InfiniSolar 10KW User manual

Hybrid 10KW PV Inverter

Version: 1.1

User Manual

Table Of Contents

1. Introduction.......................................................................................... 1

2. Important Safety Warning...................................................................... 2

3. Unpacking & Overview .......................................................................... 4

3-1. Packing List................................................................................... 4

3-2. Product Overview .......................................................................... 4

4. Installation ........................................................................................... 5

4-1. Selecting Mounting Location........................................................... 5

4-2. Mounting Unit ............................................................................... 5

5. Grid (Utility) Connection ........................................................................... 7

5-1. Preparation ................................................................................... 7

5-2. Connecting to the AC Utility ........................................................... 7

6. PV Module (DC) Connection ................................................................... 9

7. Battery Connection...............................................................................12

8. Load (AC Output) Connection ...............................................................13

8-1. Preparation ..................................................................................13

8-2. Connecting to the AC output .........................................................13

9. Communication ....................................................................................15

10. Dry Contact Signal ...............................................................................16

10-1. Pin Configuration ........................................................................16

10-2 Cable Preparation ........................................................................17

10-3. Function Description ...................................................................17

11. Relay Control Port ................................................................................19

11.1. Interface Configuration ...............................................................19

11.2. Function Description ...................................................................19

11.3. Application .................................................................................20

12. Application with Energy Meter...............................................................21

13. Commissioning.....................................................................................22

14. Initial Setup .........................................................................................23

15. Operation ............................................................................................35

12-1. Interface....................................................................................35

12-2. LCD Information Define ..............................................................35

12-3. Button Definition ........................................................................36

12-4 Query Menu Operation.................................................................37

12-5. Operation Mode & Display...........................................................40

16. Charging Management .........................................................................44

14. Maintenance & Cleaning.........................................................................46

15. Trouble Shooting ...................................................................................47

15-1. Warning List...............................................................................47

15-2. Fault Reference Codes ................................................................48

16. Specifications ........................................................................................50

1

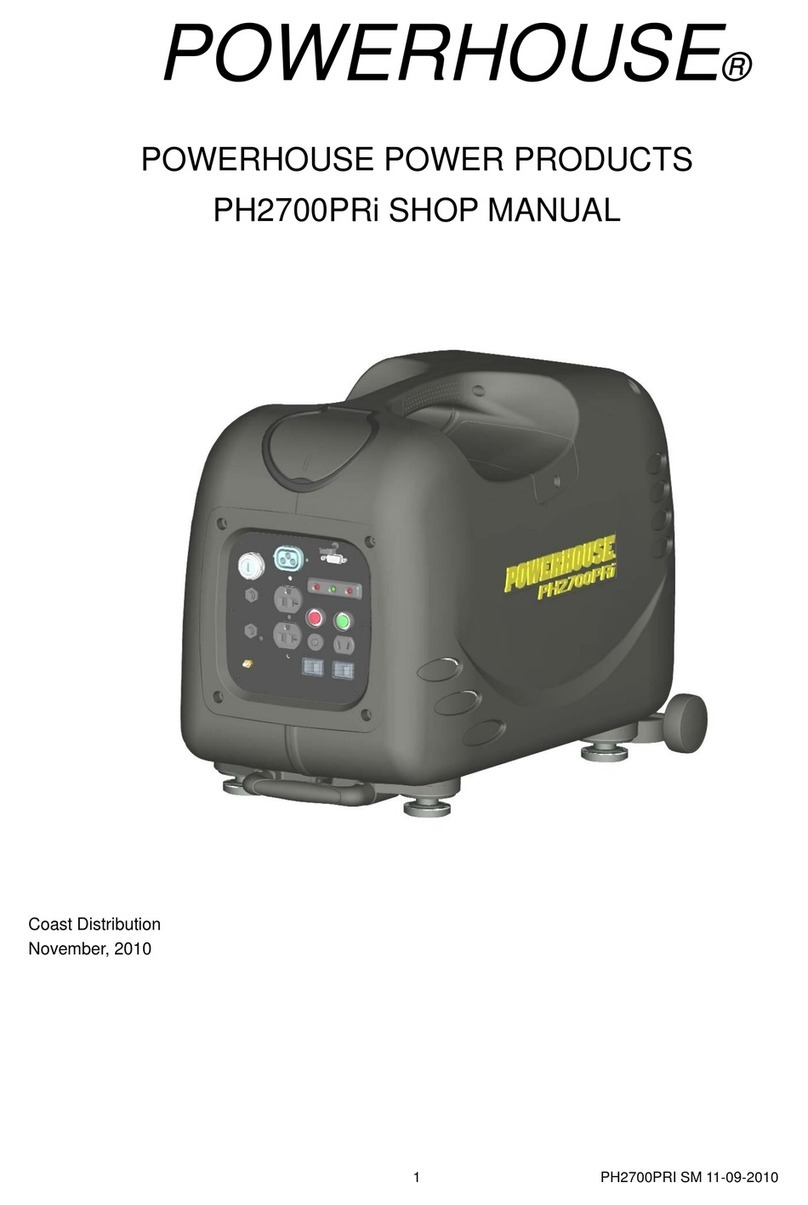

1. Introduction

This hybrid PV inverter can provide power to connected loads by utilizing PV power,

utility power and battery power.

