Ingun MA 2x09 Series User manual

Technical manual

Manual Test Fixture

MA xxxx with ATS MAxx

Technical manual MA xxxx with ATS MAxx

1 ©INGUN: Subject to technical changes without notice. E&OE.

1Product description.....................................................................................................................4

1.1 MA xxxx .........................................................................................................................................4

1.2 ATS MAxx......................................................................................................................................5

1.2.1 Standard version.............................................................................................................5

1.2.2 ESD version....................................................................................................................5

1.2.3 RF version.......................................................................................................................5

2SAFETY.........................................................................................................................................6

2.1.1 Safety advice for testing with harmless high-voltage......................................................6

2.1.2 Air distance and max. allowable current:........................................................................6

2.1.3 Commissioning of safety functions .................................................................................6

2.1.4 Dangers when operating electromagnets.......................................................................7

3Customising.................................................................................................................................7

3.1 Customising for stroke 22 mm (MA 3xxx)......................................................................................8

3.2 Customising accessories...............................................................................................................8

3.2.1 Interface blocks (SB).......................................................................................................8

3.2.2 Start-up kit (SK) ..............................................................................................................8

3.2.3 Side approach mechanism (SAM)..................................................................................8

3.2.4 Marking units (ME)..........................................................................................................9

3.2.5 Potentiometer screwing unit/key button activators .........................................................9

4Functional sequence...................................................................................................................9

5Additional Functions MAxxxx ..................................................................................................10

5.1 Protection conductor wiring and contact protection for dangerous voltages...............................10

5.2 ESD assembly .............................................................................................................................11

5.3 ESD assembly and protection conductor wiring..........................................................................11

5.4 Dual-stage contacting from bottom side......................................................................................11

5.4.1 Locked electrically.........................................................................................................13

5.4.2 Pneumatic locking.........................................................................................................14

5.4.3 Mechanical stroke limitation..........................................................................................15

5.5 Dual-stage contacting with self-opener .......................................................................................15

5.5.1 Electrical dual-stage contacting with self-opener .........................................................16

5.5.2 Pneumatic dual-stage contacting with self-opener.......................................................16

5.5.3 Mechanical dual-stage contacting with pneumatic self-opener....................................17

6Additional Functions ATS MAxx..............................................................................................18

6.1 ESD version.................................................................................................................................18

6.2 Radio frequency version..............................................................................................................18

7Optional Functions MAxxxx .....................................................................................................20

7.1 Safety switch for closed pressure frame......................................................................................20

7.1.1 Safety switch with locking NO (currentless; open) .......................................................22

7.1.2 Safety switch with locking NC (currentless; closed) .....................................................23

7.1.3 Safety switch without locking........................................................................................23

7.1.4 Magnetic safety switch..................................................................................................24

7.2 Self-opener ..................................................................................................................................24

7.2.1 Pneumatic.....................................................................................................................26

7.2.2 Electric ..........................................................................................................................27

7.3 Check for pressure frame closed.................................................................................................27

7.3.1 Check via stroke switch ................................................................................................27

7.3.2 Check stroke position by inductive sensor ...................................................................28

7.3.3 Check locking position by inductive sensor..................................................................28

7.4 Check ATS locked .......................................................................................................................28

7.5 Locking unit for closed pressure frame........................................................................................29

7.5.1 Stroke magnet NC (currentless; closed).......................................................................29

7.5.2 Stroke magnet NO (currentless; open).........................................................................30

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 2

7.5.3 Pneumatic cylinder locking ...........................................................................................30

7.6 Locking unit for pressure frame open..........................................................................................31

7.7 Pressure frame unit opening limited............................................................................................32

7.8 Upgrade kit gas pressure spring..................................................................................................32

7.9 Gas pressure springs for the drive unit (kit).................................................................................33

7.10 Hinged metal handle....................................................................................................................33

7.11 Pass / fail LED indicator...............................................................................................................34

7.12 Push button..................................................................................................................................34

7.13 Oil break.......................................................................................................................................35

7.14 Anti-pinch protection....................................................................................................................35

7.15 Extended handle..........................................................................................................................35

7.16 MA control unit.............................................................................................................................36

7.17 Magnet control unit ......................................................................................................................38

8Optionally Available ..................................................................................................................39

8.1 Dual-stage upgrade kit.................................................................................................................39

8.2 Reinforcement for customisations with large number of test points............................................40

8.2.1 Stiffener kit for NDH......................................................................................................40

8.2.2 Stiffener kit for KTE.......................................................................................................40

8.3 Insertion blocker for stroke 22mm ...............................................................................................41

8.4 Contact protection for dangerous voltage....................................................................................41

8.5 Lifting units...................................................................................................................................42

8.6 Check for “pressure frame closed” ..............................................................................................43

8.6.1 Check for pressure frame closed using two GKS.........................................................43

8.6.2 Check for pressure frame closed via stroke switch......................................................43

8.7 Actuator for safety switch with and without locking .....................................................................44

8.7.1 Actuator for single-stage...............................................................................................44

8.7.2 Actuator for dual-stage (basic unit)...............................................................................44

8.7.3 Actuator for magnetic safety switch..............................................................................45

8.8 Ground plate for ATS...................................................................................................................45

8.9 Contacting from above (mounting kit)..........................................................................................46

8.9.1 6.9.1 Normal assembly.................................................................................................46

8.9.2 ESD assembly ..............................................................................................................46

9Further maintenance ................................................................................................................46

9.1 ATS mounting check....................................................................................................................46

9.2 Replacement and wear parts MA xxxx........................................................................................47

9.2.1 9.4.1 Gas pressure spring ............................................................................................47

9.2.2 Upgrade bearing bracket set ........................................................................................47

9.3 Replacement and wear parts ATS MAxx.....................................................................................48

9.3.1 Stacking screw..............................................................................................................48

9.3.2 Pressure spring.............................................................................................................48

9.3.3 Wire mesh sealing for RF-ATS.....................................................................................48

9.3.4 Contact spring kit for RF-ATS (previous version).........................................................48

9.3.5 Probe plate (KTP).........................................................................................................48

9.3.6 Moving plate (ADP).......................................................................................................49

9.3.7 Pressure frame plate (NHP) .........................................................................................49

9.3.8 Wiring guard plate (VSP)..............................................................................................49

9.3.9 Knurled-head screw ATS..............................................................................................49

10 Technical Data ...........................................................................................................................50

10.1 Specification of components used...............................................................................................50

10.1.1 Stroke switch (Part number 20202) ..............................................................................50

10.1.2 Inductive sensor (Part number 26466) .........................................................................50

10.1.3 Inductive sensor M8x1 (Part number 33831) ...............................................................50

Technical manual MA xxxx with ATS MAxx

3 ©INGUN: Subject to technical changes without notice. E&OE.

