Infinite Transtector DCPDU2B Series User manual

Installation Manual

© 2021 Innite Electronics, Inc. Transtector is a registered trademark of Innite Electronics, Inc. | DCPDU2B-M Rev. 1

DCPDU2B Series Power Distribution Units

Installation Manual | DCPDU2B Series Power Distribution Units

2+1 (208) 635-6400 | www.transtector.com

REV DESCRIPTION CHK’d & APPR’d / DATE

1 Production Release DR / 01-29-21

Contents

1.0 INTRODUCTION...............................................................................................................4

2.0 FEATURES........................................................................................................................4

3.0 PRODUCT LINE................................................................................................................5

4.0 SAFETY & INDUSTRY STANDARDS...............................................................................6

5.0 WARRANTY (summary)....................................................................................................6

6.0 DESCRIPTION OF OPERATION......................................................................................7

7.0 SPECIFICATIONS.............................................................................................................8

8.0 FRONT PANEL DESCRIPTION ........................................................................................8

9.0 BACK PANEL DESCRIPTION...........................................................................................9

10.0 UNPACKING AND INSPECTION ....................................................................................13

11.0 INSTALLATION................................................................................................................14

13.0 SETUPAND TESTING....................................................................................................18

3

+1 (208) 635-6400 | www.transtector.com

FIGURES

Figure 1. DCPDU2B DC Power Distribution Panel........................................................................4

Figure 2. Block Diagram..................................................................................................................7

Figure 3. Front Panel View.............................................................................................................8

Figure 4. Back Panel View..............................................................................................................9

Figure 5. Input Bus Bar Detail........................................................................................................9

Figure 6. Output Barrier Strip Detail............................................................................................10

Figure 7. Alarm Connection Detail...............................................................................................11

Figure 8. Form-C Relay Schematic ..............................................................................................11

Figure 9. Chassis Ground Connection..........................................................................................12

Figure 10. Series Connection of Multiple Panels .........................................................................14

Installation Manual | DCPDU2B Series Power Distribution Units

4+1 (208) 635-6400 | www.transtector.com

OPERATING MANUAL

DCPDU2B SERIES DC POWER DISTRIBUTION PANELS

1.0 INTRODUCTION

DCPDU2BSeries circuitbreakerpanels providedistributionand overloadprotectionfor 1to20 circuits

with circuit breakers that can be eld installed/exchanged using a supplied puller tool. The panels

are only two mounting positions (3.5 inches) high.

The panels provide up to 20 breakers single bus 450A or 10A+10B 450A+450A distribution and

alarm capabilities. The A and B sections of the dual-bus panel are fully isolated, can be separately

congured for 24/48 volts and are polarity neutral. Breaker capacities range from 2.5 to 200 amperes.

Breaker alarm is indicated by a dual color LED (green/red) and Form C relay contacts for each bus.

