition is FALSE.

Result is logic “0” when switch is pressed.

Condition is TRUE.

Switch

LED indicator

Signal connector

Not press or release;

condition is FALSE.

Press; condition is TRUE.

Switch/Touch sensor

basic components

Switch/Touch sensor

schematic diagram

Release/Not press Press

14

Play with Switch sensor

The Touch / Switch Sensor module acts as a digital sensor. Connect the sensors to IN0 to IN3 respectively.

Testing

(1) Connect Switch sensor to IN3 o-BOX III controller

(2) Create the code Switch.lgo in Cricket Logo or

Switch.lbk in LogoBlocks

(3) Download the code to i-BOX III controller

(4) Press RUN switch. Press the Switch sensor and

observe the operation of Motor indicators. LED of motor

indicators are on when switch is pressed and off when

released.

Switch testing Cricket Logo example code

(Switch.lgo)

Switch testing LogoBlocks example code (Switch.lbk)

IN0 to IN3 connectors

(1) Choose Control group.

(2) Drag loop block.

(3) Drag if-then-else block.

(4) Choose Sensor group.

(8) Choose Action group.

(9) Drag on and off block.

(5) Drag in block.

(6) Double-click

on the in block.

(7) Change port

to in3.

15

Swith control LED activity

This example shows how to create the code to control LED at output port of i-BOX III controller. Switch

sensor at IN1 controls ZX-LED on P0 port. Other switch sensor is connected to IN3 of controller board and

controls ZX-LED at P0 port.

Switch controls LED Cricket Logo example code

(LEDSwitch.lgo)

Switch testing LogoBlocks example code

(LEDSwitch.lbk)

Code operation

p0 p1 are created

from global variable

This example code uses p0 and p1 variable for keeping the status of LED. If the switch at IN1 is pressed

and released, invert the current logic of P0 port from “1” to “0” or from “0” to “1” . Also switch at IN3

controls the logic at P1 port.

16

Building Robo-CIRCLE

Part list

i-BOX3.0 controller

2 of 120:1 DC motor

Gearboxes with mounting

Circle chasis

4 of 3x8mm.

at-head screws

2 of 2mm.

self-tapping screws

Box holder Wheels and Tires 2 of 33mm. metal spacer

Construction

(1) Attach 2 of DC motor gearboxes with the Box holder by 3x8mm. at-head screws at the position

following the picture below.

3x8mm.

at-head screws

3x8mm.

at-head screws

17

(2) Attach 2 of 33mm. metal spacers on the Box holder by 3x8mm. at-head screws at the position

following the picture below.

(3) Fix on the 2 wheels with rubber tires and attach them to the DCGearbox with the 2 of 2mm.

self-tapping screws provided in the kit.

Building Robo-CIRCLE

33mm. metal spacer

33mm. metal spacer

2mm. self-tapping screws

18

Building Robo-CIRCLE

(4) Attach the motor construction from step (3) with the Circle chasis at the position following the picture

below.

Tighten with 3x6mm. screws at 33mm. metal spacer position.

(5) Place i-BOX into the holder. Connect Motor A cable to the Blackconnector of ch-A and Motor B

to the white connector of ch-B.

* specic position of screw is hole of metal spacer

Your Robot is ready to GO!

Motor A is motor that is on Sensor connector side.

Motor B is motor that is on Motor connector side.

Screw position

Screw position

Motor A

Motor B

19

DC motor Gearbox operation

Robo-CIRCLE is moved by 2 of DC motor gearboxes. This topic explains about the DC motor gearbox

operation. Gears are used in tons of mechanical devices. They do several important jobs, but most

important, they provide a gear reduction in motorized equipment. This is key because, often, a small

motor spinning very fast can provide enough power for a device, but not enough torque. For instance,

an electric screwdriver has a very large gear reduction because it needs lots of torque to turn screws,

but the motor only produces a small amount of torque at a high speed. With a gear reduction, the

output speed can be reduced while the torque is increased.

Understanding the concept of the gear ratio is easy if you understand the concept of the

circumference of a circle. Keep in mind that the circumference of a circle is equal to the diameter

of the circle multiplied by Pi (Pi is equal to 3.14159...). Therefore, if you have a circle or a gear with a

diameter of 1 inch, the circumference of that circle is 3.14159 inches. Most gears that you see in real life

have teeth.

The rst driving gear of the gearbox system is a gear that attached with motor’s shaft. The next gear

is attached cause to change the speed and torque of system. It is called driven gear. If driven gear is

bigger than the driving gear; the torque increase but speed decrease. In the other hand, the driven

gear is smaller. The torque decrease and speed increase. The example simple gear system is shown in

the gure below. The rst gear is 9-teeth. Second gear is 36-teeth. The gearbox ratio of this system is 4:1

from the formula :

Teeth of the driven gear/Teeth of the driving gear

For the large gear ratio such as 64:1, we require more gears to make the system. Gears are often

connected together in gear trains.

The gure below shows the example of 64:1 ratio gear system.

Each part in the train is actually made in two parts, a small gear and a larger gear are connected to-

gether, one on top of the other. Gear trains often consist of multiple gears in the train. For this example

the gear ratio can calculate as follows :

Gear ratio of 3rd part x Gear ratio of 2nd part x Gear ratio of 1st part

36/9 x 36/9 x 36/9 = 64 : 1

Gear ratio

9-teeth driving gear

Driving gear (1) 9-teeth

Driven gear (1) 36-teeth

Driving gear (2) 9-teeth Driving gear (3) 9-teeth

Driven gear (2) 36-teeth Driven gear (3) 36-teeth

36-teeth driven gear

20

DC motor Gearbox operation

The Robo-CIRCLE gearbox ratio is 120:1. The inside gear system is shown in the picture below.

