Infinion TLD5542-1HIPOW EVAL User manual

User manual Please read the Important Notice and Warnings at the end of this document Rev.1.0

www.infineon.com page 1 of 19 2021-03-04

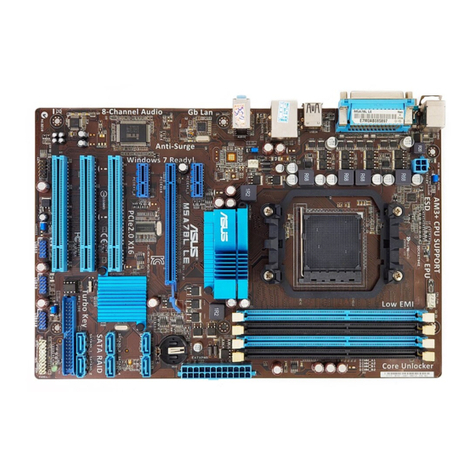

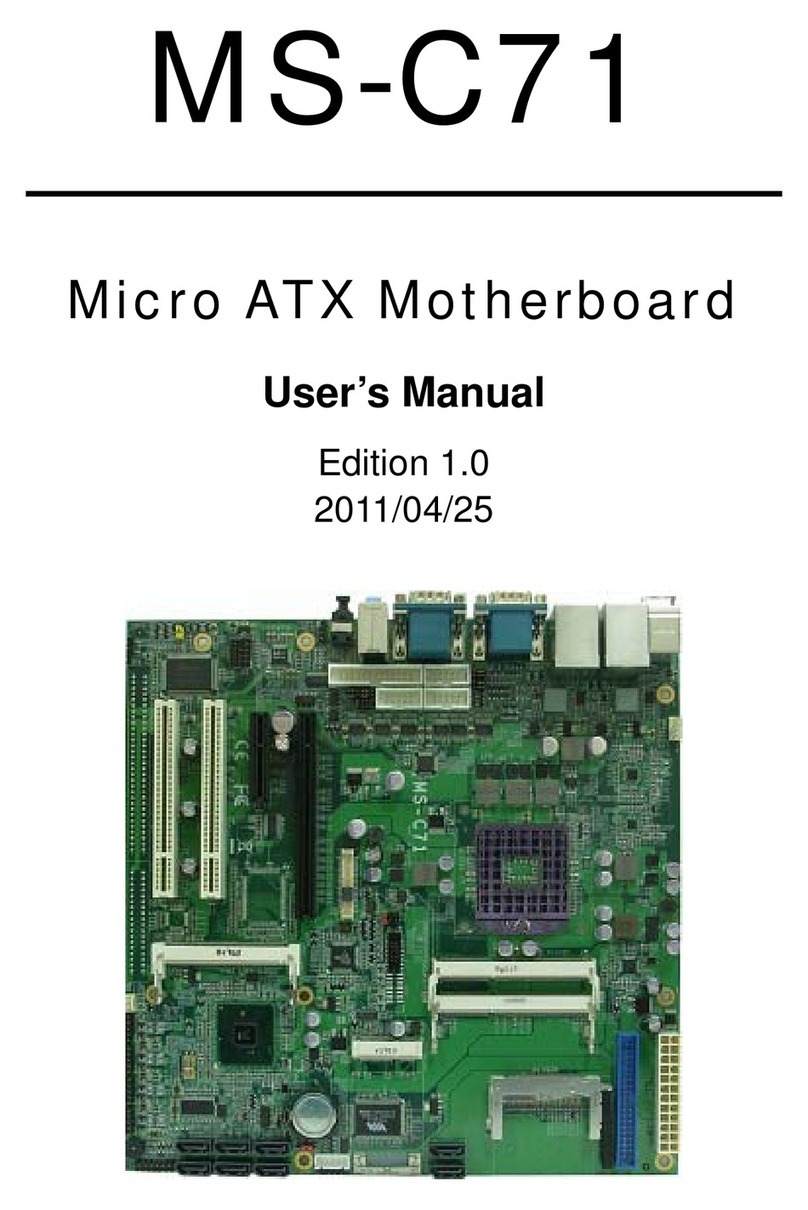

TLD5542-1HIPOW_EVAL board

Evaluation board manual

About this document

Scope and purpose

The scope of this user manual is to provide instructions on the use of the TLD5542-1HIPOW-EVAL evaluation

board.

TLD5542-1HIPOW_EVAL board is a 4-switch synchronous buck-boost regulator that demonstrates the high-

power capability of the TLD5542-1. The output is adjustable from 5 V to 24 V and the maximum output current is

25 A for up to 300 W power delivery without heatsink.

The switching frequency is 250 kHz and efficiency can go up to 98%.

The board can be configured as current regulator or voltage regulator.

Figure 1 TLD5542-1HI_POW_EVAL device board

Intended audience

Hardware engineers, software engineers, system architects

User manual 2 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Description

Table of contents

About this document......................................................................................................................... 1

Table of contents .............................................................................................................................. 2

1Description .............................................................................................................................. 3

2Quick start procedure............................................................................................................... 4

2.1 Setup as current regulator with no microcontroller..............................................................................4

2.2 Board set up as voltage regulator with no microcontroller nor PC GUI................................................6

2.3 Board set up as voltage/current regulator with PC GUI.........................................................................7

3Infineon μIO stick and Infineon Toolbox ..................................................................................... 9

3.1 Install and launch Config Wizard ..........................................................................................................10

4Board control with PC GUI........................................................................................................11

4.1 Basic user interface ...............................................................................................................................11

4.2 Engineering user interface....................................................................................................................12

5Operating range and power derating ........................................................................................14

6Electrical characteristics..........................................................................................................15

7Bill of material, PCB layout and schematic.................................................................................16

8List of references.....................................................................................................................17

Revision history...............................................................................................................................18

User manual 3 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Description

1Description

The H-bridge architecture is amongst the most efficient buck-boost topologies for high current applications. The

TLD5542-1 provides complete control and diagnostics through the SPI interface. The TLD5542-1 can also be used

in applications without microcontroller because of the limp home mode.