Figure 1 Basic hybrid PV System Overview

Depending on different power situations, this hybrid inverter is designed to generate

continuous power from PV solar modules (solar panels), battery, and the utility. When

MPP input voltage of PV modules is within acceptable range (see specification for the

details), this inverter is able to generate power to feed the grid (utility) and charge

battery. This inverter is only compatible with PV module types of single crystalline and

poly crystalline. Do not connect any PV array types other than these two types of PV

modules to the inverter. Do not connect the positive or negative terminal of the solar

panel to the ground. See Figure 1 for a simple diagram of a typical solar system with this

hybrid inverter.

Note: By following the EEG standard, every inverter sold to German area is not allowed

to charge battery from Utility. The relevant function is automatically disabled by the

software.

PV module

Battery

Hybrid inverter

Distribution Box

Electric grids

Load

2

2. Important Safety Warning

Before using the inverter, please read all instructions and cautionary

markings on the unit and this manual. Store the manual where it can be

accessed easily.

This manual is for qualified personnel. The tasks described in this manual may be

performed by qualified personnel only.

General Precaution-

WARNING! Before installing and using this inverter, read all instructions and cautionary

markings on the inverter and all appropriate sections of this guide.

WARNING! Normally grounded conductors may be ungrounded and energized when a

ground fault is indicated.

WARNING! This inverter is heavy. It should be lifted by at least two persons.

CAUTION! Authorized service personnel should reduce the risk of electrical shock by

disconnecting AC, DC and battery power from the inverter before attempting any

maintenance or cleaning or working on any circuits connected to the inverter. Turning off

controls will not reduce this risk. Internal capacitors can remain charged for 5 minutes

after disconnecting all sources of power.

CAUTION! Do not disassemble this inverter yourself. It contains no user-serviceable

parts. Attempt to service this inverter yourself may cause a risk of electrical shock or fire

and will void the warranty from the manufacturer.

CAUTION! To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that the wire is not undersized. Do not operate the Inverter with

damaged or substandard wiring.

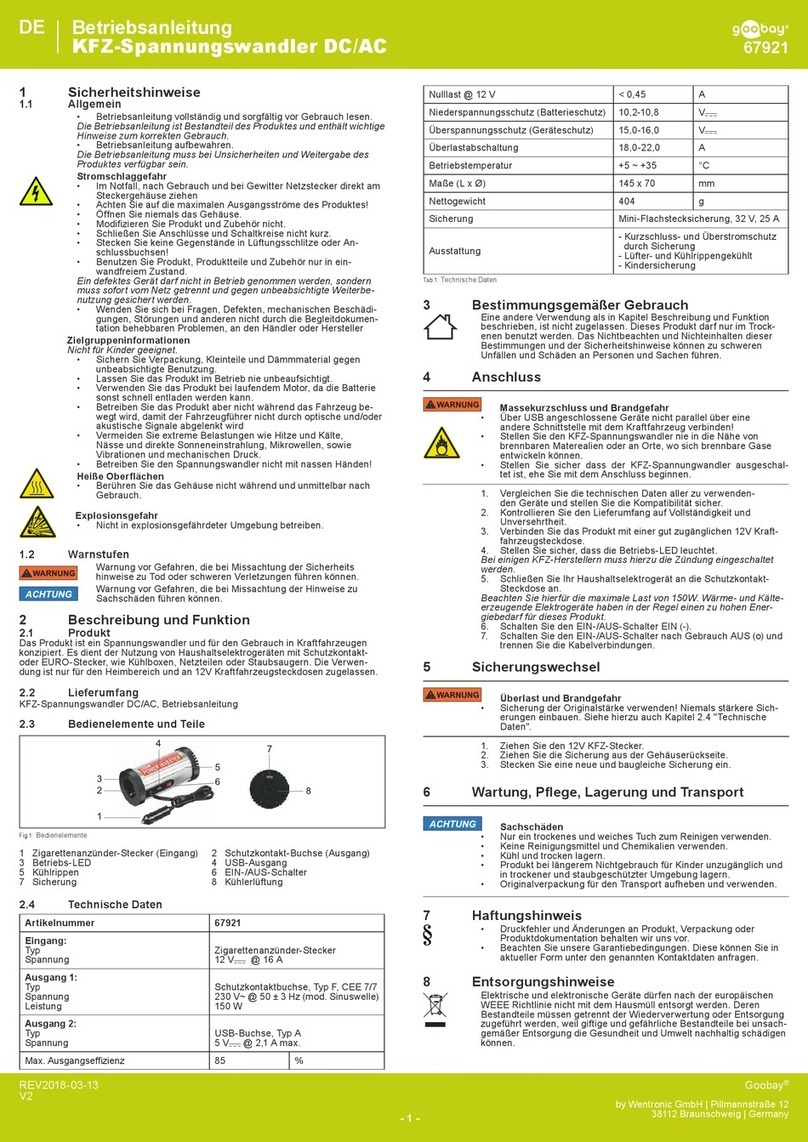

Conventions used:

WARNING! Warnings identify conditions or practices that could result in personal

injury;

CAUTION! Caution identify conditions or practices that could result in damaged to the

unit or other equipment connected.

