Ecom CN User manual

Operating Instructions

Page 2 ecom-CN

Index Page

Important hints 3

1. Instrument design 4

2. Getting started 5

3. Input or selection of a combustion plant 6

4. Gas analysis

4.1. Measurement preparation 8

4.2. Gas analysis 8

4.3. CO measurement (safety check) 10

4.4. Draught / Pressure measurement 11

4.5. Soot.. Oil trace 12

4.6. Record and print measurement 12

5. Adjustments 13

6. Control 15

7. Data processing

7.1. Menu data processing 16

7.2. Data processing via IRDA 17

7.3. Data processing via Bluetooth (option) 18

8. Maintenance tips 20

9. Technical data 24

10. FAQ 25

ecom-CN Page 3

Important hints

The ecom-CN meets the requirements of

DIN EN 50379 part of 2.

The ecom-CN may not be used for

continuous emission control!

Following minimum times must be kept, in order

to receive correct measured values:

-1 min. to calibrate the sensors at fresh air

-2 min. for stable measured values

The following substances impair the working of

the instrument:

-Cleaning agents

-Degreasers

-Wax polishes

-Adhesives

-Formaldehyde

Adjustments at burners and boilers should

be made only by specialists, who are

familiar with those installations!

1. Charge the accumulator regularly (Charge not

used instrument min. once a month)!

2. Never store the instrument with unloaded

battery!

Page 4 ecom-CN

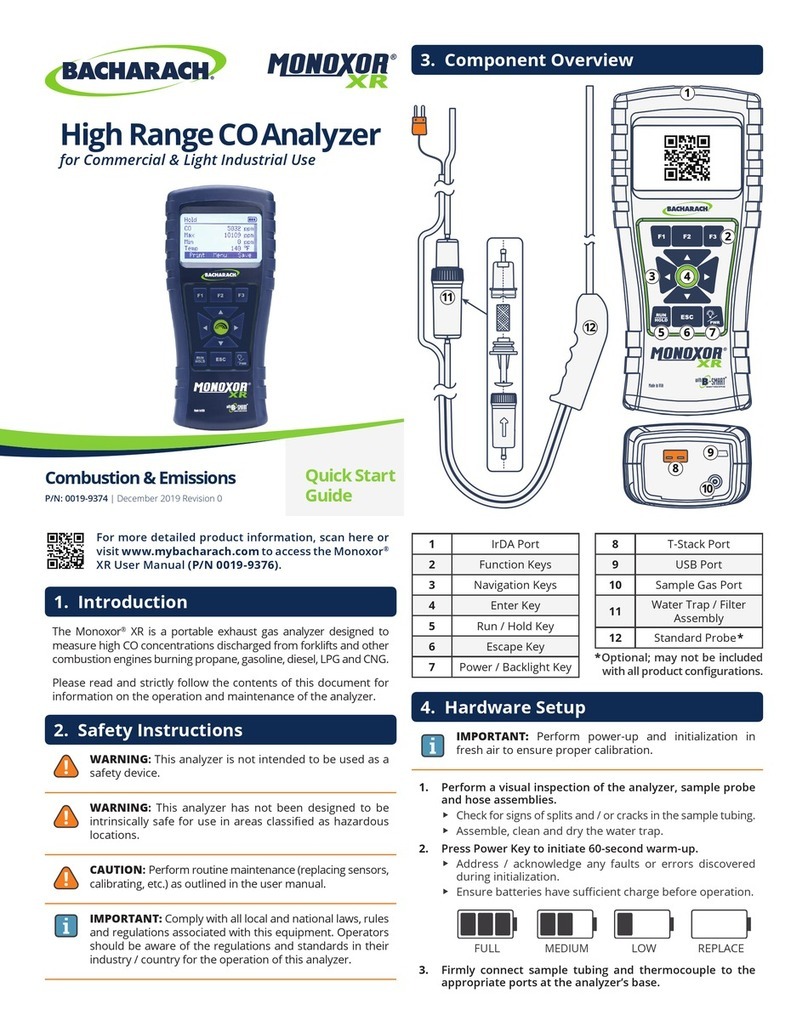

1. Instrument design

Air tempera-

ture connec-

tion

ESC key

(quit/

escape menu)