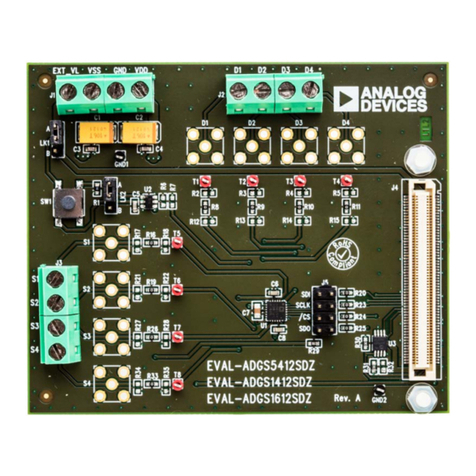

The TLD5542-1HIPOW_EVAL demonstrates the high-power capability of the TLD5542-1 as current or voltage

regulator.

The default configuration is adjustable voltage regulator with 25 A maximum output current. By reconfiguring

few solder jumps, the board becomes a current regulator for battery or supercapacitors charger applications.

The board can be controlled by the PC GUI via the Infineon µIO stick (see Chapter 4).

Figure 2 TLD5542-1 as battery charger

Figure 3 TLD5542-1 as voltage regulator

There are 2 trimmers, RVOLT and RSET, to easily adjust output voltage and output current in the entire range

(see table 6).

User manual 4 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Quick start procedure

2Quick start procedure

Below, step by step procedures are laid out for setup and running the TLD5542-1HIPOW_EVAL in all available

configurations.

Installation procedure for PC GUI (graphical user interface) and μIO stick interface is described in Chapter 4.

2.1 Setup as current regulator with no microcontroller

Setup of the board as simple current regulator, without a microcontroller connection and without µIO stick nor

PC GUI.

The device is configured in limp home. All the registers are set to their default value and the analog dimming is

provided by the voltage on the SET pin which is adjustable with RSET trimmer.

Table 1 Jumper reference and setup for current regulator

Jumper reference

Status

Description

JV1

OPEN

Bypass output current shunt resistor

JV2

OPEN

Disconnect voltage regulator feedback voltage divider

JI1

CLOSE

Connect current shunt

JVDD

CLOSE

Connect Internal 5V IVCC to VDD

J1

CLOSE

Bypass input current shunt resistor

In order to run the board in this configuration

1. Configure solder jumper for LED driver configuration as in Figure 4

2. Connect LHI (limp home) and J_PWMI jumpers

Figure 4 Jumpers to be set for current regulator mode no µC

User manual 5 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Quick start procedure

3. Connect the load (Note that the output current can be as high as 30 A if SET is adjusted to maximum)

4. Connect a 12 V power supply to the VIN connector

5. Rotate RSET trimmer completely anti-clockwise to lower the output current to the minimum

6. Connect the EN jumper to start providing output current to the load

7. Adjust IOUT with RSET (output current should be higher than 2 A for better transient response)

Figure 5 Connect power supply and load, adjust output current

Warning:

1. If the load is a battery or a supercapacitor, do not use PWMI to stop output current, use EN instead.

Otherwise, the device will affect a startup without soft-start assistance sinking high current from

the charging battery at the VOUT connector.

2. The board is not reverse protected at the input nor at the output, if a battery is connected with

reverse polarity the board or the battery may catch fire.

Correct start-up sequence, to provide current at the load is:

•Set EN to ON with PWMI kept to OFF (blue LED on the PCB turns ON)

•Set desired analog dimming level by using SET pin if limp home mode, otherwise operate via SPI

•Set PWMI to ON

User manual 6 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Quick start procedure

2.2 Board set up as voltage regulator with no microcontroller nor PC GUI

The following describes how to setup the board as a simple voltage regulator without PC GUI. No

microcontroller connection and no µIO stick is present.

Table 2 Jumper reference and setup for voltage regulator

Jumper reference

Status

Description

JV1

CLOSE

Bypass output current shunt resistor

JV2

CLOSE

Connect voltage regulator feedback voltage divider

JI1

OPEN

Disconnect current shunt from FBL

JVDD

CLOSE

Connect Internal 5V IVCC to VDD

J1

CLOSE

Bypass input current shunt resistor

1. Configure all solder jumpers as shown in Figure 6

2. Connect J_EN, LHI and PWMI jumpers

Figure 6 Jumpers to be set for voltage regulator mode no µC

3. Connect a 12 V power supply to the VIN connector

4. Rotate RSET trimmer completely clockwise (100% analog dim, improves transient response and accuracy)

User manual 7 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Quick start procedure

Figure 7 Connect power supply, turn RSET to maximum and adjust VOUT with RVOLT

5. Rotate RVOLT trimmer to obtain the desired VOUT

6. Connect the load to VOUT

2.3 Board set up as voltage/current regulator with PC GUI

The TLD5542-1 HIPOW_EVAL can be controlled by the PC GUI via a µIO stick. All the plug jumpers have to be

removed, or the µIO will not be able to control the TLD5542-1 properly.

1. Set solder jumpers for voltage (Chapter 2.1) or current (Chapter 2.2) regualtor

2. Remove jumper plugs J_LHI, J_PWMI, J_EN

Figure 8 Control with μIO stick board preparation

User manual 8 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Quick start procedure

3. Connect the μIO to J_uIO connector (pin 1 mark on PCB on RED cable strip) and uIO stick to the PC

Figure 9 Connect μIO stick, power supply, load

4. Launch Infineon Toolbox and the Config Wizard for LED, see chapter 3.1

5. Connect power supply to the VIN connector

6. Adjust for the desired output current/voltage with the GUI (see Chapter 4) and connect the load

User manual 9 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Infineon μIO stick and Infineon Toolbox

3Infineon μIO stick and Infineon Toolbox

The Infineon μIO stick is an interface device for controlling Infineon boards/kits during run time

through PC.