3

CAUTION! Under high temperature environment, the cover of this inverter could be hot

enough to cause skin burns if accidentally touched. Ensure that this inverter is away

from normal traffic areas.

CAUTION! Use only recommended accessories from installer. Otherwise, not-qualified

tools may cause a risk of fire, electric shock, or injury to persons.

CAUTION! To reduce risk of fire hazard, do not cover or obstruct the cooling fan.

CAUTION! Do not operate the Inverter if it has received a sharp blow, been dropped, or

otherwise damaged in any way. If the Inverter is damaged, please call for an RMA

(Return Material Authorization).

CAUTION! AC breaker, DC switch and Battery circuit breaker are used as disconnect

devices and these disconnect devices shall be easily accessible.

Symbols used in Equipment Markings

Refer to the operating instructions

Caution! Risk of danger

Caution! Risk of electric shock

Caution! Risk of electric shock. Energy storage timed

discharge for 5 minutes.

Caution! Hot surface

Before working on this circuit

-Isolate inverter/Uninterruptible Power System (UPS)

-Then check for Hazardous Voltage between all

terminals including the protective earth.

Risk of Voltage Backfeed

4

3. Unpacking & Overview

3-1. Packing List

Before installation, please inspect the unit. Be sure that nothing inside the package is

damaged. You should have received the following items inside of package:

Inverter unit PV connectors AC connector Mounting plate Fixing screws

Software CD Manual USB cable RS-232 cable Relay control port

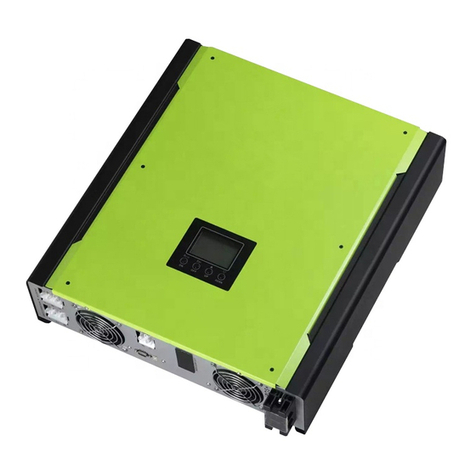

3-2. Product Overview

1) PV connectors

2) AC Grid connectors

3) Battery connectors

4) AC output connectors (Load

connection)

5) RS-232 communication port

6) USB communication port

7) Intelligent slot

8) Grounding

9) LCD display panel (Please check

section 10 for detailed LCD

operation)

10) Operation buttons

11) Dry contact

12) Battery thermal sensor

13) EPO

14) AC circuit breaker

15) DC Switch

16) Relay control port

5

4. Installation

4-1. Selecting Mounting Location

Consider the following points before selecting where to install:

Do not mount the inverter on flammable construction materials.

Mount on a solid surface

This inverter can make noises during operation which may be perceived as a

nuisance in a living area.

Install this inverter at eye level in order to allow the LCD display to be read at all

times.

For proper air circulation to dissipate heat, allow a clearance of approx. 20 cm to

the side and approx. 50 cm above and below the unit.

Dusty conditions on the unit may impair the performance of this inverter.

The ambient temperature should be between 0°C and 40°C and relative humidity

should be between 5% and 85% to ensure optimal operation.

The recommended installation position is to be adhered to (vertical).

For proper operation of this inverter, please use appropriate cables for grid

connection.

The pollution degree of the inverter is PD2. Select an appropriate mounting

location. Install the solar inverter in a protected area that is dry, free of excessive

dust and has adequate air flow. Do NOT operate it where the temperature and

humidity is beyond the specific limits. (Please check the specs for the limitations.)

Installation position shall not prevent access to the disconnection means.

This inverter is designed with IP20 for indoor applications only.

Regularly clean the fan filter.

