Infanor SMT-BD1/m User manual

SMT-BD1/m

1

SMT-BD1/m

gb

INFRANOR

®

SMT-BD1/m

Positioner

2 SMT-BD1/m

SMT-BD1/m

SMT-BD1/m

3

SMT-BD1/m

WARNING !

This is a general manual describing a series of servo amplifiers having output capability suitable for driving AC

brushless sinusoidal servo motors. This manual may be used in conjunction with appropriate and referenced

drawings pertaining to the various specific models.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60 204.1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval are only valid if the items are installed according to the

recommendations of the amplifiers manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several hundreds

of volts may remain during a few minutes).

INFRANOR drives are conceived to be best protected against electrostatic discharges. However, some

components are particularly sensitive and may be damaged. Before handling the drives and, particularly, before

any contact with the connectors, the user himself must be earthed. Place or store the drives on conducting or

electrostatically neutral areas but not on plastic areas, carpeting or insulation material that may be electrostatically

loaded.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

This manual is a translation of the original document and does not commit INFRANOR's responsibility. The french

manual is the only reference document.

©INFRANOR, March 2005. All rights reserved

Issue:5.0

!

4 SMT-BD1/m

SMT-BD1/m

5

SMT-BD1/m

Contents

Contents

PAGE

CONTENTS.............................................................................................................................................................5

CHAPTER 1 - GENERAL DESCRIPTION...............................................................................................................7

1-INTRODUCTION.............................................................................................................................................7

2-GENERAL DESCRIPTION ..............................................................................................................................7

3-COMPLIANCE WITHTHESTANDARDS ........................................................................................................7

4-OTHER DOCUMENTSTO BE USED OR THEDRIVE COMMISSIONING......................................................7

CHAPTER 2 - SPECIFICATIONS............................................................................................................................8

1-MAIN TECHNICAL DATA................................................................................................................................8

1.1 - Current ratings 220 VAC drive version .....................................................................................................8

1.2 - Current ratings for 400 VAC drive version ................................................................................................9

1.3 - Other specifications ................................................................................................................................10

2-MAIN PROTECTIONS...................................................................................................................................11

2.1 - STORED PROTECTIONS......................................................................................................................11

2.2 - FUSE PROTECTION OF THE SMT-BD1/M DRIVE VERSION 220 VAC...............................................11

2.3 - FUSE PROTECTION OF THE SMT-BD1/M DRIVE VERSION 400 VAC...............................................12

CHAPTER 3 - INPUTS-OUTPUTS........................................................................................................................13

1-CONNECTORS.............................................................................................................................................13

1.1 - Rack connectors.....................................................................................................................................13

1.2 - Drive connectors.....................................................................................................................................13

2-X1: RESOLVER CONNECTOR.....................................................................................................................14

3-X2: ENCODER CONNECTOR.......................................................................................................................14

4-X4: COMMAND CONNECTOR -SUB D25 PINS MALE.....................................................................................15

5-X6: LOGIC OUTPUTSCONNECTOR -SUB D9PINS FEMALE ........................................................................15

6-X7: LOGIC INPUTSCONNECTOR -SUB D9PINS MALE................................................................................15

7-X5: RS-232 CONNECTOR -SUB D9PINS MALE..............................................................................................16

8-X3: TEST CONNECTOR ...............................................................................................................................16

9-SPECIFICATIONS OF THELOGIC INPUTS-OUTPUTS...............................................................................16

9.1 - DEDICATED LOGIC INPUTS: FC+, FC-, INDEX, RUN AND ENABLE..................................................16

9.2 - LOGIC INPUTS START, STOP, JOG+, JOG-, IN1 TO IN8....................................................................16

9.3 - LOGIC OUTPUTS SEQ, POS, SPEED, OK, OUT1 TO OUT8...............................................................17

CHAPTER 4 - CONNECTIONS.............................................................................................................................18

1-CONNECTION DIAGRAMS...........................................................................................................................18

1.1 - POWER SUPPLY AND MOTOR CONNECTIONS.................................................................................18

1.2 - SERIAL LINK CONNECTION.................................................................................................................18

2-WIRING RECOMMENDATIONS ...................................................................................................................18

2.1 - GND WIRING AND GROUNDING .........................................................................................................18

2.2 - SHIELD CONNECTION ON THE CONNECTORS.................................................................................19

2.3 - MOTOR AND RESOLVER CABLES ......................................................................................................20

2.4 - SERIAL LINK CABLE .............................................................................................................................20

3-FIRST POWERING OF THEDRIVE..............................................................................................................20

CHAPTER 5 - FUNCTIONAL FEATURES ............................................................................................................21

1-DESCRIPTION OF THELOGIC INPUTS-OUTPUTS....................................................................................21

1.1 - LOGIC INPUTS ......................................................................................................................................21

1.2 - LOGIC OUTPUTS ..................................................................................................................................22

2-ADDRESSING...............................................................................................................................................22

3-REDUCTION OF THEPROGRAMMED SPEED VIA AN ANALOG INPUT....................................................22

CHAPTER 6 - COMMISSIONING..........................................................................................................................24

1-CHECKING THEDRIVE CONFIGURATION .................................................................................................24

2-INSTALLING THEPC SOFTWARE...............................................................................................................24

2.1 - Basic configuration .................................................................................................................................24

2.2 - Installation ..............................................................................................................................................24

2.3 - Connection to a drive and start of the software ......................................................................................24

3-PUTTINGINTOOPERATION .......................................................................................................................25

6

SMT-BD1/m

Contents

4-DRIVE COMMISSIONING AND ADJUSTMENT............................................................................................25

4.1 - PARAMETER SETTING OF MOTOR AND DRIVE................................................................................26

4.2 - MOTOR / DRIVE PARAMETER SETTING WITH A VERTICAL LOAD..................................................26

4.3 - SAVING THE DRIVE PARAMETERS ....................................................................................................27

4.4 - ENABLING .............................................................................................................................................30

4.5 - MANUAL MOVE.....................................................................................................................................31

5-PROGRAMMATION......................................................................................................................................32

5.1 - GENERAL DESCRIPTION.....................................................................................................................32

5.2 - EDITION OF A SEQUENCE...................................................................................................................33

6-PROGRAMME EXECUTION.........................................................................................................................36

7-USE OF THEOSCILLOSCOPE.....................................................................................................................36

CHAPTER 7 - TROUBLESHOOTING AND MAINTENANCE ...............................................................................38

1-SYSTEM ERROR..........................................................................................................................................38

2-STORED ERRORS .......................................................................................................................................38

2.1 - "BUSY" ...................................................................................................................................................38

2.2 - "NovRAM" or "EEPROM"........................................................................................................................38

2.3 - "°C MOTOR"...........................................................................................................................................38

2.4 - "UNDERVOLT".......................................................................................................................................39

2.5 -"°C AMPLIFIER"......................................................................................................................................39

2.6 - "POWER STAGE" ..................................................................................................................................39

2.7 - "RESOLVER"..........................................................................................................................................39

2.8 - "R.D.C" ...................................................................................................................................................39

2.9 - "I2T" ........................................................................................................................................................39

3-OPERATION PROBLEMS.............................................................................................................................40

3.1 - NO MOTOR MOVEMENT ......................................................................................................................40

3.2 - MOTOR SUPPLIED BUT NO TORQUE.................................................................................................40

3.3 - SHAFT LOCKED, ERRATIC OSCILLATIONS OR ROTATION AT MAXIMUM SPEED.........................40

3.4 - DISCONTINUOUS MOTOR ROTATION WITH ZERO TORQUE POSITIONS......................................40

3.5 - LOUD CRACKLING NOISE IN THE MOTOR AT STANDSTILL ............................................................40

3.6 - LOUD NOISE IN THE MOTOR AT STANDSTILL AND WHEN RUNNING ............................................40

4-SERVICE AND MAINTENANCE....................................................................................................................40

CHAPTER 8 - APPENDIX .....................................................................................................................................41

1-USING SMT-BD1/MWITHADISPLAY TERMINAL........................................................................................41

1.1 - CONFIGURATION .................................................................................................................................41

1.2 - USE ........................................................................................................................................................41

2-SMT-BD1/MINSTRUCTIONS LIST ...............................................................................................................43

2.1 - OVERVIEW ............................................................................................................................................43