10.1.4 Inductive sensor (Part number 36684) .........................................................................50

10.1.5 Inductive sensor (Part number 38413) .........................................................................50

10.1.6 Inductive sensor (Part number 44833) .........................................................................51

10.1.7 Stroke magnet NC (currentless; closed) (Part number 50856) ....................................51

10.1.8 Stroke magnet NO (currentless; open) (Part number 33491) ......................................51

10.1.9 Valve assembly 3/2-way (Part number 43583).............................................................51

10.1.10 Valve assembly 5/2-way (Part number 42702).............................................................51

10.1.11 Pneumatic cylinder 12-10 (Part number 49273)...........................................................52

10.1.12 Pneumatic cylinder 12-10 (Part number 43251)...........................................................52

10.1.13 Pneumatic cylinder 12-10 (Part number 49273)...........................................................52

10.1.14 Pneumatic cylinder 25-50 (Part number 39203)...........................................................52

10.1.15 Pneumatic cylinder 32-10 (Part number 39673)...........................................................52

10.1.16 Pneumatic cylinder 32-30 (Part number 28235)...........................................................52

10.1.17 Compressed air combination (Part number 14241)......................................................53

10.1.18 Brake cylinder D-040-12-040-123 (Part number 51863)..............................................53

10.1.19 LED SMD strip green (Part number 45673) .................................................................53

10.1.20 LED SMD strip red (Part number 45674) .....................................................................53

10.1.21 Push button yellow (Part number 33466) .....................................................................53

10.1.22 Push button red (Part number 33467)..........................................................................53

10.1.23 Push button green (Part number 33468)......................................................................53

11 Compatibility matrix ..................................................................................................................55

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 4

1 PRODUCT DESCRIPTION

1.1 MA xxxx

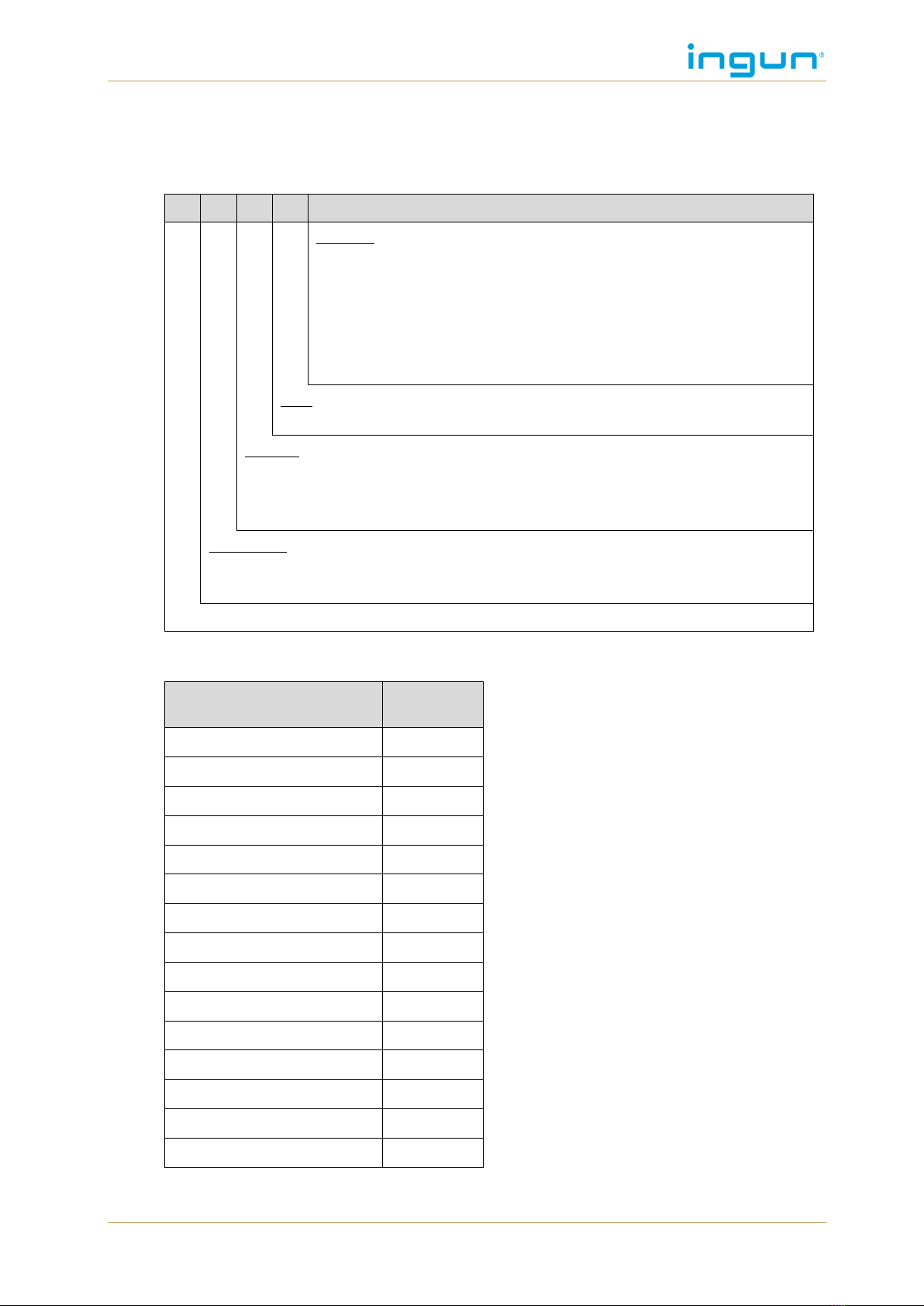

Designation convention:

MA

2

1

13

T/D/H/S-10

Options:

T= tandem version

/D = desk (desk housing) / F = flat housing

/H = fixing drive unit H = hinge “ “ = firmly screwed together

/S-n = Number of interface blocks (5 –10 pc.) / “ “ = no interface

/HG = high housing / “ “ = standard housing

/tester-interface: see matrix in test fixture catalogue

size:

09 –14

version:

0without interface

1standard with interface

2heavy-duty version

generation:

2MA with stroke 14mm

3MA with stroke 22mm

manual test fixture

Basic units with internal interface and without test system interface

Description

Part num-

ber

MA 2109/D/H/S-5

34340

MA 2111/D/H/S-5

31730

MA 2111/D/H/S-5/HG

33420

MA 2112/D/H/S-7

32660

MA 2112/D/H/S-7/HG

33460

MA 2113/D/H/S-10

32500

MA 2113/D/H/S-10/HG

32700

MA 2113T/D/H/2xS-5

32300

MA 2113T/D/H/2xS-5/HG

36666

MA 2114/D/H/S-10

34350

MA 3211/D/H/S-5

43950

MA 3212/D/H/S-7

43630

MA 3213/D/H/S-10

43580

MA 3213T/D/H/2xS-5

43970

MA 3214/D/H/S-10

43960

Technical manual MA xxxx with ATS MAxx

5 ©INGUN: Subject to technical changes without notice. E&OE.

