InfraScan 753 User manual

360°Infrascan®

Passive Infrared Motion Sensor

Installation Instructions

®

Please leave these instructions at

the installation site.

753

Series

753 Series 360° Infrascan Installation Instructions

2 of 16 © 2012 Schneider Electric. All Rights Reserved.

Contents

1.0 Product Range..................................................................................................................3

2.0 Description........................................................................................................................3

3.0 Product Selection.............................................................................................................3

4.0 How it works .....................................................................................................................4

5.0 Identification of Parts ......................................................................................................5

6.0 Installation of Location....................................................................................................6

7.0 Field of View......................................................................................................................6

8.0 Mounting Procedure.........................................................................................................7

9.0 Wiring Diagrams - 753 2-Wire Infrascan ........................................................................9

10.0 Wiring Diagrams - 753R 3-Wire Infrascan....................................................................10

11.0 Commissioning...............................................................................................................11

11.1 Set Up for Walk Test ................................................................................................11

11.2 Soft Start Feature ....................................................................................................11

12.0 Troubleshooting........................................................................................................... 12

13.0 Technical Specifications................................................................................................13

14.0 Warning- Using the 753 with Special Loads ................................................................15

15.0 Warranty ..........................................................................................................................16

753 Series 360° Infrascan Installation Instructions

3 of 16

© 2012 Schneider Electric. All Rights Reserved.

1.0 Product Range

753 Infrascan 360 Degree, 240V a.c., 50Hz, 2-Wire, 2A,

20 Minute

753R Infrascan 360 Degree, 240V a.c., 50Hz, 3-Wire, 10A,

20 Minute

2.0 Description

The Clipsal 753 Series 360 Degree Infrascan is a highly reliable, state-of-the-art

passive infrared (PIR) occupancy sensor. The unit utilises an advanced quad-

element sensor array allowing instantaneous detection of movement and features

a massive 14 metre detection range.

The unit also features a slimline, fully recessed mounting facility, making it one of

the world’s most sleek and unobtrusive 360°sensors available.

The unit is designed to monitor the immediate environment, and detect people

moving within its field of view. When movement is detected, the unit will activate an

electrical load, such as a light, in response to that movement.

Designed and developed in Australia, the unit offers benefits in security, energy

management, hospitality and true ‘hands-free’ switching convenience in a wide

range of applications.

3.0 Product Selection

Be sure to select the appropriate Infrascan product to suit your application:

• the753isa2-wire(doesnotrequireNeutralconnection),andcanonlyswitcha

limited range of load types.

• the753Risa3-wiredevice(requiresNeutralconnectiontooperate)capableof

switching a wide range of load types.

* Please refer to Technical Specifications for further information about compatible load types.

Catalogue Number Neutral

Required Maximum Load*

753 NO 2A

753R YES 10A

753 Series 360° Infrascan Installation Instructions

4 of 16 © 2012 Schneider Electric. All Rights Reserved.

4.0 How it Works

With power applied and a suitable load connected, the Infrascan can detect any

moving infrared source (for example a person) that may intrude upon its field of view.

BoththeLight-LevelandTime-Onsettingsareuseradjustablebyremovalofthe

frontsurround.Simplytwisttoremovethecoverandadjusttrimpotasrequired.

TheLight-Leveladjustmentactivatestheloaddependentontheambientlight

levelintheeldofviewofthesensor.Thisadjustmentcanbesettoallowthe

Infrascan to operate the load at any light level between full daylight and almost

complete darkness. For example, the user can ensure the load is only activated

when movement is detected at night time. During the day time, when there is

adequate natural light, the unit can be set so it does not activate the load, as it is not

necessary to do so.

TheTime-Onadjustmentvariesthetimespanthattheloadwillremainonafter

the infrared source moves out of, or stops moving within the field of view. The

loadwillautomaticallybeswitchedoffaftertheTime-Onperiodhaselapsed.Any

period between 5 seconds and approximately 20 minutes may be set by the time

adjustmentscrew.

Light-LevelAdjustment Time-OnAdjustment

Twist to Remove Surround

Note

• Thesensorheadisspeciallydesignedtogiveoptimumperformanceandis

sealed to prevent water or dust from entering the unit. Under no circumstances

should it be tampered with. There are no user serviceable parts inside.

• Donotapplyanypressureontheactualsensorlensitself,asthismaydamage

the lens, and adversely affect the performance of the unit.

753 Series 360° Infrascan Installation Instructions

5 of 16

© 2012 Schneider Electric. All Rights Reserved.

