Ingos COR 400 User manual

INGOS Ltd. COR400

CIRCULATION

Producer:

INGOS Ltd., Division of Laboratory Instruments

Supplier a service:

INGOS Ltd.

K Nouzovu 2090; 143 00 Prague 4

; Czech Republic

Tel.: + 420 225 983 400

+ 420 225 983 409

Fax: + 420 244 403 051

e-mail:instruments@ingos.cz

www:ingos.cz

17.7.2019

CIRCULATION

CHILLER

COR 400

User manual

INGOS Ltd., Division of Laboratory Instruments

INGOS Ltd.

; Czech Republic

Strana 1

COR 400

INGOS Ltd. COR400 17.7.2019

Strana 2

1. INTRODUCTION

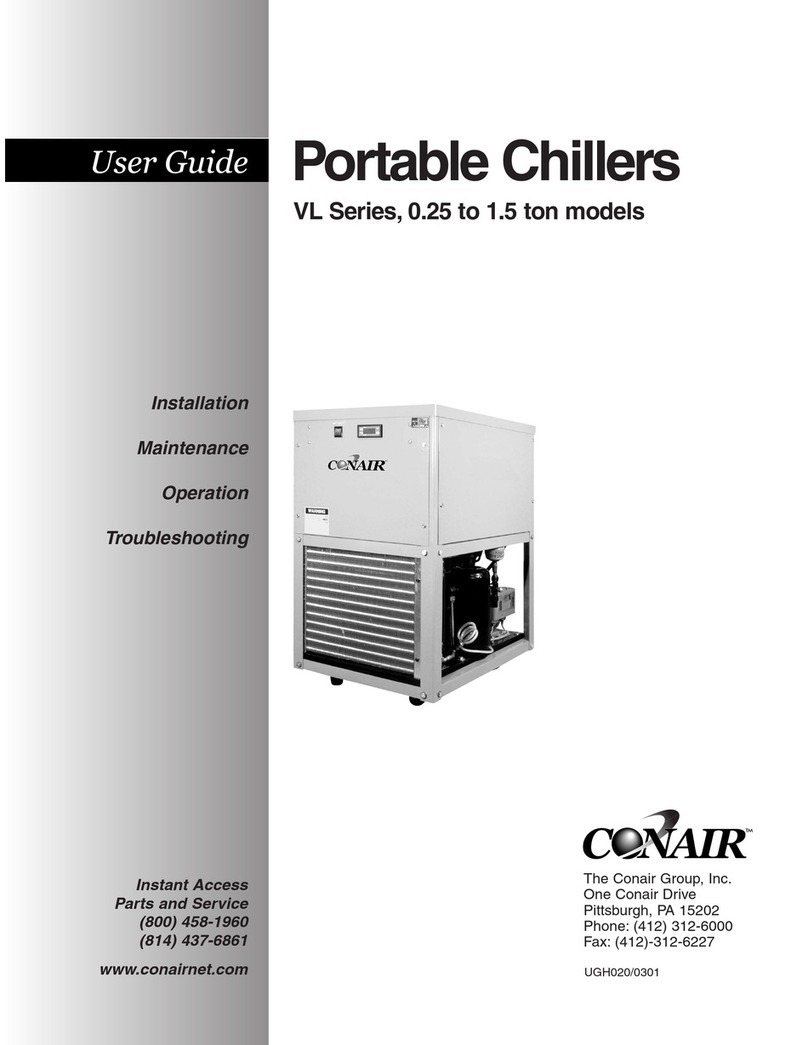

The Chiller is designed to cool the cooler rotary vacuum evaporator (it can also be used for

two rotary evaporators together). The chiller can be used for other device which need cooling. The

control module controls temperature in the cooling tanks. The chiller is designed as a single

functional instrument.

4

3

5

7

6

2

8

1

1. Switch 4. Output cooling medium 7. Grip

2. Thermostat 5. Input cooling medium 8. Socket or switch

3. Circulation pump 6. Overflow circulation pump

Fig.1 Chiller

Warning :

Using devices other than as described in the instructions can cause security breaches!