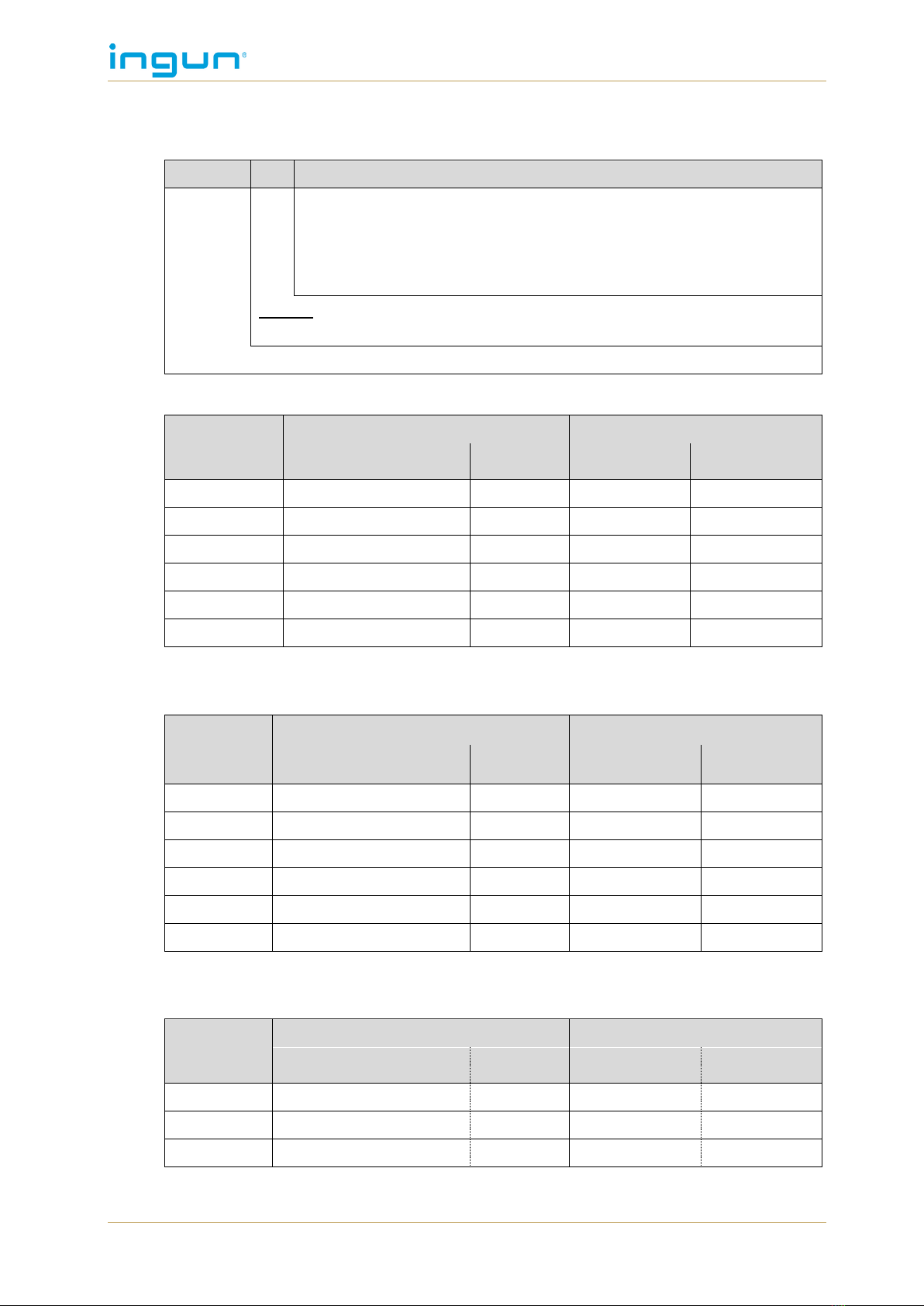

1.2 ATS MAxx

Designation convention:

ATS MA

14

/S-10

Options:

-2 Dual-stage version (only for pneumatic upgrade kit)

/S-n Number of interface blocks (5 –10 pc.) / “ “ = no interface

/ESD ESD version

/RF Radio frequency

/SN Rigid pin

version:

09 –14

Exchangeable kit MA

1.2.1 Standard version

Basic unit

with internal interface

without internal interface

Designation

Part

number

Designation

Part

number

MA 2x09

ATS MA09/S-5

45990-KIT

ATS MA09

45994-KIT

MA xx11

ATS MA11/S-5

45898-KIT

ATS MA11

45900-KIT

MA xx12

ATS MA12/S-7

45903-KIT

ATS MA12

45904-KIT

MA xx13

ATS MA13/S-10

45908-KIT

ATS MA13

45980-KIT

MA xx13T

ATS MA11/S-5

45898-KIT

ATS MA11

45900-KIT

MA xx14

ATS MA14/S-10

45983-KIT

ATS MA14

45985-KIT

The ATS is delivered as a kit and therefore is not mounted.

1.2.2 ESD version

Basic unit

with internal interface

without internal interface

Designation

Part

number

Designation

Part

number

MA 2x09

ATS MA09/S-5/ESD

46233-KIT

ATS MA09

46245-KIT

MA xx11

ATS MA11/S-5/ESD

46026-KIT

ATS MA11

46248-KIT

MA xx12

ATS MA12/S-7/ESD

46236-KIT

ATS MA12

46250-KIT

MA xx13

ATS MA13/S-10/ESD

46239-KIT

ATS MA13

46254-KIT

MA xx13T

ATS MA11/S-5/ESD

46026-KIT

ATS MA11

46248-KIT

MA xx14

ATS MA14/S-10/ESD

46242-KIT

ATS MA14

46257-KIT

The ATS is delivered as a kit and therefore is not mounted (see chapter 6.1, p. 18).

1.2.3 RF version

Basic unit

with internal interface

without internal interface

Designation

Part

number

Designation

Part

number

MA xx11

ATS MA11/S-5/HF

54111

ATS MA11/HF

54011

MA xx12

ATS MA12/S-7/HF

54112

ATS MA12/HF

54012

MA xx13

ATS MA13/S-10/HF

54113

ATS MA13/HF

54013

ATS is delivered mounted (see chapter 6.2, S. 18).

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 6

2 SAFETY

2.1.1 Safety advice for testing with harmless high-voltage

Touching of parts under voltage is regarded as not danger-

ous under the following conditions:

„At voltages with frequencies up to 500 Hz above AC 25V

or DC 60V the evoked current is due to an inductive-free

resistor of 2kOhm not greater than 3mA AC effective re-

spectively 12mA DC “(DIN EN 50191, p.5).

When testing voltages that fulfill these conditions the test

fixture can be operated also with such a high-voltage. How-

ever, special wiring components must be chosen and the wiring must be laid out for the necessary

air- and creep-paths. For this reason the additionally stated high-voltage and the applicable stated

current rating on the type label must not be exceeded.

2.1.2 Air distance and max. allowable current:

The air distance is the shortest gap between two conductive components and decisive for the

max. allowable current of the applied Interface Block pairs. The main rule for the sparkover of

sharp components in the air under standard conditions is:

for each mm distance approx. 0.8 kV.

(Max. allowable current at 170-pole Low Ohm Blocks, for example:

0.34 mm (air distance not wired) * 0.8 kV ≈ 270 V)

2.1.3 Commissioning of safety functions

The test fixture does not have its own control system. Therefore, the commissioning carried out

by the customer also includes the evaluation and control of the safety-relevant switches and sen-

sors. The demands on this part of the control unit are defined in the DIN EN ISO 13849-1 "Safety

of machines; safety-related parts of the control unit –part 1: General design guideline".

According to the risk evaluation carried out by INGUN, the test fixture with pneumatic or electro-

magnetic functions presents the following risk evaluation:

WARNING:DANGER OF INJURY!

Mechanical danger due to moving parts

Risk evaluation (according to DIN EN ISO 13849-1, risk paragraph p. 55):

Severity of the injury

S = S1 minor (normally reversible injury)

Frequency and/or

exposure to hazard

F = F1 seldom to less-frequent and/or expo-

sure to hazard is short

Possibility of avoiding

the danger

P = P2 hardly possible

This leads to a necessary performance level PL of b.

Technical manual MA xxxx with ATS MAxx

7 ©INGUN: Subject to technical changes without notice. E&OE.

Using the test fixture with low-voltage customising the following risk evaluation is given:

WARNING:DANGER OF INJURY!

Electrical dangers due to parts carrying voltage, overload and parts,

that are carrying voltage due to a faulty state

Risk evaluation (according to DIN EN ISO 13849-1):

Severity of the injury

S = S2 serious (normally irreversible injury in-

cluding death)

Frequency and/or

exposure to hazard

F = F1 seldom to less-frequent and/or exposure

to hazard is short

Possibility of avoiding

the danger

P = P2 hardly possible

This leads to a necessary performance level PL of d.