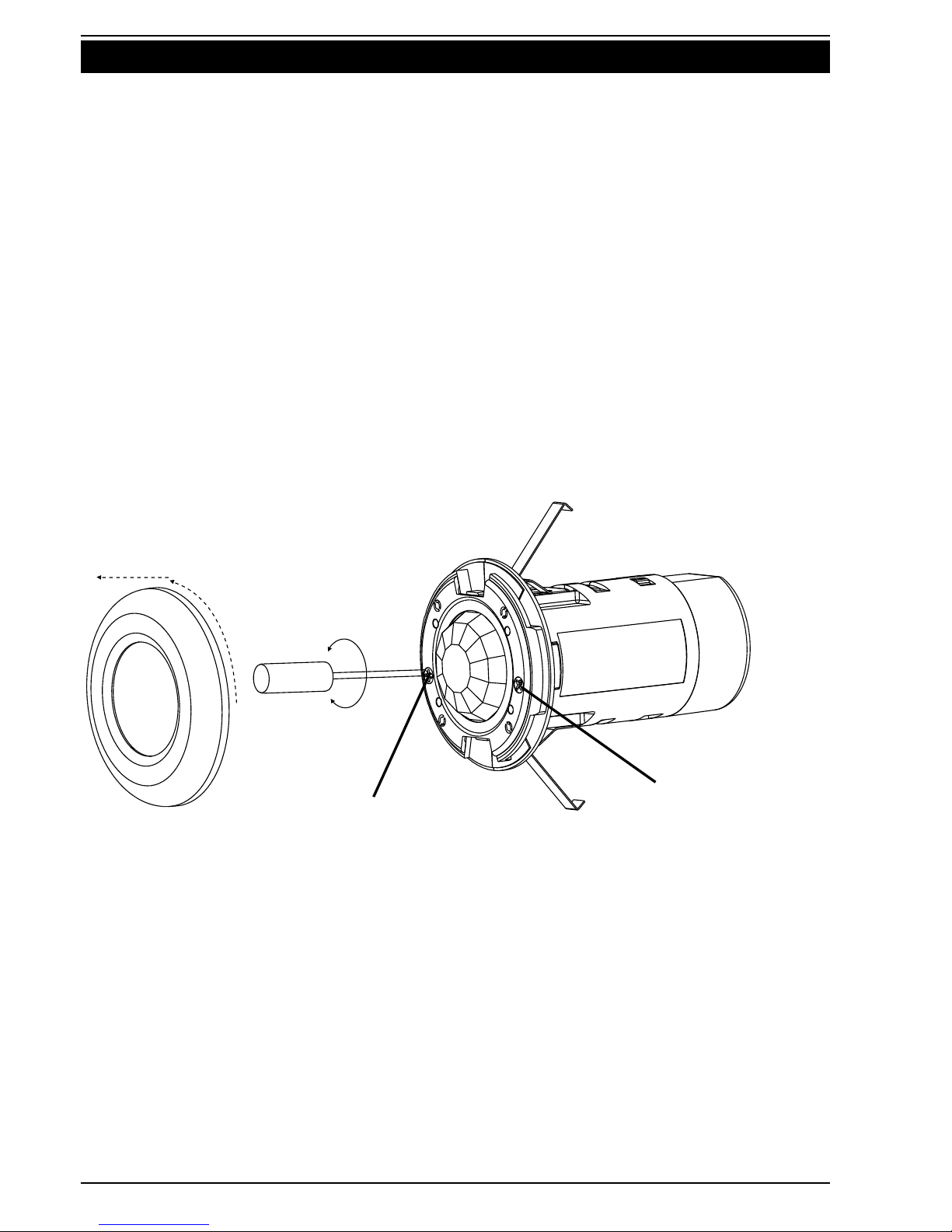

5.0 Identification of Parts

Note

• Theunitissuppliedwithanoptionalzonemask,designedtoblocktheunitfrom

detecting motion in unwanted trip areas. This might include a smaller office

space with an open doorway, where it is not desirable to activate lighting when

people pass by the open door.

• Thezonemaskincorporatesaseriesofstagedtear-awaysections,allowingfull

customisation of the field of view. Tear away sections where you want detection

to take place.

• Totthezonemask,removethesurroundanduncliptheremovablespacer.

Clip the zone mask in place and replace the surround.

• Additionalzonemasksareavailable(ClipsalCatalogueNumber753MASK).

Surround

Spring Clips

Side Cable Entry

Apertures

Cable Clamp

Top Cable Entry

Terminal Cover Screw

Terminal Cover

Sensor Lens

UserAdjustments

Removable Spacer

753MASK-ZoneMask

Figure 2

753 Series 360° Infrascan Installation Instructions

6 of 16 © 2012 Schneider Electric. All Rights Reserved.

6.0 Installation Location

An Infrascan must be positioned correctly to ensure effective operation. The field

of view is optimum when the sensor head is mounted in a vertical position at a

height of 2.4 metres and the approach path is across the face of the sensor.

Note

• DonotmounttheInfrascanclosetoobjectswhichcancreaterapidtemperature

changes, e.g. air conditioning vents, heater flues, moving water (i.e. fountains

and sprinklers). Avoid locations where condensation is likely to form on the lens.

• DonotmounttheInfrascanonanysurfacethatissubjecttomovementdueto

wind or other causes.

• Inallcases,locatetheInfrascansothattheapproachpathisacrosstheeldof

view and not directly towards the Infrascan, as a reduced detection range will

be observed.

7.0 Field of View

Arrows show direction of

approach for maximum

rated range.

Note:thattheeffective

field of view is circular,

approximately 14m

diameter, when mounted

on a ceiling 2.4m above

the floor.

8m (26 ft)

8m (26 ft)

6m (20 ft)

6m (20 ft)

4m (13 ft)

2m (7 ft)

0m (0 ft)

2m (7 ft)

4m (13 ft)

Top view at 2.4m mounting height

0m (0 ft)

Side view

2.4m (8 ft)

2.7m (9 ft)

3.0m (10 ft)

3.7m (12 ft)12m

(39 ft) 12m

(39 ft)

10m

(33 ft) 10m

(33 ft)

8m

(26 ft) 8m

(26 ft)

6m

(20 ft) 6m

(20 ft)

4m

(13 ft) 4m

(13 ft)

2m

(7 ft) 2m

(7 ft)

0m

(0 ft)

Floor

Ceiling

Note

• Thestatedeldofviewistypicalforfullbodymovementandissubjectto

variations caused by the type and quantity of clothing worn, as well as variable

background temperature characteristics and speed of movement.

• Rapidandlargetemperaturechangesmaybedetectedeveniftheyappeartobe

well beyond the field of view due to reflection off surfaces that are within the field

of view.

753 Series 360° Infrascan Installation Instructions

7 of 16

© 2012 Schneider Electric. All Rights Reserved.