Gas temperature

connection

RS232

interface

Condensate

monitoring

connection

Gas

connection

Draft

connection

Charging

socket

In the input mode the

keys are used for

numerical input

Cursor monitoring

(up/down/scroll)

Record

values

Print key

(to print menu)

Instrument

ON/OFF

Contraste

adjustment

Pressure

connection

(option)

Infrared sending di-

ode (for IR printer)

OK key

(choice confir-

mation)

Display lighting

ON/OFF

Function keys

(function shown on

display)

ecom-CN Page 5

2. Getting started

Once the instrument is switched on (press

key <I/0>) the main menu is displayed. 6

sub-menus (non visible menus can be

called up while scrolling with the arrow

keys) are listed with the following respec-

tive function:

- Gas analysis : Perform gas analysis

- Draft/Pressure : Perform draft or pressure measurement

- Soot...Oil trace : Input of soot measurement results

- Data processing : Classify measurements/Load or send data

- Adjustments : Modify instrument adjustments

- Control : Check instrument operation state

To start a measurement select the sub-menu "Comb.measurem."

using the arrow keys and confirm with <OK>. The instrument starts a

1-minute calibration phase and the fuel types selection is displayed.

The following fuel types are selectable:

Fuel types according to 1st BImSchV

Fuel oil (B)

Natural gas (B)

City gas (B)

Coke oven gas (B)

Liquid gas (B)

Use the arrow keys to select the correct fuel

type and confirm with <OK>.

The instrument will then enquire if a data

bank function is requested. If the meas-

urement values should be attributed to a

specific plant, so press <F1> (<F4> = no:

measurement will be made without classifi-

cation).

Comb.measurem.

Draft/Pressure

Soot.Oil deriv.

Data processi

ng

Adjustments

Control

Fuel type

Fuel oil (B)

CO2max : 15.4

A1Factor : 0.50

Select with ↑↓ !

Data processing

Quit with OK

Yes

No

Page 6 ecom-CN

3. Input or select a plant

In order to call up a plant which data are

already stored in the instrument or to cre-

ate a new file, the following alternatives are

possible:

Memory number: The allocation of a number is

a possibility to record a new plant in the instrument.

Select „ Memory number“ and confirm with <OK>.

Input a random memory number (0 -4000):

Example: "0"

for storage number 0

After input, press <OK> to call up the storage number. Pressing

<F3> will allocate the next free (considered from memory number 0)

memory number. Press <F4> to input a plant identification.

Hint: As the input is only numerical (max. 16 digits) it is recommend-

ed to make a date related input in order to -later on- easily find the

data record using the search function (search for date):

Once the input is finished, activate the memory number with <OK>

and access the gas analysis menu (press twice <ESC> to return to

main menu, select „Gas analysis“ and confirm with <OK>).

z.B.:0000001.25.11.99

Select by:

Select with ↑↓ !

Search word

Memory number

Nummer

Eingabe:

0000001.25.11.99

Memory number

Input:

0

Anlagennummer

oder Ähnliches

Messdatum

ecom-CN Page 7

Search word: In case the plant identification is known, so a plant

already recorded can be found out using a search machine.

Select "Search word" and confirm with

<OK>. Input 4 related digits of the plant

identification:

Input example: "25.11" for plant identification 0000001.25.11.99

After input, press <OK> to start the search. All correspondences with

this number get filtered. Use the arrow keys to scroll thru the select-

ed numbers (F1 for selection start, F2 for selection end).

Once the desired data block has been

found, press <OK> to activate and view the

previous measurement performed at this

plant (select „Look at“ and confirm with

<OK>).