For voltages greater than 240 Volt the wiring must be designed to take the necessary air and

creepage paths into consideration. Therefore, the permitted voltage stated on the label must not

be exceeded at any time.

Necessary additional functions:

Contact protection for dangerous voltage (see chapter 8.4, page 41)

Actuator for safety switch with and without locking (see chapter 8.7, page 44)

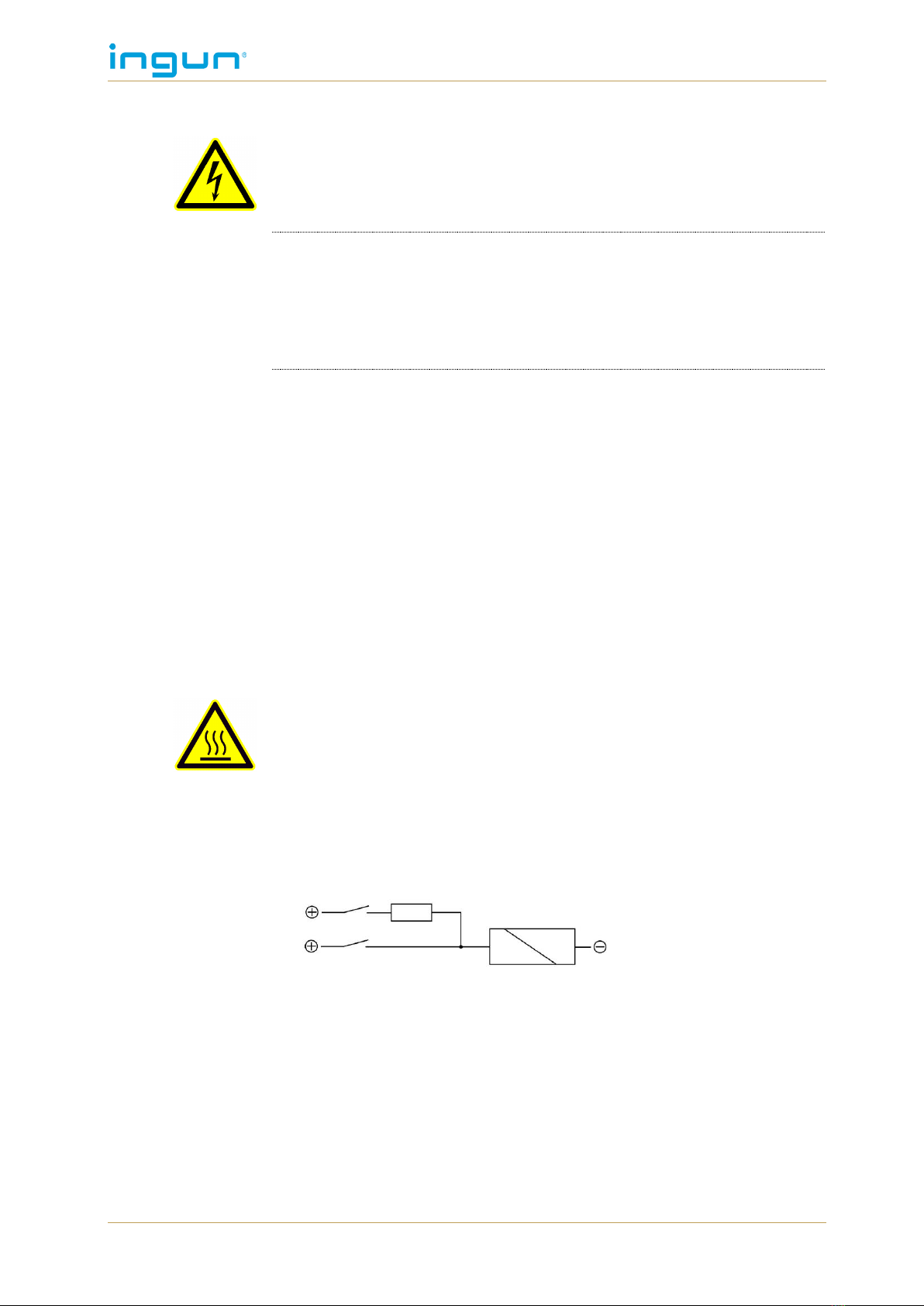

2.1.4 Dangers when operating electromagnets

Within some optional functions electromagnets are used to lock specific positions. When operat-

ing electromagnets with nominal voltage for a long time (>10 minutes) their outside get very hot.

The outer surface of electromagnets reaches high temperatures (70°C +) when nominal voltage

is applied for an extended period of time (>10 minutes).

WARNING:DANGER OF INJURY!

Thermal dangers resulting from hot surfaces

The electromagnets can heat up to 70° C when operated for a long time with

full continuous power supply.

The electromagnetic should not be active when the fixture is not being

used.

Halve the control voltage after approx. one second duty-cycle, i.e. connect

the electromagnet with two channels each and connect a resistor in the

channel for the constant current supply.

