insize ISH-BRV User manual

www.insize.com

OPERATION MANUAL

ISH-BRV

BRINELL/ROCKWELL/VICKERS

HARDNESS TESTER

MN-ISH-BRV-E

1 2

The power socket for this apparatus shall be of a one-way 3-pin

type, the earth terminal shall meet the specified requirements of

grounding protection.

This instruction manual shall be read through prior to the use of

the apparatus, to understand the detailed operation steps and

special attentions, in order to prevent apparatus damage and/or

personal injury resulted from improper operation.

All bands and shake-reducing tapes shall be carefully removed

before apparatus installation and calibration.

It is strictly prohibited to tamper with the installation position of all

electric elements. Switches, sockets etc. It may cause damage

and/or injury.

It is not permitted to rotate the pressure selecting hand-wheel or

li f ting screw du ring the testi ng p ressur e chargin g or r e lievin g

period or during the pressure keeping pressure.

Attention

The hardness is one of the important parameters to determine the

mechanical properties of the material, and the hardness test is a

way which is used to discriminate and determine the quality of

metallic materials or components of the product. The so-called

hardness is meant the capability of the material which, under a

certain condition, is capable to resist the press-in of another matter

which will not produce residual deformation itself. The larger the

resisting power is, the higher the hardness will be, and vice versa.

In the course of testing the mechanical properties, hardness

measurement is the easiest, most economical, and rapidest method,

and is also one of the measures which are used to inspect the

quality of the product during manufacturing the machine. As the

metallic hardness possesses the mutual corresponding relationship

with certain other mechanic properties, hence, most metallic

materials may approximately infer their other mechanical properties

such as strength, fatigue, creep, wearing and internal damages etc.

by determining their hardness.

Following the daily growing development of the industrial and

agricultural production as well as the scientific technology, various

kinds of different requirements are also demanded to the hardness

tester itself, especially it demands high precision in measurement

and test, and may carry out various kinds of hardness test for

different kinds of materials. Based upon this, the model ISH-BRV

Brinell, Rockwell and Vickers hardness tester which is produced by

our factory possesses the conditions which fulfill all the above

mentioned requirements.

Description

1

2

General descriptions:

Main application and characteristics:

This hardness tester possesses multistage test forces and many

kinds of indenters (table 1) which are used to measure and

determine the Brinell, Rockwell and Vickers hardness of the metallic

materials or test pieces. It is adaptable for determining the

hardness of ferrous metals (steel, cast iron pieces, mild steel and

quenched steel etc.) and non-ferrous metal (aluminium alloy and

3 4

3

copper alloy etc.), meantime it may also be used to determine the

hardness of hard alloy, carburized layer and chemically treated

layer. When purchasing, in case the necessary accessory such as

surveying microscope is not bought simultaneously, you may also

carry out the Brinell, Vickers hardness tests under the cooperation

of self -furnished surveying microscope.

The model ISH-BRV Brinell, Rockwell & Vickers hardness tester

adopts rotating type load changing mechanism as well as optical

measurement indicating system, and the microscopic survey

installation is mounted on the body of the apparatus. Hence, it is

convenient, sensible and reliable in the loading measuring system,

high precision in the shown value, it is widely adaptable to the

factory workshop, laboratory, university, college and school as well

as scientific research institute.

Table1

Test force (N) Type of

test Primary

test

force

Total

test

force

Symbol

of

hardness

value

Indenter Measuring

installation

Examples of

Measured &

tested materials

588.

4

HRA hard alloy,

carbon

carburizing steel

1471 HRC

diamond

cone

indenter

quenched steel,

adjustable

quality

steel, hard cast

iron

Rockwell

hardness

test

98.07

980.

7

HRB φ1.588

mm

steel ball

indenter

Optical

measurement

indicating

mechanism

Mild steel,

aluminium alloy

copper alloy

forgeable cast

iron

Brinell

hardness

test

306.5

612.9

1839

HB φ2.5,

φ5mm

steel ball

indenter

Surveying

microscope

Non-ferrous

metal

cast iron, soft

alloy, plastics

Vickers

hardness

test

294.2

980.7

HV30 diamond

angle

conical

indenter

Surveying

microscope

The superficial

hardness of

metallic alloy

carburized layer,

small type thin

components

1

1. Top cover 2. Veil 3. Rockwell display 4. Microscope 5. The micro-adjusting

knob 6. The indenter 7. The test piece 8. Slider 9. Dust cover 10. Rotating

wheel for lifting and lowering 11. Buffer adjusting hand wheel 12. Light source

adjusting hand wheel 13. Loading and unloading handle 14. Rear cover 15.

Load changing hand wheel 16. The fuse plug 17. The power switch

Parts descriptions:

Installation And Adjustment

Working conditions of the tester:

Under ambient temperature, i.e. between 10-30 ºC;

The relative humidity in test room shall not be over 65%;

In an environment free from vibration;

1

No corrosive medium in surrounding.

5 6

Fig.1

After the installation of the hardness tester, take away the external

white gauze strip of the machine. Remove the dust cover, use

gasoline to clean the antirust grease on the lifting and lowering

screw rod. After it is dried, coat with certain amount of thin grease

for lubrication. Then, unscrew the screws on the upper cover and

rear cover respectively, and open the upper cover and rear cover,

and unloosen the white gauze strip and rubber band which are

inside the machine and take out the oblique shape EPS which is

under the screw rod. In the course of operation, pat attention not to

touch the optical elements. After completion, close the upper cover

in time.

Tester unpacking:

Open the packing box cover and take out all cushion

materials. Remove the accessory box.

Lift the bottom plate, unscrew the two (2) M 10 bolts under the

bottom plate with a spanner, to separate the hardness tester

from bottom plate, all steps shall be done in a safe manner.

After unpacking, the tester shall be placed on a stable bench

with levelness deviation less than 1 mm/m. A hole shall be

drilled at an appropriate location on the bench (see fig 1) to

enable the lifting screw to operate properly.

2

3

4Installation of weight set:

Turn the load adjustment hand wheel to the point of 306N, install the

small "0” weight on to the hanging hook which is on the upper part of

the suspended lever, then place the other 4 weights according to the

sequence of No. 4, 3, 2, 1, respectively from the bottom to the top on

to the tray, and observe whether the installation is correct or not .

Adjustment of the loading speed:

Oil contained in the buffer has already been fully drawn out before

packaging and leaving the factory, hence, before use, oiling the

necessary. Turn the adjustment handle counter clockwise to

unloosen the needle valve, open the dust cover plate of the oil filler

hole, and push the loading handle backward in the direction, use a

needle tube to inject some 50 ml grease Then pull slowly the loading

handle back and forth, repeat in this way many times so as to make

the extra grease overflow from the oil filler hole, erase away the

overflow grease, then close the dust cover plate.

Adjust the loading speed of the buffer: switch on the power supply,

and pl a c e th e t es t p l a tf o r m . Turn th e l o a d in g h a nd l e

counterclockwise to pull it forward, so as to uplift the screw rod

slowly, when the test platform touches the plane of the surveying rod

(at that time, the indenter is not mounted yet) uplift the screw rod

continuously. When the oblong signal displayed in the reading

projecting screen and the target rod gradually uplift. Finally, when

the base line and the fixed target rod of the projecting screen

coincide, then stop to uplift the screw rod and pull the handle

backward by turning the handle in a clockwise direction, at that time,

the buffer start its action, the target rod and the signal start to lower

gradually, the quickness and slowness of the lowering speed will be

adjusted by the buffer adjustment handwheel.

5

Adjusting the clarity of the projecting target rod:

After switch on the power supply, in case it is discovered that the

projecting target rod is dim and not clear, you may rotate the knurled

nut in order to make the lamp revolve or uplift, then tighten the

knurled nut.

Installation of the microscope:

The microscope which has its internal lighting system is mounted on

the left clamping chuck of the machine body by means of its

cooperation with the sliding plate test platform, it is capable to test

the Brinell and Vickers hardness of the metallic materials.

6

7

When carrying out the Brinell, Vickers hardness test, first, mount

the sliding plate test platform on the axial hole of the lifting and

lowering screw rod, and fix it by nuts.

7 8

The microscope shall be perpendicularly fixed on the clamping

chuck, and install the exterior lighting lampshade which is used

for testing the Brinell hardness.

Use a plug to switch on the power supply, the lamp spigot is

situated on the edge of the bakelite cover.

Based upon the test method, select and mount the objective,

generally, for the Brinell hardness test, use 2.5x objective, for

the Vickers hardness test, use 5x objective.

Press several indentations step by step on the standardized test

blocks, remove the upper sliding plate under the microscope to

look for the indentation. The sliding plate which makes use of

the axis hole of the lifting and lowering screw rod as its centre

makes circumferential rotation and carefully makes the upper

and lower adjustment, align to the focal distance until the

indentation appears in the centre of the visual field, then tighten

the nut, after completion of the preparation, it is ready for test.

Inspection the precision

After making adjustment for the hardness tester according to the above

mentioned methods, then make the shown value precision inspection

for the hardness block.

Rockwell hardness test:

Measure and determine six points on the different positions of the

working surface of the standardized Rockwell hardness block, the

central distance of two adjacent indentations and the distance from

the center of the indentation to the edge of the hardness block shall

not be less than 3 mm. give up the first point, then take the mean

value of the rest five points, the difference between the mean value

and the standardized hardness block is the shown value error of the

hardness tester. The error shall not exceed ±1 HR.

Within the five points, the difference between the maximum value

and the minimum value shall not exceed that specified in the

following:

Target rod A is 1.0 HR

1

Target rod B is 1.2 HR

Target rod C: HRC 35 - 67 is 1.0 HR

HRC 20 - 35 is 1.2 HR

2Brinell hardness test:

Measure and determine five points which are evenly distributed on

the standardized Brinell hardness block, the central distance

between two adjacent indentations shall not be less than 4 times the

diameter of the indentation. The distance from the center of the

indentation to the edge of the hardness block shall not be less than

2.5 times the diameter of the indentation. The measurement for the

diameter of each indentation is carried out on two directions which

are mutually perpendicular, and take the mean value. The ratio

between the difference of the two mutually perpendicular diameter

and the shorter diameter shall not be greater than 1%.