All measured and calculated values are accessible on screens,

scrollable one after the other with the cursor keys.

Press twice <ESC> and then „ Comb.measurem.“ <OK> to start

with the next measurement.

Search word

Input:

25.11

F1:First F3:Empty

F2:Last

F4:Edit

0000001.25.11.99

Memory number 8 M

O2 3.2 %

CO2

13.1 %

CO

12 ppm

Lambda

1.18

T.Gas

184 °C

T.Air

20 °C

Losses

7.5 %

Eta

92.5 %

CO-measur.

O2 17.5 %

CO

0.0% 738 ppm

CO

123 ppm

Lambda

7.00

Gas analysis: keys

↑↓

!

Soot.Oil deriv.

Draft -0.08 hPa

T.Boilerl

65 °C

1.Soot meas.

0.5

2. Soot meas.

0.3

3. Soot meas.

0.7

Oil trace No

Measurement data

existing

Date Time

25.11.99

10:35:56

0000001.25.11.99

Memory number 8

Page 8 ecom-CN

4. Gas analysis

4.1. Measurement preparation

Prepare the instrument for operation in that you perform all connec-

tions (T-Room sensor and T-Gas, GAS and DRA of the 3-chamber

hose). Make sure that:

- the condensate pad has enough absorption capability

(condensate trap with monitoring)

- the condensate receptacle contains no humidity

(condensate trap without monitoring)

- the fine dust filter and the safety filter are not soiled

darker than number 3 on the soot scale

4.2. Gas analysis

Once the 1-minute calibration phase is over, the instrument enters

the measurement mode. The values are viewable on 4 screen pages

(3 x gas analysis; 1 x CO measurement; use the cursor keys to scroll

the pages):

1. Always position the probe in the exhaust pipe

once the calibration phase is over!

2. Never operate the instrument in the transport

case (recommended for transport)!

To obtain accurate measurement values, re-calibrate

the instrument after each measurement

(at the latest after one hour)!

O2 4.0 %

CO2

12.5 %

CO

30 ppm

Lambda

1.23

T.Gas

166 °C

T.Air

20 °C

Losses

7.0 %

Eta

93.0 %

O2

4.0 %

CO2

12.5 %

T.Air

20 °C

T.Gas

212 °C

O2

4.0 %

CO2

12.5 %

CO

30 ppm

Lambda

1.23

Always use a filtering system as per our

recommendation for combustion plants

firing solid combustibles!

ecom-CN Page 9

The position of the measured and calculated values (gas analysis)

on the display pages is free selectable.

Proceed as follows to modify the succession:

- press <F1> to activate the first line on the display

- select the measured or calculated value with the cursor keys

- press <F1> to activate the next line and so on until the last line

CO2, efficiency, losses, excess air and dew point are calculated val-

ues. They can only be determined if realistic values are available for

the basis values like O2and temperatures. It must assured that:

O2< 20,5 % and

T. Gas - T. Air > + 5 °C

The dew point can only be determined with accuracy if in the menu

"Adjustments" the current barometric air pressure is entered. This

value cannot be determined by the instrument.

If the gas temperature falls below the dew point (between 25 and 65

°C), Eta will be calculated with condensation. In the display (C) ap-

pears behind Eta.

Correct measurement values are displayed after a short delay of ca.

60 to 90 seconds which are necessary for the gas transport and the

built-up of a stable electrochemical reaction of the sensors. For re-

cording, printouts and evaluation wait until the values get stable. If

the gas values still fluctuate more than 2 ppm, so the reason can be

unstable draught conditions in the exhaust pipe.

If the measurement values are stable and the results recordable, so

press <record> (disk symbol) to transfer the values in an intermedi-

ate memory (caution: store gas analysis, CO and O2measurements

separately).