Figure 1: Activation with 2 channels

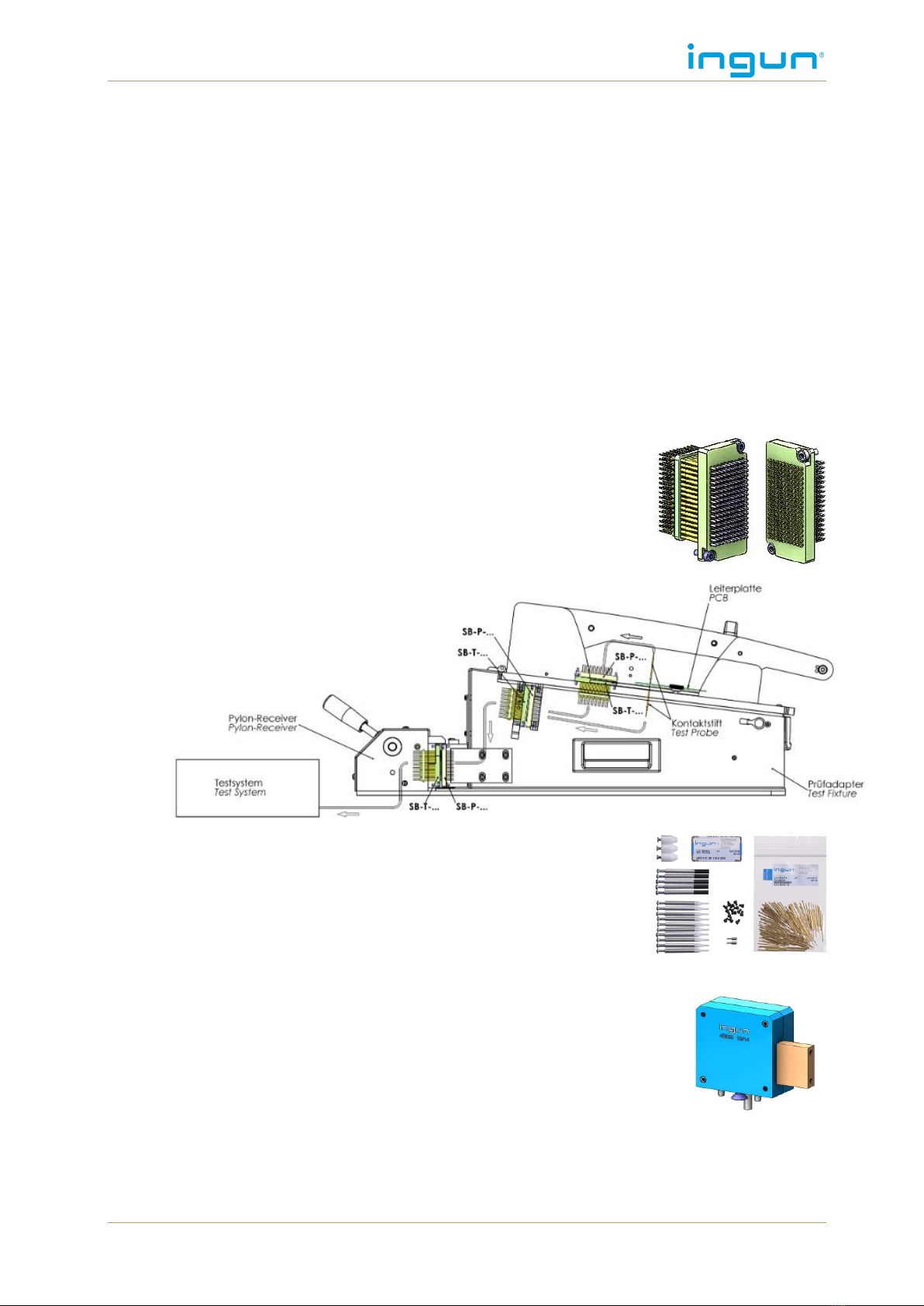

3 CUSTOMISING

The ATS is especially customised for the PCBs/UUTs to be tested. Customising normally con-

sists of spring-loaded test probes (which are installed in receptacles), the UUT/PCB centring,

the UUT/PCB support pins, the pushrods, and possibly further customising parts. Should the

UUT/PCB have side-connectors that need to be contacted, the ATS will additionally be

equipped with a connector approach mechanism (SAM).

The customising of the ATS requires care, as well as a lot of experience. High forces can occur

when there is a large number of test points. These forces can lead to deformation of the probe

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 8

plate and the pressure frame plate. Furthermore, asymmetrical positioning of the test probes

may require additional reinforcement of the unit.

The ATS customised by INGUN is optimally equipped for the test application in question so that

highly reliable testing is guaranteed.

3.1 Customising for stroke 22 mm (MA 3xxx)

The standard stroke is 14 mm. This ATS, which is especially customised for the MA 3xxx - 22 mm

stroke, cannot be used in the MA 2xxx. The 22 mm stroke ATS is equipped with a special insertion

blocker in order to prevent improper use (see chapter 8.3, p. 41).

3.2 Customising accessories

Within its wide range of different customising accessories, INGUN offers a great variety of match-

ing small parts and function units for the standard customising as well as for individual customis-

ing. The following overview shows only some of the different function units:

3.2.1 Interface blocks (SB)

INGUN interface blocks are used as electrically conductive connect-

ors for the reliable signal transfer in internal, external and customised

interfaces. Mounted with spring-loaded test probes, the matching con-

tact strokes guarantee consistently low contact resistance and con-

stant reliable contact quality. The working space is 15.1 ± 0.5 (see

product information “Interface blocks”).

Figure 2: Example of interface block installation

3.2.2 Start-up kit (SK)

INGUN offers different start-up kits for self-customising of the ATS.

These start-up kits include all common components necessary for

the customising –from the pre-centring to the spring-loaded test

probe (see product information “Start-up kits“).

3.2.3 Side approach mechanism (SAM)

Approach mechanisms enable the lateral approach of contacts. Man-

ual and automatic approach mechanisms are available. Using the

automatic, stroke-controlled approach mechanism, the vertical con-

tacting stroke is converted into a horizontal stroke (see product infor-

mation “Side approach mechanism“).

Technical manual MA xxxx with ATS MAxx

9 ©INGUN: Subject to technical changes without notice. E&OE.

3.2.4 Marking units (ME)

For the permanent “good”-marking, marking units with electrically or

pneumatically operated drive systems are available. The marking is

done in the form of a circular marking or circle point marking by

means of a scratching engraver, cutting engraver or milling en-

graver. The marking units are mounted in the replacement kit com-

pactly and precisely (see product information “Marking units”).

3.2.5 Potentiometer screwing unit/key button activators

Compact manual or automatic screwing units can be used for po-

tentiometer adjustments (see product information “Automatic screw-

ing unit for potentiometer adjustment “and “Manual tool for operating

buttons“).

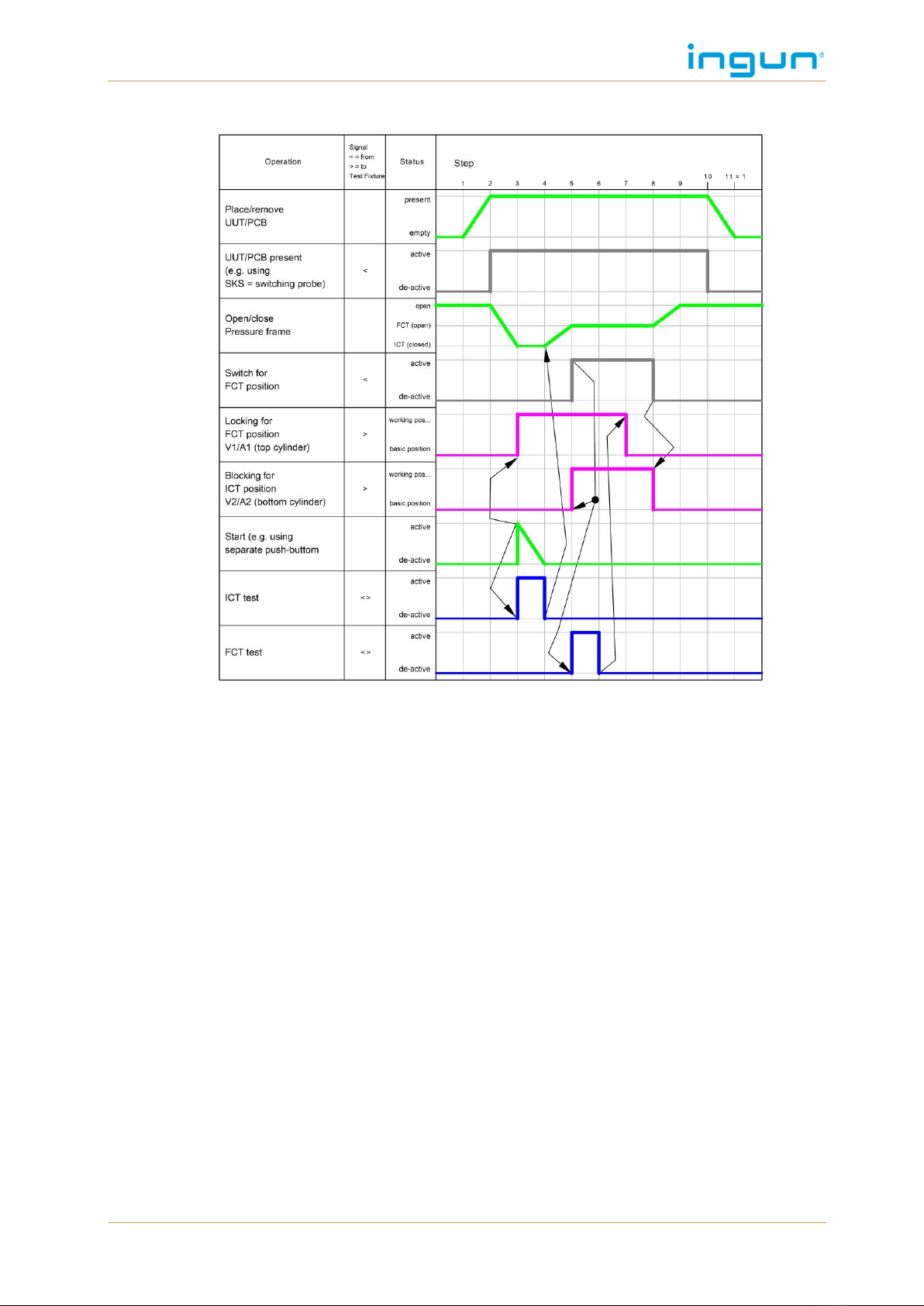

4 FUNCTIONAL SEQUENCE

The typical test sequence is displayed here using a flow-diagram. The steps carried out by the

operator are displayed in green. The UUT (Unit Under Test) detection is part of the ATS custom-

isation; it is not absolutely necessary, but highly recommended.