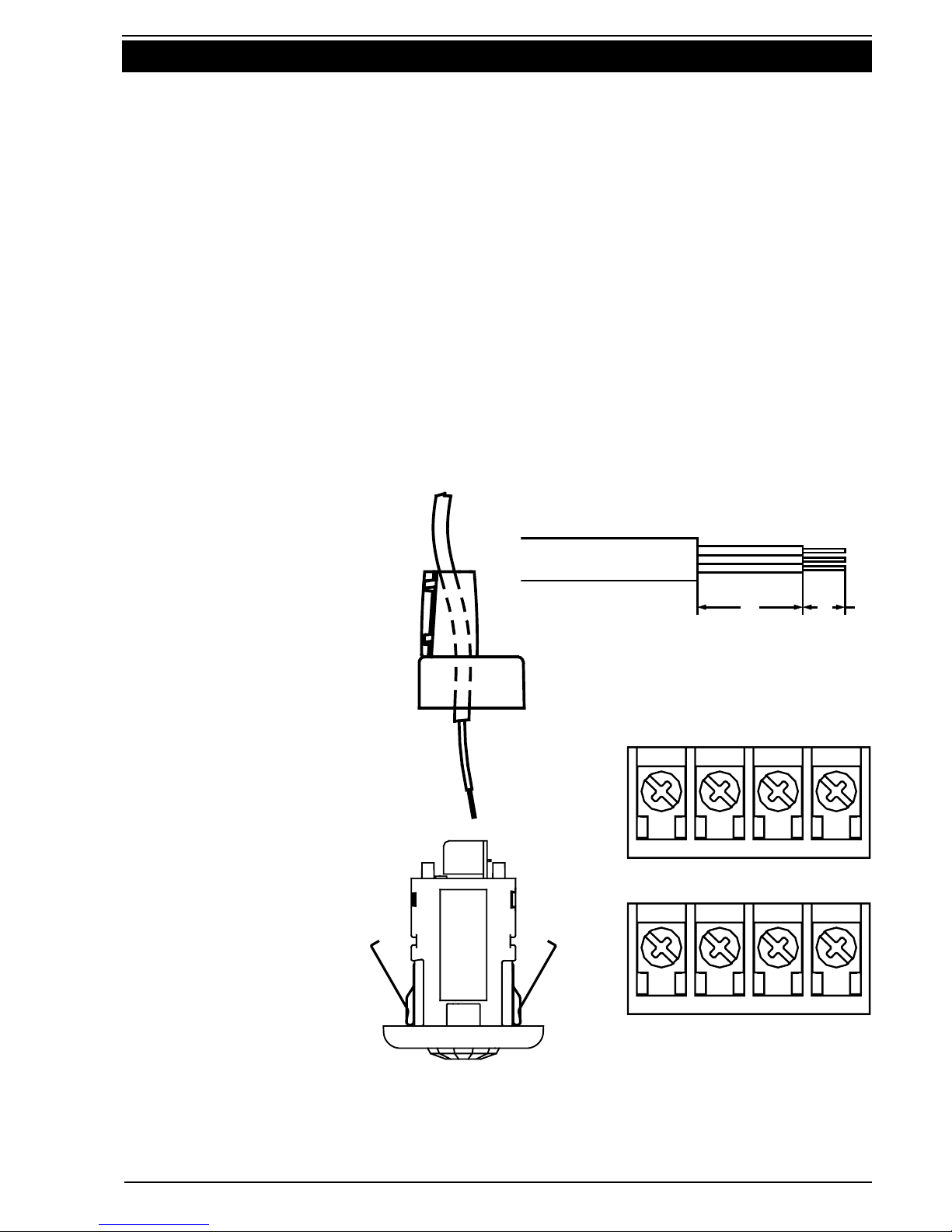

8.0 Mounting Procedures

Step 1

Using a hole saw or otherwise, cut a 50mm (2”) circular hole in the ceiling

(or ceiling tile). Draw cable through hole.

Step 2:

Remove terminal cover screw and terminal cover to expose terminals. Remove

cable entry tear-away(s) from the terminal cover as required, to suit incoming

cable.

Top Cable Entry

Punch out the top cable entry hole, then fit the cable clamp to the terminal cover.

Push the two halves so that it snaps together, and clip onto the terminal cover

entry hole. The cable clamp wraps around the incoming cable. Feed cable through.

Side Entry

DONOTUSESIDEENTRY.

Step 3

Strip cable. Terminate

incoming wiring on the

appropriate terminals as

marked. Refer to Section

9 Wiring Diagrams

for further information

about wiring for different

applications.

Step 4

Fit the terminal cover,

and secure using the

terminal cover screw.

Step 5

Depress the outer

ends of the spring clips

towards the centre of the

unit and push the unit

through the hole until it

rests flat on the ceiling.

30 12

753 LOOP LOOP LOAD A/L

753R LOOP N LOAD A/L

Terminal Detail

Cut and Strip Detail

Figure 4

753 Series 360° Infrascan Installation Instructions

8 of 16 © 2012 Schneider Electric. All Rights Reserved.