2.2 - INSTRUCTIONS LIST ............................................................................................................................44

3-HARDWARE ADJUSTMENTSLOCATION ...................................................................................................48

4-ADJUSTMENT TO VARIOUS RESOLVERS.................................................................................................51

5-ADJUSTMENT TO THEMOTOR...................................................................................................................52

5.1 - CONFIGURATION OF THE MOTOR THERMAL SENSOR...................................................................52

5.1.1 - THERMAL SENSOR PTC ...................................................................................................................52

5.1.2 - THERMAL SENSOR NTC...................................................................................................................52

5.2 -CURRENT LOOPS.....................................................................................................................................52

5.2.1 - CURRENT LOOPS ADJUSTMENT ON DRIVES WITH 400 VAC SUPPLY........................................52

5.3 - I2t PROTECTION....................................................................................................................................53

6-LOGIC CONTROL ADJUSTMENT ................................................................................................................56

6.1 - POSITIVE OR NEGATIVE LOGIC INPUTS ...........................................................................................56

6.2 - USE OF THE "AMP. READY" AND "POWER READY" OUTPUTS........................................................56

7-SERIAL LINK.................................................................................................................................................57

8-DRIVE TYPES...............................................................................................................................................58

7

SMT-BD1/m

Chapter 1 - General description

Chapter 1 - General description

1 - INTRODUCTION

Series SMT-BD1/m servo modules are PWM servo drives that provide speed control for AC sinusoidal motors

(brushless) with transmitter resolver.

The SMT-BD1/m positioner is available with two different mains supplies: 220 VAC or 400 VAC.

The plug-in positioner in 220 VAC is available either as a single-axis block version or as a multiaxis version that

can receive up to six axes in a standard 19" rack.

Both versions are including a power supply unit.

The plug-in positioner in 400 VAC is only available as a multiaxis version that can receive up to three axes in a

standard 19" rack including a power supply unit.

2 - GENERAL DESCRIPTION

The SMT-BD1/m servo modules have their own DC/DC converter to provide appropriate logic voltage to the

modules (+5 V / +/-15 V). The supply used for the logic board is the 310 VDC auxiliary supply which allows the

saving of the position signal when the power supply is off.

Each module is packaged as two 6U "double Eurocard":

- one power board with IGBT transistors and

- one logic board with DSP (Digital Signal Processing).

The SMT-BD1/m positioner can operate as a stand-alone system or in connection with a PLC or a PC.

It can execute up to 128 motion sequences. The sequences can generate position, speed or torque motions.

The SMT-BD1/m positioner generates itself the positioning trajectory by waiting for the START signal or for a

command via the serial link for starting the programme.

3 - COMPLIANCE WITH THE STANDARDS

Series SMT-BD1/m positioners with 220 VAC supply and operating in the BF rack equipped with the mains filter

BF 35 or 70, have been approved with regard to their conformity with the Electromagnetic Compatibility standards:

- EN 55011, group 1, class A, regarding the conducted and radiated radioelectric disturbances,

- CEI 801 - 2 - 3 - 4 regarding immunity.

The SMT-BD1/m positioners with 220 VAC supply, operating in the single-axis racks BM20A - BMM05F -

BMM05AF equipped with the pertaining mains filter (FN 612-20/06 or FN 356-16/06 or BF-35) have been

approved with regard to their conformity with the Electromagnetic Compatibility standards

- EN 55011, group 1, class A, regarding the conducted and radiated radioelectric disturbances,

- CEI 801 - 2 - 3 - 4 regarding immunity.

Series SMT-BD1/m positioners with 400 VAC supply and operating in the BF rack equipped with the mains filter

BF 400-35 or 400-70, have been approved with regard to their conformity with the Electromagnetic Compatibility

standards

- EN 55011, group 1, class A, regarding the conducted and radiated radioelectric disturbances,

- CEI 801 - 2 - 3 - 4 regarding immunity.

Standard to be applied to the electrical equipment of industrial machines: EN 60204-1.

Series SMT-BD1 drives have been CE marked since 1995.

4 - OTHER DOCUMENTS TO BE USED OR THE DRIVE COMMISSIONING

BF/400 rack – for the use of 400 VAC drives in multi-axis racks.

BF rack – for the use of 220 VAC drives in multi-axis racks.

BM20A / BMM05F / BMM05AF racks – for the use of 220 VAC drives in single-axis racks.

8

SMT-BD1/m

Chapter 2 - Specifications

Chapter 2 - Specifications

1 - MAIN TECHNICAL DATA

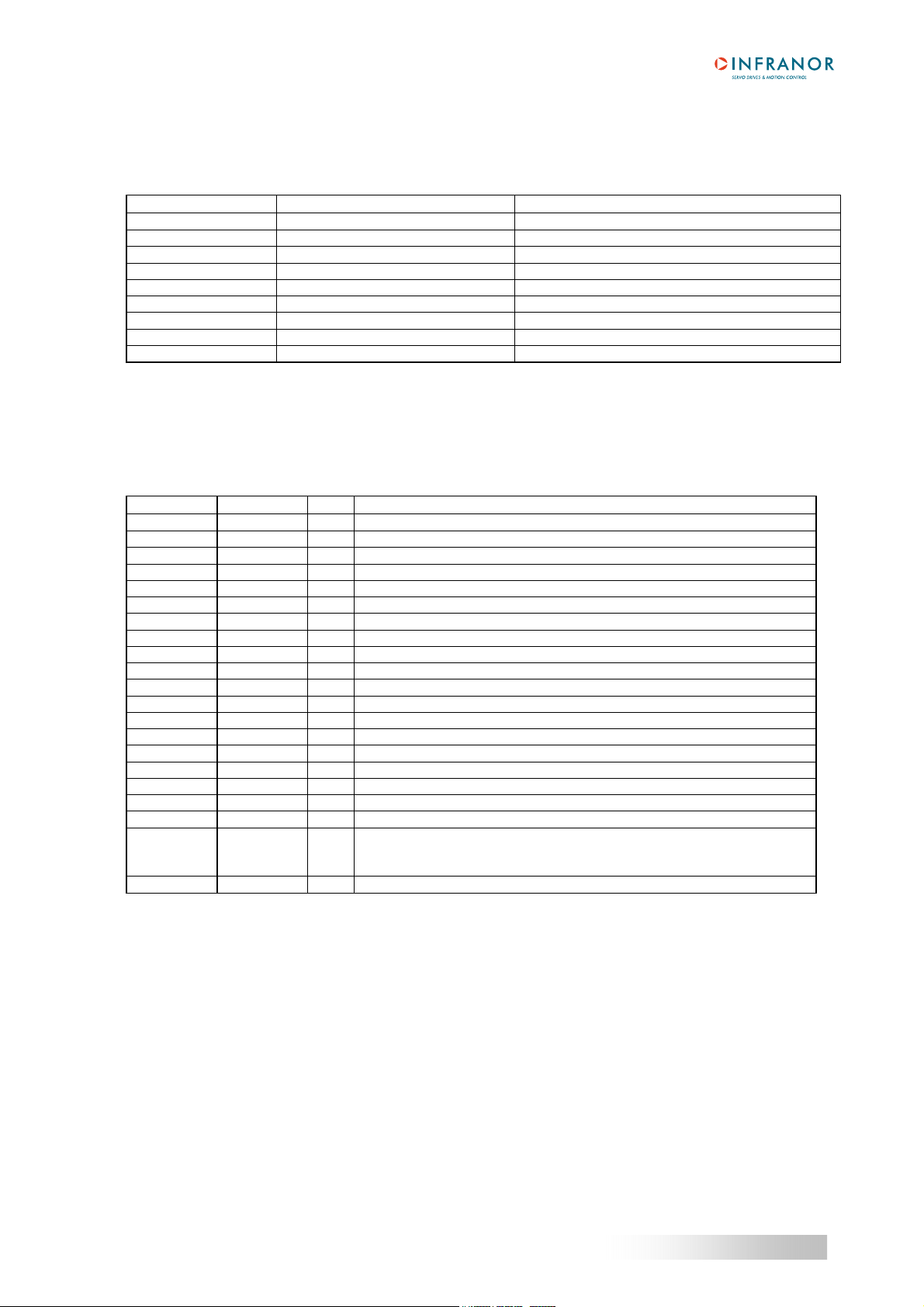

1.1 - Current ratings 220 VAC drive version

Operating voltage 310 VDC (270 VDC < DC bus < 340 VDC)