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 10

The functional sequences displayed here are the basis of INGUN product design. These can differ

depending on the test application.

5 ADDITIONAL FUNCTIONS MAXXXX

Different versions of the manual test fixtures are available with additional functions as bellow.

The “note for usage” generally must be considered because not all optional functions/additional

functions can be combined and other aspects must be considered.

5.1 Protection conductor wiring and contact protection for dangerous volt-

ages

MA 2x09

MA xx11

MA xx12

MA xx13

MA xx13T

MA xx14

40509

39851

39852

39853

39855

39854

ATS MA 09

ATS MA 11

ATS MA 12

ATS MA 13

ATS MA 11

ATS MA 14

41809

41811

41812

41813

41811

41814

When testing with a dangerous voltage (>25V AC and >60V DC) the test fixture must be

equipped with protective equipotential bonding, and protection type IP3x according to DIN EN

60529 must be fulfilled. The customising according to the low-voltage directive (NSRL) consists

of the safety protection conductor wiring (yellow/green cable) to all relevant parts and the check

via insulation resistor at pre-defined places (limit 0.3 ).

WARNING:In case of any changes of the protection conductor wiring (e.g. exchange of wires

or replacement of the cable gland), new measurement of the protection conductor

resistance is necessary!

Technical manual MA xxxx with ATS MAxx

11 ©INGUN: Subject to technical changes without notice. E&OE.

5.2 ESD assembly

MA 2x09

MA xx11

MA xx12

MA xx13

MA xx13T

MA xx14

33482

33482 (2x)

33482

ATS MA 09

ATS MA 11

ATS MA 12

ATS MA 13

ATS MA 11

ATS MA 14

See chapter 1.2.2, p. 5 for part number

In case of ESD assembly, the test fixture is equipped with an ESD wiring (black cable) with

grounding connection and a connection for an ESD antistatic strap.

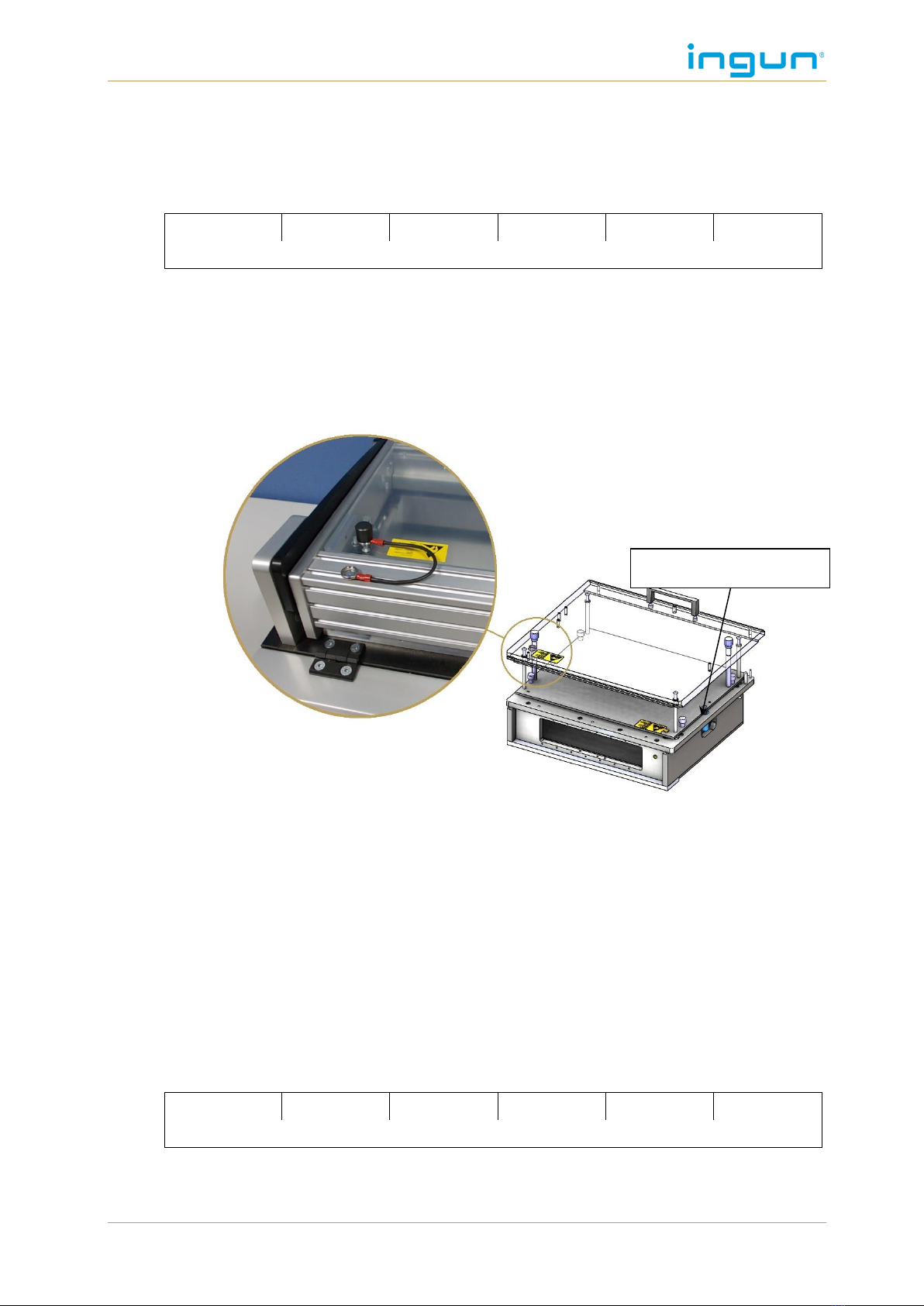

Figure 3: MA2112 with ESD assembly

Note for usage

The MA 20xx with ESD customisation not equipped with an ESD coated probe plate as

standard. An ESD coated probe plated is available upon request.

The standard transport handles are not conductive. Optionally hinged metal handles are

available (see chapter 7.11, p. 33)

For ATS and test fixtures with ESD version of the first generation, new ESD discharge

cable with ESD press-stud connector can be ordered at INGUN under Part no. 48215.

The antistatic wrist strap must not be connected to the bush of the ESD discharge ca-

ble.

5.3 ESD assembly and protection conductor wiring

MA 2x09

MA xx11

MA xx12

MA xx13

MA xx13T

MA xx14

43597

43597 (2x)

43597

ATS MA 09

ATS MA 11

ATS MA 12

ATS MA 13

ATS MA 11

ATS MA 14

Part number see chapter 1.2.2, p. 5

The above mentioned part numbers shall be used only in connection to the part numbers of the

protection conductor wiring (see chapter 5.1, p. 10).