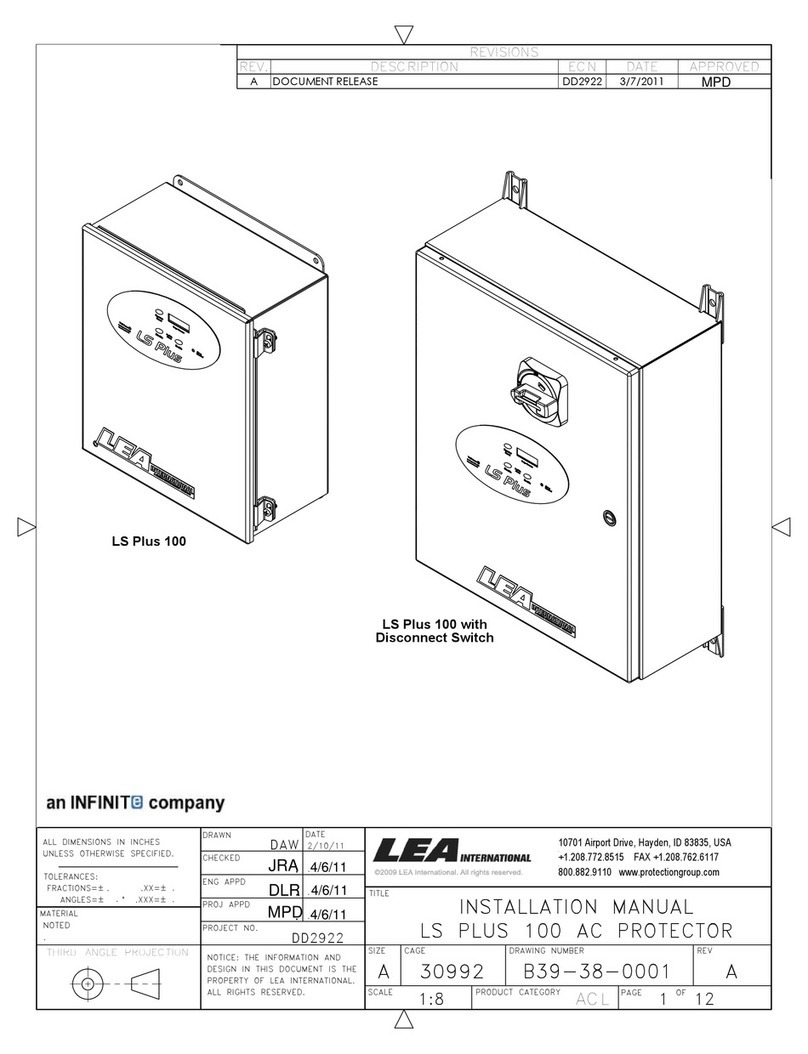

Figure 1. DCPDU2B DC Power Distribution Panel

2.0 FEATURES

48/24V Tapered entry for easy insertion

POLARITY NEUTRAL NO or NC alarm contacts

450A bus bar inputs Alarm LEDs

Single or Dual Feed Power Fail form-C alarm

Rear panel safety cover standard 19” & 23” mounting brackets

5

+1 (208) 635-6400 | www.transtector.com

3.0 PRODUCT LINE

3.1 Congurations

The following table lists the 5 available congurations of the DCPDU2B series.

STANDARD DUAL FEED CONFIGURATIONS

MODEL

NUMBER VOLTS

EACH FEED INPUT

FEEDS MAX. #

BREAKERS AMPS

EACH FEED TOTAL

AMPS

DCPDU2B-D-2X10-450 48/24 - 48/24 2 10 A side

&

10 B side 450 900

OPTIONAL SINGLE FEED CONFIGURATIONS

MODEL

NUMBER VOLTS

EACH FEED INPUT

FEEDS MAX. #

BREAKERS AMPS

EACH FEED TOTAL

AMPS

DCPDU2B-S-X20-450 48/24 1 20 450 450

3.2 Available Breakers1

AMPS PART NUMBER AMPS PART NUMBER

2.5 DCBKR2B-2.5 50 DCBKR2B-50

5 DCBKR2B-5 60 DCBKR2B-60

10 DCBKR2B-10 80 DCBKR2B-80

15 DCBKR2B-15 100 DCBKR2B-100

20 DCBKR2B-20 1252 DCBKR2B-125

25 DCBKR2B-25 1502 DCBKR2B-150

30 DCBKR2B-30 2002 DCBKR2B-200

40 DCBKR2B-40

NOTES:

1. Breakers need to be ordered individually and are shipped separately.

2. Require two positions. Includes paralleling bars to connect output load terminals.

3. Breakers are magnetic-hydraulic plug-in type with auxiliary contacts (Normally Open) and mid-trip

function. Only the following types may be installed.

2.5A to 100A:

CBI D-Frame Series single pole,

D-2A23XANBSXXXXLXB-XXXXXWDVAX2-X

or

Carling C-Series Handle single pole, CT1-B2-14-XXX-A11-MJ

125A to 200A:

CBI D-Frame Series, parallel pole,

D-2A23XBNBSXXXXLAM-XXXXXWDVAX3-X

or

Carling C-Series Handle Parallel pole, CT2-P2-04-XXX-A11-MK

Installation Manual | DCPDU2B Series Power Distribution Units

6+1 (208) 635-6400 | www.transtector.com

4.0 SAFETY & INDUSTRY STANDARDS

4.1 DCPDU2B Series power distribution panels meet the following safety requirements:

STANDARD

UL60950-1, 2nd Edition

CSA22.2 No. 60950-1, 2nd Edition

EN60950-1, 2nd Edition

4.2 DCPDU2B Series power distribution panels are CE marked to indicate conformance

to the European Union’s Low Voltage Directive.

4.3 These Distribution Panels operate at voltages that could potentially be hazardous.

Furthermore, inadvertent short circuiting of the system battery and/or rectier by mis-

connection or other error could be harmful. This product should be handled, tested

and installed only by qualied technical persons who are trained in the use of power

systems and are well aware of the hazards involved.

4.4 When operating this Distribution Panels the chassis ground terminal must be

connected to the system frame ground or other proper safety ground for the protection

of personnel.