2. DESCRIPTION AND SPECIFICATION

2.1 Description

The instrument consists of a box in which is thermostatic tank, as a source of cold a modern

compressor cooling unit Lindr is used that uses the input electric energy for direct transfer to

chilling. Cooling loop in a thermostated tank is made of stainless steel. Cooled thermostated tank is

equipped with a circulation pump. Temperature control and cooler run is through digital thermostat.

Used materials meet the highest requirements for hygiene standards and guarantee a long

working life of this cooler.

Two grips located on the sides of the cooler facilitate handling.

INGOS Ltd. COR400 17.7.2019

Strana 3

2.2 Specification

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1/4 HP

Performance 22°C =>7°C . . . . . . . . . . . . . . . . . . . . . . . . 80 l/hour

Minimum temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 1°C for water

Minimum temperature . . . . . . . . . . . . . . . . . . . . . . . . . . -20°C for antifreezing mix

Regulation accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . .±1°C

Volume of cooling tank . . . . . . . . . . . . . . . . . . . . . . . . 20 l

Displacement pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 m

Pump flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 l/hour

Cooling gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R 290

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230V, 50Hz

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . max. 391 VA

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 kg

Dimensions (w x d x h) . . . . . . . . . . . . . . . . . . . . . . . . . 530 x 330 x 474 mm

The instrument is designed for an ambient temperature 15 - 35 °C; with humidity up to 80%

without acid and caustic vapors.

3. COMMISSIONING

3.1 Unpac ing

Carefully unpack the instrument from the shipping container. Check the exterior of the

instrument, suffer during the transport from visible damage. Should any damage occur during the

transport, contact the shipping company.

According to the delivery note check all items. In case of discrepancy carefully inspect all

packing material. If any item is missing, contact the manufacturer or your supplier.

Place the instrument on the table and familiarize yourself with the distribution and function of

the controls and connections. Before operating read the instructions of this manual thoroughly.

Place the chiller so that the heat generated by the chiller may be sufficiently ventilated,

must not be placed near radiant heat or direct sunlight. The chiller should be placed on a

horizontal surface. Do not place objects the chiller that would prevent air circulation.

The chiller can in no case be put on its side even during transport!

3.1.1 What you will need

To put into operation, you will need the following items:

1. Tubing with insulation and couplings for connection to a rotary vacuum evaporator cooler.

2. 20 - 25 liters of antifreeze with a freezing point of about 5°C lower than the lowest temperature

set on the thermostat. When setting the lowest limit of temperature of 1°C and above, you can be

used water.

Fill the plastic tank with liquid to the overflow.

INGOS Ltd. COR400 17.7.2019

Strana 4

3.1.2 Connecting elements, instrument assembly

The power switch is located on the panel (green with glow lamp). Furthermore, on the panel

is switch displacement pump (red with glow lamp) and a temperature controller.

Cooled liquid output is in labeled outlet. Returning liquid input is in labeled input. Using the

supplied hoses and couplings assemble the cooling circuit and check the connection hose. Hoses

must be straight cut-away in the event that it can not be inserted into the coupling, it is necessary

to moisten the end.

3.2 Temperature controller

Display along with a button keyboard provide user comfort for direct control.

The function of the individual keys is as follows:

Button to turn on/ turn of temperature control.

Set Button to enter the setup mode.

Setting button.

Setting button.

Setting parameters

1. Enter the setup mode.

Press the SET button for more than 5 seconds, the LED turns on lights up and displays the set

temperature.

2. Setting the temperature.

Use the settings button to set the desired temperature.

3. Leave the settings mode.

Press the SET button more than 5 seconds, or in 30 seconds the thermostat (when there is no

button operation) will return to normal operating mode.

INGOS Ltd. COR400 17.7.2019

Strana 5

Entry to the mode menu

1. Entry to management menu

Press the SET button and setting button for more than 5 seconds, the LED lights and the

display shows the code F0.

2. Setting parameters

Setting buttons to select the code and press SET button.

3. Change settings

Setting buttons to set the parameters of the selected code.

4. To return to the parameter setting

Press the button SET.

5. Leave the setting mode

Press the SET button more than 5 seconds, or in 30 seconds the thermostat (when there is

no button operation) will return to normal operating mode.