Divide the difference between the mean hardness value of the five

points measured according to the above mentioned method and the

standardized hardness value by the hardness value of the

standardized block, this is the shown value error of the hardness

tester. When the test force is greater than 1839N, the tolerance

allowed is ±3%; when the test force is less than 1839N, the

tolerance allowed is ±4%.

Divide the difference between the maximum value and the minimum

value of the hardness values of the five points by the mean

hardness value of the 5 points, for the hardness block of 30D , 10D ,

it shall not exceed 3.5%; for the hardness block of 2.5D , it shall not

exceed 5.0%.

3Vickers hardness test:

Measure and determine 5 points which are evenly distributed on the

standardized Vickers hardness block, the distance between the

center of the two adjacent indentations and the distance from the

centre of the indentation to the edge of the hardness block shall not

be less than 2.5 times the diagonal length of the indentation.

Measure the two diagonals for every indentation and take its mean

value.

The ratio between the difference of two diagonals to the shorter

diagonal shall not be greater than 2%.

9 10

Divide the difference between the mean hardness value of the 5

points measured and determined according to the above mentioned

method and the hardness value of the standardized block by the

hardness value of the standardized block, this is the shown value

error of the hardness tester. The allowable tolerance is ±2%.

Divide the maximum value and the minimum value of the hardness

values of the 5 points by the mean hardness value, this is the

changeable value of the hardness tester. The allowable tolerance is

2.5%.

The shown value precision of the hardness tester has been adjusted

before leaving the factory. In case error produced due to vibration in

the course of transportation, the testing personnel shall make

suitable adjustment on the basis of understanding its structural

principles. Take away the upper cover, if the shown value measured

is greater than the marked value of the hardness block, when it is

required to lower the hardness reading, then you may use a screw-

driver to turn clockwise one degree of the slotted countersunk head

screw 2 which is on the spring leaf, meantime tighten one degree of

the slotted countersunk head screw 1 by turning it counter clockwise

of the optical lever (Fig. 2). Note the rotated degree should be

basically conformed. Test the shown value again, until it is adjusted

within the specified range of error.

If the shown value measured is less than the standardized block,

than the revolving direction of the screw shall be reversed.

Fig.2

Switch on the power supply, based upon the test method, open

the switch.

The surface of the sample to be tested shall be level, bright and

clean, it shall not present any outstanding machining traces such

as pollutants, oxidized flakes, cracks and pockets etc.

The supporting surface of the sample and the test platform shall

also keep clean, so as to ensure better closely engaged, the

relationship between the minimum thickness of the sample and

the hardness may refer to table 2, table 3 and table 4.

The preparing work before test:

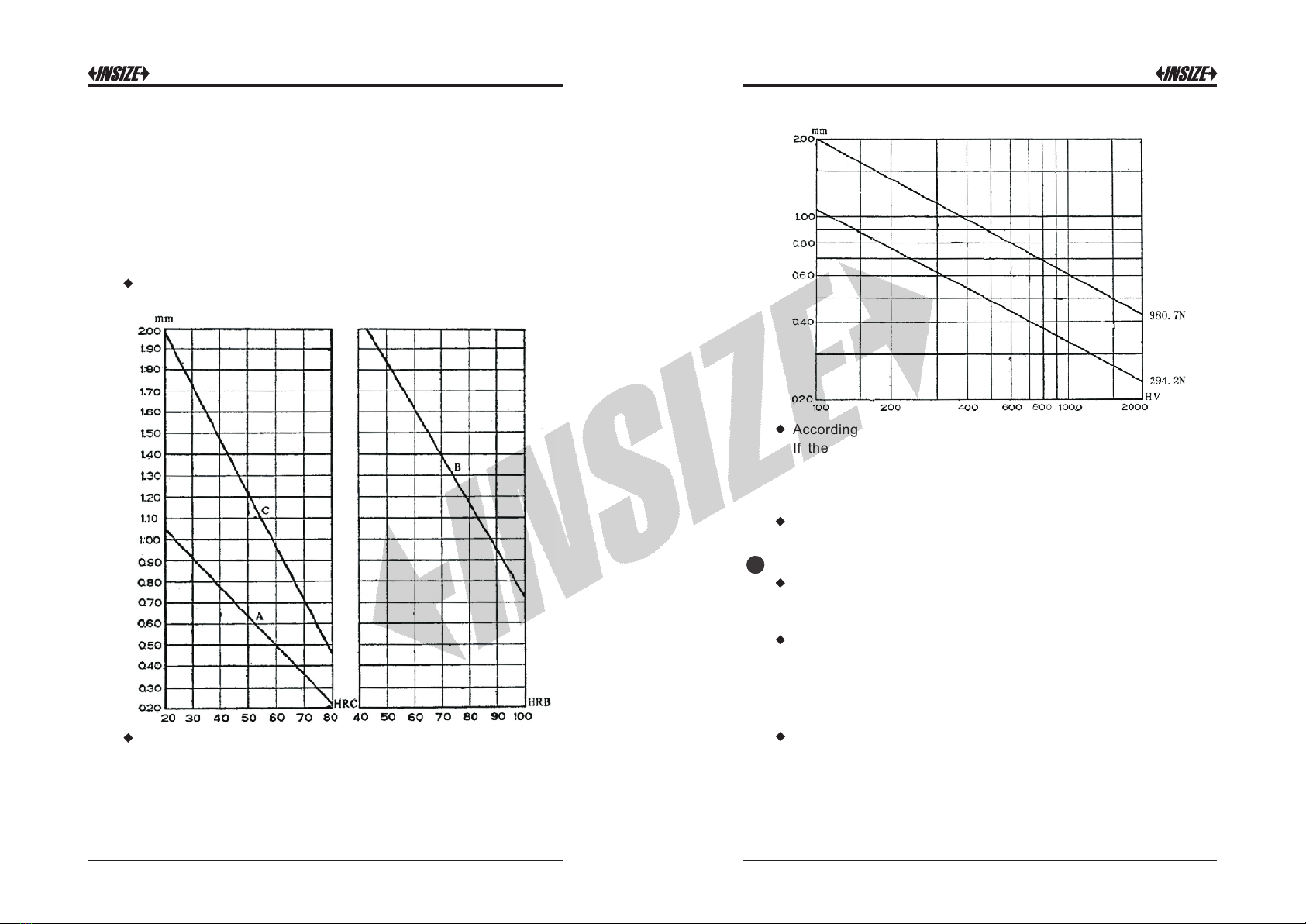

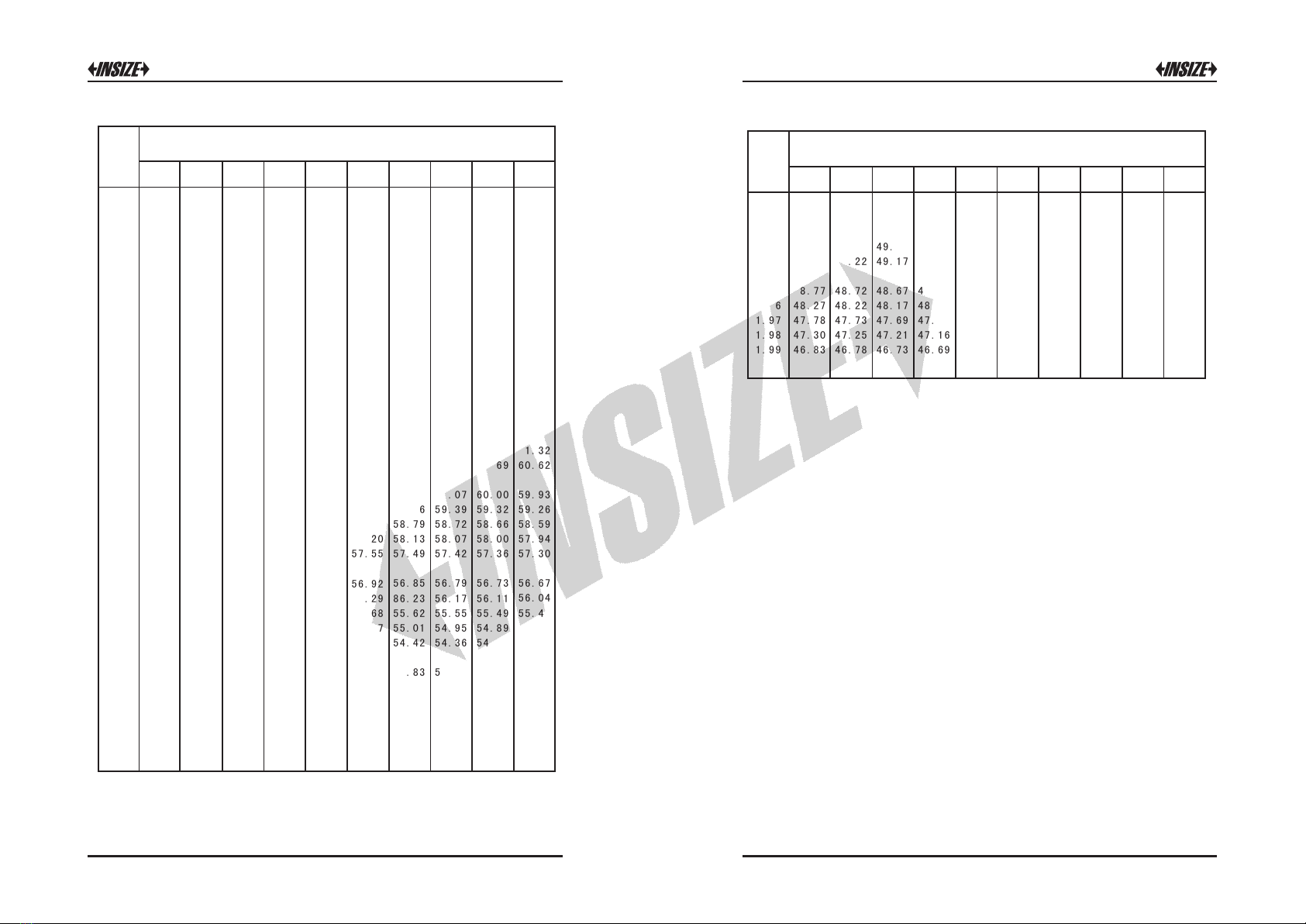

Table 2: The relationship between the minimum thickness and

hardness HB

Operation

1

11 12

Line 1: The diameter of the steel ball is 2 5mm.

