INIM Electronics FireVibes WIL0010 User manual

GENERAL DESCRIPTION

The WIL0010 remote indicator is an output device which, activated by the control panel, switches on its red light in the event of an emergency

fire alarm. It is battery powered and doesn’t need any system cabling installation.

The activation command is sent from the control panel to the indicator through the wire to wireless translator interface module and other

possible wireless expander modules. It is intended to be used within the FireVibes range of products.

LOCATION SELECTION

Select a location for the remote indicator that conforms to your local applicable safety standards and that is in a good position for sending /

receiving wireless signals to / from the father EWT100, IWT100 or XWT100 network device.

Mount the remote indicator as far as possible from metal objects, metal doors, metal window openings, etc. as well as cable conductors,

cables (especially from computers), otherwise the operating distance may greatly drop.

The WIL0010 must NOT be installed near electronic devices and computer equipment that can interfere with its wireless communication

quality.

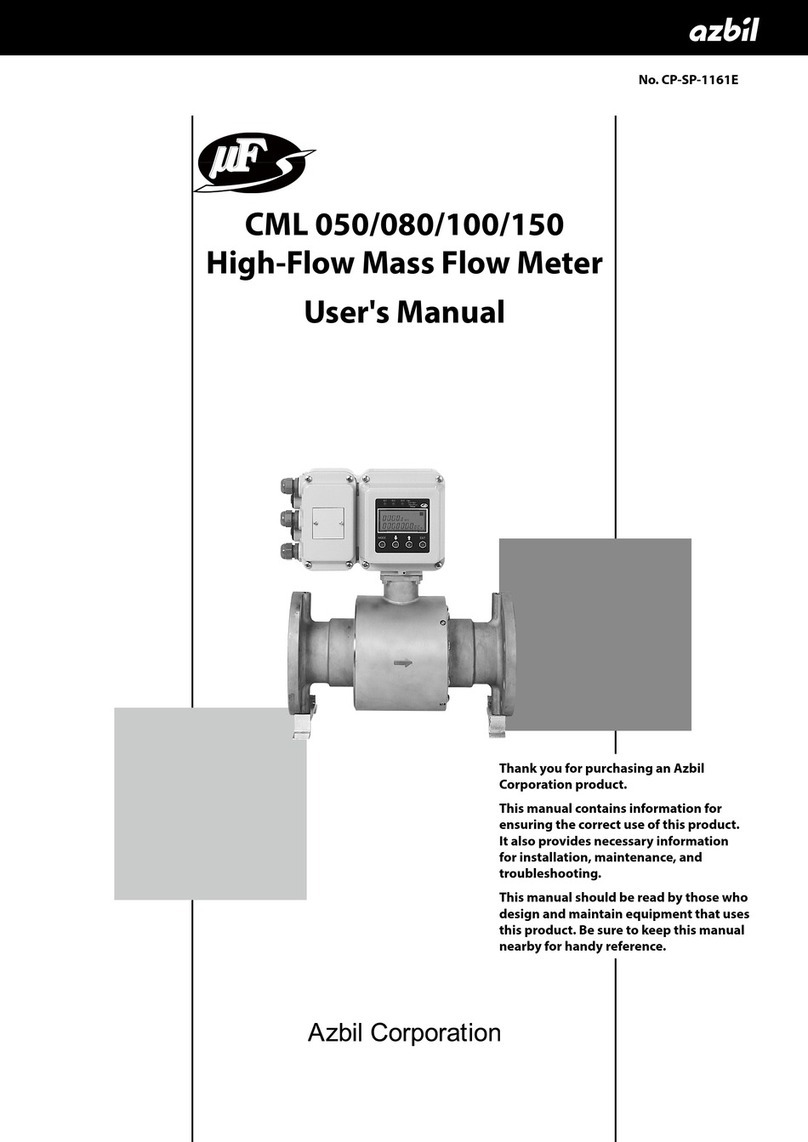

WIL0010

Wireless Remote indicator

Battery A

housing

Tamper

switch

Link program

switch

Battery B

housing

Picture 1

DEPLOYMENT PROCEDURE

1) Select a location for the remote indicator. See LOCATION SELECTION.