O2 4.0 % m

CO2

12.5 %

CO

30 ppm

Lambda

1.23

T.Gas

166 °C

T.Air

20 °C

Losses

7.0 %

Eta

93.0 %

Measurement

stored in inter-

mediate memory

Page 10 ecom-CN

They will be stored there for a later printout and, if need be, a final

data record storage (you can view the values in the intermediate

memory by pressing <F4> - during the inquiry the gas pump switch-

es off).

The CO sensor is protected against overload by the internal pro-

gramme. If the limit value of 4000 ppm is exceeded, a second pump

switches on and flows the sensor with fresh air. The sensor with can

be switched into the measuring mode by pressing the <F2> key (the

sensor can also be switched off by pressing the <F2> key).

4.3. CO measurement (safety check)

The check of gas-fired plants for operation safety reasons is per-

formed with the CO measurement. The CO content in the exhaust

pipe is measured after the flow fuse and converted on an undiluted

value (residual oxygen value in exhaust gas = 0 %).

As the gas behaviour after the flow fuse is no more homogeneous

because of the flow in of secondary air and the core stream meas-

urement could consequently be erratic, the gas analysis is performed

over the total diameter of the pipe. A multi-hole probe serves as

sampling probe hereto (optional accessory).

The calculated value indicated on the line CO 0.0% corresponds to

the measured CO content supposing that the oxygen content would

amount 0% in the same gas volume. It is consequently the undiluted

CO content in exhaust gas. Once the value is stable, press <record>

to store the value in the intermediate memory.

CO-measur.

O2 17.5 %

CO

0.0% 738 ppm

CO

123 ppm

Lambda

7.00

m

Measurement

stored in inter-

mediate memory

ecom-CN Page 11

4.4. Draft / Pressure measurement

Besides the draught measurement the ecom-CN offers the possibil-

ity of a differential pressure measurement (option). The instrument

must hereto be fitted with a second connection (pressure) on the

front.

Draft measurement:

The gas analysis mode already provides with a trend indication for

the draft conditions in the exhaust channel. The chimney draft value

is not recorded simultaneously to the other gas values (while press-

ing <record>) because the sensitive differential pressure sensor

easily tends to drift. For an exact measurement, it is consequently

recommended to re-calibrate this sensor just before analysing the

value. Select the sub-menu "Draft/Pressure" to start the measure-

ment.

The display shows the current value as

well as the mention to reset the sensor´s

zero point. Hereto release the draught

hose for a few seconds and press <OK>.

The sensor is re-calibrated.

Re-plug the draft hose. The display shows

the exact measured value which you can

store and add to all available results stored

in the intermediate memory while pressing

<record>. The recorded value is shown on

the display.

Press <ESC> to quit the draft measure-

ment mode.

Draft

-0.12

hPa

stored value:

Draft

-.-- hPa

Set zero point

Draft

-0.12

hPa

stored value:

Draft

-0.12 hPa

Set zero point

Page 12 ecom-CN

4.5. Soot...Oil trace

In the sub-menu "Soot.Oil deriv." the measurement values for boil-

er temperature, soot dot number and oil trace can be inputted.

Select the corresponding line on the display and press <OK> to acti-

vate the input. The input for boiler temperature and soot dots 1-9 can

occur one after the other using the instrument keyboard. Press

<OK> to take over the value in the measurement data record. The

result of the oil trace determination can be documented as follows:

- Place cursor on line "Oil trace"

- Use <OK> to adjust result

("No", "Yes" or "- - - ")

Once all necessary inputs have been made, press <ESC> to quit the

menu. The measurement is complete.

5.6. Record and print measurement

Press <Print> (printer symbol) to access

the printing menu. If need be, the recorded

values can be checked again („Look at“,

<OK> and scroll with the cursor keys).

If all data are correct, press „Record -> M“

and <OK> to transfer in the internal

memory. A successful transfer is character-

ized by a "M" on the upper right part of the

display.

After the gas analysis, please transfer the recorded

data (intermediate memory) into the internal

instrument memory otherwise the values will get

lost by instrument switch-off!

Soot.Oil deriv.