Test force : 1839N

Line 2: The diameter of the steel ball is Ø2.5mm.

Test force: 612.9N

Line 3: The diameter of the steel ball is Ø2.5mm.

Test force: 306.5N

Line 4: The diameter of the steel ball is Ø2.5mm.

Test force: 306.5N

Ø .

Table 3:

hardness HRC, HRB

The relationship between the minimum thickness and

Table 4: The relationship between the minimum thickness and

hardness HV

According to the shape of the test piece, select suitable platform.

If the test piece is special shaped, the test platform which is

attached together with this hardness tester cannot meet the

requirement, then you should base upon the geometric shape of

the test piece to design a special test platform by yourself.

Turn the loading handle of the hardness tester counter clockwise

to push it forward, so as to make the load in an unloading state.

2Procedures for test:

Select the indenter according to the hardness test method (table

1). Insert the handle of the indenter into the axial hole of the

surveying rod and slightly turn the fixed screw.

Select the test force according to the hardness test method.

Turn the changing handwheel clockwise, in order to make the

loading figures needed correspond to the fixed calibrated line.

Note: When the test force used is 294.2N, you should open the

rear cover, take away all weights including the small "0" weight.

Place the test piece reliably on the test platform, then turn the

rotating wheel to make the screw rod lift upward, when the test

piece is in contact with the indenter, the projecting target rod will

lift correspondingly, finally, keep the baseline of the target rod

13

approximately coincide with the fixed line of the projecting

screen. The difference allowed may be ±5 degree value.

Use the micro-adjustment knob to adjust the zero digit, so as to

keep the base line of the target entirely coincide with the

projecting screen.. If the knob is turned to the limit position, the

two lines are still not able to coincide, then it shall be unloaded,

and turn the micro-adjusting knob to the intermediate position,

and select another point on the test piece, then repeat the above

mentioned operations again.

Push the loading handle forward by turning it clockwise, during

loading, the calibrated line of the target rod which is displayed

on the projecting screen is moving up and down, until the target

rod stops to lower, then start to compute the load holding time

until the load holding time is reached, then pull the handle again

to its original position.

The reading which is the indicating target rod calibrated line on

the projecting screen to the fixed target rod line is the Rockwell

hardness value of the tested specimen.. Lower the screw rod,

make the test piece leave the indenter, move to another position

and repeat the above mentioned test.

The Brinell and Vickers hardness test shall, after the completion of

the above mentioned procedures, move the upper sliding plate and

the test piece together under the microscope, then gradually uplift

the screw rod micro-quantitatively, align it to the focal distance, and

make the image of the indentation distinct, then measure the

diameter of the indentation or the diagonal length of the indentation,

next, look over the attached table and obtain the Brinell or Vickers

hardness value. When purchasing, the surveying microscope which

forms a complete set of the apparatus is not obtained, then you may

carry out the survey by means of your own prepared surveying

microscope.

The computing method of the surveying microscope against the

indentation is as follows:

L -- the diameter of the indentation or the diagonal length in mm.

n -- number of division line measured from the indentation (i.e. the

difference between the first reading and the second reading).

3

14

I -- the minimum calibrated value of the surveying microscopic drum

wheel

It is 0.004 mm when 2.5x objective is used.

It is 0.002 mm when 5x objective is used.

For instance: Use a 5x objective to measure the Vickers indentation

of a 294.2N test force.

The first reading is 221 division line.

The second reading is 400 division line.

According to this indentation:

L = n x l = (400-221) x 0.002 = 0.358 mm.

Look over the attached table, we obtain 434HV

If the Brinell hardness test is carried out, the method of

calculation is identical.

L= n x lxb when test the Brinell hardness.

b--Indenter coefficient.

When use Ø2.5mm steel ball indenter b is 4.

When use Ø5mm steel ball indenter b is 2.

15 16

Maintenance

The test personnel shall abide by the operating regulations, the

hardness tester shall be used and maintained by assigning special

person.

The apparatus shall be in a state of unloading when turning the

changing hand wheel.

In the course of test, when the test piece and indent mutual contact,

they shall be slow and stable.

After the completion of test, you shall keep the apparatus in a state

of unloading, covered by a dust cover, the indenter and the

hardness block shall be coated with vaseline against rust.

With the exception of the lifting and lowering part of the screw rod

which shall be coated with little amount of lubricant, all of the other

parts of the hardness tester shall not be coated or injected with any

kind of lubricant.

When transporting the apparatus, the oil in the buffer shall be drawn

off, the transportation shall be carried out with its bottom supported,

no lean down to the transverse direction is allowed, it is not allowed

to touch the handle during transportation. When transporting,

fasten the optical lever by rubber band and take away the weights

and suspended lever.

Maintenance of hardness tester and matters to be noted:

2

3

4

1

5

6

98N preload, 588, 980, 1471N total load

306, 613, 1839N

294N

37.5X/75X (selectable)

180mm

546×300×767mm

90kg

0.5HR

manual

manual

200mm(from the center of indenter)

Rockwell test load

Min. Rockwell reading

Brinell test load

Vickers test load

Stage elevation

Load control

Magnification of microscope

Max. workpiece height

Max. workpiece depth

Dimension

Weight

Standard Delivery

Specification

1pc

1pc

1pc

1pc

1pc

1pc

1pc

1pc

Ø5mm Brinell indenter

Main unit

Diamond Rockwell indenter

Ø1.5875mm carbide ball indenter

Ø2.5mm Brinell indenter

Vickers indenter

Ø60mm flat anvil for Rockwell

Ø150mm flat for Rockwell anvil

V-anvil for Rockwell

1pc

1pc

1pc

1pc of each

1pc

1pc

1pc

1pc

V-anvil for Rockwell

Flat anvil for Vickers and Brinell

V-anvil for for Vickers and Brinell

Rockwell test block HRC (high, low)

Rockwell test block HRB

Brinell test block

Vickers test block

Anti-dust cover

17 18

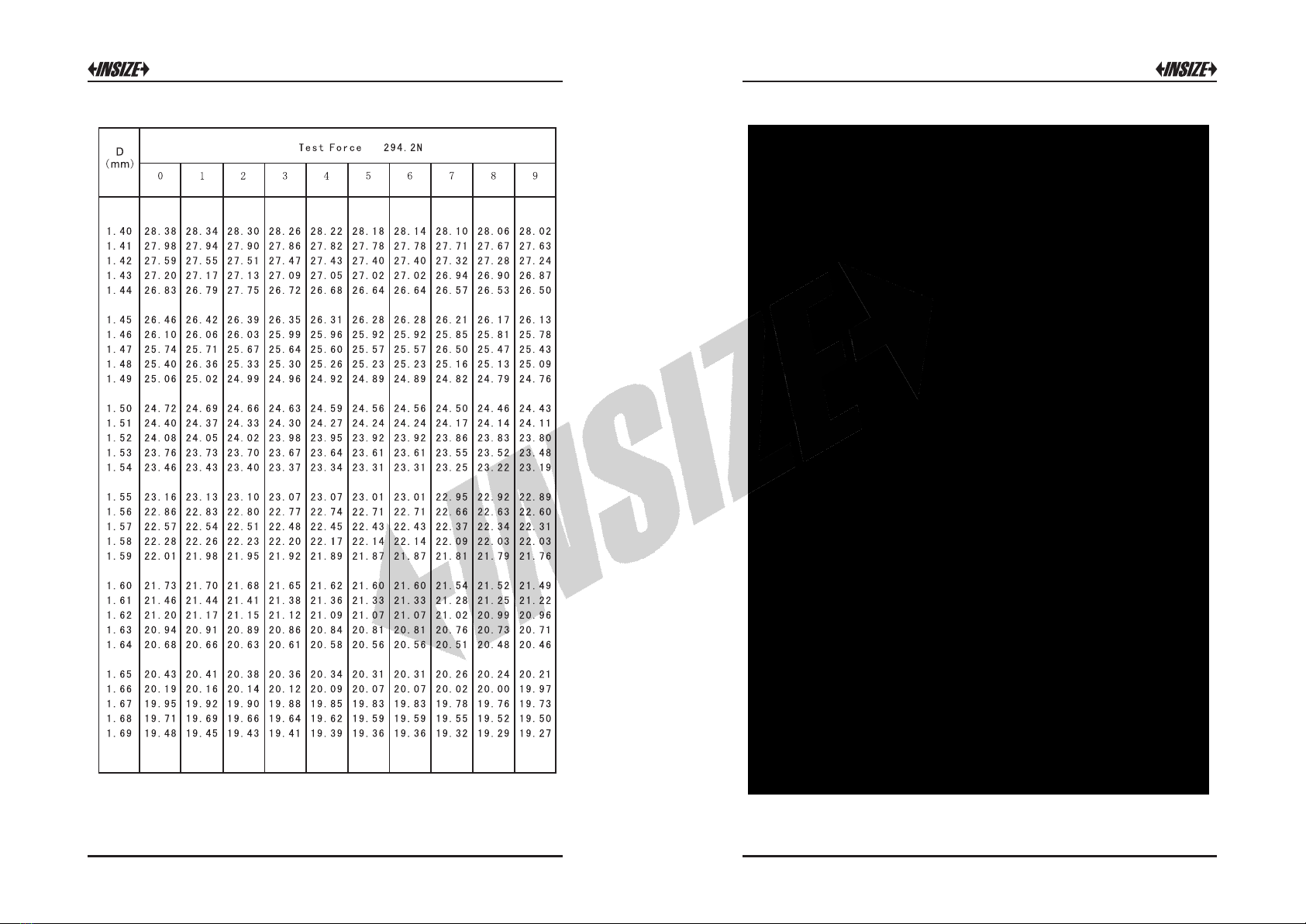

Comparison Table Of Vickers Hardness

Test Force 29 4 . 2 N

D

(mm)