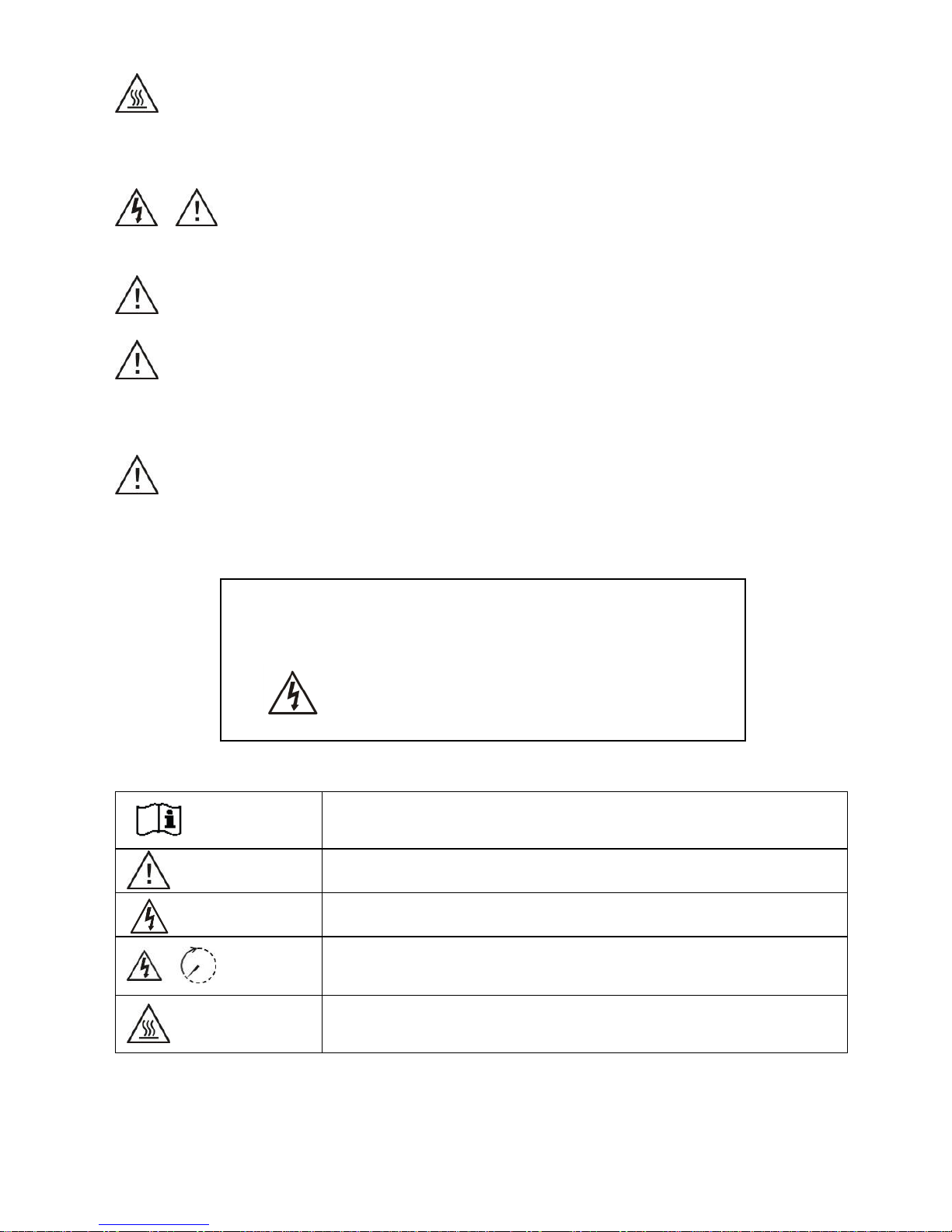

4-2. Mounting Unit

Installation to the wall should be implemented with the proper screws. After that, the

device should be bolted on securely.

The inverter only can be used in a CLOSED ELECTRICAL OPERATING AREA.

WARNING!! Remember that this inverter is heavy! Please be carefully when lifting out

from the package.

WARNING!! FIRE HAZARD.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE SURFACE

ONLY.

6

1. Drill six holes in the marked

locations with supplied six screws.

The reference tightening torque is

35 N.m.

2. Raise the inverter and place it over

the mounting plate.

3. Fix the inverter in position by

screwing the supplied two screws

(M4*12) located on the top two

sides of the inverter.

4. Check if the inverter is firmly secured.

7

5. Grid (Utility) Connection

5-1. Preparation

NOTE: The overvoltage category of the AC input is III. It should be connected to the

power distribution.

NOTE2: The inverter is built in a 25A/400V breaker to protect the inverter from AC

power damage.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for grid (utility) connection. To reduce risk of injury, please use the

proper recommended cable size as below.

Suggested cable requirement for AC wire

Nominal Grid Voltage

230VAC per phase

Conductor cross-section (mm2)

4

AWG no.