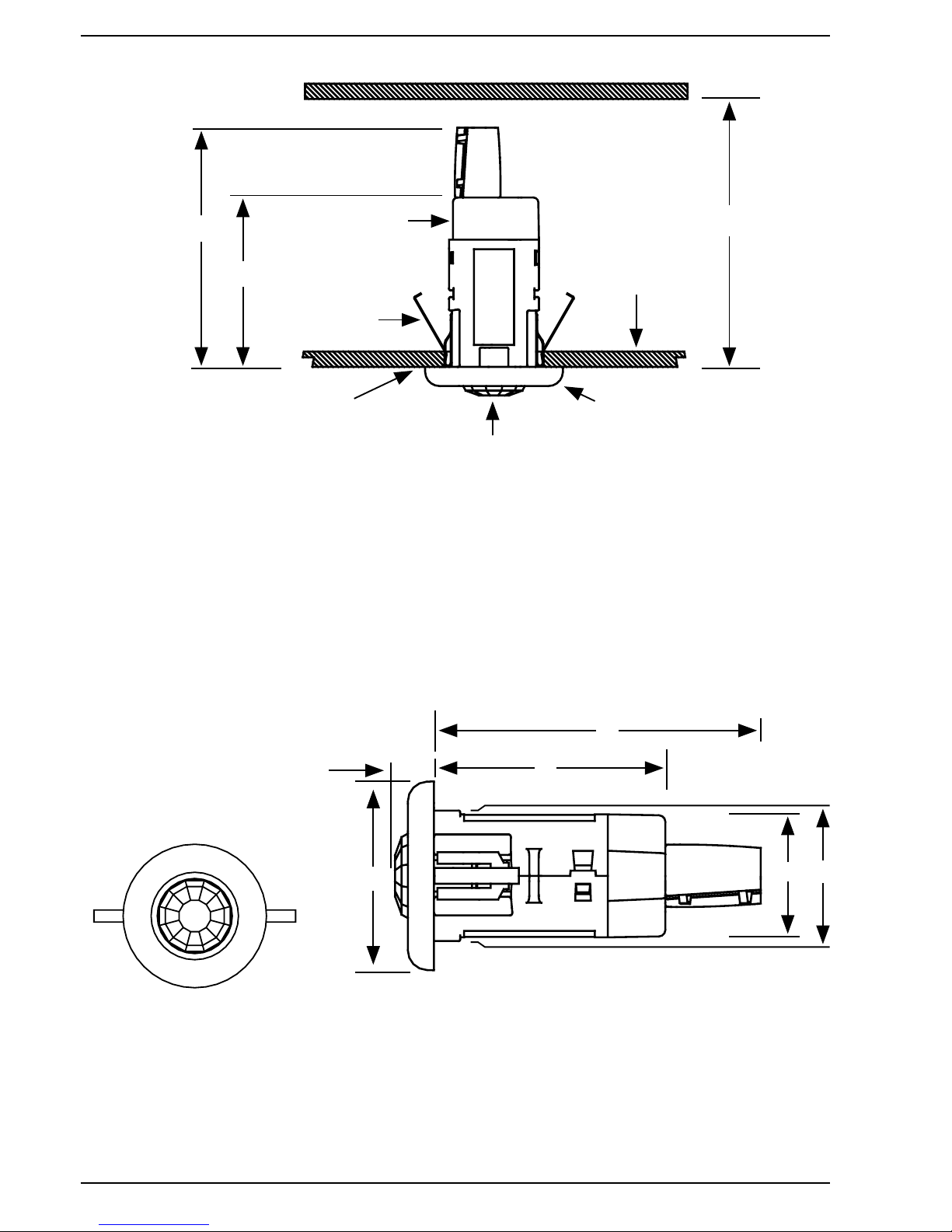

Note

• Whenmountinginsuspendedceilingsthereshouldbeatleast140mmbetween

the lower surface of the tile and the hard surface above.

• Donotapplyanypressureontheactualsensorlensitselfasthismaydamage

the lens.

NextLevel/Roof

Terminal Cover

Spring Clips

Minimum Ceiling

Thickness 8mm

Surround

Lens

Cut a 50mm Circular Hole

in Ceiling (or Ceiling Tile)

140mm Minimum

126.5mm

90mm

Figure 5

A

C

B

DE

F

A 72mm (2.83")

B 15mm (0.59")

C 89mm (3.50")

D 47mm (1.85")

E 50mm (1.97")

F 126.5mm (4.98")

Figure 6

753 Series 360° Infrascan Installation Instructions

9 of 16

© 2012 Schneider Electric. All Rights Reserved.