Auxiliary supply voltage 310 VDC (200 VDC < Uaux < 340 VDC)

Motor phase-phase output voltage 200 Vrms for 310 VDC bus

Output current ratings in pulse current mode (I2t protection in "fusing" mode)

DRIVE

TYPE

Urated

(Vrms)

Imax (Arms) Max. authorized rated current (Arms)

of the drive

1 s No fan* Fan 1* Fan 2*

SMT-BD1/m-220/04 240 4.4 2

SMT-BD1/m -220/08 240 8.8 4

SMT-BD1/m-220/12 240 13.8 6

SMT-BD1/m-220/17 240 17.7 8.5

SMT-BD1/m-220/30 240 30.8 10 12 15

SMT-BD1/m-220/30r 240 30.8 10 15

SMT-BD1/m-220/45 240 48.6 10 15 20

SMT-BD1/m-220/45r 240 48.6 10 20 23

SMT-BD1/m-220/60 240 61 10 19 25

SMT-BD1/m-220/60r 240 61 12 26 30

SMT-BD1/m-220/70 240 70 25 30 35

SMT-BD1/m-220/100 240 100 25 30 35

Output current ratings in pulse current mode (I2t protection in "limiting" mode)

DRIVE

TYPE

Urated

(Vrms)

Imax (Arms) Max. authorized rated current (Arms)

of the drive

1 s No fan* Fan 1* Fan 2*

SMT-BD1/m-220/04 240 4,4 2

SMT-BD1/m -220/08 240 8.8 4

SMT-BD1/m-220/12 240 13.8 6

SMT-BD1/m-220/17 240 17.7 8.5 8.5

SMT-BD1/m-220/30 240 30.8 8.5 12 15

SMT-BD1/m-220/30r 240 30.8 10 15

SMT-BD1/m-220/45 240 48.6 8.5 15 18

SMT-BD1/m-220/45r 240 48.6 10 20 23

SMT-BD1/m-220/60 240 61 8.5 17 20

SMT-BD1/m-220/60r 240 61 12 26 30

SMT-BD1/m-220/70 240 70 17 30 35

SMT-BD1/m-220/100 240 100 25 30 35

* Maximum ambient temperature = 40° C, fan 1 = 56 l/s, fan 2 = 90 l/s.

Note: SMT-BD1-X/X r drive types are equipped with an additional heatsink in order to improve the heat dissipation

and increase their rated current. The width of these drives is then 18 TE instead of 12 TE.

Minimum inductance between phases 1 mH

9

SMT-BD1/m

Chapter 2 - Specifications

Compliance with the standards: CE approval for - EMC standards

multi-axis operation in the BF rack with mains Immunity: CEI standards 801- 2 - 3 - 4

filter BF35 or 70 or in single-axis racks BM20A or Conducted and radiated disturbances: EN 55011,

BMM05F/05AF with filters FN 612-20/06 or Group 1, class A

FN 356-16/06 or BF-35. 360° shield and - Electrical standards for industrial machines:

equipotential according to the wiring rules EN 60204.1: - Insulator: 1500 VAC/1 min.

- Leakage current > 3 mA

(EMI filters)

Temperature * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents must be reduced

of3%/°C.

Max. temperature: 50°C

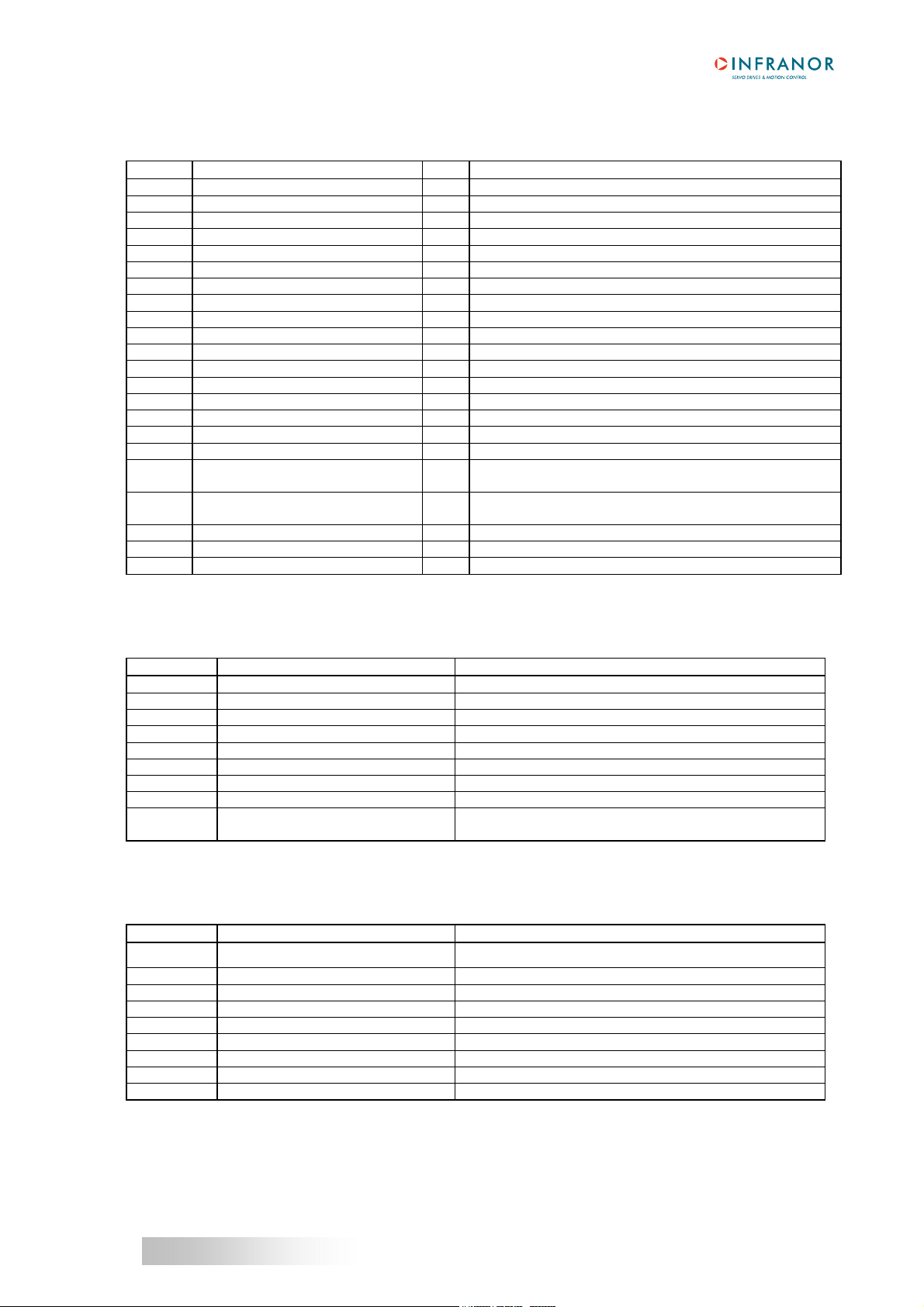

1.2 - Current ratings for 400 VAC drive version

Operating voltage 565 VDC (480 VDC < DC bus < max. 685 VDC)

Auxiliary supply voltage 310 VDC (200 VDC < Uaux < 340 VDC)

Motor phase-phase output voltage 380 Vrms for 565 VDC bus

Output current ratings in pulse current mode (I2t protection in "fusing" mode)

DRIVE

TYPE

Urated

(Vrms)

Imax

(Arms)

Max. authorized rated current (Arms)

of the drive

1 s No fan* Fan 2*

SMT-BD1/m-400/15 400 15.5 5 7.5

SMT-BD1/m-400/30 400 30 8 15

SMT-BD1/m-400/45 400 48 10 19

SMT-BD1/m-400/60 400 60 not used 28

Output current ratings in pulse current mode (I2t protection in "limiting" mode)

DRIVE

TYPE

Urated

(Vrms)

Imax

(Arms)

Max. authorized rated current (Arms)

of the drive

1 s No fan* Fan 2*

SMT-BD1/m-400/15 400 15.5 not used 5

SMT-BD1/m-400/30 400 30 not used 10

SMT-BD1/m-400/45 400 48 not used 15

SMT-BD1/m-400/60 400 60 not used 23

Maximum room temperature: 40°C, fan type 2: 90 l/s.