12

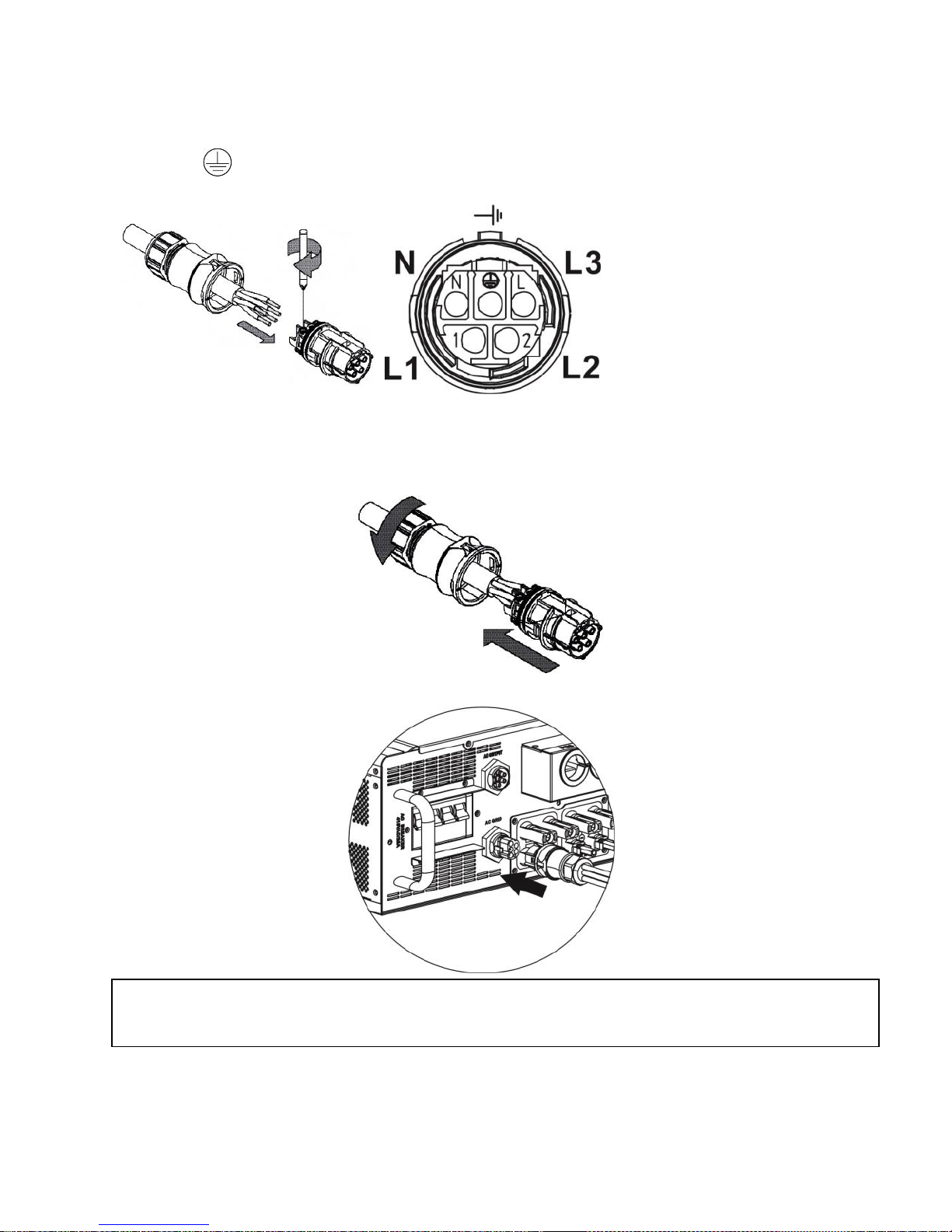

5-2. Connecting to the AC Utility

Overview of AC Connection Socket

Component

Description

A

Pressure dome

B

Sealing nut

C

Protective element

D

Socket element

Step 1: Check the grid voltage and frequency with an AC voltmeter. It should be the

same to “VAC” value on the product label.

Step 2: Turn off the circuit breaker.

Step 3: Thread the five cables through pressure dome (A), sealing nut (B) and protective

element (C) in sequence.

Step 4: Remove insulation sleeve 10 mm for five

conductors.

Step 5: Thread five cables through socket element (D) according to polarities indicated

on it and tighten the screws to fix wires.

8

L1→LINE 1 (Black)

L2→LINE 2 (Grey)

L→LINE 3 (Brown)

→Ground (Yellow-Green)

N→Neutral (Blue)

The reference tightening torque is 0.82 N.m.

Step 6: Push protective dome (C) on to socket element (D) until both are locked tightly.

Then, twist the gland so that all cables are firmly connected.

Step 7: Plug the AC connection socket into AC grid terminal of the inverter.

CAUTION: To prevent risk of electric shock, ensure the ground wire is properly earthed

before operating this hybrid inverter no matter the grid is connected or not.

9

6. PV Module (DC) Connection

CAUTION: Before connecting to PV modules, please install separately a DC circuit

breaker between inverter and PV modules.

NOTE1: Please use 1000VDC/20A circuit breaker.

NOTE2: The overvoltage category of the PV input is II.

Please follow below steps to implement PV module connection:

Step 1: Check the input voltage of PV array modules. The acceptable input voltage of the

inverter is 350VDC - 900VDC. This system is only applied with two strings of PV array.

Please make sure that the maximum current load of each PV input connector is 18.6A.

Step 2: Disconnect the circuit breaker and switch off the DC switch.