4.5 Allconnectionsto theDistributionPanelsshould becarefullychecked forerrorsbefore

applying power to them.

4.6 The internal voltages may be at hazardous potentials. The top cover should not be

removed. There are no user-serviceable components in these units. Removing the

top cover will void the warranty.

5.0 WARRANTY (summary)

DCPDU2B Series power distribution panels are warranted for two (2) years from date of

shipment against defects in material and workmanship. This warranty does not extend

to products which have been opened, altered or repaired by persons other than persons

authorized by the manufacturer or to products which become defective due to acts of God,

negligence or the failure of customer to fully follow instructions with respect to installation,

application or maintenance.

For a complete text of Transtector’s warranty conditions please request a copy from your

local Sales Oce.

7

+1 (208) 635-6400 | www.transtector.com

6.0 DESCRIPTION OF OPERATION

6.1 Power Distribution Circuits. A simplied schematic diagram of the distribution

panels is shown in Figure 2. The battery input to each load connects to a high-current

copper bus bar from which the individual fuses or circuit breakers distribute power to

the loads. The return input connects to a similar bus bar to which the individual loads

terminate. The A and B loads are totally independent and isolated with the exception

of models incorporating the ‘S’ option.

CIRCUIT

BREAKERS

BATT.

BATT.

INPUT

RET.

INPUT

RET.

HI-CURRENT BUS BAR HI-CURRENT BUS BAR

HI-CURRENT BUS BAR HI-CURRENT BUS BAR

LOADS LOADS

1 2 3... N

A SIDE

ALARM

CIRCUITS

B SIDE

ALARM

CIRCUITS

A SIDE B SIDE

-S OPTION

-S OPTION

1 2 3... N

Figure 2. Block Diagram

6.2 Alarm Circuits. The alarm circuits detect a tripped circuit breaker and, in this event,

turn on the red part of the LEDs. The alarm circuits also each drive Form C relay

contacts. If one or more circuits open or if there is an input power failure, the relays

are de-energized and the contacts are used to control external audible or visual alarms.

The A and B alarm circuits are also independent and isolated from each other.

LED & RELAY STATE MEANINGS

LED State Relay State Meaning

Green Energized (N.O. is closed) OK

Red De-energized

(N.O. is open) Breaker Trip

OFF No Input Power

Installation Manual | DCPDU2B Series Power Distribution Units

8+1 (208) 635-6400 | www.transtector.com

7.0 SPECIFICATIONS

The following specications are typical at 25°C unless otherwise noted.

INPUT/OUTPUT

Panel Capacity

@35°C..............................................................................450A per Bus

@40°C..............................................................................400A per Bus

@50°C..............................................................................320A per Bus

@70°C..............................................................................200A per Bus

Conguration ..................................450A Single Bus with 1 to 20 Breakers

900A Dual Bus 1 to 10 Breakers Each Bus

Breaker Capacity 1................................................................. 2.5A to 200A

Voltage 1.....................................................................................21-60VDC

Polarity ............................................Neutral, Positive or Negative Ground

ALARMS

Alarm Indicator ....................................................Dual Color LED Per Bus

LED Status Indication........................................................Green = Normal

Red = CB Trip Alarm

O = No Power

Alarm Relays.............................................. Form C Contacts for each Bus

SAFETY.................... UL60950-1 2nd Ed., CSA22.2 No. 60950-1 2nd Ed.,

EN60950-1 2nd Ed.

ENVIRONMENTAL

Operating Temp. Range ..................................................... -10°C to +70°C

Storage Temp. Range........................................................ -40°C to + 85°C

Humidity........................................................ 0% to 95%, Non-Condensing

PHYSICAL SPECIFICATIONS

Case Material ......................................................................................Steel

Finish............................................................................Powder Coat Black

Case Dimensions, Inches (mm) ........................3.45 H x 17.16 W x 5.98 D

(87.6 x 435.9 x 151.9

Weight (approx.)........................................................... 12.5 lbs. (5.67 kg.)

Rack Mounting...................................................................... 19 or 23 Inch

CONNECTIONS

Input Connections...........................................................................Bus Bar

Output Connections...............................................1/4-20 Stud, 2-hole lugs

Chassis Ground Connection..................................1/4-20 Stud, 2-hole lugs

Alarm Relay Connections...................Spring Clamp Terminals,16-26AWG

Notes:

1. See ordering guide to specify.

8.0 FRONT PANEL DESCRIPTION

The front panel of the DCPDU2B, shown in Figure 3 below, consists of the A and B sides

and a center section. The A and B sides can each accommodate up to 10 eld installed/

replaceable hydraulic magnetic circuit breakers rated from 2.5A to 200A. The center section

has two green/red LEDs, one for the A side (left) and the other for the B side (right). At the

bottom of this center section is a slot for a wallet and designator card. This card permits the

recording of each output circuit by number.