Minimum inductance between phases 2 mH

Compliance with the standards: CE approval for - EMC standards

multi-axis operation in the BF rack with mains Immunity: CEI standards 801- 2 - 3 - 4

filter BF-400/35 or 400/70. Conducted and radiated disturbances: EN 55011,

360° shield and equipotential according to the Group 1, class A

wiring rules. - Electrical standards for industrial machines:

EN 60204.1: - Insulator: 2500 VAC/1 min.

- Leakage current > 3 mA

(EMI filters)

Temperature * storage - 20°C to + 70°C

* operation 5°C to +40°C

From 40°C on, the rated currents must be reduced

of3%/°C.

Max. temperature: 50°C

10

SMT-BD1/m

Chapter 2 - Specifications

1.3 - Other specifications

PWM switching frequency 10 kHz

Current regulator (PI) adjusted to motor

Current loop bandwidth Cut-off frequency for 45° phase shift > 1 kHz

Internal current limitation Imax: 20 % to 100 % and I rated: 20 % to 50 %

Imax duration =1 second

Speed and position regulators Sampling period = 0,5 ms

Anti-wind-upsystem of the integrator

Adjustable digital gains

Speed loop bandwidth Selectable cut-off frequency for 45° phase shift:

50 Hz, 75 Hz or 100 Hz

Max motor speed Adjustable from 100 rpm to 10 000 rpm

Encoder position output Two A and B channels in quadradure + n zero pulses per

revolution. Programmable resolution:

max. 8 192 ppr up to 900 rpm

max. 4 096 ppr up to 3 600 rpm

max.1 024 ppr up to 10 000 rpm

Accuracy: 8 arc minutes +1/4 point

(optional: 2 arc minutes + 1/4 point)

Note

: The total position accuracy must take into account the

accuracy of the resolver used

Analog outputs (test connector) Speed input command (CV): ±10 V for ± max speed.

Speed monitor (GT): ±8 V for ±14 000 rpm, linearity: 10%

Current input command (Idc): ±10 V for ± current rating,

resolution: 8 bits

Current monitor (Imes): ±10 V for ± current rating;

resolution: 8 bits

Logic inputs Enable/Disable: ENABLE

Limitswitch+:FC+

Limitswitch-:FC-

Hominginput:INDEX

Error reset: RAZ

Optocoupled logic inputs START, STOP, JOG+, JOG-, IN1 to IN8

Relay outputs Relay contact: Umax = 60 V

Imax = 200 mA, Pmax = 10 W

"Amp. ready": closed if drive OK, open if error

"Power ready": closed if power OK, open if error

Brake control

Optocoupled logic outputs SEQ, POS, SPEED, OK, OUT1 to OUT8

Error display Front panel LEDs and diagnostic via serial link RS-232

Motor and application parameter setting Serial link RS-232

Automatic functions Drive adjustment to the motor (AUTO-PHASING)

Automatic regulator tuning (AUTO-TUNING)

Altitude 1000 m

11

SMT-BD1/m

Chapter 2 - Specifications

Moisture < 50% at 40°C and < 90% at 20°C: EN 60204-1 standard

Condensation prohibited

Cooling Natural convection or forced air according to the rated

current. Condensation prohibited.

2 - MAIN PROTECTIONS

2.1 - STORED PROTECTIONS

PROTECTION ERROR DISPLAY LED

Drive rated current overload *:

- blinking display = Idyn warning (I2t threshold reached)

- continuous display = drive disabled (I2t error)

I2t

z

Position following error Position

z

Resolver cable interruption Resolver

z

Power stage error:

- power supply overvoltage

- internal switch protection

- short-circuit between phases

- drive overtemperature for 4 A to 60 A current ratings

Power stage

zz

Resolver converter error R.D.C

z

Drive overtemperature for 70 A and 100 A current ratings °C Ampli

z

z

Power supply undervoltage Undervoltage

z

z

Motor overtemperature °C Motor

zz

z

Drive parameter memory error NovRAM

z

zz

Automatic procedure of the drive

- blinking display = procedure running

- continuous display = operating error

Busy zz

zz

: Led is unlit z: Led is lit

* The operation mode of the I2t protection is described in chapter 8, section 5. 3.

All these errors are stored in the drive, except for the "Undervoltage" error.

The reset of a stored error can be made:

- via the error RESET input of X4, pin 13,

- by switching off the drive power supply.

2.2 - FUSE PROTECTION OF THE SMT-BD1/M DRIVE VERSION 220 VAC

F1 : Control of the average DC current of the power board supply.

F2 : Control of the average DC current of the logic board supply.

DRIVE TYPE F1 - POWER F2 - LOGIC

SMT-BD1/m-220/04 to 12 10 AT 1 A

SMT-BD1/m-220/17 and 30 15 AT 1 A

SMT-BD1/m-220/45 20 AT 1 A

SMT-BD1/m-220/60 20 AT 1 A

SMT-BD1/m-220/70 - 1 A

SMT-BD1/m-220/100 - 1 A

12

SMT-BD1/m

Chapter 2 - Specifications

2.3 - FUSE PROTECTION OF THE SMT-BD1/M DRIVE VERSION 400 VAC

F2 : Control of the average DC current of the logic board supply.

DRIVE TYPE F2 - LOGIC

SMT-BD1/m-400/15 1 A

SMT-BD1/m-400/30 1 A

SMT-BD1/m-400/45 1 A

SMT-BD1/m-400/60 1 A

13

SMT-BD1/m

Chapter 3 - Inputs-Outputs

Chapter 3 - Inputs-Outputs

1 - CONNECTORS

1.1 - Rack connectors

For the 400 VAC drive version, see manual BF/400 RACK.

For the 220 VAC drive version, see manuals SMT-BM20A SINGLE-AXIS RACK or BF RACK.