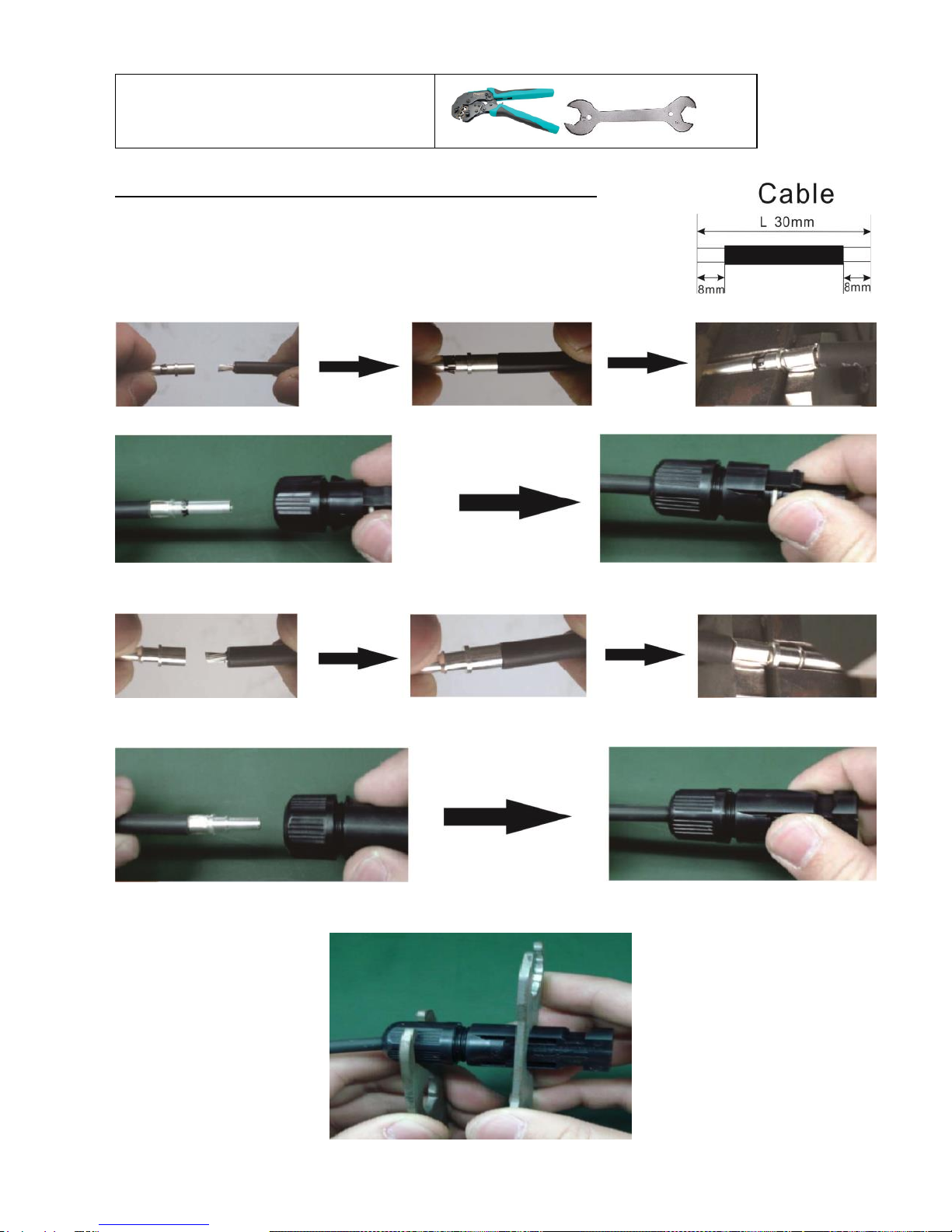

Step 3: Assemble provided PV connectors with PV modules by the following below steps.

Components for PV connectors and Tools:

Female connector housing

Female terminal

Male connector housing

Male terminal

CAUTION: Exceeding the maximum input voltage can destroy the unit!! Check the

system before wire connection.

WARNING: Because this inverter is non-isolated, only three types of PV modules are

acceptable: single crystalline and poly crystalline with class A-rated and CIGS modules.

To avoid any malfunction, do not connect any PV modules with possibility of leakage

current to the inverter. For example, grounded PV modules will cause leakage current to

the inverter. When using CIGS modules, please be sure NOT grounding.

CAUTION: It’s requested to have PV junction box with surge protection. Otherwise, it

will cause inverter damage when lightning occurs on PV modules.

10

Crimping tool and spanner

Cable preparation and connector assembly process:

Strip one cable 8 mm on both end sides and be careful NOT to

nick conductors.

Insert striped cable into female terminal and crimp female

terminal as shown below charts.

Insert assembled cable into female connector housing as shown below charts.

Insert striped cable into male terminal and crimp male terminal as shown below charts.

Insert assembled cable into male connector housing as shown below charts.