A - ALM B - ALM

123456789 10

A BUS - 450A MAX/100A MAX PER CB

123456789 10

B BUS - 450A MAX/100A MAX PER CB

NO-C-NC NO-C-NC

ALM-B

ALM-A

NO-C-NC NO-C-NC

1098765432 1

0.63

(16.0)

0.76

(19.3)

0.42

(10.7)

0.25

(6.4)

1/4-20 stud

length = 0.50 (12.7),

0.625 (15.88) spacing

1/4-20 stud

length = 0.38 (9.7),

0.625 (15.88) spacing

0.57

(14.5)

0.37

(9.4)

0.90

(22.9)

ø 0.306 (7.8)

0.49 (12.5) x

0.31 (7.9) slot

3.50

(88.9)

1.25

(31.8)

5.98

(151.9)

0.60

(15.2)

17.16

(435.9)

0.76

(19.3)

1.725

(43.82)

0.56

(14.2)

0.21

(5.3)

1.13

(28.7) 0.22

(5.6)

3.45

(87.6)

A - BUS OUTPUT FEEDB - BUS OUTPUT FEED

A - BUS RETURNB - BUS RETURN

B - BUS FEED BREAKERS

A - BUS FEED BREAKERS

Alarm connector

Chassis GND

(1/4-20 THREAD)

A - BUS INPUT

FEED

B - BUS INPUT

FEED

1098765432 1

Shorting Bus (-S Models)

OUTLINE OF SAFETY COVER

(blue dotted line)

4.60

(116.8)

0.625

(15.88)

0.500

(12.70)

0.750

(19.05)

4.642

(117.91)

Figure 3. Front Panel View

9

+1 (208) 635-6400 | www.transtector.com

9.0 BACK PANEL DESCRIPTION

9.1 Back View. Figure 4 shows the back of the DCPDU2B distribution panel. Inputs are

at the left and right ends of the back panel. Side B outputs are at two rows of barrier

terminal strips on the left side, and side A outputs are the same on the right side.

At the center of the back panel are two spring clamp terminal blocks for the Form C

relay contact outputs.

Below these is a chassis ground terminal.

A - ALM B - ALM

123456789 10

A BUS - 450A MAX/100A MAX PER CB

123456789 10

B BUS - 450A MAX/100A MAX PER CB

NO-C-NC NO-C-NC

ALM-B

ALM-A

NO-C-NC NO-C-NC

1098765432 1

0.63

(16.0)

0.76

(19.3)

0.42

(10.7)

0.25

(6.4)

1/4-20 stud

length = 0.50 (12.7),

0.625 (15.88) spacing

1/4-20 stud

length = 0.38 (9.7),

0.625 (15.88) spacing

0.57

(14.5)

0.37

(9.4)

0.90

(22.9)

ø 0.306 (7.8)

0.49 (12.5) x

0.31 (7.9) slot

3.50

(88.9)

1.25

(31.8)

5.98

(151.9)

0.60

(15.2)

17.16

(435.9)

0.76

(19.3)

1.725

(43.82)

0.56

(14.2)

0.21

(5.3)

1.13

(28.7) 0.22

(5.6)

3.45

(87.6)

A - BUS OUTPUT FEEDB - BUS OUTPUT FEED

A - BUS RETURNB - BUS RETURN

B - BUS FEED BREAKERS

A - BUS FEED BREAKERS

Alarm connector

Chassis GND

(1/4-20 THREAD)

A - BUS INPUT

FEED

B - BUS INPUT

FEED

1098765432 1

Shorting Bus (-S Models)

OUTLINE OF SAFETY COVER

(blue dotted line)

4.60

(116.8)

0.625

(15.88)

0.500

(12.70)

0.750

(19.05)

4.642

(117.91)

Figure 4. Back Panel View

9.2 Input Connections. See Figure 5. The DC power inputs to the distribution panel

are made by means of crimp type lugs to two copper bus bars on side A and side B.

The upper bus bar is the battery connection (whether + or -) and the lower bus bar

is the return (whether + or -).

