Infinion EVAL KIT HPD G1 SiC Instruction manual

Application Note Please read the Important Notice, the Safety precautions and the Warnings <Revision 1.0>

www.infineon.com <2022-05-27>

AN-HPDKIT-SiC-G1-QUICKSTART

Quickstart Manual for EVAL KIT HPD G1 SiC

About this document

Scope and purpose

This application note describes how to operate the evaluation kit “EVAL KIT HPD G1 SiC”.

Intended audience

Experienced engineers evaluating HybridPACK™ Drive CoolSiC™ power modules.

Evaluation Kit

This Evaluation Kit is to be used during the design-in process for evaluating and measuring characteristic

curves, and for checking datasheet specifications in designing inverter applications with the HybridPACK™

Drive CoolSiC™ power module and gate driver EiceDRIVERTM.

An evaluation kit is not intended to be an optimal design for every specific requirement. But it gives a good

starting point and useful design hints for serial development. Furthermore, practical experience from the

power module switching characteristic as well as the gate driver features can be obtained in the lab at a

minimum effort by using such evaluation tools.

Note: PCB and auxiliary circuits are NOT optimized for a final customer design.

Application Note 2 <Revision 1.0>

<2022-05-

27>

Important notice

Quickstart Manual for EVAL KIT HPD G1 SiC

Important notice

“Evaluation Boards and Reference Boards” shall mean products embedded on a printed circuit board

(PCB) for demonstration and/or evaluation purposes, which include, without limitation, demonstration,

reference and evaluation boards, kits and design (collectively referred to as “Reference Board”).

Environmental conditions have been considered in the design of the Evaluation Boards and Reference

Boards provided by Infineon Technologies. The design of the Evaluation Boards and Reference Boards

has been tested by Infineon Technologies only as described in this document. The design is not qualified

in terms of safety requirements, manufacturing and operation over the entire operating temperature

range or lifetime.

The Evaluation Boards and Reference Boards provided by Infineon Technologies are subject to functional

testing only under typical load conditions. Evaluation Boards and Reference Boards are not subject to the

same procedures as regular products regarding returned material analysis (RMA), process change

notification (PCN) and product discontinuation (PD).

Evaluation Boards and Reference Boards are not commercialized products, and are solely intended for

evaluation and testing purposes. In particular, they shall not be used for reliability testing or production.

The Evaluation Boards and Reference Boards may therefore not comply with CE or similar standards

(including but not limited to the EMC Directive 2004/EC/108 and the EMC Act) and may not fulfill other

requirements of the country in which they are operated by the customer. The customer shall ensure that

all Evaluation Boards and Reference Boards will be handled in a way which is compliant with the relevant

requirements and standards of the country in which they are operated.

The Evaluation Boards and Reference Boards as well as the information provided in this document are

addressed only to qualified and skilled technical staff, for laboratory usage, and shall be used and

managed according to the terms and conditions set forth in this document and in other related

documentation supplied with the respective Evaluation Board or Reference Board.

It is the responsibility of the customer’s technical departments to evaluate the suitability of the

Evaluation Boards and Reference Boards for the intended application, and to evaluate the completeness

and correctness of the information provided in this document with respect to such application.

The customer is obliged to ensure that the use of the Evaluation Boards and Reference Boards does not

cause any harm to persons or third party property.

The Evaluation Boards and Reference Boards and any information in this document is provided "as is"

and Infineon Technologies disclaims any warranties, express or implied, including but not limited to

warranties of non-infringement of third party rights and implied warranties of fitness for any purpose, or

for merchantability.

Infineon Technologies shall not be responsible for any damages resulting from the use of the Evaluation

Boards and Reference Boards and/or from any information provided in this document. The customer is

obliged to defend, indemnify and hold Infineon Technologies harmless from and against any claims or

damages arising out of or resulting from any use thereof.

Infineon Technologies reserves the right to modify this document and/or any information provided

herein at any time without further notice.