2) Unbox the remote indicator from its packaging.

3) Power up the remote indicator. See POWERING UP - FIRST TIME USE / POWERING UP - RECOVERY.

4) Link the remote indicator to the system. See LINKING - WAKE-UP / LINKING - ONE-BY-ONE.

5) Install the back cover. See FIXING THE BACK COVER.

6) Install the device onto the back cover. See HOW TO REMOVE AND REINSTALL THE FRONT COVER.

7) Test the remote indicator. See TESTING.

INIM ELECTRONICS S.R.L. VIA DEI LAVORATORI 10, FRAZIONE CENTOBUCHI, 63076 MONTEPRANDONE, ITALY

It is advisable to use the EWT100-TESTER

survey kit to locate a good wireless installation

LED INDICATOR STATUS MESSAGES

The LED indicator communicates to the final user the status of the WIL0010 .

POWERING UP AND LINKING - PRELIMINARY NOTES

TW-RI-01 needs to be powered up with the supplied batteries.

Linking is the operation through which WIL0010 is “wirelessly connected” to a EWT100, IWT100 or XWT100 FireVibes network device.

POWERING UP - FIRST TIME USE

Use this procedure the first time you power up a WIL0010 .

1) Make sure the Link / program switch is set on “ON”.

2) Insert the two supplied batteries into their device’s lodgments.

Ensure that the batteries are installed properly, with their polarities matching the indications on the device.

POWERING UP - DEVICE LINKED TO THE SYSTEM

Use this procedure when a WIL0010 is successfully linked to its FireVibes system and you have to extract one or both batteries (e.g. batteries

substitution).

1) Reinsert the battery or both batteries into their lodgments.

Do not touch the Link / program switch.

If performing a batteries substitution, use two brand new batteries and substitute both of them.

Ensure that the batteries are installed properly, with their polarities matching the indications on the device.

POWERING UP - RECOVERY

Use this procedure when you fail to link successfully a WIL0010 or you want to link it again.

1) Move alternatively the Link / program switch 5 times.

2) Set the Link / program switch on “ON”.

3) Insert the two supplied batteries into their device’s lodgments.

Ensure that the batteries are installed properly, with their polarities matching the indications on the device.

LINKING - WAKE-UP

“Wake-up” linking consists in associating one or more child devices to the FireVibes system altogether in a single operation.

Wake-up is performed either through the FireVibes Studio software or the EWT100 / IWT100 keyboard-screen interface; it CANNOT be done

through XWT100 devices.

1) Create the “virtual model” (be aware that the Output Module type has to be selected to link a remote indicator) of the WIL0010 either on

FireVides Studio or on the EWT100 / IWT100.

2) Power-up the remote indicator (either “first time use” or “recovery”).

3) Set the Link / program switch OPPOSITE to “ON”.

4) Trigger the wake-up procedure either from FireVibes Studio or from the EWT100 / IWT100.

5) Wait the end of the “wake-up” linking procedure.

6) Check on FireVibes Studio or from EWT100 / IWT100 for linking success. Consult their user manual.

2

Table 1

Please mind that LED signalling burns out bat-

tery power, therefore reducing batteries lifespan.

Device status LEDs indication

Power up (DIP on “ON”) Blinks red 4 times

Power up (DIP opposite “ON”) Blinks green 4 times

Entering wake-up mode Blinks alternatively green / red 4 times

Link success (one-by-one) Blinks green 4 times, then the same pattern again

Link failure (one-by-one) Enters wake-up mode and signals “Entering wake-up mode” following this failure

Link success (wake-up) Blinks green 4 times, then same pattern again

Link failure (wake-up) Blinks green 4 times, then blinks red on once, then blinks alternatively green / red 4 times

Normal condition LED off (can be programmed so as to blink green every wireless communication)

Alarm activation Red LED steady on

Battery fault LED off (can be programmed so as to blink amber every 5 seconds)

Tamper fault LED off (can be programmed so as to blink amber every 5 seconds)

Replaced Blinks green 4 times

LINKING - ONE-BY-ONE

“One-by-one” linking consists in associating one child device at a time to the FireVibes system.