0.37

(9.4)

0.90

(22.9)

ø

0.306 (7.8)

0.49 (12.5) x 0.31 (7.9) slot

0.76

(19.3)

1.12

(28.4)

0.56

(14.2)

1.13

(28.7)

Figure 5. Input Bus Bar Detail

Installation Manual | DCPDU2B Series Power Distribution Units

10 +1 (208) 635-6400 | www.transtector.com

9.3 Recommended Input Cable Sizes and Lugs

The following table details the recommended cable size for various input current.

MAXIMUM

CURRENT CONDUCTOR

SIZE PANDUIT CORP.

PART NUMBER TORQUE

1/4 x 20 BOLT

450A 350KCMIL LCC350-14BW-X 62 in-lbs

400A 300KCMIL LCCX250-14B-X 62 in-lbs

320A 4/0 AWG LCCX4/0-14B-X 62 in-lbs

200A 3/0 AWG LCCX3/0-14B-X 62 in-lbs

150A 1/0 AWG LCCX1/0-14B-X 62 in-lbs

9.4 Output Connections. Output connections for A and B loads are shown in Figure 4.

There are 10 sets of bus bar terminals for each side, Aand B. The connections are

numbered to correspond with the numbers of the front panel breakers. The upper

strip connections are from the battery (FEED) through the breakers; the lower strip

connections are the RETURNS. Side B is on the left and side A on the right when

viewed from the rear.

All connections use 1/4-20 threaded studs and are rated up to 100 amperes. Maximum

wire size is 2 AWG. Transtector recommends using FLEX wire with either Panduit

LCDXN2-14A-E or LCDXN2-14AF-E (90deg angle) lugs. When 125A, 150A or 200A

breakers are installed two positions are utilized. Figure 6 below shows detailed

spacing of the terminals.

A - ALM B - ALM

123456789 10

A BUS - 450A MAX/100A MAX PER CB

123456789 10

B BUS - 450A MAX/100A MAX PER CB

NO-C-NC NO-C-NC

ALM-B

ALM-A

NO-C-NC NO-C-NC

1098765432 1

0.63

(16.0)

0.76

(19.3)

0.42

(10.7)

0.25

(6.4)

1/4-20 stud

length = 0.50 (12.7),

0.625 (15.88) spacing

1/4-20 stud

length = 0.38 (9.7),

0.625 (15.88) spacing

0.57

(14.5)

0.37

(9.4)

0.90

(22.9)

ø 0.306 (7.8)

0.49 (12.5) x

0.31 (7.9) slot

3.50

(88.9)

1.25

(31.8)

5.98

(151.9)

0.60

(15.2)

17.16

(435.9)

0.76

(19.3)

1.725

(43.82)

0.56

(14.2)

0.21

(5.3)

1.13

(28.7) 0.22

(5.6)

3.45

(87.6)

A - BUS OUTPUT FEEDB - BUS OUTPUT FEED

A - BUS RETURNB - BUS RETURN

B - BUS FEED BREAKERS

A - BUS FEED BREAKERS

Alarm connector

Chassis GND

(1/4-20 THREAD)

A - BUS INPUT

FEED

B - BUS INPUT

FEED

1098765432 1

Shorting Bus (-S Models)

OUTLINE OF SAFETY COVER

(blue dotted line)

4.60

(116.8)

0.625

(15.88)

0.500

(12.70)

0.750

(19.05)

4.642

(117.91)

Figure 6. Output Barrier Strip Detail

The following table lists a range of cable sizes with matching lugs that will t the output

terminals. The indicated current rating is the maximum assuming that the cables are

bundled/conned.

11

+1 (208) 635-6400 | www.transtector.com

MAXIMUM

CURRENT CONDUCTOR

SIZE PANDUIT CORP.

PART NUMBER TORQUE

1/4 x 20 BOLT

200A (2 pos) 3/0 AWG LCDX3/0-14A-X 62 in-lbs

150A (2 pos) 1/0 AWG LCDX1/0-14A-X 62 in-lbs

125A (2 pos) 1 AWG LCDX1-14A-X 62 in-lbs

100A (1 pos) 2 AWG LCDXN2-14A-E 62 in-lbs

80A (1 pos) 4 AWG LCDX4-14A-L 62 in-lbs

60A (1 pos) 6 AWG LCDX6-14A-L 62 in-lbs

50A (1 pos) 8 AWG LCDX8-14A-L 62 in-lbs

9.5 Form C Relay Contact Outputs. The center of the back panel has connections to

the Form C relay contact outputs for connection to external audible or visual alarm

circuits. See Figure 7 below.