Application Note 3 <Revision 1.0>

<2022-05-

27>

Safety precautions

Quickstart Manual for EVAL KIT HPD G1 SiC

Safety precautions

Note: Please note the following warnings regarding the hazards associated with development systems.

Table 1 Safety precautions

Warning: The DC link potential of this board is up to 500 VDC. When measuring voltage

waveforms by oscilloscope, high voltage differential probes must be used. Failure to do

so may result in personal injury or death.

Warning: The evaluation or reference board contains DC bus capacitors which take

time to discharge after removal of the main supply. Before working on the drive

system, wait five minutes for capacitors to discharge to safe voltage levels. Failure to

do so may result in personal injury or death. Darkened display LEDs are not an

indication that capacitors have discharged to safe voltage levels.

Warning: The evaluation or reference board is connected to the grid input during

testing. Hence, high-voltage differential probes must be used when measuring voltage

waveforms by oscilloscope. Failure to do so may result in personal injury or death.

Darkened display LEDs are not an indication that capacitors have discharged to safe

voltage levels.

Warning: Remove or disconnect power from the drive before you disconnect or

reconnect wires, or perform maintenance work. Wait five minutes after removing

power to discharge the bus capacitors. Do not attempt to service the drive until the bus

capacitors have discharged to zero. Failure to do so may result in personal injury or

death.

Caution: The heat sink and device surfaces of the evaluation or reference board may

become hot during testing. Hence, necessary precautions are required while handling

the board. Failure to comply may cause injury.

Caution: Only personnel familiar with the drive, power electronics and associated

machinery should plan, install, commission and subsequently service the system.

Failure to comply may result in personal injury and/or equipment damage.

Caution: The evaluation or reference board contains parts and assemblies sensitive to

electrostatic discharge (ESD). Electrostatic control precautions are required when

installing, testing, servicing or repairing the assembly. Component damage may result

if ESD control procedures are not followed. If you are not familiar with electrostatic

control procedures, refer to the applicable ESD protection handbooks and guidelines.

Caution: A drive that is incorrectly applied or installed can lead to component damage

or reduction in product lifetime. Wiring or application errors such as undersizing the

motor, supplying an incorrect or inadequate AC supply, or excessive ambient

temperatures may result in system malfunction.

Caution: The evaluation or reference board is shipped with packing materials that

need to be removed prior to installation. Failure to remove all packing materials that

are unnecessary for system installation may result in overheating or abnormal

operating conditions.

Application Note 4 <Revision 1.0>

<2022-05-

27>

Table of Contents

Quickstart Manual for EVAL KIT HPD G1 SiC

Table of Contents

About this document....................................................................................................................... 1

Important notice ............................................................................................................................ 2

Safety precautions.......................................................................................................................... 3

Table of Contents ........................................................................................................................... 4

1How to order HybridKit Drive.......................................................................................... 5

2Feature and Limitations Overview................................................................................... 6

2.1 Block Diagram .........................................................................................................................................6

2.2 Recommended Operating Conditions....................................................................................................7

2.3 Key Features ............................................................................................................................................7

2.4 Limitations of the Evaluation Kit ............................................................................................................8

2.5 Key Components List ..............................................................................................................................8

3Quickstart Guide............................................................................................................ 9

3.1 Recommended equipment for evaluation.............................................................................................9

3.2 Connect the Evaluation Kit to power supply and load ..........................................................................9

3.3 Connect the Evaluation Kit to a cooling system ..................................................................................10

4Advanced Features .......................................................................................................11

4.1 Double Pulse Testing.............................................................................................................................11

5References and Revision History ....................................................................................12

Application Note 5 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

How to order HybridKit Drive

1How to order HybridKit Drive

The evaluation kit EVAL KIT HPD G1 SiC can be ordered via Infineon sales partners:

SAP ordering number for EVAL KIT HPD G1 SiC: SP005594933.