01 2 3456789

0.23

0.24

0.25

0.26

0.27

0.28

0.29

0.30

0.31

0.32

0.33

0.34

0.35

0.36

0.37

0.38

0.39

0.40

0.41

0.42

0.43

0.44

0.45

0.46

0.47

0.48

0.49

966

890

823

763

710

661

618

579

543

511

481

454

429

406

385

366

348

331

315

301

287

275

263

252

241

232

958

883

817

757

705

657

614

575

540

508

478

452

427

404

383

364

346

329

314

299

286

274

262

251

240

231

950

876

810

752

700

652

610

571

537

505

476

449

425

402

381

362

344

328

312

298

285

272

261

250

239

230

942

969

804

746

695

648

606

568

533

502

473

446

422

400

379

360

343

326

311

297

283

271

260

249

238

229

934

862

798

741

690

644

602

564

530

499

470

444

420

398

377

358

341

325

309

295

282

270

258

248

237

228

1007

927

856

792

736

685

639

598

561

527

496

467

441

418

396

375

357

339

323

308

294

281

269

257

247

237

227

999

919

849

786

730

680

635

594

557

523

493

465

439

415

393

373

355

337

321

307

293

280

268

256

246

236

226

990

912

842

780

725

675

631

590

554

520

490

462

436

413

391

371

353

336

320

305

291

278

266

255

245

235

225

982

905

836

775

720

671

626

589

550

517

487

459

434

411

389

370

351

334

318

304

290

277

265

254

243

234

224

974

897

829

769

715

666

622

583

547

514

484

457

432

409

387

368

349

333

317

302

289

276

264

253

242

233

222

Tes t F o r ce 2 9 4 . 2N

01 2 3456789

0.5 0

0.5 1

0.5 2

0.5 3

0.5 4

0.5 5

0.5 6

0.5 7

0.5 8

0.5 9

0.6 0

0.6 1

0.6 2

0.6 3

0.6 4

0.6 5

0.6 6

0.6 7

0.6 8

0.6 9

0.7 0

0.7 1

0.7 2

0.7 3

0.7 4

0.7 5

0.7 6

0.7 7

0.7 8

0.7 9

223

214

206

198

191

184

177

171

165

160

155

150

145

140

136

132

128

124

120

117

114

110

107

104

102

98. 9

96. 3

93. 8

91. 4

89. 1

222

213

205

197

190

183

177

171

165

159

154

149

144

140

135

131

127

124

120

117

113

110

107

104

104

98. 6

96. 1

93. 6

91. 2

88. 9

221

212

204

197

189

183

176

170

164

159

154

149

144

139

135

131

127

123

120

116

113

110

107

104

104

98. 4

95. 8

93. 3

91. 0

88. 7

220

211

203

196

189

182

176

169

164

158

153

148

143

139

135

130

127

123

119

116

113

100

106

104

104

98. 1

95. 6

93. 1

90. 7

88. 5

219

211

203

195

188

181

175

169

163

158

152

148

143

138

134

130

126

122

119

116

112

109

106

103

101

97. 9

95. 3

92. 9

90. 5

88. 2

218

210

202

194

187

181

174

168

163

157

152

147

142

138

134

130

126

122

119

115

112

109

106

103

100

97. 6

95. 1

92. 6

90. 3

88. 0

217

209

201

194

187

180

174

168

162

157

151

147

142

138

133

129

125

122

118

115

112

109

106

103

100

97. 3

94. 8

92. 4

90. 0

87. 8

216

208

200

193

186

179

173

167

161

156

151

146

142

137

133

129

125

121

118

115

111

108

105

102

99.7

97.1

94.6

92.1

89.8

87.9

216

207

200

192

185

179

172

167

161

156

150

146

141

137

132

128

125

121

118

114

111

108

105

102

99. 4

96. 8

94. 3

91. 9

89. 6

87. 4

215

207

199

191

185

178

172

166

160

155

150

146

141

136

132

128

124

121

117

114

111

108

105

102

99. 2

96. 9

94. 1

91. 7

89. 4

87. 1

D

(mm )

19 20

Tes t F o r ce 2 9 4 . 2N

01 2 3456789

0.8 0

0.8 1

0.8 2

0.8 3

0.8 4

0.8 5

0.8 6

0.8 7

0.8 8

0.8 9

0.9 0

0.9 1

0.9 2

0.9 3

0.9 4

0.9 5

0.9 6

0.9 7

0.9 8

0.9 9

1.0 0

1.0 1

1.0 2

1.0 3

1.0 4

1.0 5

1.0 6

1.0 7

1.0 8

1.0 9

86. 9

84. 8

82. 7

80. 8

78. 8

77. 0

75. 2

73. 5

71. 8

70. 2

68. 7

67. 2

65. 7

64. 3

63. 0

61. 6

60. 4

59. 1

57. 9

56. 8

55. 6

54. 5

53. 5

52. 4

51. 4

50. 4 6

49. 5 1

48. 5 9

47. 6 9

46. 8 2

86. 7

84. 6

82. 5

80. 6

78. 7

76. 8

75. 0

73. 3

71. 7

70. 1

68. 5

67. 0

65. 6

64. 2

62. 8

61. 5

60. 2

59. 0

57. 8

56. 6

55. 5

54. 4

53. 4

52. 3

51. 3

50. 3 6

49. 4 2

48. 5 0

47. 6 1

46. 7 4

89. 5

84. 4

82. 3

80. 4

78. 5

76. 6

74. 9

73. 2

71. 5

69. 9

68. 4

66. 9

65. 4

64. 0

62. 7

61. 4

60. 1

58. 9

57. 7

56. 5

55. 4

54. 3

53. 3

52. 2

51. 2

80. 2 7

49. 3 3

48. 4 1

47. 5 2

46. 6 5

86. 3

84. 2

82. 1

80. 2

78. 3

76. 5

74. 7

73. 0

71. 4

69. 8

68. 2

66. 7

65. 3

63. 9

62. 6

61. 3

60. 0

58. 8

57. 6

56. 4

55. 3

54. 2

53. 2

52. 1

51. 1

50.17

49.23

48.32

47.43

46.57

86.1

84.0

81.9

80.0

78.1

76.3

74.5

72.8

71.2

69.6

68.1

66.6

65.2

63.8

62.4

61.1

50.9

58.6

57.5

56.3

55.2

54.1

53.1

52.0

51.0

50. 0 8

49. 1 4

48. 2 3

47. 3 4

46. 4 8

85.8

83.8

81.7

79.8

77.9

76.1

74.4

72.7

71.0

69.4

67.9

66.4

65.0

63.6

62.3

61.0

59.7

58.5

57.3

56.2

55.1

54.0

53.0

51.9

50.9

49. 9 8

49. 0 5

48. 1 4

47. 2 6

46. 4 0

85. 6

83. 5

81. 5

79. 6

77. 7

75. 9

74. 2

72. 5

70. 9

69. 3

67. 8

66. 3

64. 9

63. 5

62. 2

60. 9

59. 6

58. 4

57. 2

56. 1

55. 0

53. 9

52. 8

51. 8

50. 8

49.89

48.96

48.05

47.17

46.31

85. 4

83. 3

81. 3

79. 4

77. 5

75. 7

74. 0

72. 3

70. 7

69. 1

67. 6

66. 2

64. 7

63. 4

62. 0

60. 7

59. 5

58. 3

57. 1

56. 0

54. 9

53. 8

52. 7

51. 7

50. 7 5

49. 7 9

48. 8 6

47. 9 6

47. 0 8

46. 2 3

85. 2

83. 1

81. 1

79. 2

77. 4

75. 6

73. 8

72. 2

70. 5

69. 0

67. 5

66. 0

64. 6

63. 2

61. 9

60. 6

59. 4

58. 2

57. 0

55. 9

54. 8

53. 7

52. 6

51. 6

60. 6 5

49. 7 0

48. 7 7

47. 8 7

47. 0 0

46. 1 4

85. 0

82. 9

80. 9

79. 0

77. 2

75. 4

73. 7

72. 0

70. 4

68. 8

67. 3

65. 9

64. 5

63. 1

61. 8

60. 5

59. 2

58. 0

56. 9

55. 7

54. 6

53. 6

52. 5

51. 5

50. 5 6

49. 6 0

48. 6 8

47. 7 8

46. 9 1

46. 0 6

D

(mm )