T. Boiler --- °C

1. Soot meas.

---

2. Soot meas.

---

3. Soot meas.

---

Oil trace ---

Print

Look at

Store to memory

Select with ↑↓ !

Print

Look at

Store to memory

Select with ↑↓ !

M

ecom-CN Page 13

Then a data printout can be started

(„Print“ and <OK>). The ecom-CN is pre-

set for a printout via the infrared printer

type HP 82240B.

For the case the new IR printer type ecom-

Pis in use, a corresponding selection must

be made under „Adjustments“ / „Inter-

nal“.

Please care for a frictionless (direct sight) connection between the

sending diode on the front of the instrument and the receiving diode

on the printer. The maximal distance between both units should not

exceed ca. 40 cm otherwise a troublefree transfer is no more ascer-

tained in any case.

Press <ESC> after printout termination to return to the "Main

menu".

5. Adjustments

Additionally to the functions described

above, the ecom-CN allows several ad-

justments. From the main menu select the

sub-menu "Adjustment" and confirm with

<OK>. A selection of adjustable parame-

ters is displayed which can be adjusted

according to the application. Place the

cursor on the desired line and press <OK>

to call up or modify the adjustment.

Unit

O2 reference

Air pressure

Set clock

Type of fuel

Internal

Print

Look at

Store to memory

Select with ↑↓ !

M

Page 14 ecom-CN

Unit (Adjustment via <F1> - <F3>):

- Calculation of gas concentrations in:

- ppm = volume concentration (parts per million)

- mg/m3= mass concentration per volume unit

- mg/kWh = mass concentration per performance unit

Undiluted (Adjustment via <F4>):

- Conversion of gas concentration on

entered reference oxygen:

- Formula for conversion:

O2reference (press <OK> to access input mode):

- Input of reference O2ref

Air pressure (press von <OK> to access input mode):

- Input of barometrical air pressure for the dew point calculation

Set clock (press <OK> to access input mode):

- Correction of internal clock

Type of fuel (press <OK> to access selection mode):

- Modification of adjusted fuel type

Internal (press <OK> to open menu):

- Further instrument adjustments:

Keyboard beep (<F1> for Yes / <F4> for No):

- Acoustical signal by pressure on key

Baud rate (adjustment via cursor keys):

- Adjustment of transfer speed by data transfer via RS 232

(1200 -19200 Baud)

Online data (adjustment via cursor keys):

- Adjustment if online data should be sent via RS232 or IR

Keyboard beep

Baud rate

Online data

ECOM

-P

Eta(C)

CO

9999

ppm

undiluted

ppm

mg/m3

mg/kwh

E

ref

= E

meas

*

21 – O

2ref

21 – O

2meas

ecom-CN Page 15

ECOM-P (Adjustment <F1> for Yes / <F4> for No):

- Adjusted of selected printer: „YES“ = ecom-P

„NO“ = HP 82240B

Eta(C) (<F1> for YES / <F4> for NO):

- Efficiency calculation with or without condensation gain

6. Control

The electrochemical sensors used for the gas analysis are submitted

to a wearing process and consequently do age. Along the operation

period, they alter their output values depending on the gas concen-

tration, flow duration and soiling degree of the measured gases. The

programme controls the sensors and corrects drifts. If drifts and the

correlated measurement errors increase, an error message is dis-

played. In this case the corresponding sensor must be changed by

an authorised service centre.

The control menu informs about the current status values for the

sensors and on 2 further pages (scroll display page via cursor key)

about:

- the battery voltage (charging state)

- the phone number of the next service centre

- the serial number

- the software version

- the operation hours

- the date of the last service

- the number of CO switch offs

- the number of errors occurred

O2 1034 mV

CO

-10 mV

Batt

6.42 Volt

Further info with

↑↓

!

Tel.No. 02371/945-5

Ins.No. CN

-0009 V1.1

Oper. hours 7.39

Service date

23.06.04

CO switch offs

0

Error counter

00

Further info with

↑↓

!