The evaluation kit is also available at the webshop: http://www.ehitex.com

The shipping content of the EVAL KIT HPD G1 SiC include the:

HybridPACK™Drive power module FS03MR12A6MA1B (SP001720764)

Reference aluminium cooler + recommended sealing ring

Gate driver board HPD GD BOARD G1 SIC (SP005592047)

DC-Link capacitor

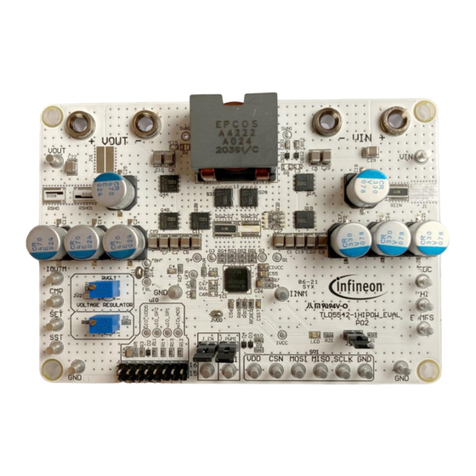

The typical appearance of the evaluation kit is shown in Figure 1.

Figure 1 Typical appearance of the evaluation kit EVAL KIT HPD G1 SiC SP005594933.

Application Note 6 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Feature and Limitations Overview

2Feature and Limitations Overview

The evaluation kit EVAL KIT HPD G1 SiC is a partial inverter system including B6 bridge power module, gate driver

board, DC-link capacitor and cooler. The evaluation kit supports the customers in their first steps in designing

applications with the HybridPACK™ Drive CoolSiC™.

2.1 Block Diagram

Figure 2 shows the block diagram with simplified signal and power flow connections as well as the implemented

key components.

Power

Supply

EiceDRIVER

U_HS

Supply

Connector X1

Interface PCB

EiceDRIVER

U_LS

Supply

EiceDRIVER

V_HS

Supply

EiceDRIVER

V_LS

Supply

EiceDRIVER

W_HS

Supply

EiceDRIVER

W_LS

Supply

PressFIT Signal connectors

Gate Driver Board

U_HS

Switch

U_LS

Switch

NTC_U

V_HS

Switch

V_LS

Switch

NTC_V

W_HS

Switch

W_LS

Switch

NTC_W

M

HybridPACKTM Drive CoolSiCTM

Liquid Cooling System

DC Link Cap

HV Supply

8..18VHybridKIT Drive SiC

Figure 2 Simplified Block Diagram

Application Note 7 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Feature and Limitations Overview

2.2 Recommended Operating Conditions

The following recommended operating conditions describe the targeted lab testing environment.

The evaluation kit is not designed for a fixed specification and it cannot be regarded as a protected system, as it

would require strict shutdown routines and would limit the main evaluation purpose. Therefore, please respect

the specifications of individual parts and especially the thermal limits.

Please see also section 2.4 to understand the limitations.

