INFLUX MEASUREMENTS FIRESURE FIREGROOVE Owner's manual

IOM FS Iss 9; April 2012; ECR1269 Page 1 of 8

1a Bennett House, The Dean, Alresford, Hampshire, UK. SO24 9BQ.

Tel: +44 (0)1962 736736 Fax: +44 (0)1962 736737 Email: sales@influxmeasurements.com

A GUIDE TO THE INSTALLATION, OPERATION AND MAINTENANCE OF

FIRESURE

FLOWMETERS IN AUTOMATIC SPRINKLER INSTALLATIONS

Contents: Page

1 Specification and Principle of Operation

1.1 I

NTRODUCTION

.......................................................................................................................................2

1.2 C

ONSTRUCTION AND

S

PECIFICATION

......................................................................................................2

1.3 P

RINCIPLE OF

O

PERATION

.......................................................................................................................2

2 Installation

2.1 P

IPE

L

INE

C

ONFIGURATION

.....................................................................................................................3

2.2 M

AIN

O

RIFICE

C

ARRIER

P

REPARATION

...................................................................................................4

2.3 C

ONNECTING THE

B

YPASS

I

NDICATOR

...................................................................................................5

2.4 I

NSTALLATION

I

N

-L

INE

...........................................................................................................................6

3 Operation

3.1 F

LOW

T

EST

R

ANGES

...............................................................................................................................7

3.2 F

LOW

T

ESTING AND

R

EADING

................................................................................................................7

3.3 F

AULT

C

HECKING

...................................................................................................................................7

4 Maintenance

4.1 C

HANGING

G

LASS

I

NDICATOR

................................................................................................................8

4.2 R

ECOMMENDED

S

PARES

........................................................................................................................8

LPS 1045.1

Cert No.

464a/01

-

10

M e a s u r e m e n t s L t d

F

IRESURE

F

LOWMETER

T

YPES

–

A

PPROVED BY

LPCB

T

YPE

-

F

IREGROOVE

T

YPE

-

F

IREFLANGE

T

YPE

-

F

IREFLANGE

Quality Systems Certificate No. 464

Assessed to ISO 9001:2008

MANAGEMENT

SYSTEMS

IOM FS Iss 9; April 2012; ECR1269 Page 2 of 8

1 Specification and Principle of Operation

Firegroove and Fireflange Type

1.1 Introduction

The Firesure flowmeter is a direct reading flowmeter, approved for use under the LPCB rules for automatic

sprinkler installations.

These meters have been approved for installation with gauge glass in the vertical position. There must be at least

five diameters of straight pipe upstream and downstream of the orifice plate. The isolating valve on the pressure

tappings must be kept closed when the meter is not being used. A spare gauge glass must be provided and

located in the cabinet containing the stock of replacement sprinklers.

1.2 Construction and Specification

Main Orifice Carrier - 316 stainless steel flow orifice mounted in a polyester coated mild steel carrier

Bypass Flow Indicator - Nickel-plated copper tubing and brass connections

Stainless steel filter element, restrictor rodding and float indicator

Boroscilicate glass indicator tube

Viton and polyurethane seals

Max Operating Pressure - 16 bar

Max Operating Temperature - 90°C maximum

Connection - Fireflange - Wafer style bolted between flanges

Firegroove – Cut groove pipe ends using approved pipe couplings

1.3 Principle of Operation

Water flow through the main orifice, creates a pressure difference between the two pressure tapping ports. These

pressure ports are connected across the bypass flow indicator, causing a small bypass flow through the indicator,

directly related to the flow through the main orifice. An indicating float positioned within the glass tube can be

read against scale markings, which show the flow rate delivery of the installation.