Then, use spanner to screw pressure dome tightly to female connector and male

connector as shown below.

11

Step 4: Check correct polarity of connection cable from PV modules and PV input

connectors. Then, connect positive pole (+) of connection cable to positive pole (+) of

PV input connector. Connect negative pole (-) of connection cable to negative pole (-) of

PV input connector.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for PV module connection. To reduce risk of injury, please use the

proper recommended cable size as below.

Conductor cross-section (mm2)

AWG no.

4

12

CAUTION: Do NOT touch the inverter to avoid electric shock. When PV modules are

exposed to sunlight, it may generate DC voltage to the inverter.

CAUTION: Never directly touch terminals of the inverter. It will cause lethal electric

shock.

12

7. Battery Connection

CAUTION: Before connecting to batteries, please install separately a DC circuit

breaker between inverter and batteries.

NOTE1: Please only use sealed lead acid battery, vented and Gel battery. Please check

maximum charging voltage and current when first using this inverter. If using Lithium

iron or Nicd battery, please consult with installer for the details.

NOTE2: Please use 60VDC/300A circuit breaker.

NOTE3: The overvoltage category of the battery input is II.

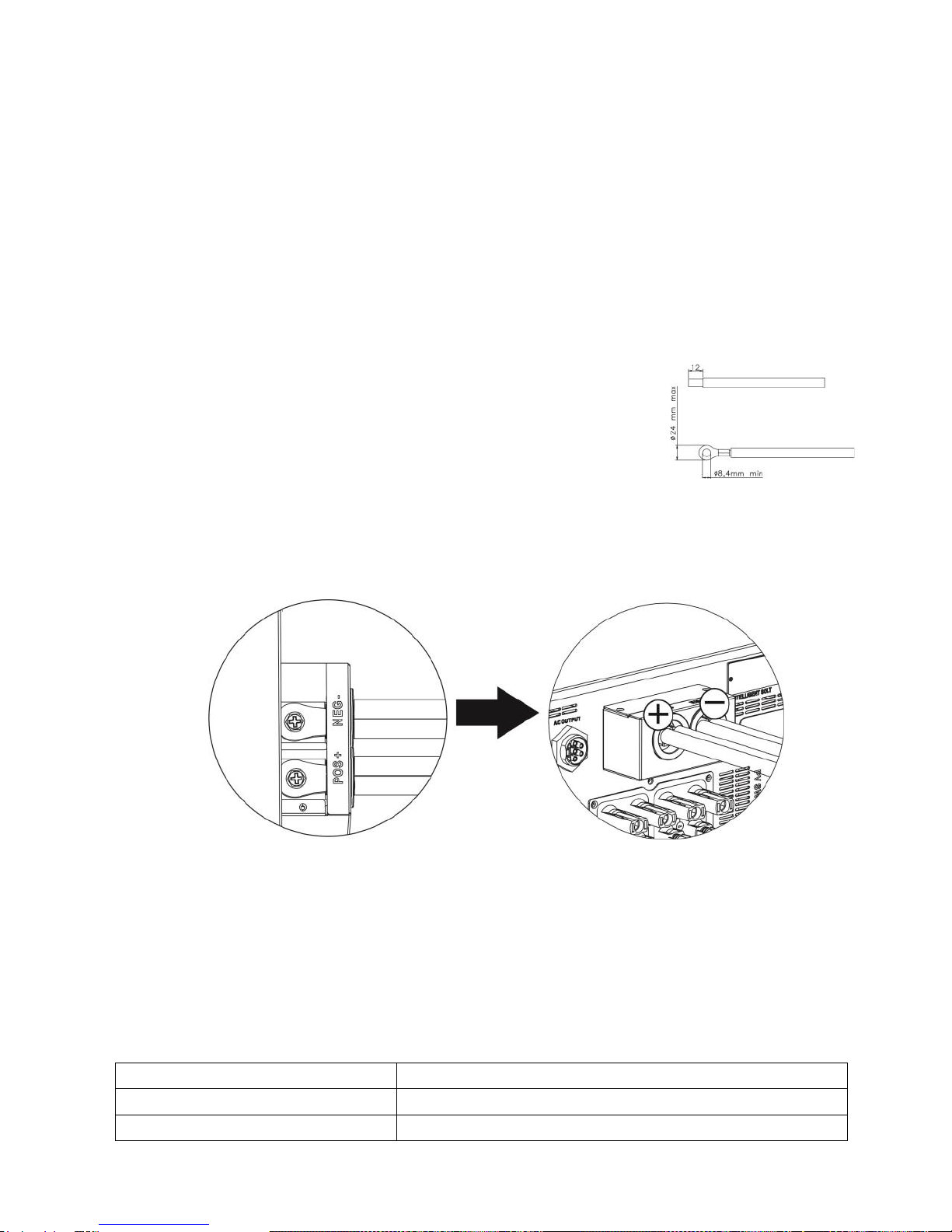

Please follow below steps to implement battery connection:

Step 1: Check the nominal voltage of batteries. The nominal input voltage for inverter is

48VDC.