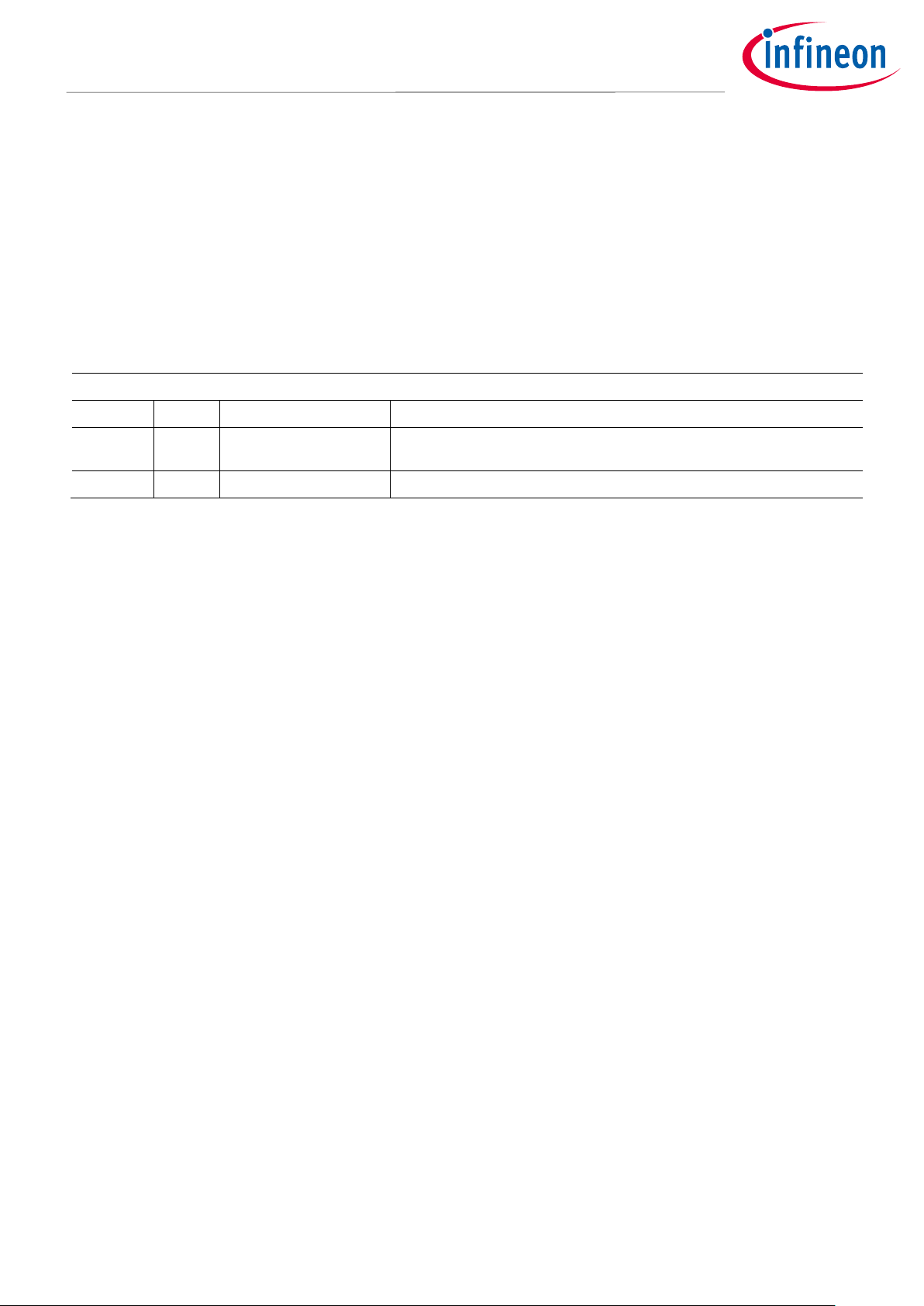

Table 2 Operating Conditions

Type

Symb

Min

Max

Conditions

Gate Driver Board Supply

Vsupply

8V

18V

Working Voltage

(DC-Link Voltage)

VDC

0V

500V

Gate driver board’s creepage

and clearance distances

comply with norm IEC-60664-

1 for 500V.

Transient Phase Current

Iph

-800A

+800A

limited by Tvj,op_max

HybridPACKTM Drive CoolSiCTM

module

Junction Temperature

Tvj,op

-40°C

150°C

PCB Temperature

TPCB

150°C

Ambient Temperature

Tamb

75°C

Limited by TPCB. A higher Tamb

is achievable at active cooling

like a fan

Switching frequency

fsw

20 kHz

Limited by TPCB. A higher fsw is

achievable at low ambient

temperature or active cooling

like a fan

2.3 Key Features

The key features can be summarized:

Inverter evaluation kit for xEV main inverter applications (up to 200 kW).

Automotive power module HybridPACK™Drive CoolSiCTM FS03MR12A6MA1B.

Automotive gate driver solution based on EiceDRIVER™1EDI3033AS.

SiC MOSFET desaturation (short circuit) detection.

NTC temperature measurement featured by ADC of EiceDRIVER™.

DC-Link voltage measurement featured by ADC of EiceDRIVER™.

Gate driver board’s creepage and clearance distances comply with norm IEC-60664-1 for 500V working

voltage.