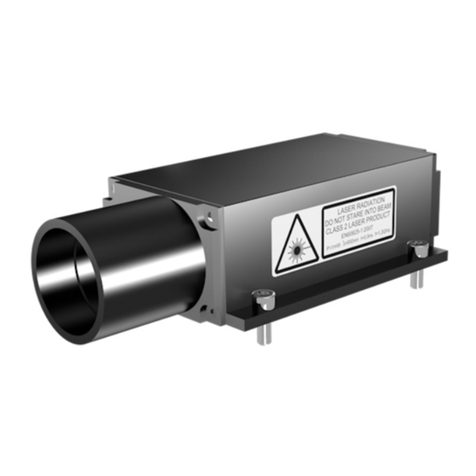

Main Orifice

Carrier

Pressure

Tapping Ports

Bypass Flow

Indicator

IOM FS Iss 9; April 2012; ECR1269 Page 3 of 8

2 Installation

2.1 Pipe Line Configuration

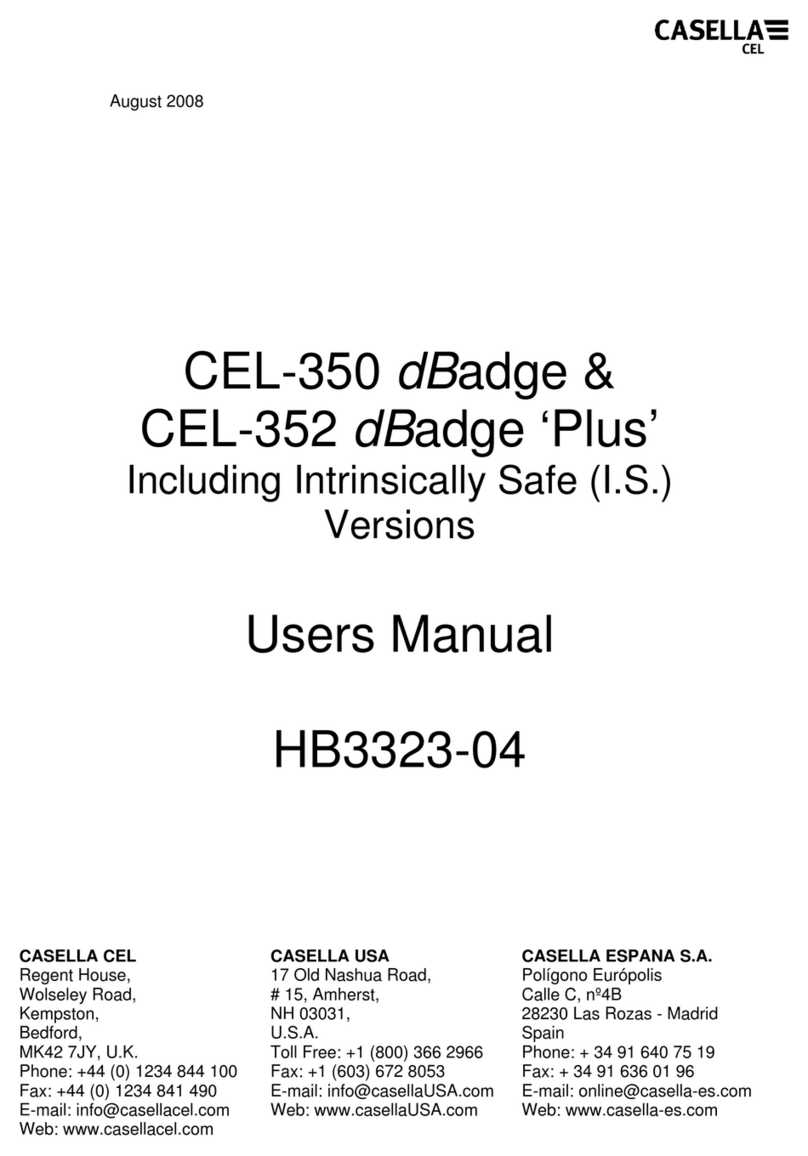

464a/01, 464a/06 F3/1, F3/6 50 250 BS1387

464a/02, 464a/07 F3/2, F3/7 80 400 BS1387

464a/03, 464a/08 F3/3, F38 100 500 BS1387

464a/04, 464a/09 F3/4, F3/9 150 750 BS1387

464a/05, 464a/10 F3/5, F3/10 200 1000 BS3600

LPCB Ref. No. Type Nom. Size mm A mm Pipe Spec.

Recommended pipeline configuration for automatic sprinkler installation of Firesure Flowmeter.