Tel.No. 02371/945-5

Ins.No. CN

-0009 V1.1

Page 16 ecom-CN

7. Data processing

7.1. Menu data processing

The menu „Data processing“ allows the selection

of the following functions:

Select:

This sub-menu enables to search for or

create a plant file for the allocation of

measurement values (see chapter 3.).

Look at:

The recorded values of the selected plant can

be viewed (see chapter 3.).

Load data:

Possibility of data import e.g. from Chimney Sweepers Management

Programmes (check the transfer options of your software and if need

be, adjust them at the instrument / see chapter 6.).

Proceed as follows:

1. Connect instrument and PC with a current RS232 cable.

2. Select “Load data“ and confirm with <OK>.

3. Answer following question with Yes (<F1>).

4. Decide if the date recorded in the instrument can be deleted (<F1>

for Yes / <F4> for No).

5. Start the data transfer at the PC.

Transmit data:

The date record completed with values can be transferred to the PC

programme using this function (procedure identical to „Load data“).

Format memory:

This function is normally only needed by the initial adjustment of the

instrument by the manufacturer (preparation of internal memory to

data receipt). Caution: All recorded values will get lost !

Select

Look at

Load data

Transmit data

Format memory

ecom-CN Page 17

7.2. Data processing via IRDA

The following possibilities are available for data processing via IRDA:

1.Using the measurement data management programme MiniDV

(gratis software from ecom GmbH).

Hereto the following adjustments must be made at the ecom-CN:

Adjustments-Internal-Baud rate->IRDA

and

Adjustments-Internal-Online data->none

2.Using the online data record programme DASNT

(gratis software from ecom GmbH).

Hereto the following adjustments must be made at the ecom-CN:

Adjustments-Internal-Baud rate->IRDA

and

Adjustments-Internal-Online data->DAS

3.Using the PDA solution

The infrared interface of the PDA can be used to transfer measure-

ment data stored temporarily from the ecom-CN into the PDA.

ecom GmbH offers a programme called CNIrDA which can be start-

ed as process e.g. from a management programme for chimney

sweepers. By calling-up, this programme performs the communica-

tion between PDA and instrument and provides with an ANSI text file

named ECOM.TXT as a result. This file covers the measurement

results transferred from the instrument to the PDA. To transfer data

blocks from the ecom-CN to the PDA, the following adjustments

must be made at the instrument:

Adjustments-Internal-Baud rate-IRDA

and

Adjustments-Internal-Online data DS->COM

The communication will not function without these adjustments.

Once the programme is called up, it will be tried via infrared signal to

establish a communication to the ecom-CN. Hereto both the inter-

faces of the instrument and of the PDA must be directed in front of

each other. Press the button „Back“ to stop the search. The pro-

grammes is then finished and no file ECOM.TXT is written.

Page 18 ecom-CN

Once the ecom-CN is identified, the message

„Connection build-up ...“ and then „Start trans-

fer at ecom-CN“ are displayed.

Press the „Print“ key to start transferring the

data stored in the ecom-CN. Once the transfer

is completed, the measurement values are

displayed in a table on the PDA.

The user can then decide if he wants to keep

the values. By pressing the key „Cancel“ the

measurement values get deleted and the pro-

gramme turns back in receiving mode.

Pressing the key „Accept“ generates the data to be written in the file

ECOM.TXT and the programme is finished. The transfer between

PDA and instrument is secured via a check sum. In case of transfer

problems, the error message „Transfer error“ is displayed.

7.3. Data processing via Bluetooth (option)

The following possibilities of data processing via Bluetooth are avail-

able:

1. Using the measurement data management programme

MiniDV

(gratis software from ecom GmbH).

Hereto the following adjustments must be made at the ecom-CN:

Adjustments-Internal-Baud rate->Bluetooth

and

Adjustments-Internal-Online data->none

2. Using the online data record programme DASNT

(gratis software from ecom GmbH).