Application Note 8 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Feature and Limitations Overview

2.4 Limitations of the Evaluation Kit

The evaluation kit should not be regarded as a protected system. It was designed for evaluation under lab

conditions with minimum automatic shutdown routines. The design was intended to be usable also under

extreme conditions where protection mechanisms would limit the evaluation possibilities. The evaluation kit is

not protected against:

Over- & under- voltages on the signal connectors.

Overvoltages of the HV working voltage

(>500V should be avoided)

Overtemperature of the PCB and Module.

The power module NTC temperature info is read as a digital signal, but no shutdown limit is set.

Testing at higher switching frequencies than 20 kHz may require active cooling of the gate driver board

at high ambient temperature.

Please read and understand the manual and the safety precautions.

Please note that the list are giving examples and should not be seen as exhaustive.

2.5 Key Components List

Some key components can be found in Table 3. The evaluation kit uses more active and passive components

which are not listed here.

Table 3 Key components list.

Part Number

Manufacturer

Description / Implementation

FS03MR12A6MA1B

Infineon

Automotive HybridPACK™Drive CoolSiC™ power module

with 1200V SiC MOSFET

1EDI3033AS

Infineon

Automotive Isolated Gate Driver EiceDRIVER™

TLE8386-2EL

Infineon

Automotive SMPS controller used in 500kHz SEPIC converter

B25655P8307K351

TDK

Automotive PCC DC-Link Capacitor 855V, 300μF

P301085-A2

(B78308-A2387-A003)

TDK

Automotive Transformer 1:1.07 with 10mm creepage

distance

Application Note 9 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Quickstart Guide

3Quickstart Guide

This chapter explains briefly the recommended lab equipment and how to connect the evaluation kit. Please

ensure an appropriate current/power/voltage limit of the source. It can happen at any time that the inverter

changes the output conditions and/or stops immediately.

3.1 Recommended equipment for evaluation

To perform evaluation tests with the EVAL KIT HPD G1 SiC, following equipment is minimum recommended.

Logic Supply: 8-18V, 2A.

Pulse generator: 0V…5V

Power Source: minimum 30V/2A.

up to 500V/600A depending on evaluation tests.

Load: passive 3-phase inductive load or alternative

3-phase asynchronous (induction) machine.

Scope: 4 channel scope.

Cooling system: Optional for light load tests.

For high power tests use cooling with 10L/min and <2bar absolute pressure

operation.