5.4 Dual-stage contacting from bottom side

The manual test fixtures are available as dual-stage basic units with electromagnetic limitation of

the contacting stages. The combined stroke is achieved manually. The first contacting stage for

ICT is achieved as soon as the pressure frame is completely closed. The second contacting stage

for FCT (that lies above the first contacting stage) is achieved by lifting the operating handle. The

limitation of both contacting stages is carried out electromagnetically by means of two stroke

magnets. To open the pressure frame, a push button switch must be activated. A standard ex-

changeable kit (ATS) with dual-stage customisation is used.

connection

ESD antistatic strap

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 12

The sequence of this dual-stage contacting is displayed in the following functional diagram:

Note for usage

Cannot be used with the option “locking unit for closed pressure frame” (see chapter

7.5, p. 29).

In case assembly is done with high forces (many contact probes) the option “oil break”

is necessary (see chapter 7.13, p. 35).

A “pressure frame closed” check is necessary using the dual-stage function (see chap-

ter 7.3, p. 27).

Premature opening of the fixture can cause the locking mechanism to jam.

The ICT position is only locked during FCT testing (see description).

This dual-stage function is exclusively for contacting from the bottom side. (Dual-stage

contacting from the top side is possible as a specialised solution in the exchangeable kit)

Combination with self-opener, see chapter 5.5, pg. 15

Technical manual MA xxxx with ATS MAxx

13 ©INGUN: Subject to technical changes without notice. E&OE.

5.4.1 Locked electrically

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

60859 (left)

59508 (left)

-

59508 (left)

60856 (right)

102597 (right)

-

102597 (right)

ATS MA09

ATS MA11

ATS MA12

ATS MA13

ATS MA11

ATS MA14

48266

Figure 4: Basic unit with electromagnetic dual-stage locking unit

Specification of the components used:

Stroke magnet NC (currentless; closed) (Part number 50856) (see chapter 10.1.7, p.51)

Inductive sensor (Part number 38413) (see chapter 10.1.5, p. 50)

The electromagnetic in currentless locking unit used here must be actively switched to the

“open” setting.

CAUTION:BURNING ON HOT SURFACES!

Hot coil housing on electromagnets

Use INGUN magnet control when electromagnets are switched on for ex-

tended periods of time.

Sensor for

FCT position

electromagnet for

FCT position

electromagnet for

blocking the

ICT position

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 14

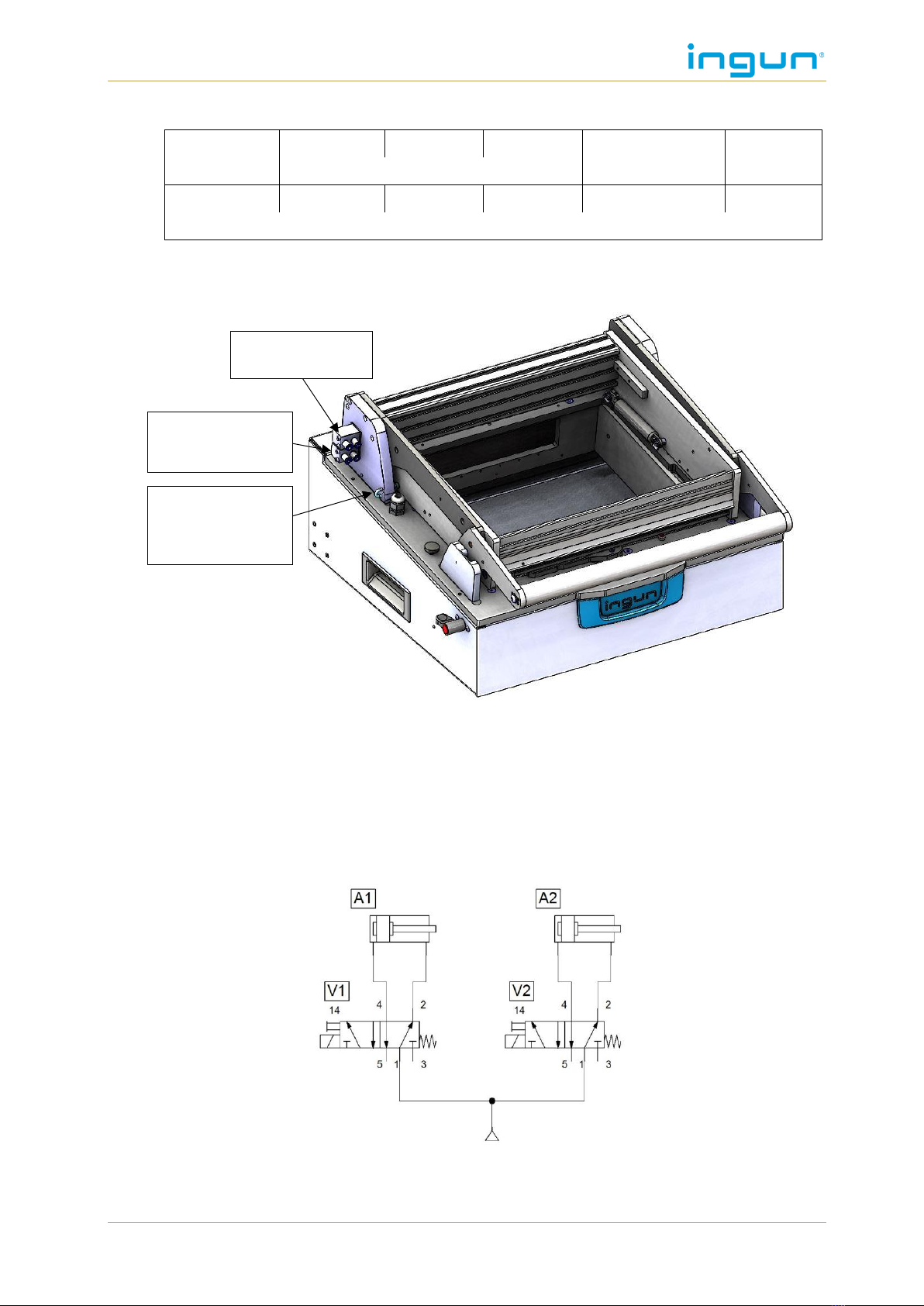

5.4.2 Pneumatic locking

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

59555

59507

59507/100700 *)

59507

ATS MA09

ATS MA11

ATS MA12

ATS MA13

ATS MA11

ATS MA14

48266

*) Part 59507 is mounted on the left side of the left drive unit and part 100700 is mounted on the

right side of the right drive unit.

Figure 5: Basic unit with pneumatic dual-stage locking

Specification of the components used:

Inductive sensor (Part number 38413) (see chapter 10.1.5, p. 50)

Pneumatic cylinder 12-10 (Part number 49273)(see chapter 10.1.11, p. 52

Specification of optional components (not included in delivery):

Valve assembly 5/2-way (Part number 42702) (see chapter 10.1.10, p. 51)

Compressed air combination (Part number 14241) (see 10.1.17, p. 53)

Pneumatic plan

pneumatic cylinder

for FCT position

sensor for

second contacting

stage (FKT posi-

tion)

pneumatic cylinder

for blocking the ICT

position

Technical manual MA xxxx with ATS MAxx

15 ©INGUN: Subject to technical changes without notice. E&OE.