Tes t F o r ce 2 9 4 . 2 N

01 2 3456789

1.1 0

1.1 1

1.1 2

1.1 3

1.1 4

1.1 5

1.1 6

1.1 7

1.1 8

1.1 9

1.2 0

1.2 1

1.2 2

1.2 3

1.2 4

1.2 5

1.2 6

1.2 7

1.2 8

1.2 9

130

1.3 1

1.3 2

1.3 3

1.3 4

1.3 5

1.3 6

1.3 7

1.3 8

1.3 9

45.98

45.15

44.35

43.57

42.81

42.07

41.34

40.64

39.95

39.28

38.63

38.00

37.38

36.77

36.18

35.60

35.04

34.49

33.95

33.43

32.92

32.42

31.93

31.45

30.98

30.52

30.08

29.64

29.21

28.79

45.89

45.07

44.27

43.49

42.73

41.99

41.27

40.57

39.89

39.22

38.57

37.93

37.32

36.71

36.12

35.55

34.99

34.44

33.90

33.38

32.87

32.37

31.88

31.40

30.94

30.48

30.03

29.60

29.17

28.75

45.81

44.99

44.19

43.41

42.66

41.92

41.20

40.50

39.82

39.15

38.50

37.87

37.25

36.65

36.06

35.49

34.93

34.38

33.85

33.33

32.82

32.32

31.83

31.36

30.89

30.43

29.99

29.55

29.13

28.71

45. 7 3

44. 9 1

44. 1 1

43. 3 4

42. 5 8

41. 8 5

41. 1 3

40. 4 3

39. 7 5

39. 0 9

38. 4 4

37. 8 1

37. 1 9

36. 5 9

36. 0 1

35. 4 3

34. 8 7

37. 3

33. 8 0

33. 2 8

32. 7 7

32. 2 7

31. 7 8

31. 3 1

30. 8 4

30. 3 9

29. 9 5

29. 5 1

29. 0 9

28. 6 7

45. 6 4

44. 8 3

44. 0 3

43. 2 6

42. 5 1

41. 7 7

41. 0 6

40. 3 6

39. 6 8

39. 0 2

38. 3 8

37. 7 5

37. 1 3

36. 5 3

35. 9 5

35. 3 8

34. 8 2

34. 2 8

33. 7 4

33. 2 2

32. 7 2

32. 2 2

31. 7 4

31. 2 6

30. 8 0

30. 3 4

29. 9 0

29. 4 7

29. 0 4

28. 6 3

45. 5 6

44. 7 5

43. 9 6

43. 1 8

42. 4 3

41. 7 0

40. 9 9

40. 2 9

39. 6 2

38. 9 6

38. 3 1

37. 6 8

37. 0 7

36. 4 7

35. 8 9

35. 3 2

34. 7 6

34. 2 2

33. 6 9

33. 1 7

32. 6 7

32. 1 7

31. 6 9

31. 2 1

30. 7 5

30. 3 0

29. 8 3

29. 4 2

29. 0 0

28. 5 9

45.48

44.67

43.88

43.11

42.36

41.63

40.92

40.23

39.55

38.89

38.25

37.62

37.01

36.41

35.83

35.26

34.71

34.17

33.64

33.12

32.62

32.12

31.34

31.17

30.71

30.26

29.81

29.38

29.96

28.55

45.40

44.59

43.80

43.03

42.29

41.56

40.85

41.16

39.48

38.83

38.19

37.56

36.95

36.36

35.78

35.21

34.65

34.11

33.59

33.07

33.57

33.07

31.59

31.12

30.66

30.21

29.77

29.34

28.92

28.51

45. 3 1

44. 5 1

43. 7 2

42. 9 6

42. 2 1

41. 4 9

40. 7 8

40. 0 9

39. 4 2

38. 7 6

38. 1 2

37. 5 0

36. 8 9

36. 6 0

35. 7 2

35. 1 5

34. 6 0

34. 0 6

33. 5 3

33. 0 2

32. 5 2

32. 0 2

31. 5 4

31. 0 7

30. 6 2

30. 1 7

29. 3 0

29. 7 3

29. 8 3

28. 4 6

45.23

44.43

43.64

42.88

42.14

41.14

40.71

40.02

39.35

38.70

38.06

37.44

36.83

36.24

35.66

35.10

34.55

34.01

33.48

32.97

32.47

31.98

31.50

31.03

30.57

30.12

29.68

29.25

28.83

28.42

D

(mm)

21

22

23

24

01 2 3456789

0.7 0

0.7 1

0.7 2

0.7 3

0.7 4

0.7 5

0.7 6

0.7 7

0.7 8

0.7 9

0.8 0

0.8 1

0.8 2

0.8 3

0.8 4

0.8 5

0.8 6

0.8 7

0.8 8

0.8 9

0.9 0

0.9 1

0.9 2

0.9 3

0.9 4

0.9 5

0.9 6

0.9 7

0.9 8

0.9 9

378

368

358

348

338 . 6

329 . 7

321 . 0

312 . 8

304 . 8

297 . 1

289 . 7

282 . 6

275 . 8

269 . 2

262 . 8

256 . 7

250 . 7

245 . 0

239 . 5

234 . 1

228 . 9

223 . 9

219 . 1

214 . 4

209 . 9

205 . 0

210 . 0

297 . 1

193 . 1

189 . 2

377

367

357

347

337.7

328.8

320.2

312.0

304.0

296.4

289.0

287.9

275.1

268.5

262.2

256.1

250.1

244.4

238.9

233.6

228.4

223.4

218.6

213.9

209.4

205.5

200.8

196.7

192.7

188.8

376

366

356

346

336 . 8

327 . 9

319 . 4

311 . 1

303 . 2

295 . 6

28.3

281 . 2

274 . 4

267 . 9

261 . 6

255 . 5

249 . 6

243 . 9

238 . 4

233 . 1

227 . 9

222 . 9

218 . 1

213 . 5

209 . 0

204 . 6

200 . 4

196 . 3

192 . 3

188 . 4

375

365

355

346

335 . 9

327 . 0

318 . 5

310 . 3

302 . 5

294 . 9

287 . 6

280 . 6

273 . 8

264 . 2

260 . 9

254 . 9

249 . 0

243 . 3

237 . 8

232 . 5

227 . 4

222 . 5

217 . 7

213 . 0

208 . 5

204 . 2

200 . 0

195 . 9

191 . 9

188 . 1

374

364

354

344

335 . 0

326 . 2

317 . 7

309 . 5

301 . 7

294 . 1

286 . 9

279 . 9

273 . 1

266 . 6

260 . 3

254 . 3

245 . 8

242 . 8

237 . 3

232 . 0

226 . 9

222 . 0

217 . 2

212 . 6

208 . 1

203 . 8

199 . 5

195 . 5

191 . 5

187 . 7

373

363

353

343

334.1

325.3

316.9

308.7

300.9

293.4

286.2

279.2

272.5

266.0

259.7

253.7

247.8

244.2

236.8

231.5

226.4

221.0

216.7

212.1

207.7

203.3

196.1

195.1

191.1

187.3

372

362

352

342

333.2

324.5

316.0

307.9

300.2

292.7

285.4

278.5

371.8

265.3

259.1

253.1

247.3

241.7

236.2

231.0

225.9

221.0

216.3

211.7

207.2

202.9

198.7

194.7

190.7

186.9

370

360

350

340 . 5

331 . 4

322 . 7

314 . 4

306 . 4

298 . 8

291 . 2

284 . 0

277 . 1

270 . 5

264 . 1

257 . 9

251 . 9

246 . 1

240 . 6

235 . 2

230 . 0

224 . 9

220 . 0

215 . 3

210 . 8

206 . 3

202 . 1

197 . 9

193 . 9

190 . 0

186 . 2

371

361

351

341

332 . 3

323 . 6

315 . 2

307 . 2

299 . 4

291 . 9

284 . 7

277 . 8

271 . 1

264 . 7

258 . 5

252 . 5

246 . 7

241 . 1

235 . 7

230 . 5

225 . 4

220 . 5

215 . 8

211 . 2

206 . 8

202 . 5

198 . 3

194 . 3

190 . 4

186 . 6

369

359

349

339 . 6

330 . 5

321 . 9

313 . 6

305 . 6

297 . 9

290 . 5

283 . 3

276 . 5

269 . 8

263 . 4

257 . 3

251 . 3

245 . 6

240 . 0

234 . 6

229 . 4

224 . 4

219 . 9

214 . 9

210 . 3

205 . 9

201 . 6

197 . 5

193 . 5

189 . 6

185 . 8

Tes t F o r ce 9 8 0 . 7N

D

(mm )

Tes t F o r ce 9 8 0 . 7N

1 2 3456780 9

0.4 2

0.4 3

0.4 4

0.4 5

0.4 6

0.4 7

0.4 8

0.4 9

0.5 0

0.5 1

0.5 2

0.5 3

0.5 4

0.5 5

0.5 6

0.5 7

0.5 8

0.5 9

0.6 0

0.6 1

0.6 2

0.6 3

0.6 4

0.6 5

0.6 6

0.6 7

0.6 8

0.6 9

1003

958

916

876

839

805

772

742

713

686

660

636

613

591

571

551

553

515

498

482

467

453

439

426

413

401

389

998

953

912

873

836

802

769

739

710

683

658

634

611

589

569

549

531

513

497

481

466

451

438

424

412

400

388

994

949

908

869

832

798

766

736

707

681

655

631

609

587

567

547

529

521

495

479

464

450

436

423

411

399

387

989

945

904

865

829

795

763

733

705

678

653

629

606

585

565

546

527

510

493

478

463

449

435

422

409

398

386

985

941

900

861

825

792

760

730

702

675

650

627

604

583

563

544

526

508

492

476

461

447

434

421

408

396

385

980

936

896

858

822

788

757

727

699

673

648

624

602

581

561

542

524

507

490

475

460

446

432

419

407

395

384

975

932

892

854

818

785

754

724

696

670

645

622

600

579

559

540

522

505

489

473

458

444

431

418

406

394

383

971

928

888

850

815

782

751

721

694

668

643

620

598

577

557

538

520

503

487

472

457

443

430

417

405

393

382

967

924

884

847

812

779

748

719

691

665

641

617

596

575

555

536

519

502

486

470

456

442

428

416

403

382

381

100 8

962

920

880

843

808

775

745

716

688

663

638

615

593

573

553

535

517

500

484

469

454

440

427

414

402

391

380

D

(mm )