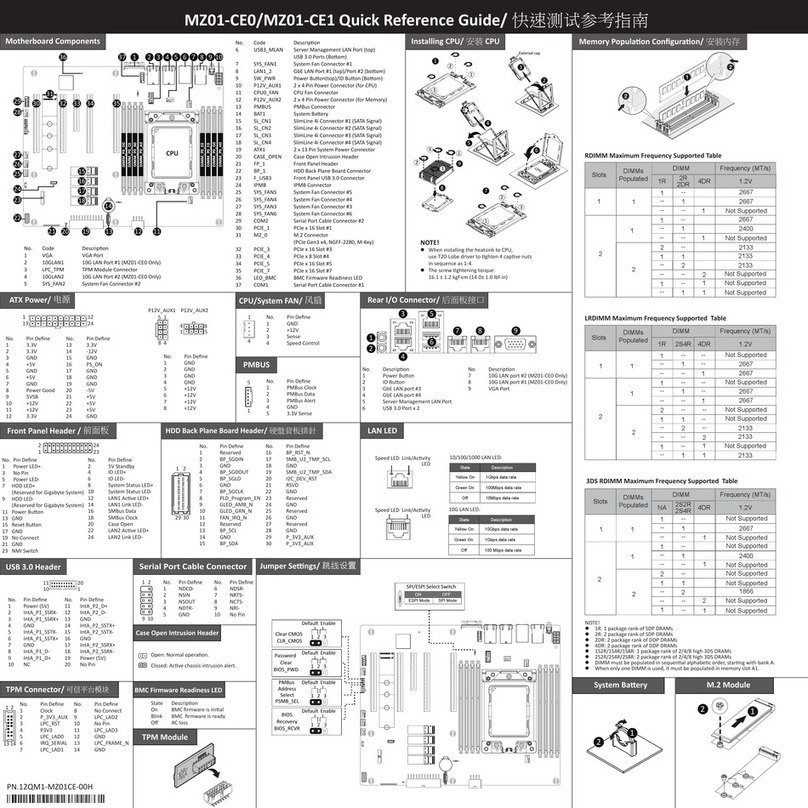

3.2 Connect the Evaluation Kit to power supply and load

The right connection of power supplies and load is shown in Figure 3a. The high voltage DC source has to be

connected to the capacitor. Depending on the required currents for the evaluation tests it can be required to

mount a busbar over all DC-, DC+ connections. Some busbar examples for high power load tests are shown in

Figure 3b and c. For low loads and high power short-term operation it is typically enough to connect the high

voltage DC source only at the center DC-Link connections with the cable shoes included in the standard shipping

content of the evaluation kit.

Refer to [2] Infineon Application Note AN-HPDKIT-SiC-G1-GATEDRIVE, “User Manual for HPD GD BOARD G1 SiC”

for logic supply connection on gate driver board.

Application Note 10 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Quickstart Guide

a)

b)

c)

Figure 3 Typical appearance of the evaluation kit and required supplies and load connections (a). For long-

term high power load tests a busbar with appropriate current carrying capability may be required at the DC

terminals. Concepts with additional external busbars are shown in (b), this example shows solutions from

TDK/Epcos [3]. Concepts with busbars integrated in the capacitor is shown in (c), this example shows a

solution from SB Electronics [4].

3.3 Connect the Evaluation Kit to a cooling system

The cooler can be connected via the ½ inch G series British standard pipe interface as shown in Figure 4. Please

use as cooling fluid 50% water / 50% ethylene glycol and ensure that the cooling fluid corrosion protection is

compatible with aluminium cooler and Ni plated baseplate (like typical released automotive cooling mixtures).

Do not use pure water cooling fluids as it might damage the power module and reference cooler.

Figure 4 Typical appearance of the evaluation kit and the cooling system interface.

Application Note 11 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

Advanced Features

4Advanced Features

4.1 Double Pulse Testing

For a deeper investigation of the corresponding switching characteristics, it is sometimes useful to perform

double pulse tests rather than inverter tests. Such tests can be easily performed by using the following sequence:

1. Connect supplies, load and pulse generator properly

2. Turn on the logic supply (8..18V)

3. Activate and enable gate driver EiceDRIVERTM

4. Turn on the high voltage supply and perform double pulse tests

Refer to [2] Infineon Application Note AN-HPDKIT-SiC-G1-GATEDRIVE, “User Manual for HPD GD BOARD G1 SiC”

for gate driver board configuration detail, such as logic supply connection, enabling gate driver EiceDRIVERTM,

etc.

The pulse generator can be connected to test pads on the gate driver board as shown in Figure 5.

Figure 5 Example how test pads on the gate driver board can be utilized for double pulse test.

Application Note 12 <Revision 1.0>

<2022-05-

27>

Quickstart Manual for EVAL KIT HPD G1 SiC

References and Revision History

5References and Revision History

The referenced application notes can be found at http://www.infineon.com

[1] Infineon Application Note AN-HPD-ASSEMBLY, “Assembly Instructions for the HybridPACK Drive”

[2] Infineon Application Note AN-HPDKIT-SiC-G1-GATEDRIVE, “User Manual for HPD GD BOARD G1 SiC”

[3] TDK/Epcos Capacitor “B25655P5507K***”

[4] SBE Electronics Capacitor “700D50794-204” OR “700D50795-186”

Revision History

Date

Version

Changed By

Change Description

2022-May

1.0

Dehuai Jiang

(IFAG ATV HP HMD TM)

Initial Version

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

ifx1owners.

Edition <2022-05-27>

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2022 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

AN-HPDKIT-SiC-G1-QUICKSTART

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Table of contents

Other Infinion Motherboard manuals