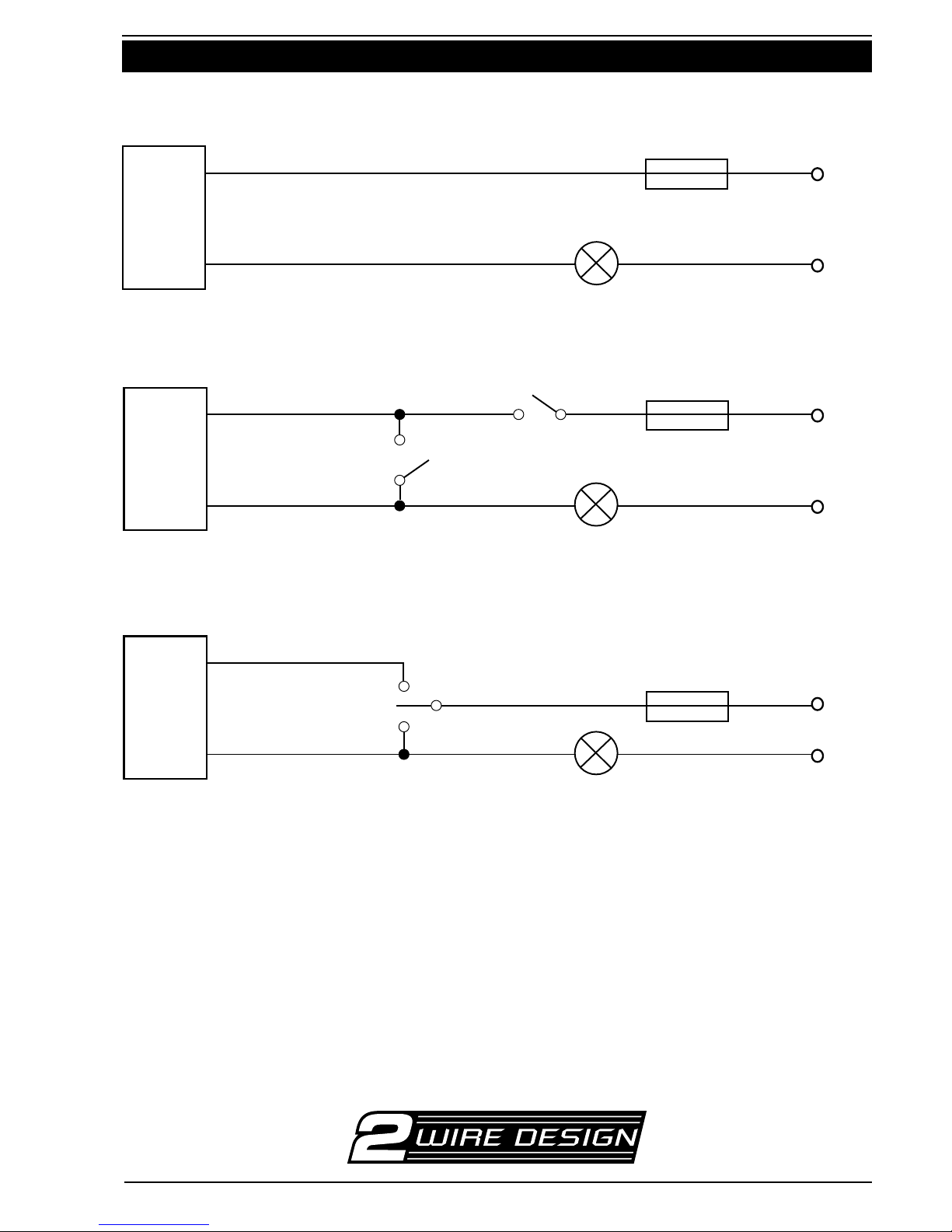

9.0 Wiring Diagrams - 753 2-Wire Infrascan

1(a) Automatic operation

1(b) Automatic with manual override ON or OFF

1(c) ON, OFF or AUTOMATIC operation using a three position switch

Note

• WhenswitchingtoAUTOforanyoftheabovecongurationstheInfrascanwill

turnon.Allow30secondsplusTime-Onperiodforthesensortostabilisefor

normal operation. Wiring diagram 1(a), without override switches is preferred as

there is no settling period.

• Morethanone753CANNOTbeconnectedinparalleltoacommonload.

If parallel connection of multiple devices to control a common load is required,

useCat.No.753R.

Load

Active/Line

10A Fuse or MCB

753

Black/White

A

N

Red/Brown

Load

Active/Line

10A Fuse or MCB

753

Black/White2x30Mor30MAM

Off

Auto

On Auto

A

N

Load

Red/Brown

Load

Active/Line

753

Black/White39MAOM

On

Auto 10A Fuse or MCB

Off

A

N

Load

Red/Brown

Load

753 Series 360° Infrascan Installation Instructions

10 of 16 © 2012 Schneider Electric. All Rights Reserved.

10A Fuse or MCB

753R

Load

Active

Black/Blue

Load

Red/Brown

White

Neutral

A

N

Auto

753R

39MAOM

10A Fuse or MCB

Off

Load

On

Active

Black/Blue

Load

Red/Brown

White

Neutral

A

N

On

10A Fuse or MCB

753R

2x30M or 30MAM

Auto

Load

Off

Active

Black/Blue

Load

Red/Brown

White

Neutral

A

N

Auto

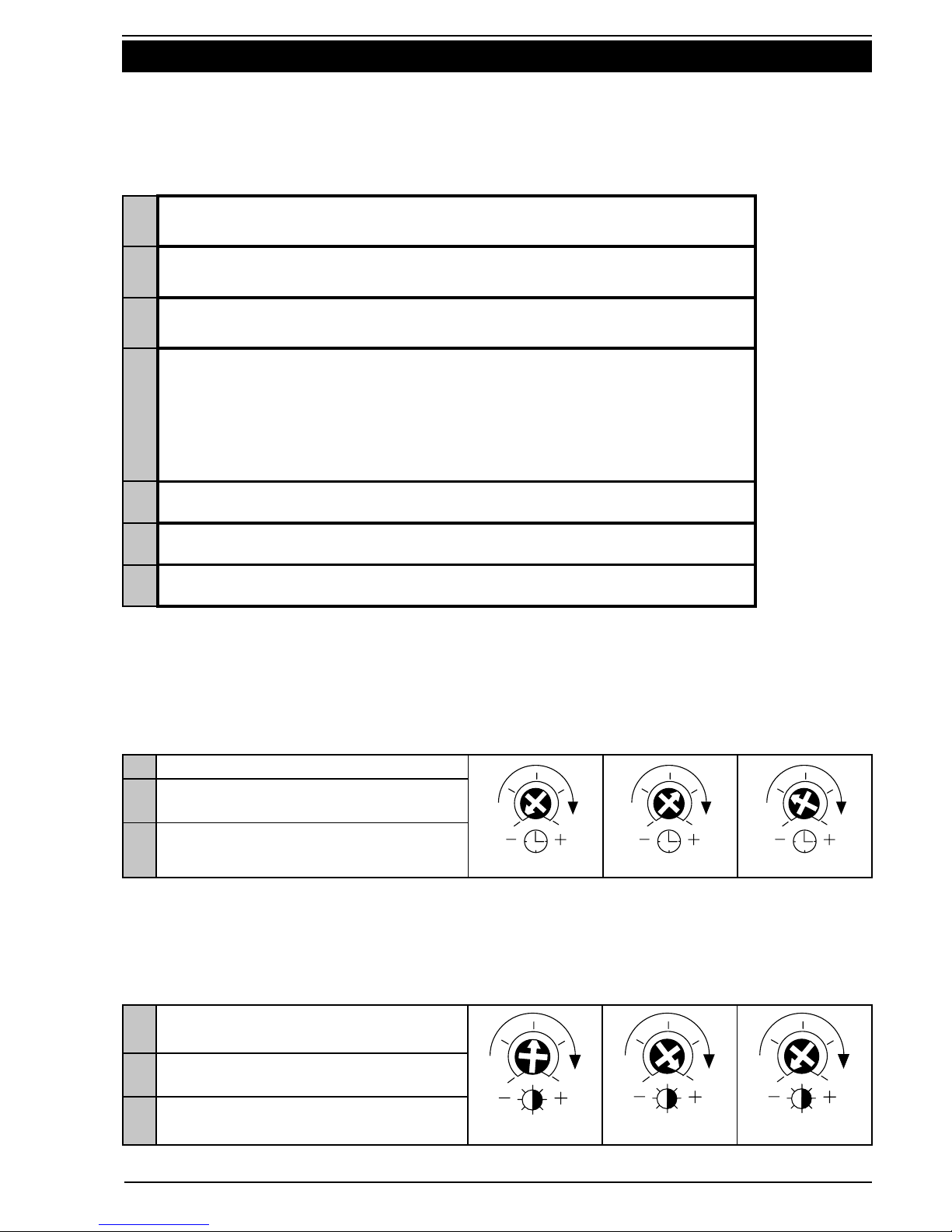

10.0 Wiring Diagrams - 753R 3-Wire Infrascan

2(a) Automatic operation

2(b) Automatic with manual override ON or OFF

2(c) ON, OFF or AUTOMATIC operation using a three position switch

Warning

• Itisillegalforpersonsotherthanlicensedelectriciansorpersonsauthorised

by legislation to work on fixed wiring of any electrical installation. Penalties for

conviction are severe.