5.4.3 Mechanical stroke limitation

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

50914

50912

50913

50912 (2x)

50913

ATS MA09

ATS MA11

ATS MA12

ATS MA13

ATS MA11

ATS MA14

48266

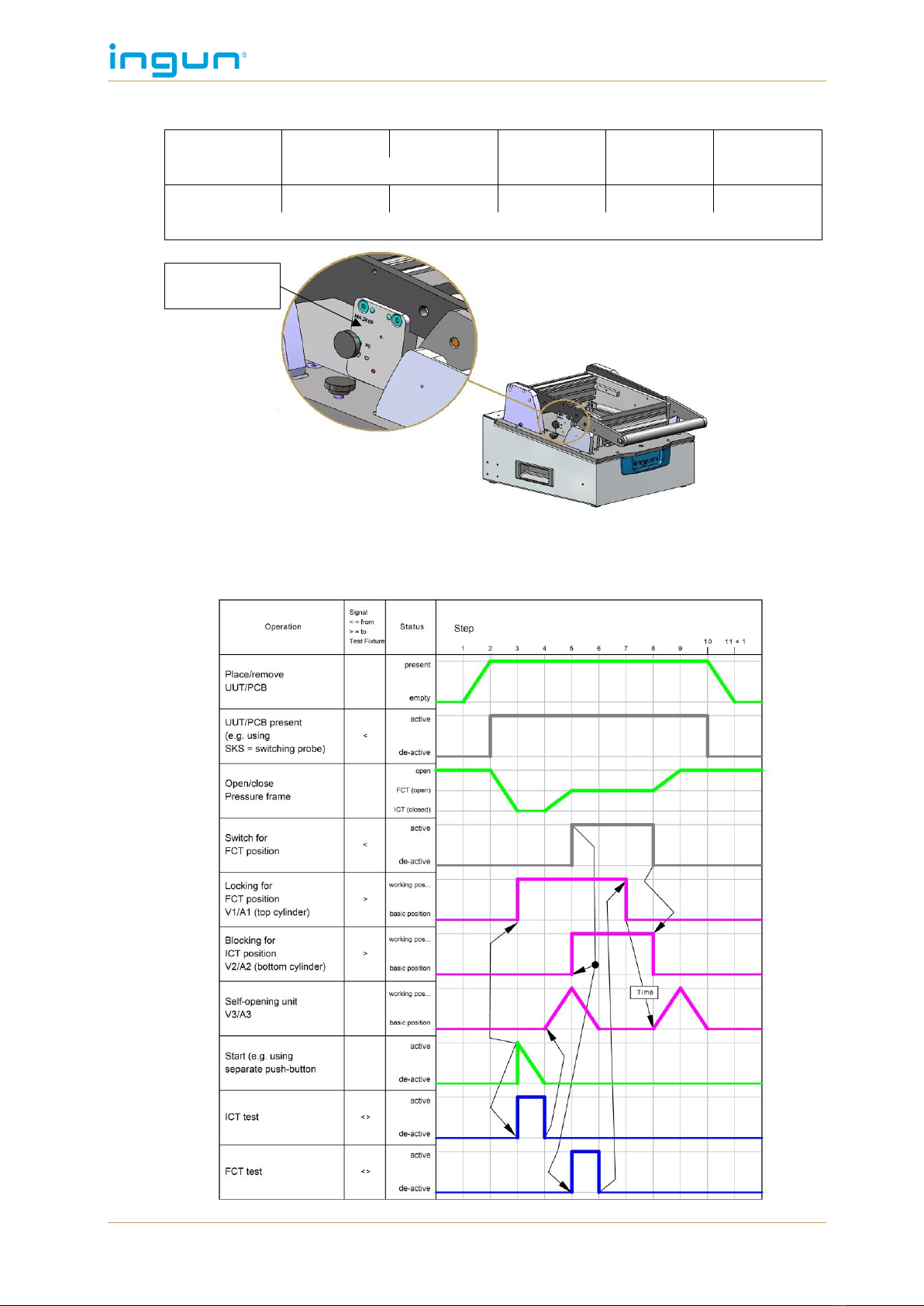

5.5 Dual-stage contacting with self-opener

The dual-stage contacting process with self-opener is shown in the following function diagram:

dual-stage

mechanism

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 16

5.5.1 Electrical dual-stage contacting with self-opener

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

-

45220

45220

45220 (2x)

45220

-

59508

59508

59508/100696 *)

59508

-

59558

59559

59558 (2x)

59559

*) Part 59508 is mounted on the left side of the left drive unit and part 100696 is mounted on the

right side of the right drive unit.

5.5.2 Pneumatic dual-stage contacting with self-opener

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

42701

42700

42700

42700 (2x)

42700

59555

59507

59507

59507/100700

59507

51434

59558

59559

59558 (2x)

59559

59507

42700

59558

59508

45220

59558

Technical manual MA xxxx with ATS MAxx

17 ©INGUN: Subject to technical changes without notice. E&OE.

Specification of the components used:

Inductive sensor (Part number 38413) (see chapter 10.1.5, p. 50)

Pneumatic cylinder 12-10 (Part number 49273)(see chapter 10.1.11, p. 52

Specification of optional components (not included in delivery):

Valve assembly 5/2-way (Part number 42702) (see chapter 10.1.10, p. 51)

Compressed air combination (Part number 14241) (see 10.1.17, p. 53)

Pneumatic plan

5.5.3 Mechanical dual-stage contacting with pneumatic self-opener

MA 2x09

MA 2x11

MA 2x12

MA 2x13

MA 2x13T

MA 2x14

42701

-

-

-

-

103550

-

-

-

-

51434

-

-

-

-

Technical manual MA xxxx with ATS MAxx

©INGUN: Subject to technical changes without notice. E&OE. 18

6 ADDITIONAL FUNCTIONS ATS MAXX

The exchangeable kits are available with the following additional functions:

6.1 ESD version

ATS MA 09

ATS MA 11

ATS MA 12

ATS MA 13

ATS MA 11

ATS MA 14

See chapter 1.2.2, p. 5 for part number

An ESD version is available for electrostatic sensitive components. This affects the manual fixture

and requires a specialised exchangeable kit. In this case, all components in the basic unit are

electrically attached to the ground connection on the back panel of the basic unit. Grounding is

done by the customer using a connection cable with 1.5 mm² cross section. Grounding of the

bottom part takes place automatically via a spring-loaded discharge probe, assembled in the basic

unit. Grounding of the top part of the exchangeable kit takes place via a grounding cable installed

at the basic unit which must be plugged to the pressure frame plate.

Part number see chapter 1.2.2, p. 5

Figure 6: ATS as ESD version with pressure frame unit wiring

Note for usage

ESD function of ATS is only achieved in connection with the additional function of the

ESD assembly in the test fixture (Part no. 33482 ESD assembly / Part no. 43597 ESD

customising with protection conductor wiring).

ESD function is only achieved with respective ESD components such as ESD pushrods

and ESD pre-centring.

The ESD layer around the GKS has to be removed.

For ATS and test fixtures with ESD version of the first generation, new ESD discharge

cable with ESD press-stud connector can be ordered at INGUN under Part no. 48588.

(For more information see product information “Premium ESD-customising”)

6.2 Radio frequency version

ATS MA 09

ATS MA 11

ATS MA 12

ATS MA 13

ATS MA 11

ATS MA 14

See chapter.1.2.3, p. 5 for part numbers

The radio frequency exchangeable kits are used to contact highly sensitive RF boards precisely

and reliably, and to measure the radio frequency signals in a fail-safe way (see product infor-

mation “MA radio frequency exchangeable kits“).

ESD interface contact

Technical manual MA xxxx with ATS MAxx

19 ©INGUN: Subject to technical changes without notice. E&OE.

See chapter.1.2.3, p. 5 for part numbers

Figure 7: ATS MA12/HF backside

without internal interface

Figure 8: ATS MA12/S-7/HF backside

with internal interface

Spare parts and parts subject to wear can be found under chapter 9.3.3, page 48.

This manual suits for next models

5

Table of contents

Other Ingun Test Equipment manuals