•Enables the connection between the evaluation board and USB for SPI programming and monitoring

by using the Config Wizard software, which can be downloaded via the Infineon Toolbox [1]

•Plugs into the evaluation board via a standard 16-pin connector and allows easy interface to the

microcontroller via USB for SPI, CAN and LIN communication

Figure 10 Infineon μIO stick

The Infineon Toolbox it is a single platform interface which allows for:

•Quick installation of tools by name or QR code

•Help with documentation

•Viewing and starting installed tools from built-in launcher

•Receiving update notifications

Figure 11 Infineon Toolbox

For details about Infineon toolbox and μIO stick check the Infineon website: Infineon Toolbox.

User manual 10 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Infineon μIO stick and Infineon Toolbox

3.1 Install and launch Config Wizard

1. Open the “Manage tools” tab

2. Search for “Config Wizard for LED” and click on “Install” button

Figure 12 Install Config Wizard for LED

3. Select “My Tools” tab on Infineon Toolbox

4. Press “Start” on the config wizard for LED to start

Figure 13 Start Config Wizard tool

5. Click on TLD5542-1 icon to start the LED GUI interface

Figure 14 Launch TLD5542-1 GUI

User manual 11 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Board control with PC GUI

4Board control with PC GUI

The TLD5542-1 PC GUI consists of 2 interfaces:

•Basic user interface

•Engineering user interface

The GUI works only if the TLD5542-1 evaluation board is correctly connected to the μIO stick and power supply

is applied to the VIN connector.

4.1 Basic user interface

Basic user interface allows simplified access to the main registers on TLD5542-1 (e.g. analog dimming with a

knob) and provides direct feedback on TLD5542-1 status, showing indicators for each standard diagnosis

register bit.

It is possible to provide EN signal and PWMI without the need for a function generator.

In order to turn on the device press the EN button, the “Active” indicator shall turn on.

Only once the device is on, the desired analog dimming value can be set by the ”Analog Dimming” knob on the

“Dimming” tab.

Correct startup sequence is:

•Have a power supply connected at VIN

•Set EN to ON with PWMI kept to OFF (blue LED on the PCB turns ON)

•Set desired analog dimming level (RSET trimmer if limp home mode otherwise via GUI)

•Set PWMI to ON

Figure 15 TLD5542-1 GUI –Basic user interface

On the “Diagnosis/Monitoring” tab, (see Figure 15) the standard diagnosis register is provided, showing

information on the working status of the device.

User manual 12 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Board control with PC GUI

On the “Compensation Setting” tab (see Figure 16 ), it is possible to tune the compensation transfer function in

order to have the smoothest transition from buck-boost to boost mode, which depends on the switching

frequency (385 kHz for the TLD5542-1 HIPOW _EVAL board)

Figure 16 TLD5542-1 GUI basic user interface –compensation and EMC tabs

4.2 Engineering user interface

The engineering user interface allows the user to send a sequence of SPI commands to the TLD5542-1. PWMI

and EN pin control is also possible on this interface.

The suggested sequence of operations in order to send the SPI commands is as follows:

1. Write the list of SPI commands that has to be sent

2. Turn on the device by pressing the EN button

3. Press the SEND button to send commands on the list, starting from the black row in the list Figure 17

4. Enable the switching activity by pressing PWMI button

Figure 17 TLD5542-1 GUI –Engineering user interface

User manual 13 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Board control with PC GUI

It is possible to describe each command with a comment and to save the list of commands by clicking on the

“Save” button.

It is possible to set the delay applied before executing the next command in the “Delay” column, the accuracy

of the timer is approximately 10 ms.

Figure 18 TLD5542-1 GUI –writing comment - saving command list - delay between commands

User manual 14 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Operating range and power derating

5Operating range and power derating

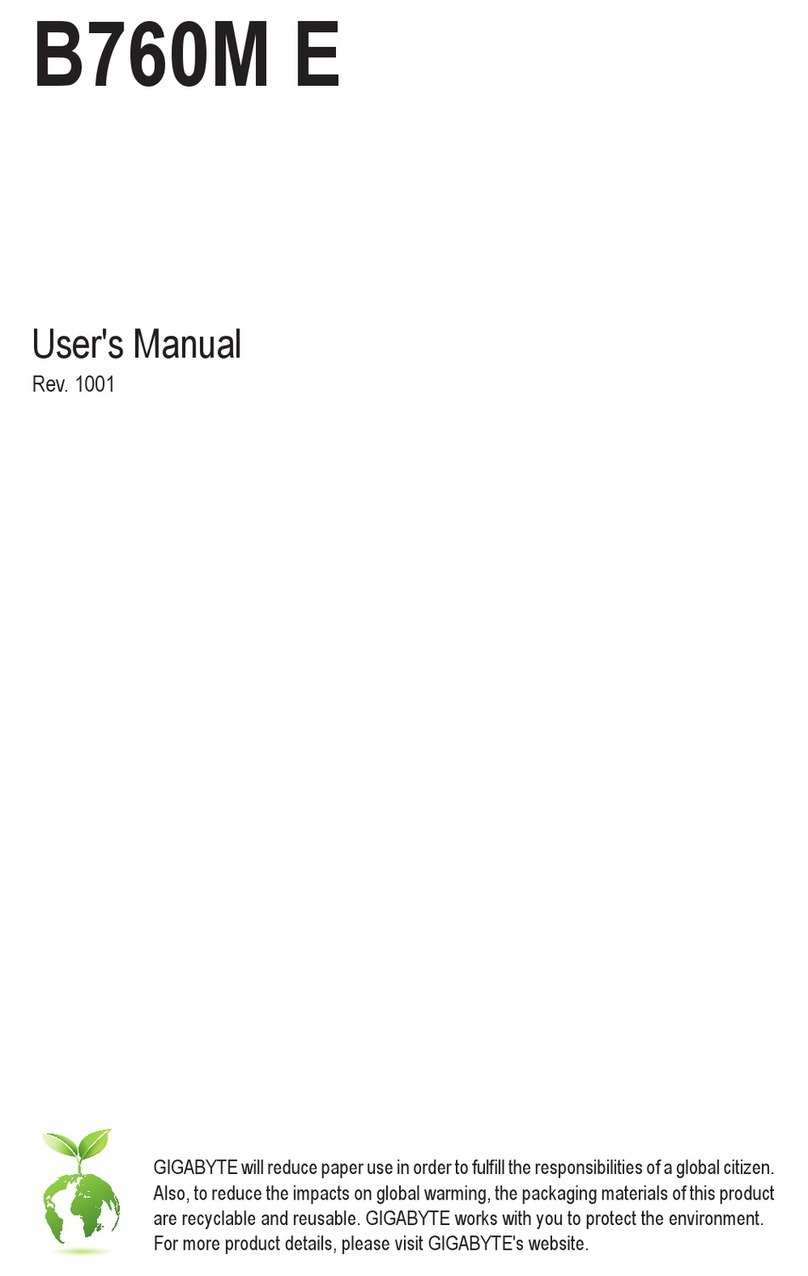

The TLD5542-1HIPOW-EVAL has very high efficiency, so it can deliver up to 300 W at the output without a

heatsink at TA= 25°C, for VIN down to 9 V.

