v

7-1

7-2

7-3

Section 7. REMOTE CONTROLLER FUNCTIONS SECTION...............................................

7-2. List of Simple Setting Items................................................................................................. 7-47-3. Detailed Settings Function .................................................................................................. 7-57-4. List of Detailed Setting Items .............................................................................................. 7-87-5. Simple Setting Items ............................................................................................................

7-107-6. Detailed Setting Items ........................................................................................................ 7-137-7. Remote Controller Servicing Functions .......................................................................... 7-147-8. Test Run Function ..............................................................................................................

7-1. Simple Settings Function ....................................................................................................

8-1

8-2

8-3

Section 8. HOW TO INSTALL THE WIRELESS REMOTE CONTROLLER RECEIVER.......

Important Safety Instructions ...............................................................................................

Optional Controller (Remote Controller) ..............................................................................

8-5

8-5

8-3

8-6

8-7

8-8

8-8

8-9

8-9

8-9

8-11

8-12

8-13

8-14

8-14

8-16

8-20

60Bὒᕞࢩࣥࢢࣝኳᇙ60LQGE

8-1. Names and Functions ..........................................................................................................

8-2. Installing Batteries ...............................................................................................................

8-3. Setting the Current Time .....................................................................................................

8-4. Operation ..............................................................................................................................

8-5. Timer Operation ...................................................................................................................

8-6. Adjusting the Wind Direction ..............................................................................................

8-7. Operating Multiple In/Outdoor Units Simultaneously (Group Control) ..........................

8-8. Using the Remote Controller ..............................................................................................

8-9. For Best Results ..................................................................................................................

8-10. Addresses ..........................................................................................................................

8-11. Emergency Operation ......................................................................................................

8-12. Miscellaneous Settings ....................................................................................................

8-13. Before Requesting Service ..............................................................................................

How to Install the Wireless Remote Controller Receiver ..................................................

8-14. Common to All Models ....................................................................................................

8-15. CZ-RWSC3 ........................................................................................................................

8-16. Common to All Models ....................................................................................................