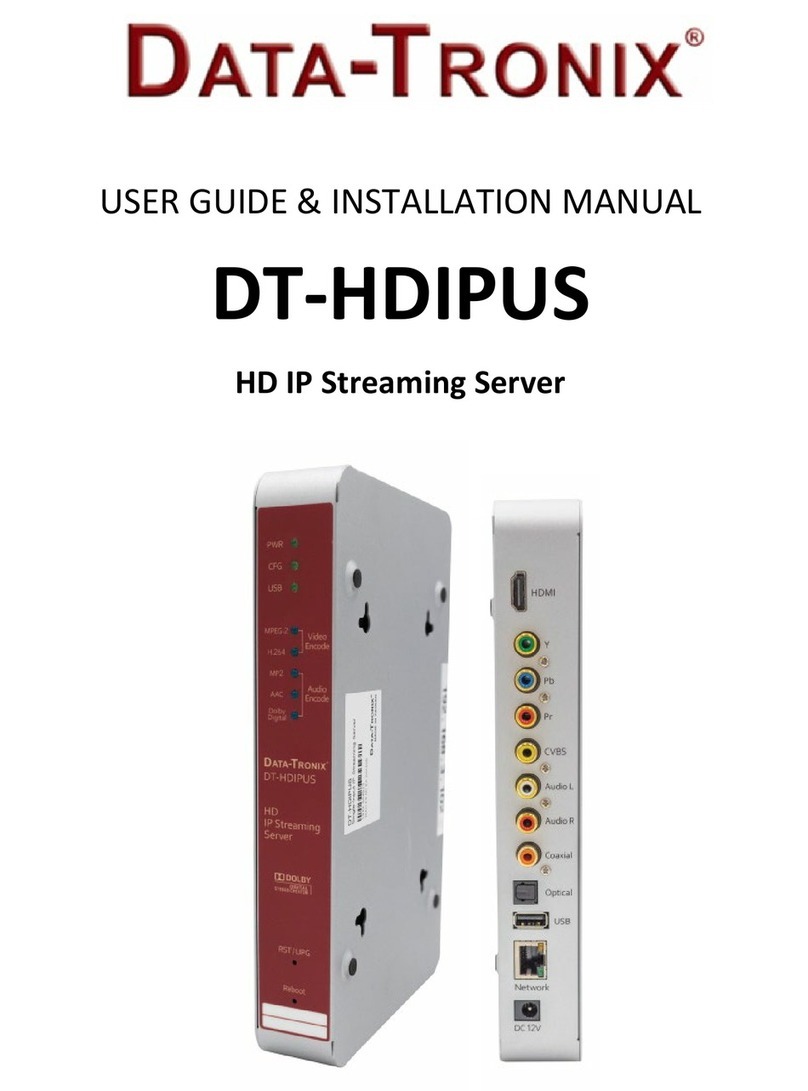

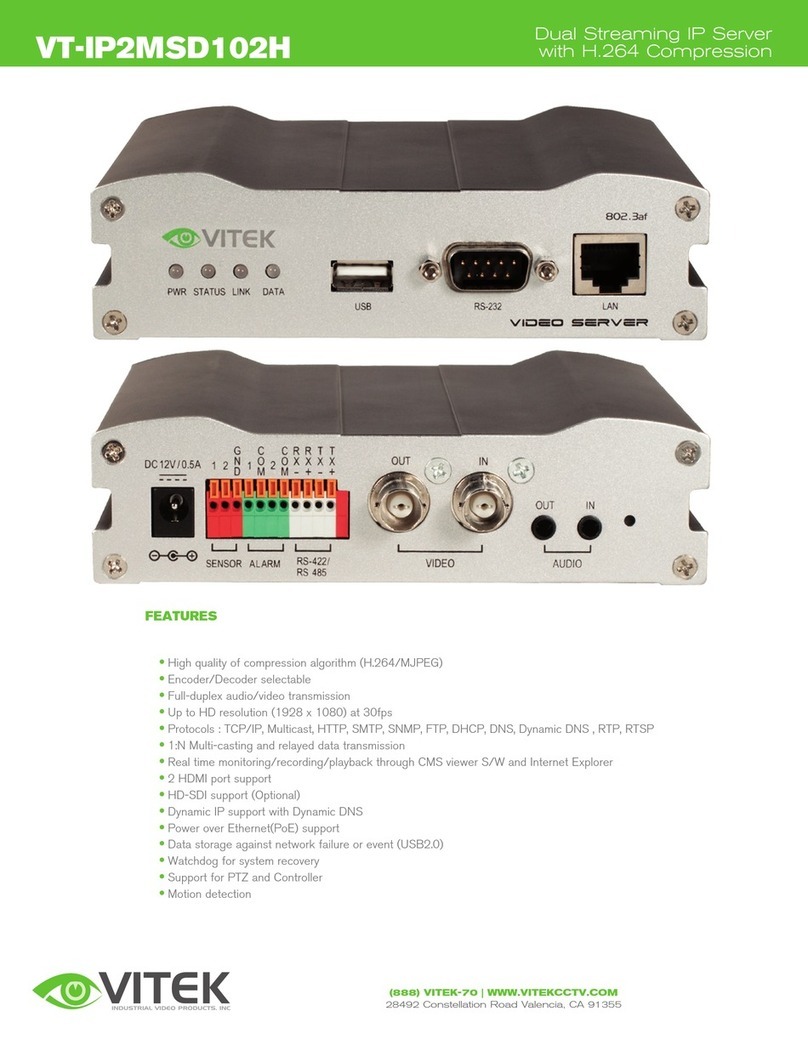

1.2 - Drive connectors

Front panel connectors

X1 Resolver

X5 Serial link RS-232

X2 Encoder

X4 Command

X6 Programmable

logic outputs

X7 Logic inputs

X3 Test

14

SMT-BD1/m

Chapter 3 – Inputs-Outputs

2 - X1: RESOLVER CONNECTOR

Sub D 9 pins female.

PIN FUNCTION REMARKS

1 TC (pin H sensor connector) If thermal switch connected to X1

6 Shield connection If no "360°" connection on the connector

2 TC (pin I sensor connector) If thermal switch connected to X1

7 S1 (pin C sensor connector) MAVILOR motor

3 S3 (pin D sensor connector) MAVILOR motor

8 S4 (pin B sensor connector) MAVILOR motor

4 S2 (pin A sensor connector) MAVILOR motor

9 R2 (pin F sensor connector) MAVILOR motor

5 R1 (pin E sensor connector) MAVILOR motor

For the connection of other resolvers than the resolver used on MAVILOR motors, see Chapter 8, section 4.

3 - X2: ENCODER CONNECTOR

Sub D 25 pins female

PIN SIGNAL I/O DESCRIPTION

1 /CZ O Differential output of the encoder marker pulse (5 V 20 mA max.)

2 CZ O Differential output of the encoder marker pulse

3 /CA O Differential output of the encoder channel A (5 V 20 mA max.)

4 CA O Differential output of the encoder channel A

5 /CB O Differential output of the encoder channel B (5 V 20 mA max.)

6 CB O Differential output of the encoder channel B

7, 10, 11 0 V

14 START I Optocoupled logic input

15 STOP I Optocoupled logic input

16 WAIT I Optocoupled logic input

17 TEACH I Optocoupled logic input

24 5 V 5 V jumper must be closed

8 JOG+ I Optocoupled logic input

18 JOG- I Optocoupled logic input

9 SEQ O Optocoupled logic output

20 POS O Optocoupled logic output

21 SPEED O Optocoupled logic output

22 OK O Optocoupled logic output

23 GND (24 V) Mass of external 24 V

12 24 V I 24 V input. This input must be used only if one of the outputs SEQ,

SPEED, POS and OK is used and if the OUT1 to OUT8 outputs are not

wired.

25 GND

15

SMT-BD1/m

Chapter 3 - Inputs-Outputs

4 - X4: COMMAND CONNECTOR - Sub D 25 pins male

PIN FUNCTION I/O REMARKS

1 Limit switch + I Positive or negative logic

14 Limit switch - I Positive or negative logic

24 0V limit switch I

20 ENABLE I Positive or negative logic

23 0 Volt ENABLE I

4 RUN I Positive or negative logic

7 INDEX/CLR I Positive or negative logic

25 0 V logic input

13 RESET I Error RESET via 0 volt (contact between pins 13 and 12)

12 0V RESET I

15 Reserved

16 0 V analog I

17 Analog input I Speed reduction option

3 Reserved

10 Speed monitor GT O

2 Current monitor Imes (DAC OUT2) O

11 0 Volt analog output O

18, 19 Amp. ready O Relay contact, closed when drive OK

Pmax = 10 W with Umax = 60 V or Imax = 200 mA

8, 9 Brake control output O Relay contact.

Pmax = 10 W with Umax = 60 V or Imax = 200 mA

21 +15 Volts O Max. 50 mA

22 -15 Volts O Max. 50 mA

5, 6 Unconnected

5 - X6: LOGIC OUTPUTS CONNECTOR - Sub D 9 pins female

PIN SIGNAL DESCRIPTION

1 OUT1 Programmable output n° 1

2 OUT2 Programmable output n° 2

3 OUT3 Programmable output n° 3

4 OUT4 Programmable output n° 4

5 OUT5 Programmable output n° 5

6 OUT6 Programmable output n° 6

7 OUT7 Programmable output n° 7

8 OUT8 Programmable output n° 8

9 24 V This 24 V must be used if one of the OUT1 to OUT8

outputs is wired

6 - X7: LOGIC INPUTS CONNECTOR - Sub D 9 pins male

PIN SIGNAL DESCRIPTION

1 IN1 Logic input n° 1

2 IN2 Logic input n° 2

3 IN3 Logic input n° 3

4 IN4 Logic input n° 4

5 IN5 Logic input n° 5

6 IN6 Logic input n° 6

7 IN7 Logic input n° 7

8 IN8 Logic input n° 8

9 GND 24 V Mass of external 24 V

16

SMT-BD1/m

Chapter 3 – Inputs-Outputs

7 - X5: RS-232 CONNECTOR - Sub D 9 pins male

PIN FUNCTION REMARKS

5 0 V GND (shield connection if no "360°" connection on the connector)

3 TXD Transmit data RS 232

2 RXD Receive data RS 232

6 TXH Transmit data RS 422

7 TXL Transmit data RS 422

8 RXL Receive data RS 422

9 RXH Receive data RS 422

8 - X3: TEST CONNECTOR

PIN FUNCTION REMARKS

1 - 6 0 Volt

2 Current input command IDC ± 10 V; resolution: 8 bits, linearity: 10 % (DAC out 1)*

3 Reversed analog input ± 10 V for ± max. speed

4 Speed monitor GT ± 8 V for ± 14000 rpm

5 Current monitor Imes ± 10 V; resolution: 8 bits, linearity: 10 % (DAC out 2)*

* : 10 V for drive current rating.