40mm

A

A

90mm

Firegroove

Fireflange

From Pump

Return

Optional Full Bore

Isolation Valve

Control

Valve

Sizes 50-150 Size 200

100mm

Firegroove

IOM FS Iss 9; April 2012; ECR1269 Page 4 of 8

2.2 Main Orifice Carrier Preparation

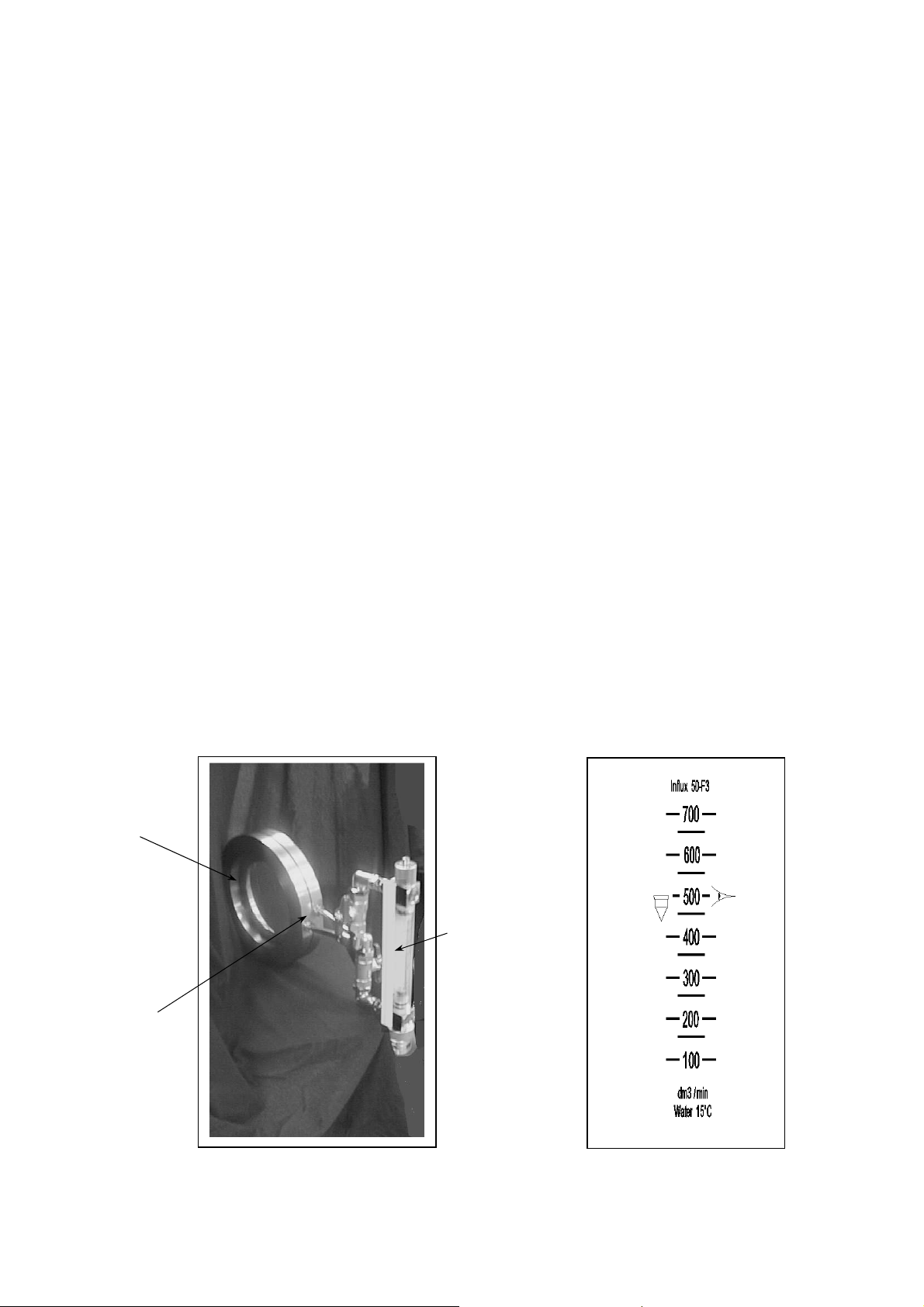

a) For Horizontal Pipe Work Mounting – Connect joggled connection pipes as shown

or

b) For Vertical Pipe Work Mounting – Connect joggled connection pipes as shown

c) Rotate Pipes to Position Shown in a) or b)

Check pipes for horizontal alignment.