ALM-B

ALM-A

NO-C-NC NO-C-NC

Figure 7. Alarm Connection Detail

Connection is made via two Phoenix Contact spring clamp terminal blocks. J3 is for

the Form C relay contact of side B and J4 is for the Form C relay contact of side B.

Terminals 1, 2 and 3 viewed from left to right are the normally open (NO) common

(C) and normally closed (NC) contacts, respectively. See gure 8 below.

“Normally Closed” and “Normally Open” are dened with the distribution panel powered

and providing power to all outputs, i.e., no circuit breakers tripped.

The ratings of the relay contacts are 0.6A at 125VAC or 2A at 30VDC. The spring

clamp terminals accept wire sizes nos. 16 to 26 AWG.

When the input power is connected to a side (A or B), the Form C relay of that side

is energized. If there is either loss of input power, one or more circuit breakers trip or

the relay is de-energized, the normally open contacts close and the normally closed

contacts open. See gure 8 below.

RELAY

C

ONTACTS

OUTPUTS

NC

C

NO

Figure 8. Form-C Relay Schematic

Installation Manual | DCPDU2B Series Power Distribution Units

12 +1 (208) 635-6400 | www.transtector.com

9.6 Chassis Ground Connection. Thisis locatedonthe leftsideof thechassis asshown

in gure 9 below and is a pair of 1/4-20 bolts.

A - ALM B - ALM

123456789 10

A BUS - 450A MAX/100A MAX PER CB

123456789 10

B BUS - 450A MAX/100A MAX PER CB

NO-C-NC NO-C-NC

ALM-B

ALM-A

NO-C-NC NO-C-NC

1098765432 1

0.63

(16.0)

0.76

(19.3)

0.42

(10.7)

0.25

(6.4)

1/4-20 stud

length = 0.50 (12.7),

0.625 (15.88) spacing

1/4-20 stud

length = 0.38 (9.7),

0.625 (15.88) spacing

0.57

(14.5)

0.37

(9.4)

0.90

(22.9)

ø 0.306 (7.8)

0.49 (12.5) x

0.31 (7.9) slot

3.50

(88.9)

1.25

(31.8)

5.98

(151.9)

0.60

(15.2)

17.16

(435.9)

0.76

(19.3)

1.725

(43.82)

0.56

(14.2)

0.21

(5.3)

1.13

(28.7) 0.22

(5.6)

3.45

(87.6)

A - BUS OUTPUT FEEDB - BUS OUTPUT FEED

A - BUS RETURNB - BUS RETURN

B - BUS FEED BREAKERS

A - BUS FEED BREAKERS

Alarm connector

Chassis GND

(1/4-20 THREAD)

A - BUS INPUT

FEED

B - BUS INPUT

FEED

1098765432 1

Shorting Bus (-S Models)

OUTLINE OF SAFETY COVER

(blue dotted line)

4.60

(116.8)

0.625

(15.88)

0.500

(12.70)

0.750

(19.05)

4.642

(117.91)

Figure 9. Chassis Ground Connection

The recommended cable size for this connection is 2/0 AWG terminated with a Panduit

LCDN2/0-14A-X or equivalent lug. Torque bolts to 62 in-lbs.

NOTE THAT IT IS ESSENTIAL THAT THIS TERMINAL IS CONNECTED TO THE

SYSTEM FRAME GROUND TO ENSURE SAFE OPERATION.

retaining screws

extraction tab

13

+1 (208) 635-6400 | www.transtector.com

10.0 UNPACKING AND INSPECTION

10.1 This DCPDU2B Series power distribution panel was carefully tested, inspected and

packaged for shipment from our factory. The unit and circuit breakers are shipped

separately. Upon receipt of the unit it should be carefully unpacked and inspected

for any damage in shipment.

10.2 If there is evidence of damage, do not attempt to test the unit. The freight carrier

should be notied immediately and a claim for the cost of the rectier system should

be led with the carrier for direct reimbursement. Be sure to include the model and

serial number of the damaged unit in all correspondence with the freight carrier. Also

save the shipping carton and packing material as evidence of damage for the freight

carrier’s inspection.

10.3 Transtector will cooperate fully in case of any shipping damage investigation.

10.4 Always save the packing materials for later use in shipping the unit. Never ship the

unit without proper packing.

Installation Manual | DCPDU2B Series Power Distribution Units

14 +1 (208) 635-6400 | www.transtector.com

11.0INSTALLATION

11.1 Mounting. This distribution panel can be mounted in either 19- or 23-inch racks by

using the supplied reversible brackets. Mount it from the front of the rack using the

correct osets to align with existing rack-mounted equipment. The bracket osets

are every quarter inch from front to back.