Figure 19 Thermal acquisition, voltage REG, VIN = 12 V, VOUT = 12 V, IOUT = 25 A, TA= 25°C no heatsink

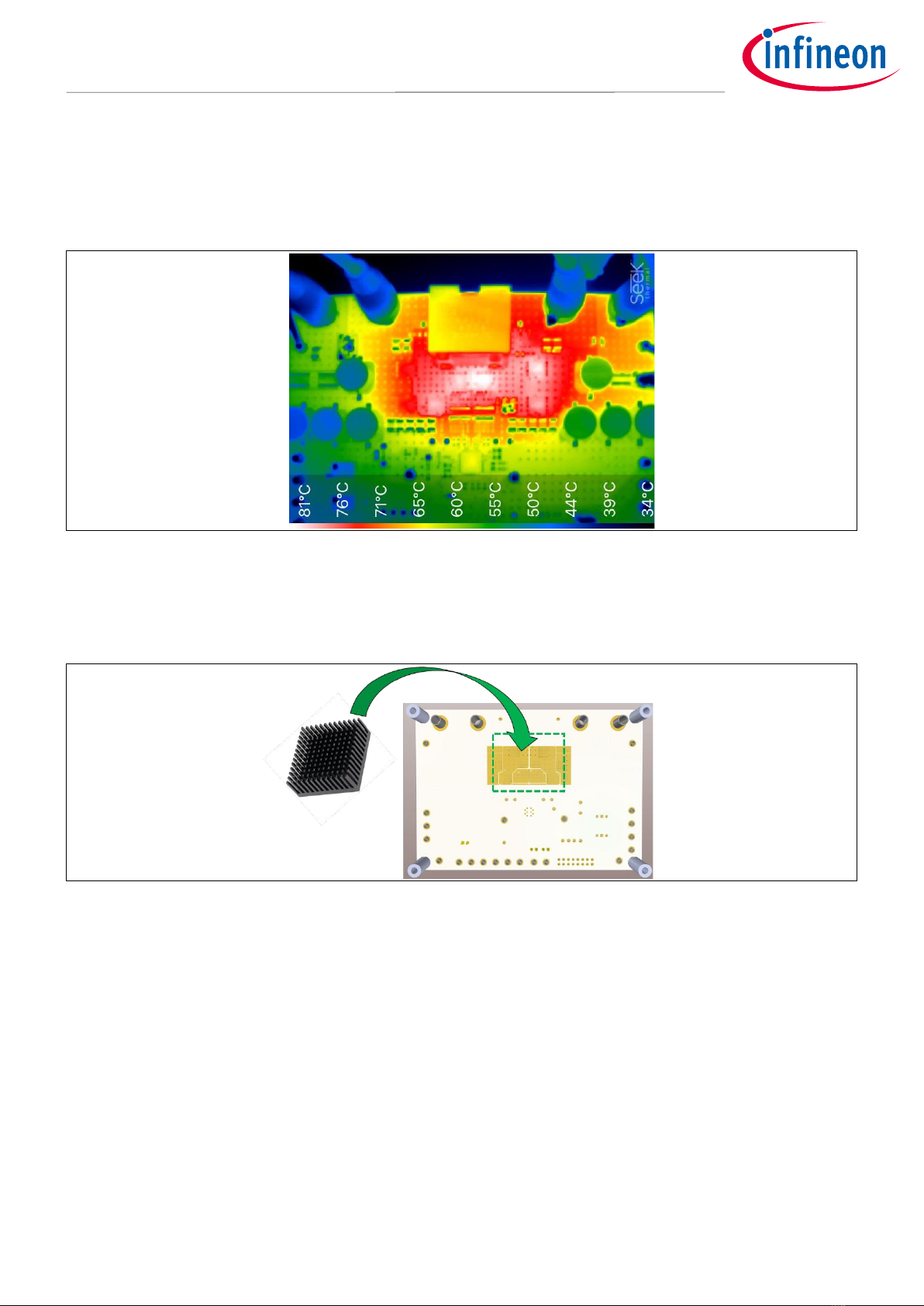

Please note that the module does not implement thermal protection, so ensure proper cooling when output

power exceeds the power-derating curve. The heatsink must be positioned below the switching MOSFETs as

shown in Figure 20.

Figure 20 Optional heatsink placement

The heatsink shall be electrically insulated from the PCB, by means of a thermal pad.

User manual 15 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Electrical characteristics

6Electrical characteristics

Table 3 TLD5542-1 HIPOW -EVAL version S03 P01 –electrical characteristics

Parameter

Symbol

Value

Unit

Note/Test Condition

Min.

Typ.

Max.