25

26

01 2 3456789

1.30

1.31

1.32

1.33

1.34

1.35

1.36

1.37

1.38

1.39

1.40

1.41

1.42

1.43

1.44

1.45

1.46

1.47

1.48

1.49

1.50

1.51

1.52

1.53

1.54

1.55

1.56

1.57

1.58

1.59

109 . 7

108 . 1

106 . 4

104 . 8

103 . 3

101 . 7

100 . 3

98.8

97.4

96.0

94.6

93.3

92.0

90.4

89.4

88.2

87.0

85.8

84.7

83.5

82.4

81.3

80.3

78.2

78.2

77.2

76.2

75.2

74. 2 8

73. 3 5

109 . 6

107 . 9

106 . 3

104 . 7

103 . 1

101 . 6

100 . 1

98. 7

97. 2

95. 8

94. 5

93. 1

91. 8

90. 6

89. 3

88. 1

86. 9

85. 7

84. 5

83. 4

82. 3

81. 2

80. 2

79. 1

78. 1

77. 1

76. 1

75. 1

74. 1 9

73. 2 6

109 . 4

107 . 7

106 . 1

104 . 5

103 . 0

101 . 4

100 . 0

98. 5

97. 1

95. 7

94. 3

93. 0

91. 7

90. 4

89. 2

88. 0

86. 8

85. 6

84. 4

83. 3

82. 2

81. 1

80. 1

79. 0

78. 0

77. 0

76. 0

75. 0

74. 0 9

73. 1 7

109 . 2

107 . 6

105 . 9

104 . 4

102 . 8

101 . 3

99. 8

98. 4

97. 0

95. 6

94. 2

92. 9

91. 6

90. 3

89. 1

87. 8

86. 6

85. 5

84. 3

83. 2

82. 1

81. 0

79. 9

78. 9

77. 9

76. 9

75. 9

74. 9

74. 0 0

73. 0 7

109 . 1

107 . 4

105 . 8

104 . 2

102 . 7

101 . 1

99. 7

98. 2

96. 8

95. 4

94. 1

92. 7

91. 4

90. 2

88. 6

87. 7

95. 5

85. 3

84. 2

83. 1

82. 0

80. 9

79. 8

78. 8

77. 8

76. 8

75. 8

74. 8 5

73. 9 1

72. 9 8

108 . 9

107 . 2

105 . 6

104 . 5

102 . 5

101 . 0

99. 5

98. 1

96. 7

95. 3

93. 9

92. 6

91. 3

90. 1

88. 8

87. 6

96. 4

85. 2

84. 1

93. 0

81. 9

80. 8

79. 7

78. 7

77. 7

76. 7

75. 7

74. 7 5

73. 8 1

72. 8 9

108 . 7

107 . 1

105 . 5

103 . 9

102 . 4

100 . 9

99. 4

97. 9

96. 5

95. 2

93. 8

82. 5

91. 2

89. 9

88. 7

87. 5

86. 3

85. 1

84. 0

82. 9

81. 8

80. 7

79. 6

78. 6

77. 6

76. 6

75. 6

74. 6 5

73. 7 2

72. 8 0

108 . 4

106 . 7

105 . 1

103 . 6

102 . 1

100 . 6

99. 1

97. 7

96. 3

94. 9

93. 5

92. 2

90. 9

89. 7

88. 4

87. 2

86. 0

84. 9

83. 8

82. 6

81. 5

80. 5

79. 4

78. 4

77. 4

76. 4

75. 4

74. 4 7

73. 5 4

72. 6 2

108.6

106.9

105.3

103.7

102.2

100.7

99. 2

97. 8

96. 4

95. 0

93. 7

92. 4

91. 1

89. 8

88. 6

87. 4

86. 2

85. 0

83. 9

82. 7

81. 7

80. 6

79. 5

78. 5

77. 5

76. 5

75. 5

74.56

73.63

72.71

108 . 2

106 . 6

105 . 0

103 . 4

101 . 9

100 . 4

98. 9

97. 5

96. 1

94. 7

93. 4

92. 1

90. 8

89. 6

88. 3

87. 1

85. 9

84. 8

83. 6

82. 5

81. 4

80. 4

79. 3

78. 3

77. 3

76. 3

75. 3

74. 3 8

73. 4 4

72. 5 3

Tes t F o r ce 9 8 0 . 7N

D

(mm)

01 2 3456789

1.00

1.01

1.02

1.03

1.04

1.05

1.06

1.07

1.08

1.09

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

1.19

1.20

1.21

1.22

1.23

1.24

1.25

1.26

1.27

1.28

1.29

185 . 4

181 . 8

178 . 2

174 . 8

171 . 4

168 . 2

165 . 0

162 . 0

159 . 0

156 . 1

153 . 3

150 . 5

147 . 8

145 . 2

142 . 7

140 . 2

137 . 8

135 . 5

133 . 2

130 . 9

128 . 8

126 . 7

124 . 6

122 . 6

120 . 6

118 . 7

116 . 2

115 . 0

113 . 2

111 . 4

185 . 1

181 . 4

177 . 9

174 . 5

171 . 1

167 . 9

164 . 7

161 . 7

158 . 7

154 5 . 8

153 . 0

150 . 2

147 . 6

145 . 0

142 . 4

140 . 0

137 . 6

135 . 2

133 . 0

130 . 7

128 . 6

126 . 4

124 . 4

122 . 4

120 . 4

118 . 5

116 . 6

114 . 8

113 . 0

111 . 3

184.7

181.1

177.5

174.1

170.8

167.6

164.4

161.4

158.4

155.5

152.7

150.0

147.3

144.7

142.2

139.7

137.3

135.0

132.7

130.5

128.3

126.2

124.2

122.2

120.2

118.3

116.4

114.6

112.8

111.1

184.3

180.7

177.2

173.8

170.5

167.2

164.1

161.1

158.1

155.2

152.4

149.7

147.0

144.5

141.9

139.5

137.1

134.8

132.5

130.3

128.1

126.6

124.0

122.0

120.0

118.1

116.2

114.4

112.7

110.7

184 . 0

180 . 4

176 . 8

173 . 6

170 . 1

166 . 9

163 . 8

160 . 8

157 . 8

154 . 9

152 . 1

149 . 4

147 . 0

144 . 5

141 . 9

139 . 5

137 . 1

134 . 8

132 . 5

130 . 3

127 . 9

125 . 8

123 . 8

121 . 8

119 . 8

118 . 3

116 . 4

114 . 6

112 . 8

111 . 1

183 . 6

180 . 0

176 . 5

173 . 1

169 . 8

166 . 6

163 . 5

160 . 5

157 . 5

154 . 7

151 . 9

149 . 2

146 . 5

143 . 9

141 . 4

139 . 0

136 . 6

134 . 3

132 . 1

129 . 9

127 . 7

125 . 6

123 . 6

121 . 6

119 . 6

117 . 7

115 . 9

114 . 1

112 . 3

110 . 6

183 . 2

179 . 6

176 . 2

172 . 8

169 . 5

166 . 3

163 . 2

160 . 2

157 . 2

154 . 4

151 . 6

148 . 9

146 . 3

143 . 7

141 . 2

138 . 8

136 . 4

134 . 1

131 . 8

129 . 6

127 . 5

125 . 4

123 . 4

121 . 4

119 . 4

117 . 5

115 . 7

113 . 9

112 . 1

110 . 4

182.5

178.9

175.5

172.1

168.8

165.7

162.6

159.6

156.7

153.8

151.0

148.4

145.7

143.2

140.7

138.3

135.9

133.6

131.4

129.2

127.1

125.0

123.0

121.0

119.1

117.2

115.3

113.5

111.8

110.1

182 . 9

179 . 3

175 . 8

172 . 4

169 . 2

166 . 0

162 . 9

159 . 9

156 . 9

154 . 1

151 . 3

148 . 6

146 . 0

143 . 4

141 . 0

138 . 5

135 . 2

133 . 9

131 . 6

129 . 4

127 . 3

125 . 2

123 . 2

121 . 2

119 . 3

117 . 4

115 . 5

113 . 7

112 . 0

110 . 2

182.1

178.6

175.1

171.8

168.5

165.3

162.3

159.3

156.4

153.5

150.8

148.1

145.5

142.9

140.5

138.0

135.7

133.4

131.2

129.0

126.9

124.8

122.8

120.8

118.9

117.0

115.2

113.4

111.6

109.9

D

(mm)

Tes t F o r ce 9 8 0 . 7N

27

28

01 2 3456789

1.6 0

1.6 1

1.6 2

1.6 3

1.6 4

1.6 5

1.6 6

1.6 7

1.6 8

1.6 9

1.7 0

1.7 1

1.7 2

1.7 3

1.7 4

1.7 5

1.7 6

1.7 7

1.7 8

1.7 9

1.8 0

1.8 1

1.8 2

1.8 3

1.8 4

1.8 5

1.8 6

1.8 7

1.8 8

1.8 9

72.44

71.54

70.66

69.79

68.95

68.11

67.29

66.49

65.70

64.93

64.16

63.42

62.68

61.96

61.25

60.55

59.86

59.19

58.53

57.87

57.23

56.60

55.98

55.37

54.77

54.18

53.60

53.03

52.47

51.91

72.35

71.45

70.57

69.71

68.86

68.03

67.21

66.41

65.62

64.85

64.09

63.34

62.61

61.89

61.18

60.48

59.80

59.12

58.46

57.81

57.17

56.54

55.92

55.31

54.71

54.12

53.54

52.97

52.41

51.86

72. 2 6

71. 3 6

71. 4 8

69. 6 2

68. 7 8

67. 9 5

67. 1 3

66. 3 3

65. 5 5

64. 7 7

64. 0 1

63. 2 7

62. 5 4

61. 8 2

61. 1 1

60. 4 1

59. 7 3

59. 0 6

58. 4 0

57. 7 5

57. 1 1

56. 4 8

55. 8 6

55. 2 5

54. 6 5

54. 0 6

53. 4 9

52. 9 2

52. 3 5

51. 8 0

72. 1 7

71. 2 7

70. 4 0

69. 5 4

68. 6 9

67. 8 7

67. 0 5

66. 2 5

65. 4 7

64. 7 0

63. 9 4

63. 1 9

62. 4 6

61. 7 4

61. 0 4

60. 3 4

59. 6 6

58. 9 9

58. 3 3

57. 6 8

57. 0 4

56. 4 2

55. 8 0

55. 1 9

54. 5 9

54. 0 1

53. 4 3

52. 8 6

52. 3 0

51. 7 5

72.08

71.19

70.31

69.45

68.61

67.78

66.97

66.17

65.39

64.62

63.86

63.12

62.39

61.67

60.97

60.27

59.59

58.92

58.26

57.62

56.98

56.35

55.74

55.13

54.53

53.95

53.37

52.80

52.24

51.69

72.99

71.10

70.22

69.37

68.53

67.70

66.89

66.09

65.31

64.54

63.79

63.05

62.32

61.60

60.90

60.21

59.53

58.86

58.20

57.55

56.92

56.29

55.68

55.07

54.48

53.89

53.31

52.75

52.19

51.64

71. 9 0

71. 0 1

70. 1 4

69. 2 8

68. 4 4

67. 6 2

66. 8 1

66. 0 2

65. 2 4

64. 4 7

63. 7 1

62. 9 7

62. 2 5

61. 5 3

60. 8 3

60. 1 4

59. 4 6

58. 7 9

58. 1 3

57. 4 9

56. 8 5

86. 2 3

55. 6 2

55. 0 1

54. 4 2

53. 8 3

53. 2 6

52. 6 9

52. 1 3

51. 5 8

71. 7 2

70. 8 3

69. 9 7

69. 1 1

68. 2 8

67. 4 6

66. 6 4

65. 8 6

62. 0 8

64. 3 2

63. 5 7

62. 8 3

62. 1 0

61. 3 9

60. 6 9

60. 0 0

59. 3 2

58. 6 6

58. 0 0

57. 3 6

56. 7 3

56. 1 1

55. 4 9

54. 8 9

54. 3 0

53. 7 2

53. 1 4

52. 5 8

52. 0 2

51. 4 8

71. 8 1

70. 9 2

70. 0 5

69. 2 0

68. 3 6

67. 5 4

66. 7 3

65. 9 4

65. 1 6

64. 3 9

63. 6 4

62. 9 0

62. 1 7

61. 4 6

60. 7 6

60. 0 7

59. 3 9

58. 7 2

58. 0 7

57. 4 2

56. 7 9

56. 1 7

55. 5 5

54. 9 5

54. 3 6

53. 7 7

53. 2 0

52. 6 3

52. 0 8

51. 5 3

71. 6 3

70. 7 5

69. 8 8

69. 0 3

68. 2 0

67. 3 8

66. 5 7

65. 7 8

65. 0 0

64. 2 4

63. 4 9

62. 7 5

62. 0 3

61. 3 2

60. 6 2

59. 9 3

59. 2 6

58. 5 9

57. 9 4

57. 3 0

56. 6 7

56. 0 4

55. 4 3

54. 8 3

54. 2 4

53. 6 6

53. 0 9

52. 5 2

51. 9 7

51. 4 2

Tes t F o r ce 9 8 0 . 7N

D

(mm )

