Safety instructions

WARNING

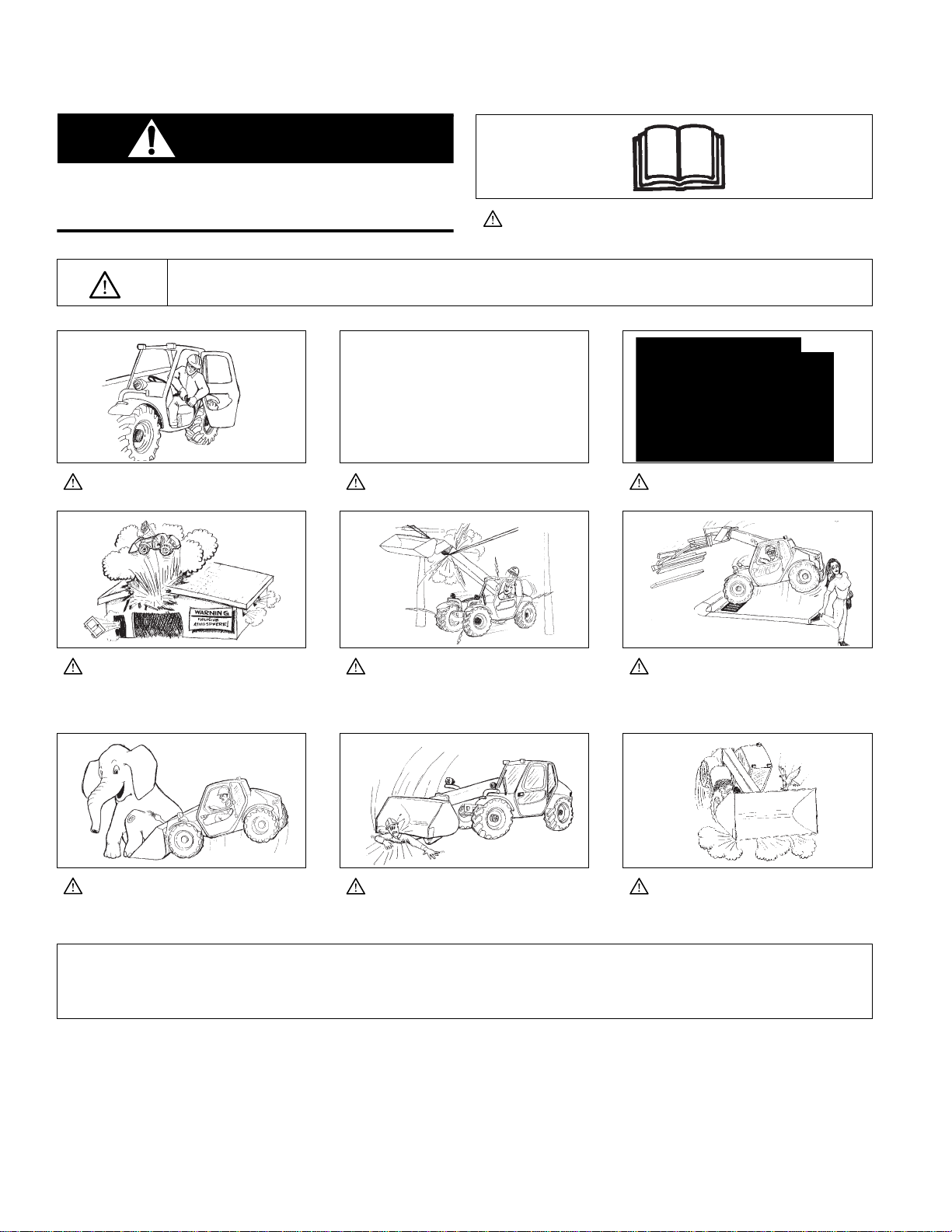

Operators must read and understand instructions

before running the machine. Untrained operators can

cause injury or death.

• SEAT BELT: Check belt fasteners and check for damaged strap

or buckle.

• OPERATOR CAB (ROPS & FOPS): It must be on the machine with

all fasteners tight. Never use the machine without the right side

window.

• OPERATOR'S HANDBOOK: Must be in cab.

• MACHINE SIGNS (Decals): Replace if Damaged

• SAFETY TREADS: Replace if Damaged

• GRAB HANDLES: Replace if Damaged

• PARKING BRAKE

• WINDOWS AND MIRRORS: Clean and check for broken window

or mirror. Replace if Damaged

Never use the telescopic handler without instructions. See the

machine signs (decals), Operation & Maintenance Manual, AEM

Safety Manual and data sheets located in the cab.

Safety Alert Symbol: This symbol with a warning statement means: “Warning, be alert! Your safety is involved!” Care-

fully read the message that follows.

Always fasten seat belt securely.