Input voltage

VIN

7.5

–

35

V

Power derating may occur for VIN < 9 V

Output voltage

VOUT

2

5

–

24

24

V

Current regulator mode

Voltage regulator mode

Output current

IOUT

0

–

25

A

Output power

POUT

-

300

400

–

W

W

No heatsink VIN 9 V to 35 V, TA= 25°C

With heatsink VIN 9 V to 35 V, TA= 25°C

Switching

frequency

Switching

frequency

–

250

–

kHz

Spread spectrum deviation is present

PWM frequency

PWMfreq

100

–

500

Hz

–

System

efficiency

η

–

97

96

–

%

Voltage mode: VIN = 12 V VOUT = 12 V IOUT = 25 A

Current mode: VIN = 12 V VOUT = 12 V IOUT = 20 A

User manual 16 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

Bill of material, PCB layout and schematic

7Bill of material, PCB layout and schematic

Table 4 Bill of material

Designator

Value

Footprint

Quantity

C1, C5, C9, C19, C20, C27, C28, C29

10µF 50V X7R 1210

C1210

8

C2, C6, C7, C8, C10, C11, C13, C22

22µF 25V X7R 1210

C1210

8

C4, C69, CSST

22nF 50V

C0603

3

C12, C14, C24, C25

470µF 25V PCR1E471MCL1GS

CE D10 CASE G

4

C16, C17, C18, C21

330µF 35V PCR1V331MCL1GS

CE D10 CASE G

4

C26, C55, CEN

1µF 50V 0805

C0805

3

C56, CBS1, CBS2

100nF 50V

C0603

3

CC1

33nF 25V

C0603

1

CIVCC

10µF 6,3V 0805 X7R

C0805

1

CMP, CSN, EN, EOMFS, GND, GND3, GND4,

GND5, IINM, IOUTM, LEDC, LHI, MISO, MOSI,

PWMI, SCLK, SET, SST, VDD, VIN, VOUT

Mill-Max 2501-2-00-80-00-00-

07-0

–

21

D2, D3, D4, DBS1, DBS2

NXP_BAT46WJ

SOD323F

5

GND2, GND-, VIN+, VOUT+

Keystone 575-8

4

IC1

TLD5542-1QV

VQFN48 7X7 P05

1

J_EN, J_LHI, J_PWMI

TSW-102-08-G-S

CON-M-THT-TSW-

102-08-G-S

3

J_uIO

Header 8X2(tyco 5-146254-8)

HDR2X8

1

L1

TDK B82559A5332A024

IND SMD B82559A

1

LED

WURTH 150080BS75000

LED 0805 BLU

1

Q1A, Q1B, Q3A, Q3B

IAUC80N04S6L032

PG-TDSON-8-33

4

Q2A, Q4A, Q4B

IAUC100N04S6L020

PG-TDSON-8-33

3

R1, R9, R17, RC1, RVL, R5, R21

1.5kΩ 1%

R0603

7

RFREQ,R89, R90

47kΩ 1%

R0603

3

R3,R10,R18

4.7kΩ 1%

R0603

3

R4, R7, RG1A, RG1B, RG2A, RG2B, RG3A,

RG3B, RG4A, RG4B

1Ω

R0603

10

R11, R12, R13, R14, R16

150Ω 1%

R0603

5

R2,RVH

24kΩ 1%

R0603

2

RSET, RVOLT

Bourns 3266Y-1-203LF

–

2

RSHO1,RSHO

10mΩ FC4L64R010FER

–

2

RSWCS2,RIIN

1.5mΩ PML100HZPJV1L5

–

2

C3, C15, C67, C68, FBH, FBL, G1, G2, G3, G4,

IVCC, SWN1, SWN2, uIO_AD0, uIO_GP1,

uIO_GP2, uIO_VDD5, VFB, Q2B, R6, R8,

RSWCS1

NOT POPULATED

–

–

Spacer 12mm

Wurth 702935000

–

4

A

B

C

D

E

A

B

C

D

E

12345678

12345678

Capacitors are 0603 X7R 10%

Remarks: if not specified differently

connect exposed pad to GND

Place C67 and RVFBL1 close to IC

CSST 22nF 50V

RFREQ

47k 1%

RVL

1k5 1%

RG1A

1

RG2A1

RG3A 1

RG4B

1

R6

NO_POP

C15

NO_POP

R8

NO_POP

C3

NO_POP CBS1

100nF 50V

CBS2

100nF 50V

CIVCC

10uF 6,3V0805 X7R

VIN

44

IIN2

43

SET

22

EN/INUVLO

41

COMP

19

SOFT_START

38

IIN1

42

PWMI

24

IINMON

39

SYNC

34

IOUTMON

16

FREQ

35

VDD

31

CSN

28

SI

30

SO

27

SCLK

29

VSS

26

AGND

40

IVCC_EXT 47

IVCC 46

BST1 3

BST2 10

HSGD1 2

SWN1 4

LSGD1 6

SWCS 17

SGND 18

PGND1 5

SWN2 9

PGND2 8

LSGD2 7

HSGD2 11

VFB 20

FBH 13

FBL 14

DIM_HALF

36

TEST2

25

LHI

37

FILT

23

N.C. 1

N.C. 12

N.C. 15

VFB_VIN 21

EOMFS

32

LEDCURR

33

N.C.

45

N.C.

48

EP

EP

IC1

TLD5542-1QV

L1

TDKB82559A5332A024

RVH

24k 1%

C1 10uF 50VX7R 1210

DBS1

NXP_BAT46WJ

DBS2

NXP_BAT46WJ

C13 22uF 25VX7R1210

C7 22uF 25VX7R1210

C11 22uF 25VX7R1210

C55

1uF50V0805

C5 10uF 50VX7R 1210

C56

100nF 50V

C67

NO_POP120pF 25V

GND

GND

GND

GND

GND

GND

GND

GND GND

GND

GND

GND

GND

VIN

GND

GND

VCCINT

VCCINT

VCCINT

GND GND

GND

GND

GND

SCLK

MOSI

MISO

CSN

PWM_uIO

GND

30A@

30A@

30A@

diff.

diff.