01 2 3456789

1.90

1.91

1.92

1.93

1.94

1.95

1.96

1.97

1.98

1.99

51. 3 7

50. 8 3

50. 3 0

49. 7 8

49. 2 7

48. 7 7

48. 2 7

47. 7 8

47. 3 0

46. 8 3

51. 3 1

50. 7 8

50. 2 5

49. 7 3

49. 2 2

48. 7 2

48. 2 2

47. 7 3

47. 2 5

46. 7 8

51. 2 6

50. 7 2

50. 2 0

49. 6 8

49. 1 7

48. 6 7

48. 1 7

47. 6 9

47. 2 1

46. 7 3

51. 2 1

50. 6 7

50. 1 5

49. 6 3

49. 1 2

48. 6 2

48. 1 2

47. 6 4

47. 1 6

46. 6 9

51. 1 5

50. 6 2

50. 0 9

49. 5 8

49. 0 7

48. 5 7

48. 0 7

47. 5 9

47. 1 1

46. 6 4

51. 1 0

50. 5 7

50. 0 4

49. 5 3

49. 0 2

48. 5 2

48. 0 3

47. 5 4

47. 0 6

46. 5 9

51. 0 4

50. 5 1

49. 9 9

49. 4 7

48. 9 7

48. 4 7

47. 9 8

47. 4 9

47. 0 2

46. 5 5

50. 9 4

50. 4 1

49. 8 9

49. 3 7

48. 8 7

48. 3 7

47. 8 8

47. 4 0

46. 9 2

46. 4 5

50.99

50.46

49.94

49.42

48.92

48.42

47.93

47.44

46.97

46.50

50. 8 8

50. 3 6

49. 8 3

49. 3 2

48. 8 2

48. 3 2

47. 8 3

47. 3 5

46. 8 7

46. 4 1

Tes t F o r ce 9 8 0 . 7N

D

(mm)

29

30

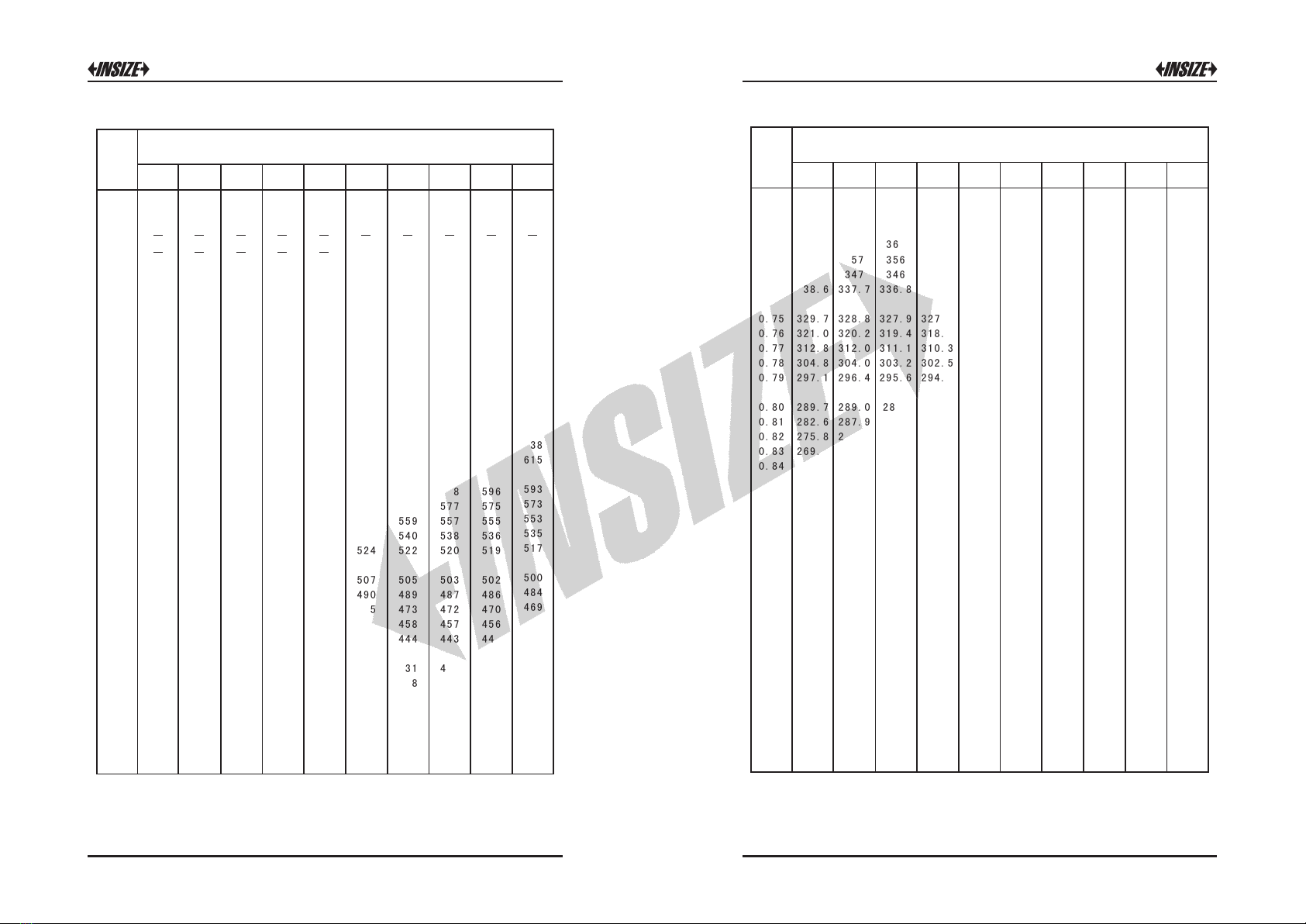

Dia m e t er

Bal l D i a me t e r D =2. 5 m m Ball D i a m et e r D = 5mm

183 9 N

2

(30D)

612 . 9 N

2

(10D)

306 . 5 N

2

(5D)

612 . 9 N

2

(2.5D)

2.8 9

2.9 0

2.9 1

2.9 2

2.9 3

2.9 4

2.9 5

2.9 6

2.9 7

2.9 8

2.9 9

3.0 0

3.0 1

3.0 2

3.0 3

3.0 4

3.0 5

3.0 6

3.0 7

3.0 8

3.0 9

3.1 0

3.1 1

3.1 2

3.1 3

3.1 4

3.1 5

3.1 6

3.1 7

3.1 8

3.1 9

448

444

441

438

435

432

429

426

423

420

417

415

412

409

406

404

401

398

395

393

390

388

385

383

380

378

375

373

370

368

366

140

139

138

137

136

135

135

134

133

132

131

130

129

128

128

127

126

125

124

123

123

122

70. 1

69. 6

69. 1

68. 4

68. 2

67. 7

67. 3

66. 8

66. 4

65. 9

65. 5

65. 0

64. 6

64. 2

63. 8

63. 3

62. 9

63. 5

62. 1

61. 7

61. 3

60. 9

35. 0

34. 8

34. 6

34. 3

34. 1

33. 9

33. 6

33. 4

33. 2

33. 0

32. 7

32. 5

32. 3

32. 1

31. 9

31. 7

31. 5

31. 3

31. 1

30. 9

30. 7

30. 5

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306 . 5 N

2

(5D )

612.9N

2

(2.5D)

3.2 0

3.2 1

3.2 2

3.2 3

3.2 4

3.2 5

3.2 6

3.2 7

3.2 8

3.2 9

3.3 0

3.3 1

3.3 2

3.3 3

3.3 4

3.3 5

3.3 6

3.3 7

3.3 8

3.3 9

3.4 0

3.4 1

3.4 2

3.4 3

3.4 4

3.4 5

3.4 6

3.4 7

3.4 8

3.4 9

363

361

359

356

354

352

350

347

345

343

341

339

337

335

333

331

329

326

325

323

321

319

317

315

313

311

309

307

306

304

121

120

120

119

118

117

117

116

115

114

114

113

112

112

111

110

110

109

108

108

107

106

106

105

104

104

103

102

102

101

60. 5

60. 1

59. 8

59. 4

59. 0

58. 6

58. 3

57. 9

57. 5

57. 2

56. 8

56. 5

56. 1

55. 8

55. 4

55. 1

54. 8

54. 4

54. 1

53. 8

53. 4

53. 1

52. 8

52. 5

52. 2

51. 8

51. 5

51. 2

20. 9

50. 6

30. 3

30. 1

29. 9

29. 7

29. 5

29. 3

29. 1

29. 0

28. 8

28. 6

28. 4

28. 2

28. 1

27. 9

27. 7

27. 5

27. 4

27. 2

27. 0

26. 9

26. 7

26. 6

26. 4

26. 2

26. 1

25. 9

25. 8

25. 6

25. 5

25. 3

Dia m e t er

Bal l D i a me t e r D =2. 5 m m Ball Diameter D=5mm

Comparison Table Of Brinell Hardness

31

Diameter

183 9 N

2

(3 0 D )