Hereto the following adjustments must be made at the ecom-CN:

Adjustments-Internal-Baud rate->Bluetooth

and

Adjustments-Internal-Online data->DAS

ecom-CN Page 19

3. Using the PDA solution

The Bluetooth interface (option) of the PDA can be used to transfer

current measurement data from the ecom-CN into the PDA.

The communication via a virtual Bluetooth COM port is used as

transfer principle. ecom GmbH offers a programme called CNRe-

mote which can be started e.g. from a management programme for

chimney sweepers as process.

By calling-up, this programme performs the communication between

PDA and instrument and provides with an ANSI text file named

ECOM.TXT as a result. This file covers the measurement results

transferred from the instrument to the PDA.

The programme CNRemote runs on PDA with Bluetooth interface

and the operating programme Microsoft Windows Mobile 2003 or

higher. The programme needs the Microsoft Compact Net Frame-

work version 2.0 or higher. The programme assumes an ecom-CN

with firmware version 1.9 or higher as well as the Bluetooth option. If

a corresponding firmware update is needed, contact your authorised

ecom service centre.

The following adjustments must be made at the ecom-CN in order to

transfer data records to the PDA:

Adjustments-Internal-Baud rate-Bluetooth

and

Adjustments-Internal-Online data-Remote

The communication will not function without these adjustments.

Once the programme is started with /Programmes/ecom/ecom.exe

the user must select in the rider „Adjustments“ the serial Bluetooth

port made available by the PDA operation system. The installation of

the serial Bluetooth port is described in the PDA documentation.

If no Bluetooth-able PDA or no Bluetooth-able ecom CN is available,

the user can work with demonstration measurement data while acti-

vating the function „Simulate instrument“.

Page 20 ecom-CN

The desired function can be selected in the rider „Measurement da-

ta“. The following functions are available for the remote operation of

the ecom-CN:

Gas analysis

Starts gas analysis procedure until the key „Stop“ is pressed

O2 check

Starts O2 check until the key „Stop“ is pressed

Draught

Starts draught measurement until the key „Stop“ is pressed

Draught=0

Zeroes draught sensor

Stop

Quits active measurement

Quit

Closes the programme without data export in the file ECOM.TXT

Accept

Closes the programme with data export in the file ECOM.TXT

During the measurement procedure, the cur-

rent values are displayed in a table on the

PDA.

If the button „Accept“ is pressed, the data get

written in the file ECOM.TXT and the pro-

gramme gets closed. The transfer between

PDA and instrument is secured by a check

sum. By transfer errors, the error message

„Transfer error“ is displayed.

8. Maintenance tips

To secure the accuracy of your measuring instrument we recom-

mend the annual check by an authorized ecom partner. In the case

of strong demand (e.g. permanent several hours of measurement

per day, rough conditions etc.) shorter intervals between checks

should be selected - please contact your ecom partner. All ecom

partners are listed under www.ecom.de. Do not use other sensors or

feelers than those we selected and keep in mind that service jobs

made by unauthorised centres will result in a complete warranty loss.

Other manuals for CN

1

Table of contents

Other Ecom Measuring Instrument manuals

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom i.roc Ci70 -Ex Installation instructions

Ecom

Ecom Ex-Tacho 10 User manual

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom J2KN User manual

Ecom

Ecom ECOM-D User manual

Ecom

Ecom ECOM-D User manual

Ecom

Ecom J2KNpro Tech User manual

Ecom

Ecom UNO-CO User manual

Popular Measuring Instrument manuals by other brands

P3 International

P3 International P4460 Operation manual

Endress+Hauser

Endress+Hauser ORIA15 Brief operating instructions

FLIR

FLIR CM78 user manual

Precision CAM

Precision CAM Cowcam user manual

Swoffer Instruments

Swoffer Instruments 2100-1518 Operating and maintenance instructions

Mahr

Mahr umaxum II instruction manual