• Installationmustbecarriedoutinaccordancewithlocalwiringrules(AS/

NZS3000AustraliaandNewZealand).

753 Series 360° Infrascan Installation Instructions

11 of 16

© 2012 Schneider Electric. All Rights Reserved.

1Connect unit to mains power and allow at least 30 seconds for the unit to

stabilise before conducting any tests.

2Twist and remove the front surround and use a screwdriver to set the

‘Time-On’adjustmentfullyanti-clockwise(5secondtimerset).

3Setthe‘Light-Level‘sensoradjustmentfullyanti-clockwise(unitsetto

respond in light or dark conditions).

4

Walk slowly around the area in the desired field of view to confirm the load

is activated from within the desired area.

Check that the unit responds appropriately when entering the room.Check

that the unit does not trigger unnecessarily when walking past open entry

ways(e.g.adjoininghallwayorcorridor).Fitthezonemaskifnecessaryto

restrict the field of view to avoid nuisance tripping.

5Set the ‘Light-Level’ as desired for activation at dusk for normal operation.

6Setthe‘Time-On’intervaltothedesiredtimefornormaloperation.

7Replace the front surround.

11.0 Commissioning

WhensettingtheTime-OnorLight-Leveladjustmentskeepclearofthefieldofview

whenassessingtheeffectoftheadjustment.

11.1 Set Up for Walk Test

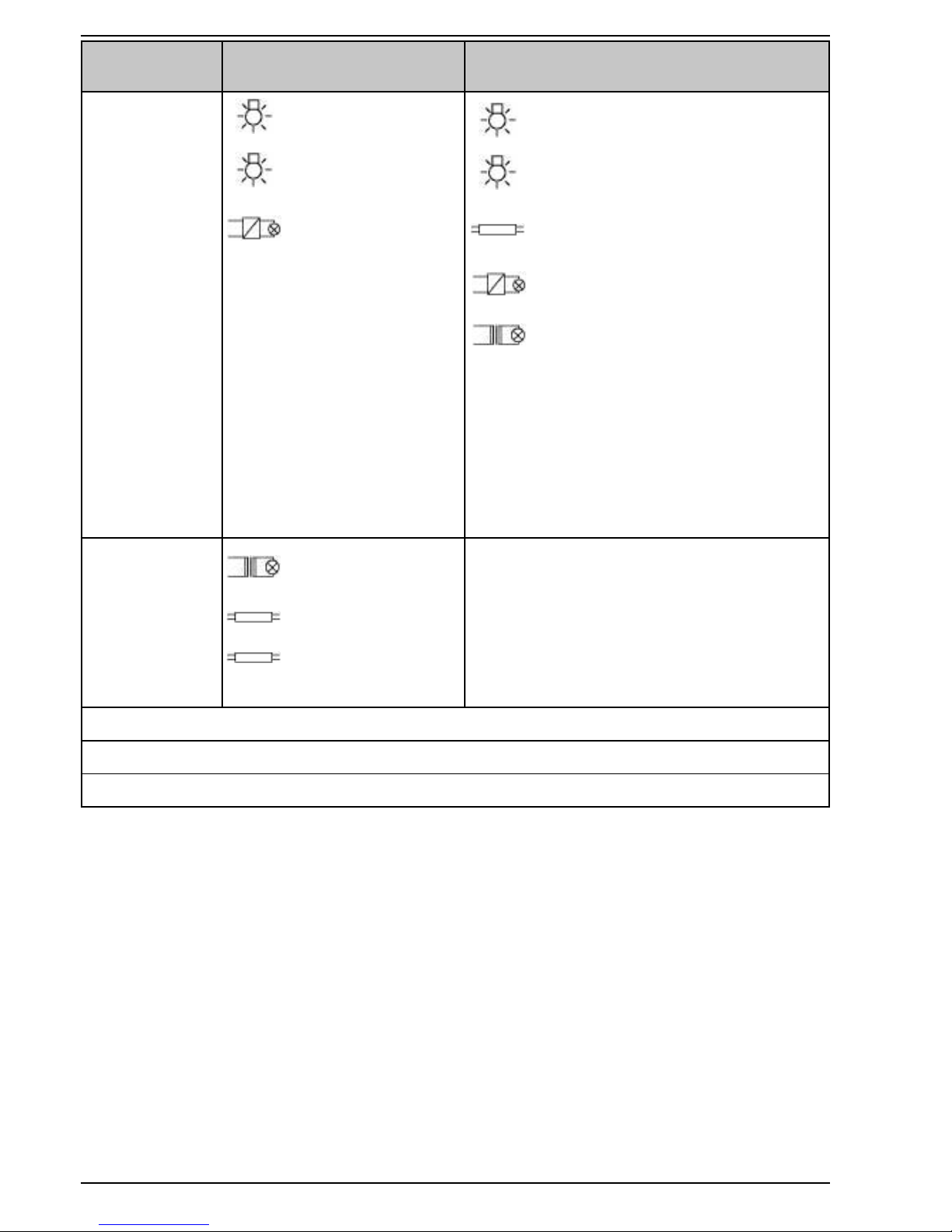

11.2 AdjustmentOfTime-OnandLight-LevelSettings

Time-OnAdjustment

AdjustmentRange:Fivesecondsto20minutes.

Rotate clockwise to set required time-out period.

Light-LevelAdjustment

AdjustmentRange:Oneluxtofullsunlight.