Ensure that the pipes spacing matches the rear bypass indicator connections.

Tighten pressure tapping nuts.

Flow Direction

Up

Flow

Direction

Left to

Right

Flow

Direction

Right to Left

Flow Direction

Down

White

Red

White

Red

White

White

Red

Red

Tighten

IOM FS Iss 9; April 2012; ECR1269 Page 5 of 8

2.3 Connecting the Bypass Indicator

Rear view of indicator piping as

supplied suitable for connection to

main orifice carrier for horizontal

flow right to left or vertical flow

upward.

Rear view of indicator adjusted and

suitable for connection to main

orifice carrier for horizontal flow left

to right or vertical flow downwards.

To adjust loosen nuts, rotate arms to

position shown and retighten nuts.

Connect Bypass unit to main orifice

carrier ensuring that ‘white’ marked

pressure point connects with ‘white’

handled tap and ‘red’ pressure point

connects with ‘red’ handled tap.

Tighten connecting nuts, keeping

indicator vertical.

Remove red plastic stop and

retaining rod from top block.

Remove retaining screw and

assemble restrictor and bleed

assembly to indicator top block

with retaining screw in place.

White

Red

White

Red

nut

IOM FS Iss 9; April 2012; ECR1269 Page 6 of 8

2.4 Installation In-Line

a) Ensure direction arrow is consistent with viewed direction of flow and position Fireflange between pipeline

flanges concentrically. Concentricity can be achieved by ensuring the carrier outside diameter is central to

the fixing bolts.

b) Firegroove type should be fitted with approved couplings suitable for groove cut joints.

c) When fitting Fireflange type, ensure that any sealing gaskets do not obstruct the pipe line or carrier bore.

Size/model Min ID Gasket Permissible

50 53mm

80 79mm

100 103mm

150 155mm

200 204mm

Red

White

IOM FS Iss 9; April 2012; ECR1269 Page 7 of 8

3 Operation

3.1 Flow Test Ranges

The Firesure flowmeter is designed to test that the automatic sprinkler installation meets the required flow rate

needs. Each size of flowmeter meets a particular duty as shown below.

Size Flow Range

50 150-700

80 300-1600

100 500-3500

150 900-7900

200 2000-15000

3.2 Flow Testing and Reading

3.3 Fault Checking

Observation Possible Causes Remedy

No Flow Indication. Bypass taps closed.

Restrictor clogged.

Connections reversed to flow.

Open Taps.

Press & release restrictor button or

remove and visually check

restrictor.

Check procedure.

Flow Indication Low. Restrictor clogged.

Filter heavily clogged.

Air trapped in bypass.

Orifice carrier reverse installed

As above.

Remove and clean filter.

Bleed air from bypass.

Check flow direction against

carrier label arrow.

Open

1. With bypass taps in closed position direct flow through

meter pipe line.

2. Open bypass indicator taps.

3. Bleed air from bypass by opening bleed assembly one

revolution.

4. Close bleed assembly when air is bled.

5. Press restrictor button full home and release.

6. Flow rate is shown by aligning the top of the float with scale

markings. Test flows are highlighted on the scale.

7. When test is completed, close bypass taps and drain by

opening drain assembly and bleed assembly one turn.

8. Visually check filter bowl. If dirty, remove by unscrewing

fully and clean filter element.