Step 2: Use two battery cables. Remove insulation sleeve 12

mm and insert conductor into cable ring terminal. Refer to

right chart.

Step 3: Remove battery cover and follow battery polarity guide

printed near the battery terminal! Place the external battery cable ring terminal over the

battery terminal.

RED cable to the positive terminal (+);

BLACK cable to the negative terminal (-).

WARNING! Wrong connections will damage the unit permanently.

Step 4: Make sure the wires are securely connected. The reference tightening torque is

2.04 N.m.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for battery connection. To reduce risk of injury, please use the proper

recommended cable size as below.

Nominal Battery Voltage

48V

Conductor cross-section (mm2)

85

AWG no.

3/0

13

8. Load (AC Output) Connection

8-1. Preparation

CAUTION: To prevent further supply to the load via the inverter during any mode of

operation, an additional disconnection device should be placed on in the building wiring

installation.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for AC connection. To reduce risk of injury, please use the proper

recommended cable size as below.

Model

10KW

Nominal Grid Voltage

208/220/230/240 VAC per phase

Conductor cross-section (mm2)

4

AWG no.

12

8-2. Connecting to the AC output

Overview of Load Connection Socket

Component

Description

A

Pressure dome

B

Sealing nut

C

Protective element

D

Socket element

Step 1: Thread the five cables through A, B and C in sequence.

Step 2: Remove insulation sleeve 10 mm for five

conductors.

Step 3: Connect wires according to polarities indicated

on the Socket element (D) and tighten the screws after connection.

L1→LINE 1 (Black)

L2→LINE 2 (Grey)

L→LINE 3 (Brown)

→Ground (Yellow-Green)

N→Neutral (Blue)

The reference tightening torque is 0.82 N.m.

14

Step 4: Insert C to D, until C and D are locked together. Then twist the gland so that the

cable is firmly connected.

Step 5: Plug the socket into the terminal.

CAUTION: It’s only allowed to connect load to “AC Output Connector”. Do NOT connect

the utility to “AC Output Connector”.

CAUTION: Be sure to connect L terminal of load to L terminal of “AC Output Connector”

and N terminal of load to N terminal of “AC Output Connector”. The G terminal of “AC

Output Connector”is connected to grounding of the load. Do NOT mis-connect.

15

9. Communication

The inverter is equipped with several communication ports and it is also equipped with a

slot for alternative communication interfaces in order to communicate with a PC with

corresponding software. This intelligent slot is suitable to install with SNMP card and

Modbus card. Follow below procedure to connect communication wiring and install the

software.

For RS232 port, you should use a DB9

cable as follows:

For USB port, you should use a USB cable

as follows:

For Dry contact port, you should use a

RJ45 cable as follows:

For SNMP or MODBUS card, you should

use RJ45 cables as follows:

Please install monitoring software in your computer. Detailed information is listed in the

next chapter. After software is installed, you may initial the monitoring software and

extract data through communication port.

16

10. Dry Contact Signal

There is one dry contact available on the bottom panel. It could be used to

remote control for external generator.

10-1. Pin Configuration

Pin

Function

1

N/A

2

N/A

3

N/A

4

N/A

5

Dry Contact-Common

6

N/A

7

Dry Contact (NO)

8

N/A

Internal circuit of dry contact:

12

34

56

78

Common

Normally open

Electric Parameter of dry contact:

Parameter

Symbol

Max.

Unit

Relay DC voltage

Vdc

30

V

Relay DC current

Idc

1

A

Note: The application of the dry contact should not exceed the electric

parameter shown as above. Otherwise, the internal relay will be damaged.

17

10-2 Cable Preparation

Please prepare a cable as below:

Below chart is a recommended external circuit wiring.

12

34

56

78

+12V

Generator

Trigger

10-3. Function Description

Unit

Status

Condition

Dry contact

port:

Pin5 & Pin 7

Power Off

Unit is off and no output is powered.

Open

Power On

Battery voltage is lower than setting battery

cut-off discharging voltage when grid is

available.

Close

Battery voltage is lower than setting battery

cut-off discharging voltage when grid is

unavailable.

Close

Battery voltage is higher than below 2 setting

values:

1. Battery re-discharging voltage when grid

is available.

2. Battery re-discharging voltage when grid

unavailable.

Open

You can set the related parameters in software. Refer to below chart:

18

Table of contents

Other InfiniSolar Inverter manuals

Popular Inverter manuals by other brands

Veichi

Veichi SI30 series manual

Enercell

Enercell 175-Watt Pocket Power Inverter user guide

IO-Power Technology

IO-Power Technology Cloudy-Solar Collection IOP-USSS-12V1224-OA... user manual

Northern Lights

Northern Lights NL773LW3 Operator's manual

OmniPower

OmniPower OHY1P4803 user manual

Victron energy

Victron energy Phoenix Inverter Smart 12/1600 manual