—— CONTENTS ——

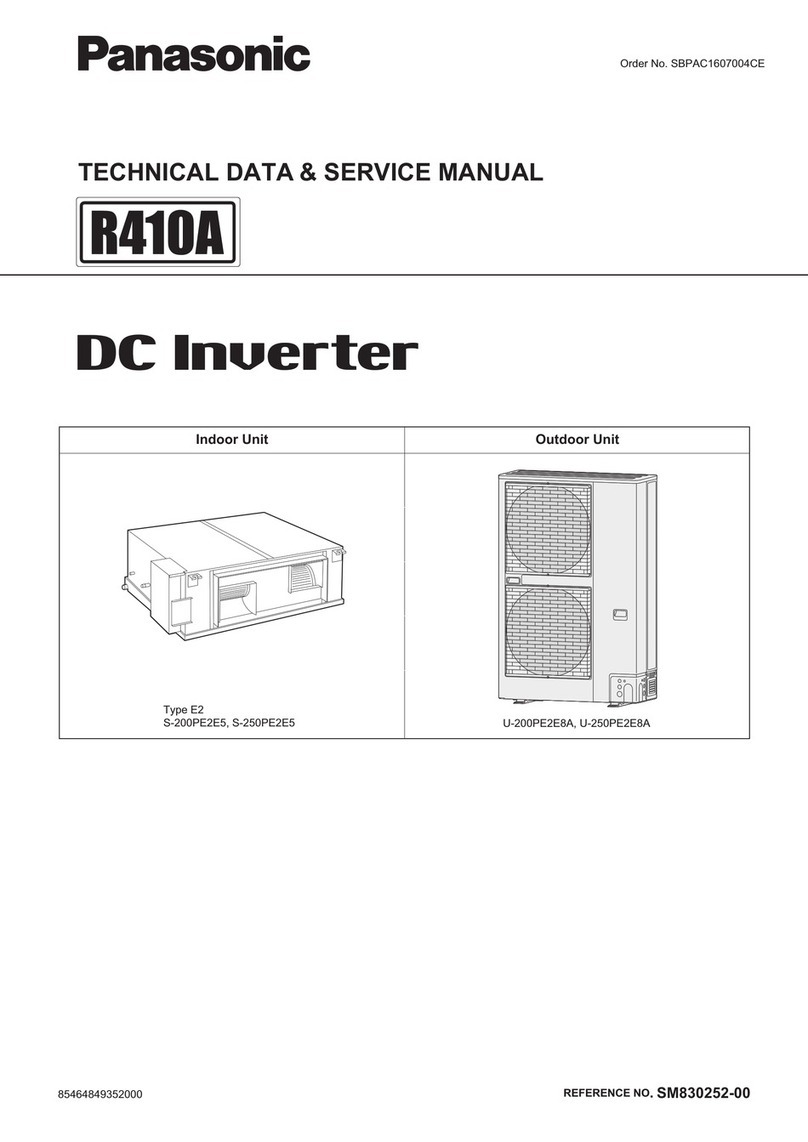

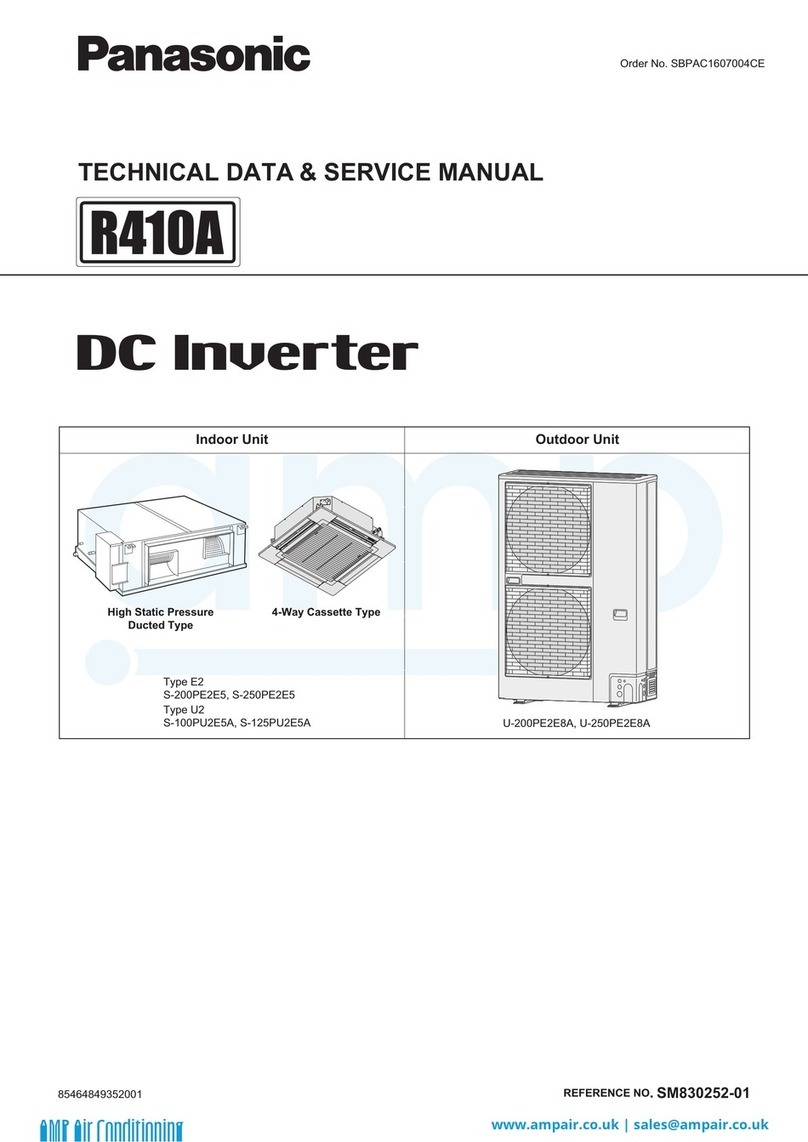

Section 1. SPECI FI CA TI ONS

1-1. U nit Specif ications

1-2. M aj or Component Specif ications

1-3 . Other Component Specif ications

1-4. D imensional D ata

1-5 . Ref rigerant Flow D iagram

1-6 . Operating Range

...................................................................................................1-1

...............................................................................................................2-1

...............................................................................................3 -1

.......................................................................................1-14

.................................................................................................................1-18

...................................................................................................1-22

..................................................................................................................1-23

.................................1-24

........................................................................................................1-26

........................................................................................................1-3 4

.....................................................................................................1-41