Setting item Range setting parameters Factory setting code

Temperature difference 1°C ~ 16°C 1°C F0

Compressor delay 0 ~ 9 minute 0 minute F1

Lower limit temperature up to -40°C -20°C F2

Upper limit temperature up to +70°C 20°C F3

Selectable mode 1:cooling; 2:heating; 3:alarm 1 F4

Temperature calibration -5°C ~ +5°C 0 F5

3.3 Switching on the instrument

The procedure to turn on the instrument is as follows:

1. Plug the instrument into the mains with corresponding voltage.

2. Check hose connections.

3. Turn on the power switch.

4. Set the temperature regulator.

5. Turn on the circulating pump.

INGOS Ltd. COR400 17.7.2019

Strana 6

4. ROUTINE MAINTENANCE AND SERVICE

At the latest after six months of operation, replace the contents of the bath. Periodically check

the cleanliness and filling of bath. During sanitizing the water temperature must not be higher than

40°C. Cleaning of all external surfaces of the instrument should be done with a soft cloth. You can

use common cleansers. Do not leave the instrument on a surface contaminated from corrosive

substances. This could cause damage of paint on the instrument. The surface of the instrument clean

with a soft cloth.

Cleaning the condenser perform at least 1x per month by sweeping, or air pressure, or CO

2

.

Fan cover by pulling upward pull of metal trails. Unscrew the fastening screws from the cooler on

the condenser side. Loose cover first pull up upwards 3 cm, than pull to the side. Loosen the other

side of the cover so that you can pull the whole cover of metal trails. Now you can clean the

condenser.

Warning: When cleaning, unplug the instrument!

Ejecting the fan Putting the fan in place Unscrewing the cover

Removing the cover Condenser ready for cleaning

5. ACCESSORIES

2 pcs Set of hoses and couplings for connection RVO 400

INGOS Ltd. COR400 17.7.2019

Strana 7

6. WARRANTY, OPERATING CONDITIONS

For the instrument the manufacturer provides a warranty of two years from the delivery to the

customer. The instrument may be used only in the manner described in this manual. The producer is

not liable for damages resulting for failure to comply with the conditions set in this manual.

The instrument is designed for an ambient temperature 15 - 35 °C; with humidity up to 80%

without acid and caustic vapors. The inlet cord plugs into a socket circuit featuring protection 16 A.

All warranty and post warranty repairs are to be performed by the manufacturer, or its

authorized body.

Warning!

For using water as coolant, set in mode F2 lower limit of the temperature at 1°C and above.

7. WASTE DISPOSAL

At the end of life discard the instrument according to valid regulations on waste or return to

the vendor or producer for liquidation.

The instrument contains a cooling gas R 290.

The instrument is destroyed as electronic waste.

8. CONTENT

1.

INTRODUCTION ......................................................................................................................2

2.

DESCRIPTION AND SPECIFICATION ..................................................................................2

2.1

Description..............................................................................................................................2

2.2

Specification............................................................................................................................3

3.

COMMISSIONING....................................................................................................................3

3.1

Unpacking ...............................................................................................................................3

3.1.1

What you will need..........................................................................................................3

3.1.2

Connecting elements, instrument assembly.....................................................................4

3.2

Temperature controller............................................................................................................4

3.3

Switching on the instrument....................................................................................................5

4.

ROUTINE MAINTENANCE AND SERVICE .........................................................................6

5.

ACCESSORIES..........................................................................................................................6

6.

WARRANTY, OPERATING CONDITIONS ...........................................................................7

7.

WASTE DISPOSAL...................................................................................................................7

8.

CONTENT..................................................................................................................................7

Table of contents

Popular Chiller manuals by other brands

Daikin

Daikin EWAD TB Installation, operation and maintenance manual

Lindab

Lindab PLAFOND Series installation instructions

Unical

Unical HP_OWER ONE 70R User's and installer's manual

teca

teca RLC-1402HC Product information packet

MTA

MTA Aries AS 201 FC Operating and instruction manual

Daikin

Daikin EWYD-4ZB Installation, operation and maintenance manual