GND

Date: 01/03/2021 Sheet: 1/1

REV:

TITLE: TLD5542-1HIPOW_EVAL

Document Number: S03

GND

C68

NO_POP220pF 50V

BST1

BST2

GND

Place C68 close to IC

D3

NXP_BAT46WJ

D4

NXP_BAT46WJ

CSN

MOSI

MISO

SCLK

Resistors are 0603 5%

REVISION HISTORYFROM S02 to HIGH POW S03

changed Q1Ato Q4B MOS

Changed R5 to 1k5

Changed Default Jumpers to VREG

R89

47k 1%

R90

47k 1%

C69

22nF50V

GND

Vin

R4

1

GND

VCCINT

VCCINT

VHB

VDD

21

JV1

CLOSE

R17

1k5 1%

C4

22nF50V

GND

R2

24k1%

SET

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

J_uIO

Header 8X2(tyco 5-146254-8)

PWM_uIO

SCLK

CSN

MOSI

MISO

EN_uIO

VDD

VDD

30A@

R10

4k71%

D2

NXP_BAT46WJ

EN_uIO

R18

4k7 1%

21

JV2

CLOSE

GND

R3

4k7 1%

VHB

GND

R5

1k5 1%

COMP

VOUT

GND

GND

C24

470uF 25VPCR1E471MCL1GS

VReg->Close

Close=>Vreg

Open=>VReg

GND5

GND

Vout

CMP

EN

PWMI

SCLK

CSN

MISO

MOSI

VDD PWMI

PWMI

CSN

MOSI

MISO

SCLK

EN_INUVLO

VDD

uIO connector

GND

GND

LEDC

EOMFS

EOMFS

LEDCURR

LEDCURR

EOMFS

SPI

IOUTMON

GND

COMP

R11 1501%

R12 1501%

R13 1501%

R14 1501%

VIN+

Keystone 575-8

GND2

Keystone 575-8

VOUT+

Keystone 575-8

GND-

Keystone 575-8

R9

1k5 1%

Q1B

IAUC80N04S6L032

Q3A

IAUC80N04S6L032

Q4A

IAUC100N04S6L020

LHI

1

2

J_LHI

TSW-102-08-G-S

LHI

EN_INUVLO

2 1

JVDD

CLOSE

13

2RVOLT

Bourns 20k 3266Y-1-203LF

1 3

2

20K

RSET

Bourns 20k 3266Y-1-203LF

CC1

33nF 25V RC1

1k5 1%

FB_P

FB_N

VCCINT R1

1k5 1%

VCCINT

VCCINT

GND

VCCINT

IVCC

N.P.

1

2

J_PWMI

TSW-102-08-G-S

1

2

J_EN

TSW-102-08-G-S

uIO_AD0 N.P.

uIO_GP1 N.P.

uIO_GP2 N.P.

G1

N.P.

G2

N.P. SWN1 SWN2

G3

N.P.

G4

N.P.

VFB

N.P.

FBL

N.P.

FBH

N.P.

IOUTM

K A

LED

WURTH 150080BS75000

SST

uIO_VDD5 N.P.

R16

1501%

2 1

JI1

OPEN

VIN

Q2B

NO_POP

Q1A

IAUC80N04S6L032

Q2A

IAUC100N04S6L020 Q3B

IAUC80N04S6L032

Q4B

IAUC100N04S6L020

C20 10uF 50V X7R 1210

C6 22uF 25V X7R 1210

GND

C8 22uF 25V X7R 1210

C10 22uF 25V X7R 1210

GNDGND

C22 22uF25VX7R1210

C2 22uF 25V X7R 1210

GND GND

C12 470uF25VPCR1E471MCL1GS

GND

C14 470uF25VPCR1E471MCL1GS

GND

C25

470uF 25VPCR1E471MCL1GS

IINM

R7

1

C26

1uF50V0805

VIN

C17 330uF35VPCR1V331MCL1GS

GND GND

C18 330uF35VPCR1V331MCL1GS

C29

10uF 50VX7R1210

GND

RIIN

1,5m PML100HZPJV1L5

12

1S

2S

RSWCS1

NO POP

1 2

1S

2S RSWCS2

1,5m PML100HZPJV1L5

RSHO1

10mOhm FC4L64R010FER

GND GND

21

J1

CLOSE

C16

330uF 35VPCR1V331MCL1GS

GND GND

C21

330uF 35VPCR1V331MCL1GS

C9

10uF 50VX7R1210

C27 10uF 50V X7R 1210

C28

10uF 50V X7R 1210

VHB

GNDGND GND

RSHO

10mOhm FC4L64R010FER

+VOUT

GND3

GND4

R21

1k5 1%

RG2B1

RG1B

1

RG4A

1

RG3B1

CEN

1uF 50V0805

GND

C19 10uF 50V X7R 1210

GND

VIN undervoltage set to 7,2V (7,4V Exit)