612.9N

2

(1 0 D )

306.5N

2

(5 D )

612 . 9 N

2

(2.5D )

3.50

3.51

3.52

3.53

3.54

3.55

3.56

3.57

3.58

3.59

3.60

3.61

3.62

3.63

3.64

3.65

3.66

3.67

3.68

3.69

3.70

3.71

3.72

3.73

3.74

3.75

3.76

3.77

3.78

3.79

302

300

298

297

295

293

292

290

288

286

285

283

252

280

278

277

275

274

272

271

269

268

266

265

263

262

260

259

257

256

101

100

99. 5

98. 9

98. 3

97. 7

97. 2

96. 6

96. 1

95. 5

94. 9

94. 4

93. 9

93. 3

92. 8

92. 3

91. 8

91. 2

90. 7

90. 2

89. 7

89. 2

88. 7

88. 2

87. 7

87. 2

86. 8

86. 3

85. 8

85. 3

50.3

50.0

49.7

49.4

49.2

48.9

48.6

48.3

48.0

47.7

47.5

47.2

46.9

46.7

46.4

46.1

45.9

45.6

45.4

45.1

44.9

44.6

44.4

44.1

43.9

43.6

43.4

43.1

42.9

42.7

25. 2

25. 0

24. 9

24. 7

24. 6

24. 4

24. 3

24. 2

24. 0

23. 9

23. 7

23. 6

23. 5

23. 3

23. 2

23. 1

22. 9

22. 8

22. 7

22. 6

22. 4

22. 3

22. 2

22. 1

21. 9

21. 8

21. 7

21. 6

21. 5

21. 3

Ba l l D ia m e te r D = 2. 5 mm Ball Diameter D=5mm

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306.5N

2

(5D )

612.9N

2

(2.5 D )

3.8 0

3.8 1

3.8 2

3.8 3

3.8 4

3.8 5

3.8 6

3.8 7

3.8 8

3.8 9

3.9 0

3.9 1

3.9 2

3.9 3

3.9 4

3.9 5

3.9 6

3.9 7

3.9 8

3.9 9

4.0 0

4.0 1

4.0 2

4.0 3

4.0 4

4.0 5

4.0 6

4.0 7

4.0 8

4.0 9

255

253

252

250

249

248

246

245

244

242

241

240

239

237

236

235

234

232

231

230

229

228

226

225

224

223

222

221

219

218

84. 9

84. 4

83. 9

83. 5

83. 0

82. 6

82. 1

81. 7

81. 3

80. 8

80. 4

80. 0

79. 6

79. 1

78. 7

78. 3

77. 9

77. 5

77. 1

76. 7

76. 3

75. 9

75. 7

75. 1

74. 7

74. 3

73. 9

73. 5

73. 2

72. 8

42. 4

42. 2

42. 0

41. 7

41. 5

41. 3

41. 1

40. 9

40. 6

40. 4

40. 2

40. 0

39. 8

39. 6

39. 4

39. 1

38. 9

38. 7

38. 5

38. 3

38. 1

37. 9

37. 7

37. 5

37. 3

37. 1

37. 0

36. 8

36. 6

36. 4

21. 2

21. 1

21. 0

20. 9

20. 8

20. 6

20. 5

20. 4

20. 3

20. 2

20. 1

20. 0

19. 9

19. 8

19. 7

19. 6

19. 5

19. 4

19. 3

19. 2

19. 1

19. 0

18. 9

18. 8

18. 7

18. 6

18. 5

18. 4

18. 3

18. 2

Dia m e t er

Bal l D i a me t e r D =2. 5 m m Ball D i a m et e r D = 5mm

32

33

34

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

4.18

4.19

4.20

4.21

4.22

4.23

4.24

4.25

4.26

4.27

4.28

4.29

4.30

4.31

4.32

4.33

4.34

4.35

4.36

4.37

4.38

4.39

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306 . 5 N

2

(5D )

612 . 9 N

2

(2.5 D )

217

216

215

214

213

212

211

210

209

208

207

205

204

203

202

201

200

199

198

198

197

196

195

194

193

192

191

190

189

188

72. 4

72. 0

71. 7

71. 3

71. 0

70. 6

70. 2

69. 9

69. 5

69. 2

68. 8

68. 5

68. 2

67. 8

67. 5

67. 1

66. 8

66. 5

66. 2

65. 8

65. 5

65. 2

64. 9

64. 6

64. 2

63. 9

63. 6

63. 3

63. 0

62. 7

36. 2

36. 0

35. 8

35. 7

35. 5

35. 3

35. 1

34. 9

34. 8

34. 6

34. 4

34. 2

34. 1

33. 9

33. 7

33. 6

33. 4

33. 2

33. 1

32. 9

32. 8

32. 6

32. 4

32. 3

32. 1

32. 0

31. 8

31. 7

31. 5

31. 4

18.1

18.0

17.9

17.8

17.7

17.6

17.6

17.5

17.4

17.3

17.2

17.1

17.0

17.0

16.9

16.8

16.7

16.6

16.5

16.5

16.4

16.3

16.2

16.1

16.1

16.0

15.9

15.8

15.8

15.7

Diameter

Bal l D i a me t e r D =2. 5 m m Ball D i a m et e r D = 5mm

4.4 0

4.4 1

4.4 2

4.4 3

4.4 4

4.4 5

4.4 6

4.4 7

4.4 8

4.4 9

4.5 0

4.5 1

4.5 2

4.5 3

4.5 4

4.5 5

4.5 6

4.5 7

4.5 8

4.5 9

4.6 0

4.6 1

4.6 2

4.6 3

4.6 4

4.6 5

4.6 6

4.6 7

4.6 8

4.6 9

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306.5N

2

(5D )

612 . 9 N

2

(2.5 D )

187

186

185

185

184

183

182

181

180

179

179

178

177

176

175

174

174

173

172

171

170

170

169

168

167

167

166

165

164

164

62.4

62.1

61.8

61.5

61.2

30.9

60.6

60.4

60.1

59.8

59.5

59.2

59.0

58.7

58.4

58.1

57.9

57.6

57.3

57.1

56.8

56.5

56.3

56.0

55.8

55.5

55.3

55.0

54.8

54.5

31. 2

31. 0

30. 9

30. 8

30. 6

30. 5

30. 3

30. 2

30. 0

29. 9

29. 8

29. 6

29. 5

29. 3

29. 2

29. 1

28. 9

28. 8

28. 7

28. 5

28. 4

28. 3

28. 1

28. 0

27. 9

27. 8

27. 6

27. 5

27. 4

27. 3

15. 6

15. 5

15. 5

15. 4

15. 3

15. 2

15. 2

15. 1

15. 0

14. 9

14. 9

14. 8

14. 7

14. 7

14. 6

14. 5

14. 5

14. 4

14. 3

14. 3

14. 2

14. 1

14. 1

14. 0

13. 9

13. 9

13. 8

13. 8

13. 7

13. 6

Dia m e t er

Bal l D i a me t e r D =2. 5 m m Ball D i a m et e r D = 5mm

35

36

4.7 0

4.7 1

4.7 2

4.7 3

4.7 4

4.7 5

4.7 6

4.7 7

4.7 8

4.7 9

4.8 0

4.8 1

4.8 2

4.8 3

4.8 4

4.8 5

4.8 6

4.8 7

4.8 8

4.8 9

4.9 0

4.9 1

4.9 2

4.9 3

4.9 4

4.9 5

4.9 6

4.9 7

4.9 8

4.9 9

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306.5N

2

(5D )

612.9N

2

(2.5 D )

163

162

161

161

160

159

158

158

157

156

156

155

154

154

153

152

152

151

150

150

149

148

148

147

146

146

145

144

144

143

54. 3

54. 0

53. 8

53. 5

53. 3

53. 0

52. 8

52. 6

52. 3

52. 1

51. 9

51. 7

51. 4

51. 2

51. 0

50. 7

50. 5

50. 3

50. 1

49. 8

49. 6

49. 4

49. 2

49. 0

48. 8

48. 6

48. 4

48. 1

47. 9

47. 7

27. 1

27. 0

26. 9

26. 8

26. 6

26. 5

26. 4

26. 3

26. 2

26. 1

25. 9

25. 8

25. 7

25. 6

25. 5

25. 4

25. 3

25. 1

25. 0

24. 9

24. 8

24. 6

24. 6

24. 5

24. 4

24. 3

24. 2

24. 1

24. 0

23. 9

13. 6

13. 5

13. 4

13. 4

13. 3

13. 3

13. 2

13. 1

13. 1

13. 0

13. 0

12. 9

12. 9

12. 8

12. 7

12. 7

12. 6

12. 6

12. 5

12. 5

12. 4

12. 4

12. 3

12. 2

12. 2

12. 1

12. 1

12. 0

12. 0

11. 9

Dia m e t er

Bal l D i a me t e r D =2. 5 m m Ball D i a m et e r D = 5mm

5.00

5.01

5.02

5.03

5.04

5.05

5.06

5.07

5.08

5.09

5.10

5.11

5.12

5.13

5.14

5.15

5.16

5.17

5.18

5.19

5.20

5.21

5.22

5.23

5.24

5.25

5.26

5.27

5.28

5.29

183 9 N

2

(30D )

612 . 9 N

2

(10D )

306 . 5 N

2

(5D )

612 . 9 N

2

(2.5 D )

143

142

141

141

140

140

139

138

138

137

137

136

135

135

134

134

133

133

132

132

131

130

130

129

129

128

128

127

127

126

47. 5

47. 3

47. 1

46. 9

46. 7

46. 5

46. 3

46. 1

45. 9

45. 7

45. 5

45. 3

45. 1

45. 0

44. 8

44. 6

44. 4

44. 2

44. 0

43. 8

43. 7

43. 5

43. 3

43. 1

42. 9

42. 8

42. 6

42. 4

42. 2