9 - SPECIFICATIONS OF THE LOGIC INPUTS-OUTPUTS

9.1 - DEDICATED LOGIC INPUTS: FC+, FC-, INDEX, RUN AND ENABLE

Input impedance : 4,7 kΩ

Response time : 500 µs

These inputs can be configurated in positive or negative logic by means of jumpers (see chapter 8, section

6.1 "Positive or negative logic inputs")

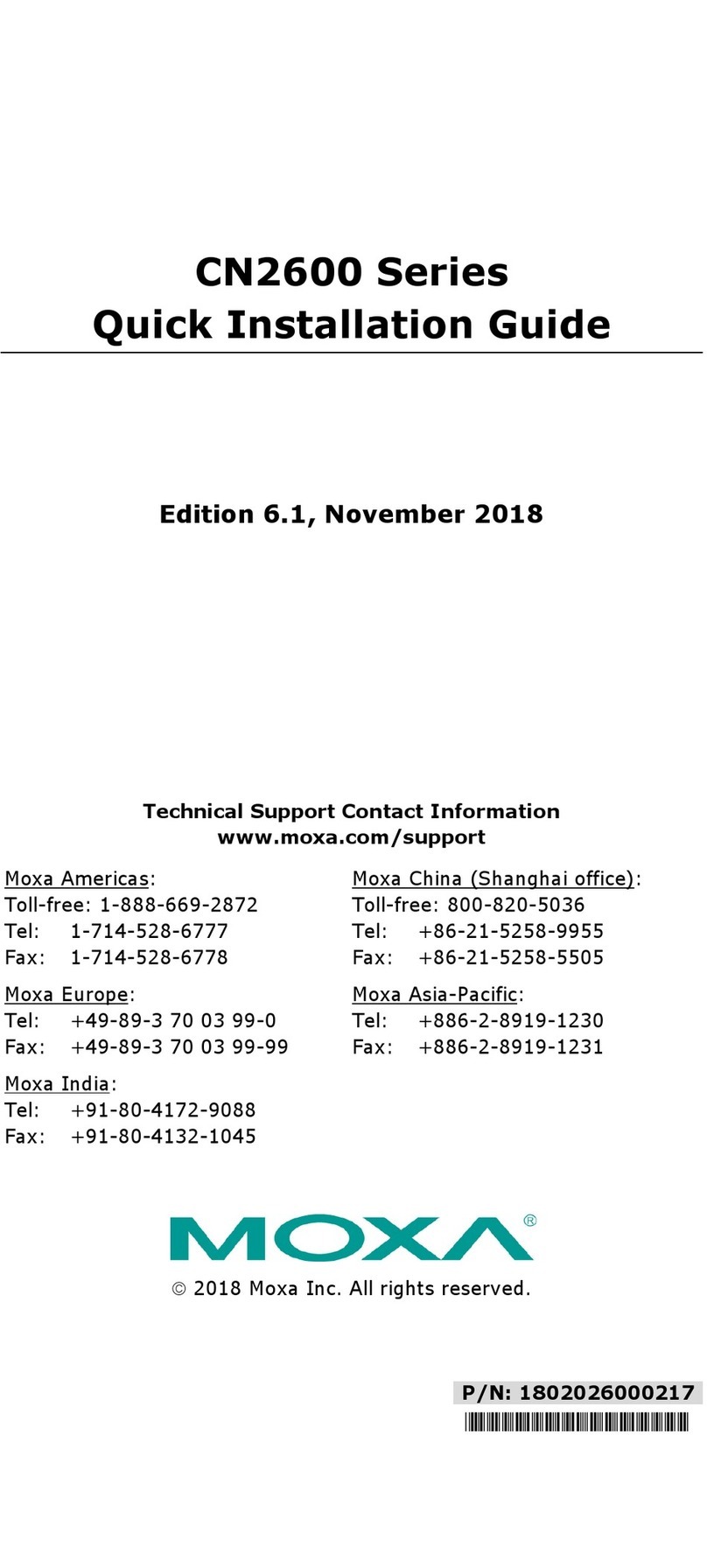

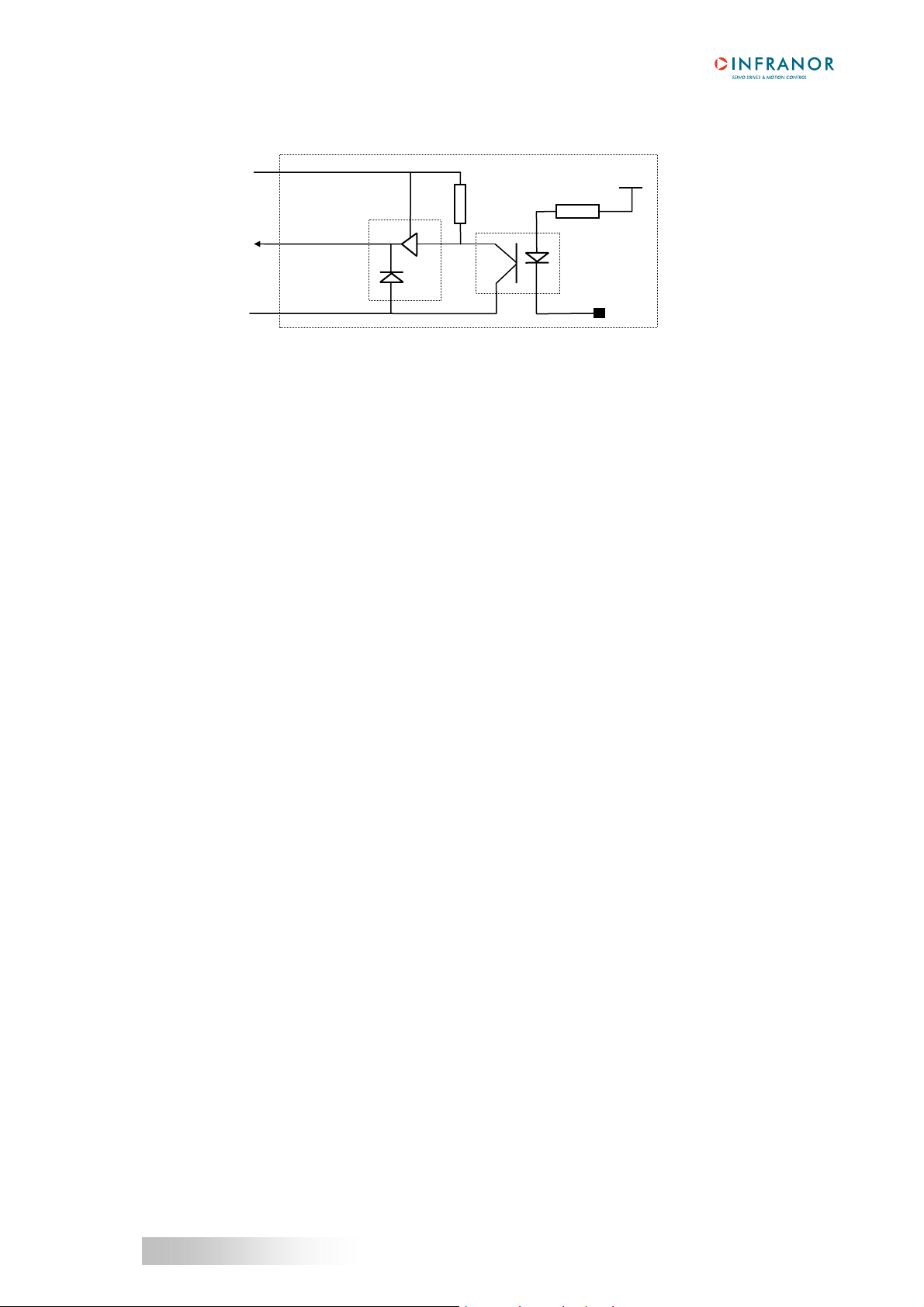

9.2 - LOGIC INPUTS START, STOP, JOG+, JOG-, IN1 TO IN8

The input voltage corresponds

to level 1 and is between 5 V

and 24 V

The polarity of these inputs can be reversed by a software parameter (see chapter 6, section 4.3.1 "Inputs -

outputs configuration").