Close=>IReg

IReg->Open

Open=>IReg

PIC101

PIC102

COC1

PIC201

PIC202

COC2

PIC301

PIC302

COC3

PIC401

PIC402

COC4

PIC501

PIC502

COC5

PIC601

PIC602

COC6

PIC701

PIC702

COC7

PIC801

PIC802

COC8

PIC901

PIC902

COC9

PIC1001

PIC1002

COC10

PIC1101

PIC1102

COC11

PIC1201

PIC1202

COC12

PIC1301

PIC1302

COC13

PIC1401

PIC1402

COC14

PIC1501

PIC1502

COC15

PIC1601

PIC1602

COC16

PIC1701

PIC1702

COC17

PIC1801

PIC1802

COC18

PIC1901

PIC1902

COC19

PIC2001

PIC2002

COC20

PIC2101

PIC2102

COC21

PIC2201

PIC2202

COC22

PIC2401

PIC2402

COC24

PIC2501

PIC2502

COC25

PIC2601 PIC2602

COC26

PIC2701

PIC2702

COC27

PIC2801

PIC2802

COC28

PIC2901

PIC2902

COC29

PIC5501

PIC5502

COC55

PIC5601

PIC5602

COC56

PIC6701

PIC6702

COC67

PIC6801

PIC6802

COC68

PIC6901

PIC6902

COC69

PICBS101

PICBS102

COCBS1

PICBS201

PICBS202

COCBS2

PICC101

PICC102

COCC1

PICEN01

PICEN02

COCEN

PICIVCC01

PICIVCC02

COCIVCC

PICMP01

COCMP

PICSN01

COCSN

PICSST01

PICSST02

COCSST

PID20A PID20K

COD2

PID30A PID30K

COD3

PID40A PID40K

COD4

PIDBS10A

PIDBS10K

CODBS1

PIDBS20A

PIDBS20K

CODBS2

PIEN01

COEN

PIEOMFS01

COEOMFS

PIFBH01

COFBH

PIFBL01

COFBL

PIG101

COG1

PIG201

COG2

PIG301

COG3

PIG401

COG4

PIGND01

COGND

PIGND201

COGND2

PIGND301

COGND3

PIGND401

COGND4

PIGND501

COGND5

PIGND001

COGND0

PIIC101

PIIC102

PIIC103

PIIC104

PIIC105

PIIC106

PIIC107

PIIC108

PIIC109

PIIC1010

PIIC1011

PIIC1012

PIIC1013

PIIC1014

PIIC1015

PIIC1016

PIIC1017

PIIC1018

PIIC1019

PIIC1020

PIIC1021

PIIC1022

PIIC1023

PIIC1024

PIIC1025

PIIC1026

PIIC1027

PIIC1028

PIIC1029

PIIC1030

PIIC1031

PIIC1032 PIIC1033

PIIC1034

PIIC1035

PIIC1036

PIIC1037

PIIC1038

PIIC1039

PIIC1040

PIIC1041

PIIC1042

PIIC1043

PIIC1044

PIIC1045

PIIC1046

PIIC1047

PIIC1048

PIIC10EP

COIC1

PIIINM01

COIINM

PIIOUTM01

COIOUTM

PIIVCC01

COIVCC

PIJ101 PIJ102

COJ1

PIJ0EN01

PIJ0EN02

COJ0EN

PIJ0LHI01

PIJ0LHI02

COJ0LHI

PIJ0PWMI01

PIJ0PWMI02

COJ0PWMI

PIJ0uIO01 PIJ0uIO02

PIJ0uIO03 PIJ0uIO04

PIJ0uIO05 PIJ0uIO06

PIJ0uIO07 PIJ0uIO08

PIJ0uIO09

PIJ0uIO010

PIJ0uIO011 PIJ0uIO012

PIJ0uIO013 PIJ0uIO014

PIJ0uIO015 PIJ0uIO016

COJ0uIO

PIJI101

PIJI102

COJI1

PIJV101

PIJV102

COJV1

PIJV201

PIJV202

COJV2

PIJVDD01

PIJVDD02

COJVDD

PIL101

PIL102

COL1

PILED0A

PILED0K

COLED

PILEDC01

COLEDC

PILHI01

COLHI

PIMISO01

COMISO

PIMOSI01

COMOSI

PIPWMI01

COPWMI

PIQ1A0D

PIQ1A0G

PIQ1A0S

COQ1A

PIQ1B0D

PIQ1B0G

PIQ1B0S

COQ1B

PIQ2A0D

PIQ2A0G

PIQ2A0S

COQ2A

PIQ2B0D

PIQ2B0G

PIQ2B0S

COQ2B

PIQ3A0D

PIQ3A0G

PIQ3A0S

COQ3A

PIQ3B0D

PIQ3B0G

PIQ3B0S

COQ3B

PIQ4A0D

PIQ4A0G

PIQ4A0S

COQ4A

PIQ4B0D

PIQ4B0G

PIQ4B0S

COQ4B

PIR101

PIR102

COR1

PIR201

PIR202

COR2

PIR301

PIR302

COR3

PIR401

PIR402

COR4

PIR501

PIR502

COR5

PIR601

PIR602

COR6

PIR701

PIR702

COR7

PIR801

PIR802

COR8

PIR901

PIR902

COR9

PIR1001

PIR1002

COR10

PIR1101 PIR1102

COR11

PIR1201 PIR1202

COR12

PIR1301 PIR1302

COR13

PIR1401 PIR1402

COR14

PIR1601

PIR1602

COR16

PIR1701

PIR1702

COR17

PIR1801

PIR1802

COR18

PIR2101

PIR2102

COR21

PIR8901

PIR8902

COR89

PIR9001

PIR9002

COR90

PIRC101

PIRC102

CORC1

PIRFREQ01

PIRFREQ02

CORFREQ

PIRG1A01 PIRG1A02

CORG1A

PIRG1B01 PIRG1B02

CORG1B

PIRG2A01 PIRG2A02

CORG2A

PIRG2B01 PIRG2B02

CORG2B

PIRG3A01

PIRG3A02

CORG3A

PIRG3B01

PIRG3B02

CORG3B

PIRG4A01

PIRG4A02

CORG4A

PIRG4B01

PIRG4B02

CORG4B

PIRIIN01

PIRIIN01S

PIRIIN02

PIRIIN02S

CORIIN

PIRSET01

PIRSET02

PIRSET03

CORSET

PIRSHO01

PIRSHO01S

PIRSHO02

PIRSHO02S

CORSHO

PIRSHO101

PIRSHO101S

PIRSHO102

PIRSHO102S

CORSHO1

PIRSWCS101

PIRSWCS101S

PIRSWCS102

PIRSWCS102S

CORSWCS1

PIRSWCS201

PIRSWCS201S

PIRSWCS202

PIRSWCS202S

CORSWCS2

PIRVH01 PIRVH02

CORVH

PIRVL01

PIRVL02

CORVL

PIRVOLT01

PIRVOLT02

PIRVOLT03

CORVOLT

PISCLK01

COSCLK