.............................................................................................1-6 8

............................................................................................................1-7 1

.............................................................................1-7 1

.........................................................................1-7 2

...................................................1-7 3

................................................................1-7 3

....................................................................................................................1-8 8

.............................................................................3 -2

................................................................................3 -4

.........................................................................................1-6

.................................................................................................................1-2

1-7 . Capacity Correction G raph A ccording to Temperature Condition

1-8 . Noise Criterion Curv es ......................................................................................................1-29

1-9. I ndoor Fan Perf ormance

1-10 . EL ECTRI CA L WI RI NG

1-11. I nstallation I nstructions

Section 2. TEST RU N

Section 3 . EL ECTRI CA L D A TA

3 -2. I ndoor U nits (Electric Wiring D iagram)

3 -1. Outdoor U nits (Electric Wiring D iagram)

................................................................................4-1

..................................................................................................................4-2

............................................4-8

Section 4. PROCESS A ND FU NCTI ONS

4-2. Outdoor U nit Control PCB (A CX A 7 3 -0 47 7 0 , A CX A 7 3 -0 47 5 0 )

4-1. Control Functions

..........................................................................................5 -1

........................................................5 -2

.............................................................................5 -4

Section 5 . TROU BL E D I A G NOSI S

.....................................................................................................5 -5

.....................................................................................5 -3 2

...............5 -3 3

.....5 -3 4

...................................................................................5 -3 5

........................................................................................5 -3 6

................................................................5 -3 7

.............5 -3 8

5 -1. Contents of Remote Controller Switch A larm D isplay

5 -2. Outdoor U nit Control Panel L ED D isplay

5 -3 . PA C Sy stem A larm Codes

5 -4. I nspection of Parts (Outdoor U nit)

5 -5 . Sy mptom: Thermostat in OFF continues or cy cles OFF & ON too f req uently

5 -6 . Sensor Temperature D isplay Function

(D isplay ed regardless of operation and stop)

5 -7 . Table of Thermistor Characteristics

5 -8 . How to Remov e the Compressor

5 -9. How to Remov e the Electrical Component Box

5 -10 . Sy mptom: Thermostat in OFF continues or cy cles OFF & ON too f req uently

..............................6 -1

.................................................................................................................................6 -2

................................................................................................................................6 -2

Section 6 . OU TD OOR U NI T M A I NTENA NCE REM OTE CONTROL L ER

.........................................................................6 -3

....6 -8

...6 -10

........................................................6 -11

6 -1. Ov erv iew

6 -2. Functions

6 -3 . Normal D isplay Operations and Functions

6 -4.

M onitoring Operations: D isplay of I ndoor U nit and Outdoor U nit Sensor Temperatures

6 -5 . M onitoring the Outdoor U nit A larm History : D isplay of Outdoor U nit A larm History

6 -6 . Settings M odes: Setting the Outdoor U nit EEPROM

..........................................................................................................2-2

....................................................................................................................................2-22-2. Caution ...............................................................................................................2-22-3 . Test Run Procedure ....................................................................................2-32-4. I tems to Check Bef ore the Test Run ................................................................................2-32-5 . Test Run U sing the Remote Controller

.............................................................................................................................2-42-6 . Precautions .........................................................2-52-7 . Table of Self -D iagnostic Functions and Corrections

.......................................................................................................................2-62-8 . Sy stem Control ......................................................................................................2-122-9. Caution f or Pump D own

2-1. Preparing f or Test Run

I ndoor U nits (Ty pe E1, E3 )

..........................................................................4-124-3 . Outdoor U nit HI C Board (A CX A 7 3 -0 47 6 0 ) ...........................................................4-134-4. I ndoor U nit Control PCB Switches and Functions

1-12. HOW TO PROCESS TU BI NG

1-13 . V A CU U M PU RG I NG

1-14. REG A RD I NG REFRI G ERA NT FI L L I NG

1-15 . PRECA U TI ONS REG A RD I NG TEST RU N

1-16 . CHECK S A FTER I NSTA L L A TI ON HA V E COM PL ETED

1-17 . REG A RD I NG D EL I V ERY TO THE CU STOM ER

1-19. Capacity Table

.........................................................................................................................1-7 4

1-18 . Supplement

SM830262-00_大洋州向け シングル天埋_TD&SM.indb 6 18/01/26 14:04:02