A minimum air clearance of 1.5” above and below the unit must be maintained after

installation in the rack. Care should be taken not to compromise the stability of the

rack by the installation of this unit.

11.2 Connections. Input connections should be made with two-terminal crimp type lugs.

See Sections 9.2 and 9.3.

Connection to Supply

a) Connect to a reliably grounded 24VDC to 48VDC SELV source.

b) The branch circuit over-current protection shall be sized appropriate to the input

current and shall not exceed 600A.

c) Use minimum 350Kmcm copper conductors for max. rated input current.

d) A readily accessible disconnect device that is suitably approved and rated is

recommended to be incorporated in the eld wiring.

e) To be installed in a Restricted Access Location.

NOTE: Single feed models have both left and right side input bus bars tted. It is

only necessary to connect the input feed to one side for correct operation.

The unused side is directly connected to the live input feed and can be used for

supplying additional panels. See gure 10 below.

CAUTION: The total load must not exceed 450A on any one pair of bus bars in the

chain.

450A MAX. FEED

RETURN

Figure 10. Series Connection of Multiple Panels

Output connections are made to individual output bus bars and common return. See

Section 9.4 and Figure 6.

15

+1 (208) 635-6400 | www.transtector.com

The Form C relay contact output connections are made to the spring clamp terminal

blocks. See Section 9.5. The chassis ground connection is made to the 1/4-20 studs.

See Section 9.6. This safety ground connection should be made before operating

the panel.

11.3 Checking Connections. Carefully check the polarity of input connections to the

distribution panel and output connections to the load before operating the panel.

Reverse connections will not harm the distribution panel which is POLARITY

NEUTRAL but may cause serious harm to the load. Check to make sure that the

chassis safety ground connection is made. Make sure that all connections are clean

and secure to minimize contact resistance.

11.4 Rear Safety Cover. Once all of the above have been completed, t the clear plastic

safety cover to the back of the unit using the supplied mounting studs and screws.

Instruction for tting the mounting studs the panel are included in the accessory kit.

Installation Manual | DCPDU2B Series Power Distribution Units

16 +1 (208) 635-6400 | www.transtector.com

12.0 INSTALLING CIRCUIT BREAKERS

The DCPDU2B Series employs pluggable circuit breakers that can be easily installed, removed

or replaced using the supplied puller tools. This operation is carried out without the need to

dismount the unit from it’s installation.

Installation,removal or replacement of acircuit breakerand connectionor disconnection ofa

load circuit should be carried out only by only by qualied technical persons who are trained

in the use of power systems and are well aware of the hazards involved.

Although it may be necessary on some occasions to carry out this operation while power

remains applied to the panel, it is always preferable to switch o the power if possible before

proceeding.

12.1 Removing the cover plate. To remove the cover plate undo the two knurled retaining

screws at the left and right side of the unit and pull forward.

12.2 Removing a breaker or blanking panel. To remove a breaker pull the toggle switch

handle using the supplied puller tool until the breaker comes free. To remove a

blanking panel lever it out at the top or bottom using a at bladed screwdriver.

12.3 Installing a breaker or blank panel. To insert a breaker carefully push the breaker

rmly into the socket and make sure that it is fully seated. To t a blanking panel use

the two supplied retaining screws to t it into position.

Repeat the above procedure from 12.2 to 12.3 for all positions and then replace the

cover plate.

12.4 Conditions for breaker positioning. For thermal reasons, when operating the panel

continuously at the current ratings stated in note (2) on page 15, the circuit breaker

current shall not exceed the continuous rating as dened in the table.

Adjoining gaps on each side of the circuit breaker must be provided for current ratings

70A to 200A. None are required for 2.5A to 60A.

Circuit Breaker Gap Requirements

CB Current

Rating Number

Poles Max. Continuous

Load Adjoining Gap

(each side)

2.5A to 60A 1 80% of CB rating

(70% @ 70°C) NO

70A to 100A 1 75% of CB rating

(50% @ 70°C) YES

125A to 200A 2 62.5% of CB rating

(37.5% @ 70°C) YES

17

+1 (208) 635-6400 | www.transtector.com

The above table is based on the following:

1) Use of Carling (C Series) breakers or CBI (D Frame) breakers. Breakers in these

series are equivalent in t, form, and function and can be used interchangeably

within the same system.