4,7 KΩ

Log Log -

5 V

4,7 V 47 nF

47 KΩ

SMT-BD1/m

Logic input

0 V

SMT-BD1/m

PC829

5 V

2.2 KΩ

100 KΩ100 nF

17

SMT-BD1/m

Chapter 3 - Inputs-Outputs

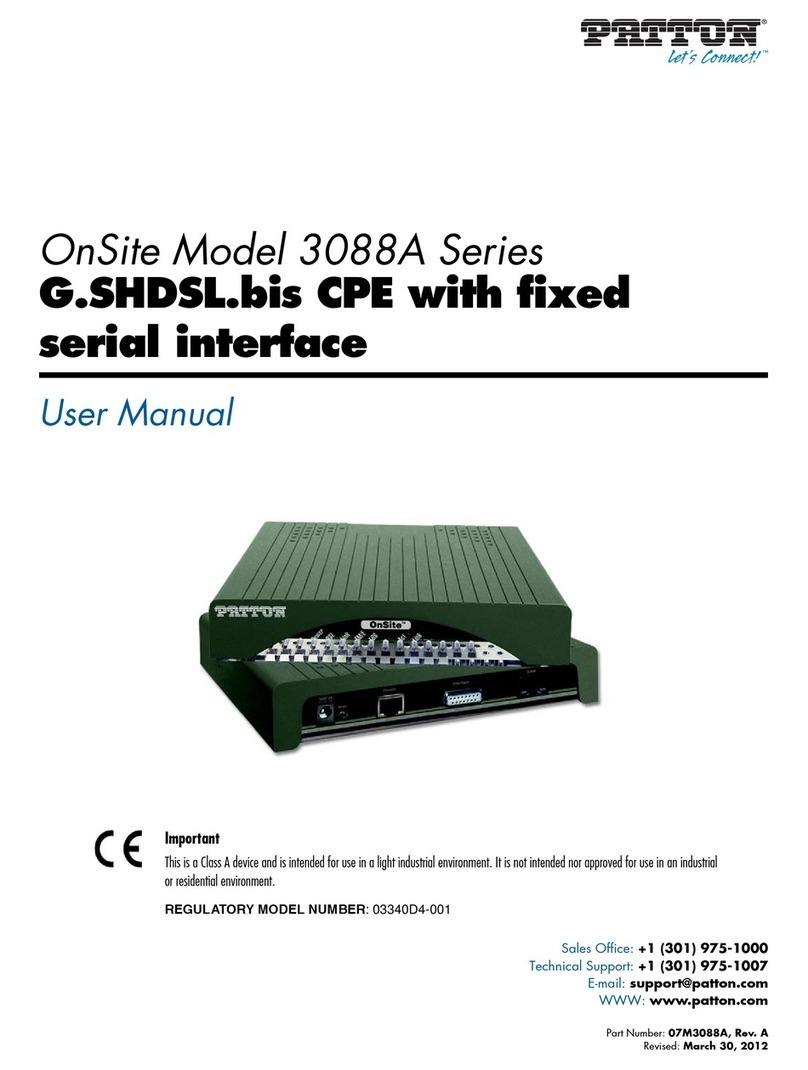

9.3 - LOGIC OUTPUTS SEQ, POS, SPEED, OK, OUT1 TO OUT8

The output current is

350 mA for the 8 outputs

OUT1toOUT8.

The polarity of these inputs can be reversed by a software parameter (see chapter 6, section 4.3.1 "Inputs -

outputs configuration").

The parallel connection of these outputs must be made by means of diods.

IMPORTANT NOTE

If the 24 V is available when the drive is off, the logic SEQ, POS, SPEED, OK, OUT1 to OUT8 are set at

24 V.

SMT-BD1/m

Logic output

0 V

PC829

5 V

UDN2987A

24 V

18

SMT-BD1/m

Chapter 4 – Connections

Chapter 4 - Connections

1 - CONNECTION DIAGRAMS

1.1 - POWER SUPPLY AND MOTOR CONNECTIONS

For the 400 VAC drive, see manual BF/400 Rack.

For the 220 VAC drive, see manuals BF Rack or SMT-BM20 A / BMM05F/AF single-axis racks.

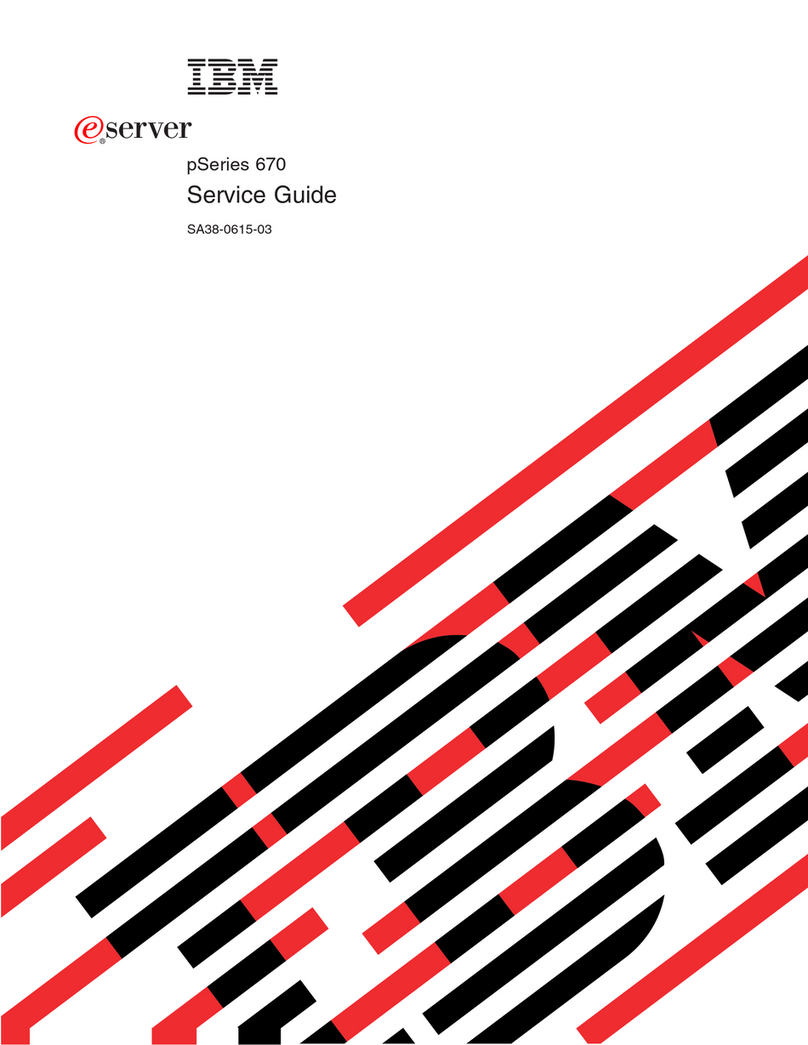

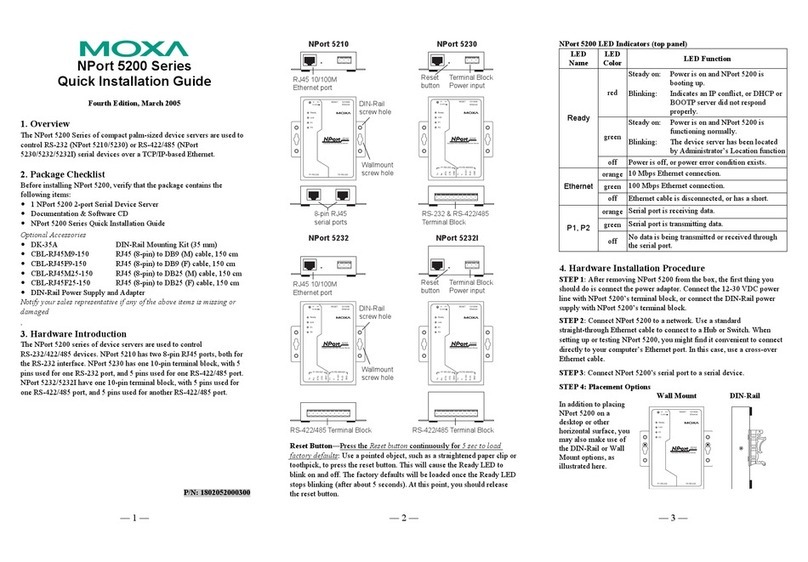

1.2 - SERIAL LINK CONNECTION

2 - WIRING RECOMMENDATIONS

(according to standards CEI 801 and EN55011 - see diagram "Shield connection on the connectors" –

Chapter 4, section 2.2).