Do not have any part of your body out-

side the cab

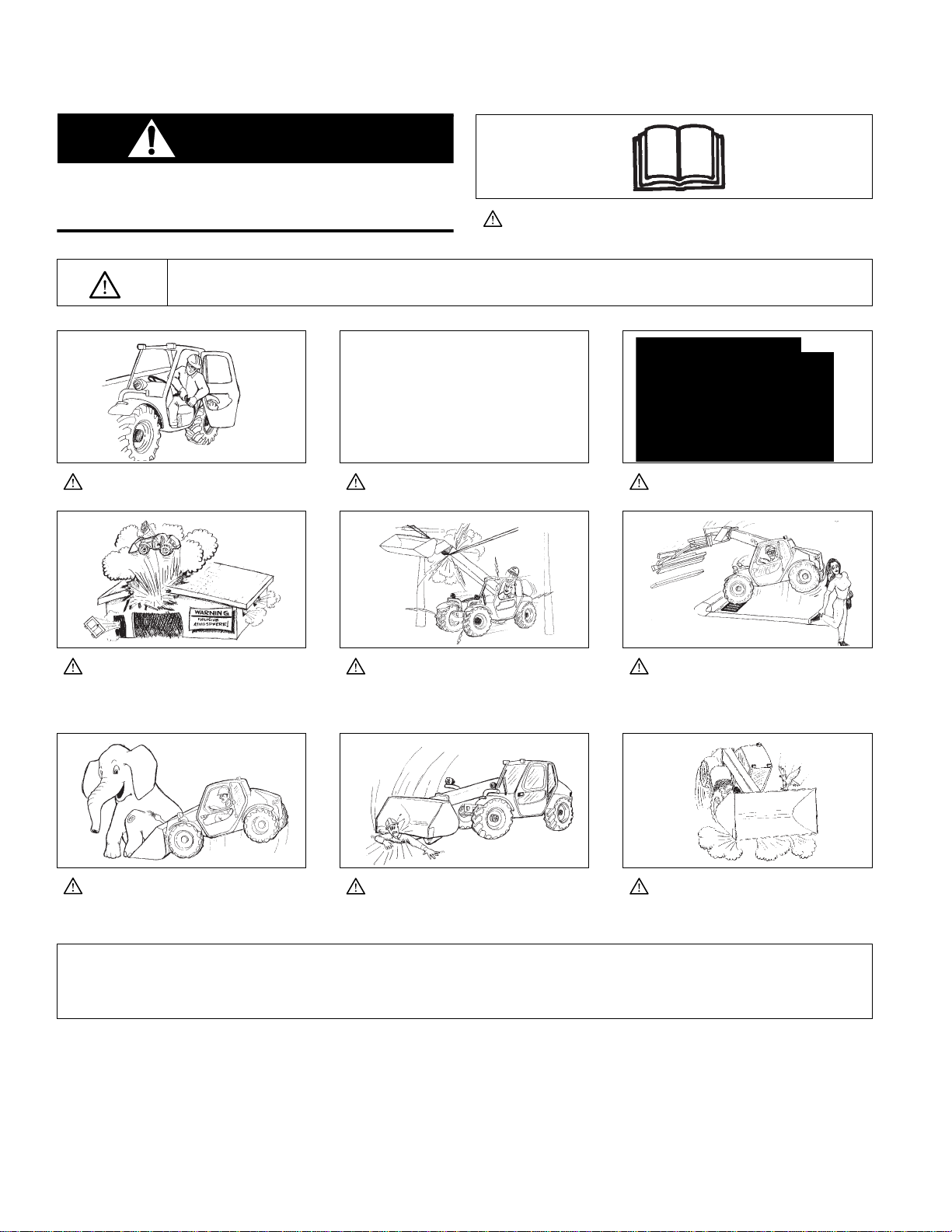

Never use the telescopic handler with-

out operator cab (ROPS & FOPS). Never use the machine as a working

platform or an elevator unless it is

equipped with a IR-approved platform.

Do not use the machine where exhaust

can contact flammable material, explo-

sive dust or gases.

Check for underground or overhead

lines in the area before operating the

machine.

Keep a minimum distance of 8 m

between the nearest line and the

machine arm, attachment, or load.

Never transport a load when raised.

Do not travel or turn with the lift arms

up.

Load, unload and turn on flat level

ground.

Never exceed rated operating capacity.

Keep to the limits of the machine's

Rated Capacity Chart and/or the attach-

ment's nominal capacity.

Never leave telescopic handler with

engine running or with lift arms up.

To park, engage parking brake and put

attachment flat on the ground.

Never modify equipment.

Only use attachments that are approved

by IR for this type of telescopic handler.

Correct Incorrect

ncorrec

ncorrec

ncorrec

ncorrec

ncorrec

ncorrec

ncorrec

SAFETY EQUIPMENT

The IR telescopic handler must be equipped with safety systems necessary for each job. Ask your dealer for information on the safe use

of attachments and accessories.

Find manuals at https://best-manuals.com