2) The DCPDU2B panel is rated for continuous operation at a maximum input of

450A per side @ 35C max., 400A per side @ 40C max., 320A per side @ 50C

max., and 200A per side @ 70C max.

12.5 Connecting or disconnecting load circuits. In cases where a breaker has been

installed follow the instructions in section 9.4 to connect the new output wiring. Ensure

that the breaker is in the OFF position until all connections have been made and

thoroughly checked.

Remember that if any 125A, 150A or 200A breakers have been tted these will require

that the supplied link bar is tted across the associated output bus bars.

Note that if power remains applied to the panel during breaker installation the

alarm LED will show red and the alarm relay will be activated until the new

cables have been connected and the breaker set to the ON position.

Installation Manual | DCPDU2B Series Power Distribution Units

18 +1 (208) 635-6400 | www.transtector.com

13.0SETUP AND TESTING

13.1 It is not necessary to have the distribution panel mounted in a rack for initial testing.

This can be done on a bench. It is also not necessary to have loads connected to

the panel for this testing.

13.2 With the input power source o, connect the input wires to the A side of the distribution

panel. Connect ground to the chassis ground terminal. Set all circuit breakers to on.

13.3 Turn on the input power source. The A side LED should be green. If it is red, one

of the circuit breaker is tripped. If the LED is o, there is no input power to the unit.

Check the output voltage at each set of output terminals with a digital voltmeter.

13.4 With the A side LED green, use an ohmmeter to check the Form C relay contact

outputs. On J4 measure the resistance between pins 1 and 2. This should read

“open”. Measure the resistance between pins 2 and 3. This should read “short”.

13.5 On the A side trip circuit breaker no. 1. The A side LED should turn red. On J4

measure the resistance between pins 1 and 2. This should read “short”. Measure the

resistance between pins 2 and 3. This should read “open”. Reset the circuit breaker.

13.6 On the A side check each succeeding breaker by tripping it, and verify that the LED

turns red. It is not necessary to recheck the Form C relay contacts.

13.7 Repeat the same tests of Sections 13.2 through 13.6 on the B side of the distribution

panel, use J3 to check the Form-C relay operation.

13.8 The distribution panel may now be connected to its intended application.

13.9 If the distribution panel did not operate properly in the above tests, go back and double

check the connections and the polarity of the input source to make sure it is correct.

Please note that there are no user serviceable parts inside either the modules or the

shelves and that opening either will void the warranty.

Installation Manual | DCPDU2B Series Power Distribution Units

19 +1 (208) 635-6400 | www.transtector.com

This document is believed to be correct at time of publication and TRANSTECTOR accepts no responsibility for

consequences from printing errors or inaccuracies. Specications are subject to change without notice.

About Transtector Systems:

Transtector Systems, an Infinite Electronics brand, leads the industry with a comprehensive product

portfolio and specialized expertise in consulting, design and manufacturing of AC, DC, data and signal

surge protection, communications power cabinets, and EMP protection.

Transtector provides valuable end-to-end power and signal integrity solutions for markets that include

telecommunications, medical imaging, transportation, energy, security and the military. Our goal is to

support the urgent surge-protection requirements of our customers with responsive customer service,

technical support and a wide-range of quality AC, DC and data line surge protection products in-stock and

available for same-day shipping.

Contact us at +1 208 635 6400 or online at www.transtector.com.

About Infinite Electronics:

Infinite Electronics is a leading global supplier of electronic components serving the urgent needs of

engineers through a family of highly recognized and trusted brands. Our portfolio brands are specialists

within their respective product set, offering broad inventories of engineering-grade product, paired with

expert technical support and same day shipping. Over 100,000 customers across a diverse set of markets

rely upon Infinite Electronics to stock and reliably ship urgently needed products every day.

Product support can be obtained using the following addresses and telephone numbers.

TRANSTECTOR

10701 N Airport Rd

Hayden, ID 83815

United States

Phone: +1.208.635.6400

Toll Free: 1.800.882.9110

Web site – www.transtector.com

Table of contents

Other Infinite Power Distribution Unit manuals

Popular Power Distribution Unit manuals by other brands

Jung

Jung A521UF Series quick start guide

LynTec

LynTec Xtend Power Control Series Instruction bulletin

Panamax

Panamax BlueBOLT C3-IP quick start guide

Eaton

Eaton Advanced Enclosure Power Distribution Unit... user guide

Siemens

Siemens SIVACON 8PS BD2 Series installation instructions

AC Infinity

AC Infinity AC-TCA1 user manual