Rotate clockwise to avoid having load activated when natural light is adequate.

aMinimum setting (five seconds).

a b c

bSet for areas with constant occupation

but infrequent movement.

cSet for areas with less occupation but

constant movement.

aTo activate the load at dusk, set

adjustmenttothisarea.

abc

bLoad activated at night only.

cLoad activated both day and night.

753 Series 360° Infrascan Installation Instructions

12 of 16 © 2012 Schneider Electric. All Rights Reserved.

12.0 Troubleshooting

Problem Possible Cause Possible Action

Light turns on

for no apparent

reason.

Momentary power failure. None,unitwillresetafter

Time-Out.

Unseen target. Checkforanimals,e.g.dogs/

cats, etc.

Extreme draughts of hot and

cold air.

Check doors, windows or air

conditioning outlets.

Trees/bushesmovinginthe

wind.

Re-aim sensor head.

Vehicular or pedestrian traffic

on edge of field of view.

Re-aim sensor head.

Light turns on

during daylight.

Wrong setting on Light

Adjustment.

Reset according to

Commissioning Instructions.

Lights do not

turn on in

dim and dark

conditions.

Wrong setting on Light

Adjustment.

Reset according to

Commissioning Instructions.

Light globe blown. Replace light globe.

Light remains

permanently on.

Manual override switch fitted

and set to Manual.

Reset according to

Commissioning Instructions.

Moving infrared source being

detected.

Note: do not mount too close

toobjectswhichcanchange

temperature rapidly, e.g. air

conditioner vents, heater

flues, moving water (i.e.

fountains, sprinklers).

Remove unwanted infrared

source. If unable to resolve,

blank off viewing window.

Light should turn off after

Time-Out.Iflightstillremains

on, call installer.

Note

• Takecarenottoscratchordamagethetranslucentwindowonthefrontof

the Infrascan, as it forms part of the optical detection system. For continued

optimum performance ensure that the window is cleaned periodically with mild

soap, water and a soft cloth.

753 Series 360° Infrascan Installation Instructions

13 of 16

© 2012 Schneider Electric. All Rights Reserved.

13.0 Technical Specifications

Catalogue Number 753 753R

OperatingVoltage 200 – 265V 50Hz a.c.

Maximum Load Current 2A 10A

Minimum Load (Watts)* 40W 0W

MaximumOff-StateLeakageCurrent 10mA 0mA

Stand-By Power Consumption < 1W < 1W

Conductors Required 2-WIRE 3-WIRE

NeutralRequired NO YES

OperatingTemperatureRange 0° - 50°C

Warm-Up Time 30 seconds

Rated Detection Field at Maximum

Sensitivity**

360°, circular detection field

14 meters diameter

OptimalMountingHeightforRated

Detection Field 2.4 metres

Timer Delay Range 5 seconds to 20 minutes,

useradjustable***

Light Level Inhibit Threshold Continuous from 1 lux to full sunlight,

useradjustable

Mounting Surface Ceiling mount

OverallDimensions 72mm diameter x 141.5mm high

Cut-OutDimension 50mm holesaw

Cables Accommodated 4 terminals, up to 2 x 2.5mm2

cable per terminal

753 Series 360° Infrascan Installation Instructions

14 of 16 © 2012 Schneider Electric. All Rights Reserved.

M

Catalogue

Number 753 753R

Compatible

Load Types

Incandescent

240V Halogen

Iron Core

Transformers****

Incandescent

240V Halogen

Fluorescent

Iron Core Transformers

Electronic Transformers

Small Motor Loads 5A

- Shaded Pole Induction

Motors 5A Max

(exhaust fans)

- Split Phase Induction Motors

5A Max (ceiling fans)

Incompatible

Load Types

Electronic

Transformers

Fluorescent

Loads

Discharge Lamps

Motor Loads

N/A

Specifications Typical @ 240V a.c., 25°C

Nouserserviceablepartsinside.

ThisproductisrecommendedforINDOORUSEONLY.

* The 753 2-Wire Infrascan must be connected to a minimum 40W load, unless the 31CAP (sold

separately) is fitted. Failure to do so may cause unexpected or erratic switching of the load.

** The range specifications given are based on a 90kg person travelling at greater than 1 metre

per second across the field of view, where there is a temperature differential greater than 5°

Celsiusbetweenthepersonandthebackground.Objectsthatarehotterormovingfaster(e.g.

motor vehicle on nearby roadway) may be detected at greater distances. A person covered in

heavy clothing or walking directly towards the sensor may not be detected until they get much

closer to the unit.

***OthermodelsareavailablewithlongerTime-Outranges,designated753Rxx

(wherexxistheTime-Outperiodinminutes).

****Onlyiron-coretransformerscompatiblewithelectronicswitchesmaybeusedtoensure

compliance with IEC 60669-2-1.

M

753 Series 360° Infrascan Installation Instructions

15 of 16

© 2012 Schneider Electric. All Rights Reserved.