PISET01

COSET

PISST01

COSST

PISWN101

COSWN1

PISWN201

COSWN2

PIuIO0AD001

COuIO0AD0

PIuIO0GP101

COuIO0GP1

PIuIO0GP201

COuIO0GP2

PIuIO0VDD501

COuIO0VDD5

PIVDD01

COVDD

PIVFB01

COVFB

PIVIN01

COVIN

PIVIN001

COVIN0

PIVOUT01

COVOUT

PIVOUT001

COVOUT0

PIC2202

PIJV102

PIRSHO02

PIRSHO101

PIVOUT01

PIVOUT001

NL0VOUT

PICBS102

PIDBS10K

PIIC103

NLBST1

PICBS202

PIDBS20K

PIIC1010

NLBST2

PICMP01

PIIC1019

PIRC102

NLCOMP

PICSN01

PIJ0uIO09

PIR1101

NLCSN

POCSN

PICEN02

PID20K

PIEN01

PIIC1041

PIR301

PIR502

NLEN0INUVLO

PIEOMFS01

PIIC1032

PIR8901

NLEOMFS

PIFBL01

PIIC1014

PIJI102

PIR1602

PIR1702

PIRVOLT01

NLFB0N

PIFBH01

PIIC1013

PIR1601

PIRSHO01S

PIRSHO102S

PIRVH02

NLFB0P

PIC101

PIC201

PIC301

PIC401

PIC501

PIC601

PIC701

PIC801

PIC901

PIC1001

PIC1101

PIC1202

PIC1301

PIC1402

PIC1501

PIC1602

PIC1702

PIC1802

PIC1901

PIC2001

PIC2102

PIC2201

PIC2402 PIC2502

PIC2701 PIC2801

PIC2901

PIC5501

PIC5601

PIC6701

PIC6801

PIC6901

PICC102

PICEN01

PICIVCC02

PICSST01

PIGND01

PIGND201

PIGND301

PIGND401

PIGND501

PIGND001

PIIC101

PIIC105

PIIC108

PIIC1012

PIIC1015

PIIC1026

PIIC1034

PIIC1036

PIIC1040

PIIC1045 PIIC1048

PIIC10EP

PIJ0uIO02

PIJV201

PIR501

PIR1002

PIR2101

PIRFREQ01

PIRSET01

PIRSWCS102 PIRSWCS201

PIRVL01

PIC6902

PIIC1016

PIIOUTM01

NLIOUTMON

PIIC1033

PILEDC01

PIR9002

NLLEDCURR

PIIC1037

PILHI01

PIR102

NLLHI

PIJ0uIO013

PIMISO01

PIR1301

NLMISO

POMISO

PIJ0uIO015

PIMOSI01

PIR1201

NLMOSI

POMOSI

PIC202 PIC602

PIC702

PIC802

PIC1002

PIC1102

PIC1201

PIC1302

PIC1401

PIC2401 PIC2501

PIJV101

PIQ4A0D

PIQ4B0D

PIRSHO01

PIRSHO102

PIC302

PIR801

PIC402

PIR1701

PIC1502

PIR601

PIC2601

PIIC1042

PIR402

PIC2602

PIIC1043

PIR701

PIC6702

PIIC1020

PIRVH01

PIRVL02

PIVFB01

PIC6802

PIIC1023

PICBS101

PIIC104

PIL102

PIQ1A0S

PIQ1B0S

PIQ2A0D

PIQ2B0D

PIR802

PISWN101

PICBS201

PIIC109

PIL101

PIQ3A0D

PIQ3B0D

PIQ4A0S

PIQ4B0S

PIR602

PISWN201

PICC101

PIRC101

PICSST02

PIIC1038

PISST01

PID20A

PIJ0uIO08

POEN0uIO

PID30A

PIJ0uIO014

POPWM0uIO

PID30K

PID40K

PIR901

PIR1001

PID40A

PIJ0PWMI02

PIG101

PIQ1A0G

PIRG1A02

PIG201

PIQ2A0G

PIRG2A02

PIG301

PIQ3B0G

PIRG3B02

PIG401

PIQ4B0G

PIRG4B02

PIIC102

PIRG1A01

PIRG1B01

PIIC106

PIRG2A01

PIRG2B01

PIIC107

PIRG3A01

PIRG3B01

PIIC1011

PIRG4A01

PIRG4B01

PIIC1017

PIRSWCS101S PIRSWCS202S

PIIC1018

PIRSWCS102S PIRSWCS201S

PIIC1022

PIRSET02

PISET01

PIIC1027

PIR1302

PIIC1028

PIR1102

PIIC1029

PIR1402

PIIC1030

PIR1202

PIIC1035

PIRFREQ02

PIIC1039

PIIINM01

PIJ0EN02

PIR302

PIJ0LHI01

PIR101

PIJ0uIO01

PIJ0uIO03 PIJ0uIO04

PIuIO0VDD501

PIJ0uIO05 PIJ0uIO06

PIJ0uIO07

PIJ0uIO010

PIuIO0GP201

PIJ0uIO012

PIuIO0GP101

PIJ0uIO016

PIuIO0AD001

PIJI101

PIRSHO02S

PIRSHO101S

PIJV202

PIR1801

PILED0K

PIR2102

PIQ1B0G

PIRG1B02

PIQ2A0S

PIQ2B0S

PIQ3A0S

PIQ3B0S

PIRSWCS101 PIRSWCS202

PIQ2B0G

PIRG2B02

PIQ3A0G

PIRG3A02

PIQ4A0G

PIRG4A02

PIR201

PIRSET03

PIR401

PIRIIN01S

PIR702

PIRIIN02S

PIR1802

PIRVOLT02

PIRVOLT03

PIIC1024

PIPWMI01

PIR902

NLPWMI

PIJ0uIO011

PIR1401

PISCLK01

NLSCLK

POSCLK

PICIVCC01

PIDBS10A

PIDBS20A

PIIC1021

PIIC1025

PIIC1046

PIIC1047

PIIVCC01

PIJ0LHI02

PIJ0PWMI01

PIJVDD01

PILED0A

PIR202

PIC5602

PIIC1031

PIJVDD02

PIR8902

PIR9001

PIVDD01

PIC102 PIC502

PIC902

PIC1601

PIC1701

PIC1801

PIC1902

PIC2002

PIC2101

PIC2702 PIC2802

PIC5502

PIIC1044

PIJ102

PIJ0EN01

PIQ1A0D

PIQ1B0D

PIRIIN02

PIC2902

PIJ101

PIRIIN01

PIVIN01

PIVIN001

POCSN

POEN0uIO

POMISO

POMOSI

POPWM0uIO

POSCLK

User manual 18 of 19 Rev.1.0

2021-03-04

TLD5542-1HIPOW_EVAL board

Evaluation board manual

List of references

Revision history

Document

version

Date of release

Description of changes

Rev.1.0

2021-03-04

Initial User Manual

Table of contents

Other Infinion Motherboard manuals