9. After draining close filter and bleed assemblies.

Closed

Open

Closed

Filter and Drain Assembly

Red Tap

White

Tap

6

IOM FS Iss 9; April 2012; ECR1269 Page 8 of 8

4 Maintenance

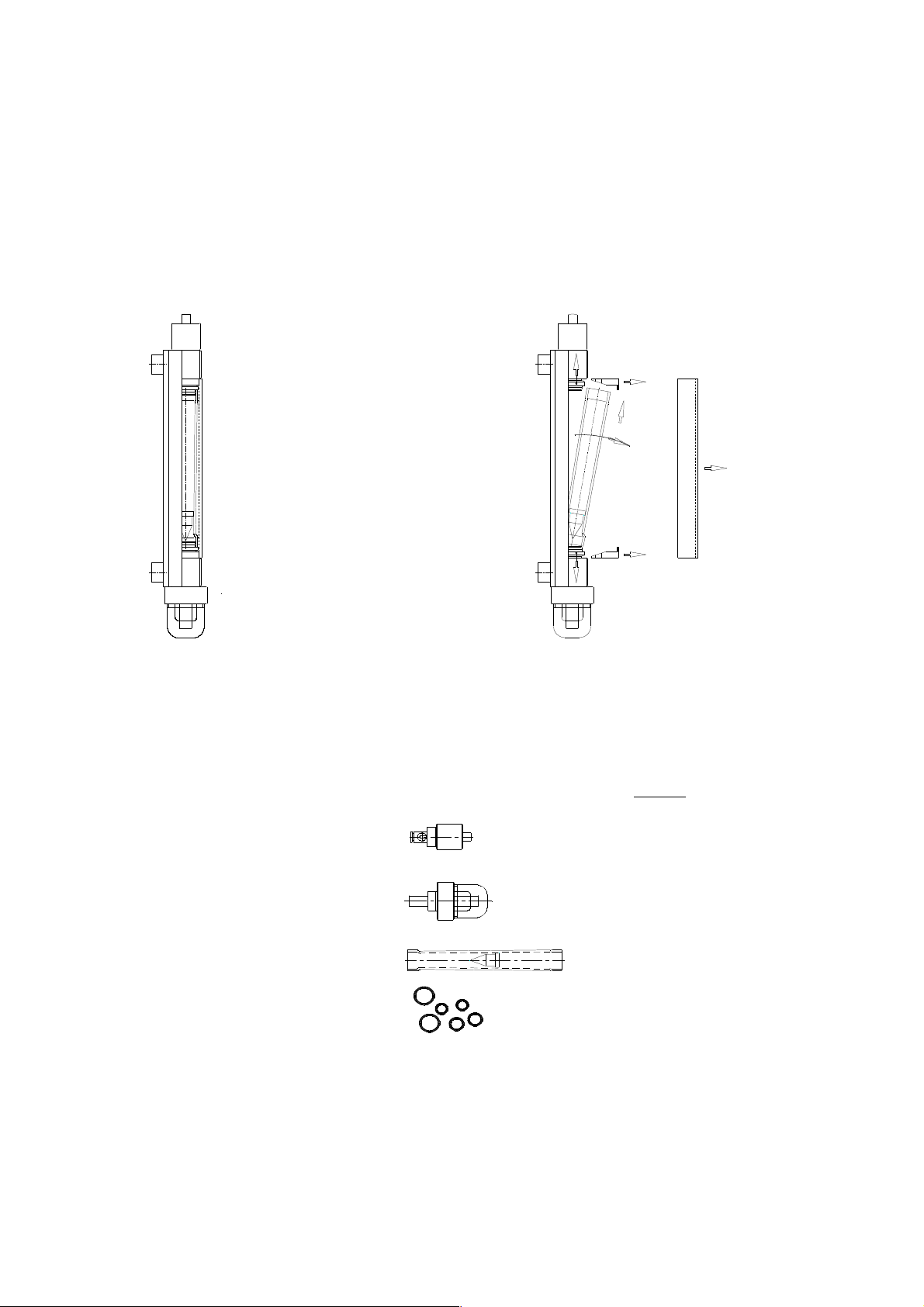

4.1 Changing Glass Indicator

In case of breakage a glass tube indicator would be required. Refer first to the black printed Firesure model

number F3/- on the carrier label or tube before ordering a replacement.

NOTE: This model uses BLACK scaled tubes. These should not be replaced with RED scaled tubes which are

used for the extended indicator model (Firesure X).

4.2 Recommended Spares

If the installation and operating procedures are followed there should be no need for maintenance. In the event of

accidental damage or loss the following spare parts are available:

Restrictor and bleed assembly

Filter element and drain

Glass Tube Indicator

Seals Kit

Part No.

S1000

S1001

F3/-

S1002

3

2

4

5

1

2

3

1. Remove Cover

2. Remove Wedges

3. Push inserts back into end

blocks

4. Tilt glass out of backplate

5. Assembly is in reverse

order.

This manual suits for next models

1

Table of contents