2.1 - GND WIRING AND GROUNDING

CAUTION !

Each potential conducting element MUST be shielded. Several wires in the same sleeve must be twisted and

shielded.

A shield has no effect if it is not connected:

- to a reference potential,

- via a connection as short as possible (some centimeters; 10 cm is prohibited),

- by a "360°" shield connection, that means that the whole circumference of the shield sleeve must be

connected to the reference conductor by a metal collar.

According to the CEI 801 standard, connectors must be made of metal or metal plated and must allow a 360°

shield connection.

Long reference potential connections (especially with the ground) are suitable ONLY if these connections have a

very low impedance (less than 0,1 Ω). Any shield that is not used as a conductor can be connected at both ends if

it is connected at both ends over 360° by means of metal connections ensuring the shield continuity.

The reference potential is the ground.

Cables with low potential should NEVER run in the proximity of power lines.

If there is a potential reference, like a main chassis or a cabinet with a low impedance between its various

elements, it should be used for short connections and be grounded itself.

SMT-BD1/m

X5

PC

Serial port

360° shield connection

Sub D 9pts female Sub D 9pts female

RxD 2

TxD 3

GND 5 5 GND

2 RxD

3 TxD

19

SMT-BD1/m

Chapter 4 - Connections

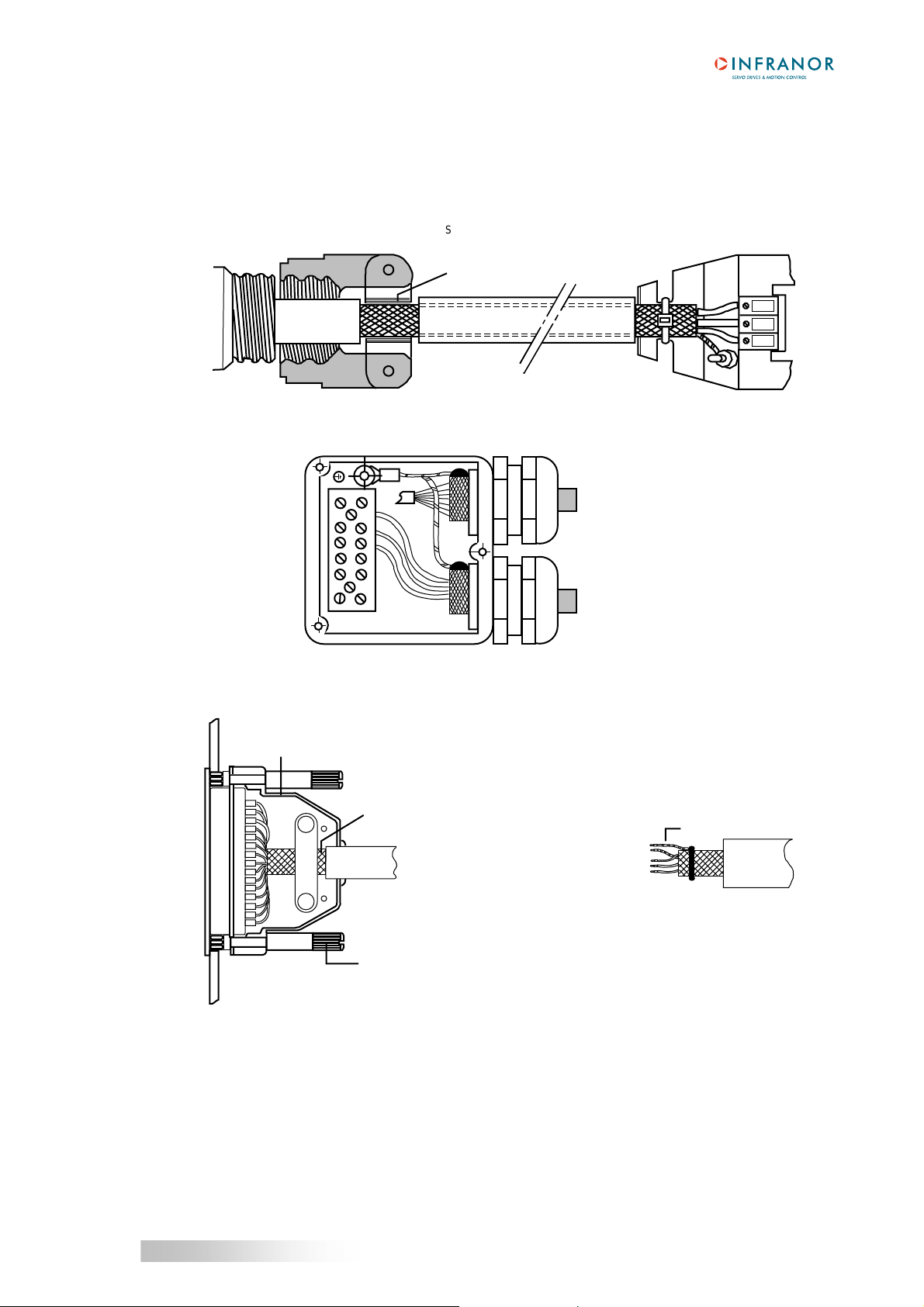

2.2 - SHIELD CONNECTION ON THE CONNECTORS

RULE

The shield must never be interrupted over the whole cable length.

X

X

W

V

U

L1 L2 U WN

V

;

Self-sticking copper ribbon if necessary,

for increasing the shield diameter in order

to get it correctly tightened

under the clamp

Motor connector for

resolver and motor BF RACK

Ground

The cable can be soldered on the shield

because the connector box is metallic.

This solution does not exactly meet

the EMC requirements but

it is acceptable.

Motor connector box

Metallic or metal plated plastic

SUB-D pin package

360°shield ensured by

the tightening clamp

The fastening screws must

be tightened in order to ensure

the shield continuity on the

amplifier housing

INFRANOR

amplifier

SUB-D connectors

Ground

U

V

W

As short as possible

SMT.AS / M.AS

SMT-BM 20 A

NOTE

When the shield connection over 360° is made by means of a collar, there is no need for an additional connection

on the appropriate SUB-D connector.

20

SMT-BD1/m

Chapter 4 – Connections

2.3 - MOTOR AND RESOLVER CABLES

Motors and resolvers are grounded via their housing.

Cable ends should have a metal connectors with collars allowing a 360° shield connection.

The resolver cable must be pair twisted and shielded (sin, cos, ref.). Motor cables MUST also be shielded.

2.4 - SERIAL LINK CABLE

The serial link cable must also be shielded according to the above mentioned shielding recommendations.

CAUTION !

Command cables (resolver, serial link, inputs/outputs) and power cables must be connected and disconnected

with the drive OFF.

3 - FIRST POWERING OF THE DRIVE

The auxiliary power supply must be switched on before the power supply.

Test the auxiliary supply:

Rated value: 230 Vrms single-phase

Maximum value (must not be exceeded) < 260 Vrms (all mains variation tolerances included).

Switch on the auxiliary supply. The green "ON" Led must be lit and the UNDERVOLT. error displayed.

Test the power supply:

220 V drive version: Rated value = 230 Vrms between phases.

Maximum value (must not be exceeded) < 260 Vrms (all mains variation tolerances included).

400 V drive version: : Rated value = 400 Vrms between phases.

Maximum value (must not be exceeded) < 480 Vrms (all mains variation tolerances included).

Switch on the power supply. The UNDERVOLT. error Leds must be off. The braking resistor must remain cold.

NOTE

The ENABLE and RUN signals must be inactive.

CAUTION

The braking resistor is under high voltage.

After switching off the drive, wait at least 5 seconds before switching it on again.

Table of contents