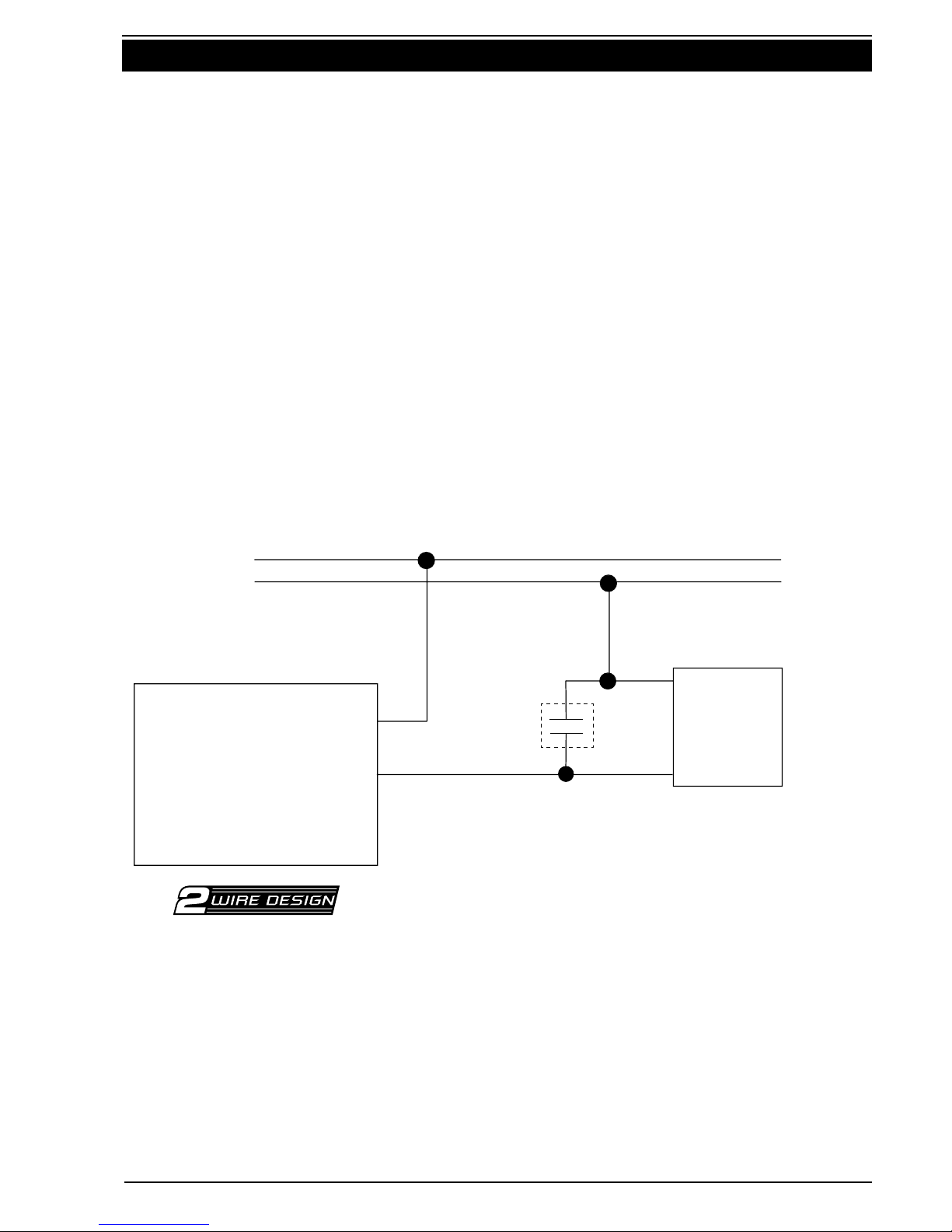

14.0 Warning- Using the 753 with Special Loads

Small Loads (<40W)

The 753 product can only drive loads greater than 40W. If you wish to drive a

smaller load, the 31CAP Load Correction Device is required to be fitted in parallel

with the load. For example: when driving a single contactor, be sure to use the

31CAP.

Loads which are Sensitive to Leakage Currents

The 753 is a two-wire device. Two-wire devices draw their power through the load.

Ifthisdeviceisusedinconjunctionwithaload,whichcannotprovideenough

continuous load current in the off-state, or the load is sensitive to a high off-

state leakage current (for example: relays, contactors, various loads with built-in

electronic control, etc.) a 31CAP Load Correction Device must be connected in

parallel with the load.

Small(Non-PowerFactorCorrected)FluorescentLoads

When a 31CAP is fitted, some small non-power factor corrected fluorescent

loads may be controlled using the 753. Success varies from manufacturer to

manufacturer. Recommend testing before installation. Installation must be

compliant with local wiring rules.

Line

Neutral

Line

Load

31CAP Load

31CAP Load Correction Device

753

Note

• Pleasenotethe753Risathree-wiredevice,andswitchestheloadusingan

internal relay. Power is not drawn through the load and so the 31CAP is not

required.

F1985/05

CLIPCOM24868June 2012

Schneider Electric (Australia) Pty Ltd

Contact us: clipsal.com/feedback

National Customer Care Enquiries:

Tel 1300 2025 25

Fax 1300 2025 56

Schneider Electric (Australia) Pty Ltd reserves the right to change specifications, modify

designs and discontinue items without incurring obligation and whilst every effort is made to

ensure that descriptions, specifications and other information in this catalogue are correct, no

warranty is given in respect thereof and the company shall not be liable for any error therein.

© 2012 Schneider Electric. All Rights Reserved.

Trademarks are owned by Schneider Electric Industries SAS or its affiliated companies.

15.0 Warranty

1. The benefits conferred herein are in addition to, and in no way shall be deemed to

derogate; either expressly or by implication, any or all other rights and remedies in

respect to the Clipsal product, which the consumer has under the Commonwealth

Trade Practices Act or any other similar State or Territory Laws.

2. The warrantor is Schneider Electric (Australia) Pty Ltd of 33-37 Port Wakefield

Road, Gepps Cross, South Australia 5094. Telephone (08) 8161 0511. With

registered offices in all Australian States.

3. This Clipsal product is guaranteed against faulty workmanship and materials for

a period of two (2) years from the date of installation.

4. Schneider Electric (Australia) Pty Ltd reserves the right, at its discretion, to either

repair free of parts and labour charges, replace or offer refund in respect to any

article found to be faulty due to materials, parts or workmanship.

5. ThiswarrantyisexpresslysubjecttotheClipsalproductbeinginstalled,wired,

tested, operated and used in accordance with the manufacturer’s instructions.

6. All costs of a claim shall be met by Schneider Electric (Australia) Pty Ltd, however

shouldtheproductthatisthesubjectoftheclaimbefoundtobeingoodworking

order all such costs shall be met by the claimant.

7. When making a claim the consumer shall forward the Clipsal product to the nearest

office of Schneider Electric (Australia) Pty Ltd with adequate particulars of the

defect within 28 days of the fault occurring. The product should be returned securely

packed, complete with details of the date and place of purchase, description of load,

and circumstances of malfunction.

This manual suits for next models

1

Table of contents