Robo-CIRCLE gearbox includes 5 of gears and 4 parts following the gure below. First driving gear is

8-teeth gear. The gear ratio of this system is :

Gear ratio part 4 x Gear ratio part 3 x Gear ratio part 2 x Gear ratio part 1

X X X

Driven gear (4) 28-teeth Driven gear (3) 36-teeth Driven gear (2) 36-teeth Driven gear (1) 36-teeth

= 118.59 : 1. It is 120:1 approximation.

Driving gear (4) 17-teeth Driving gear (3) 9-teeth Driving gear (2) 9-teeth Driving gear (1) 8-teeth

Calculation :

Driving gear (1) 8-teeth

Driven gear (1) 36-teeth Driven gear (3) 36-teeth

Driven gear (2) 36-teeth Driven gear (4) 28-teeth

Driving gear (3) 9-teeth

Driving gear (2) 9-teeth Driving gear (4) 17-teeth

This manual suits for next models

1

Table of contents

Popular Toy manuals by other brands

Fei Bao

Fei Bao Velox Assembly manual

KidKraft

KidKraft Step 'N Store 15602D Assembly instructions

Faller

Faller 2 WARNING GROSSES WITH FLASHING LIGHTS instructions

American Printing House

American Printing House Code & Go Robot Mouse Activity Set Activity guide

VTech Baby

VTech Baby Roar & Explore Wheel Parents' guide

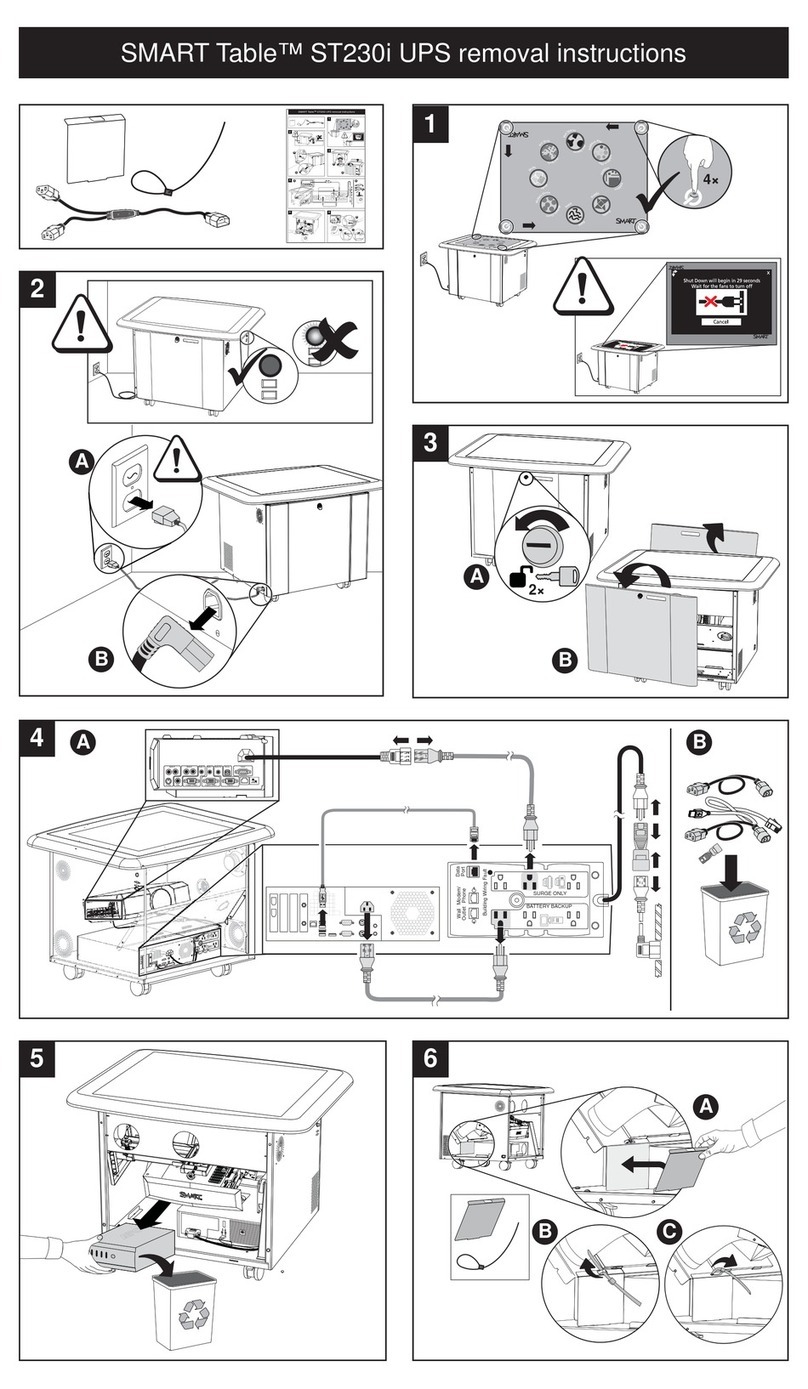

SMART

SMART Table ST230i Removal Instructions

Mattel

Mattel Barbie T2694-0520 instructions

Faller

Faller 131242 manual

LeapFrog

LeapFrog Interactive Wooden Animal Puzzle instruction manual

Mega Construx

Mega Construx Kubros Halo Spartan Recon DXB91 Assembly instructions

Carson

Carson BIG Hughes 500 instruction manual

Fisher-Price

Fisher-Price GVY94 manual