This operation is performed either through the FireVibes Studio software or the EWT100 / IWT100 keyboard-screen interface; it CANNOT be

done through XWT100 devices.

1) Create the “virtual model” of the child device (be aware that the Output Module type has to be selected to link a remote indicator) either on

FireVibes Studio or on the EWT100 / IWT100.

2) Trigger the linking procedure either from FireVibes Studio or from the EWT100 / IWT100.

3) Power-up the child device (either “first time use” or “recovery”).

4) Set the child device’s Link / program switch OPPOSITE to “ON”.

5) Wait the end of the “one-by-one” linking procedure.

6) Check on FireVibes Studio or from EWT100 / IWT100 for linking success. Consult their user manual.

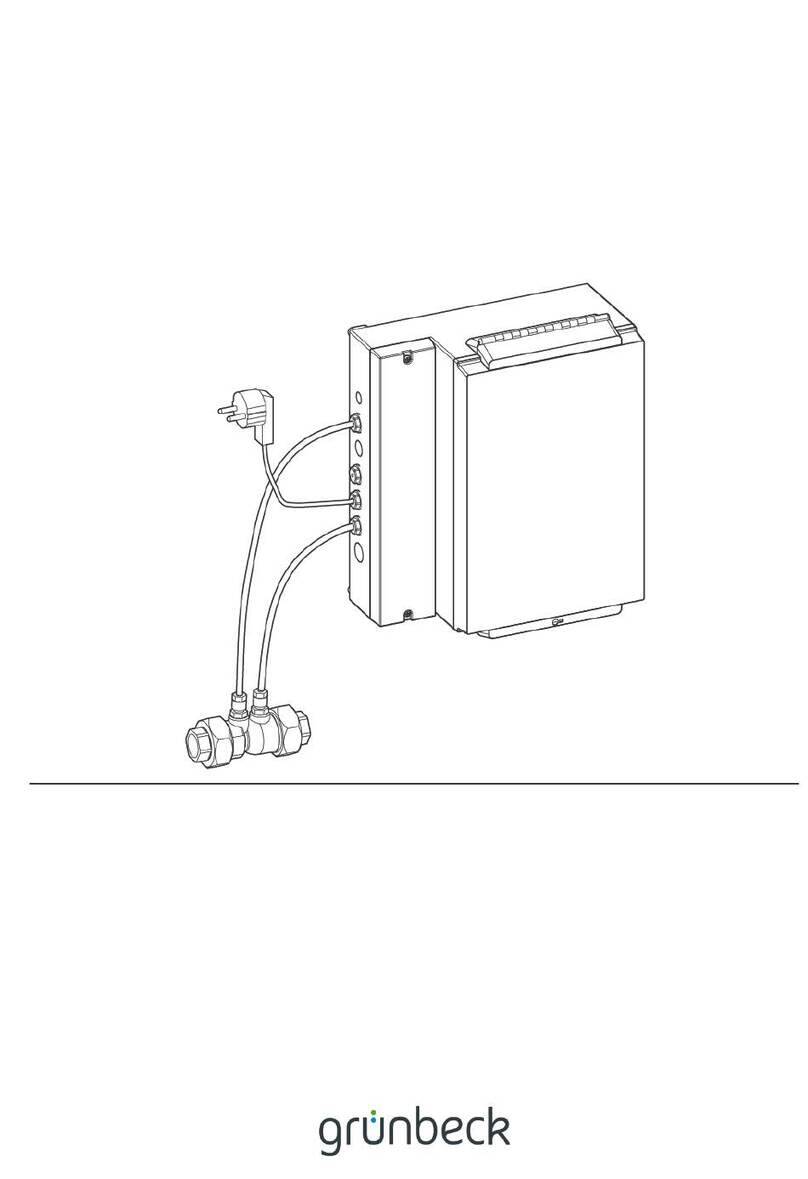

FIXING THE BACK COVER

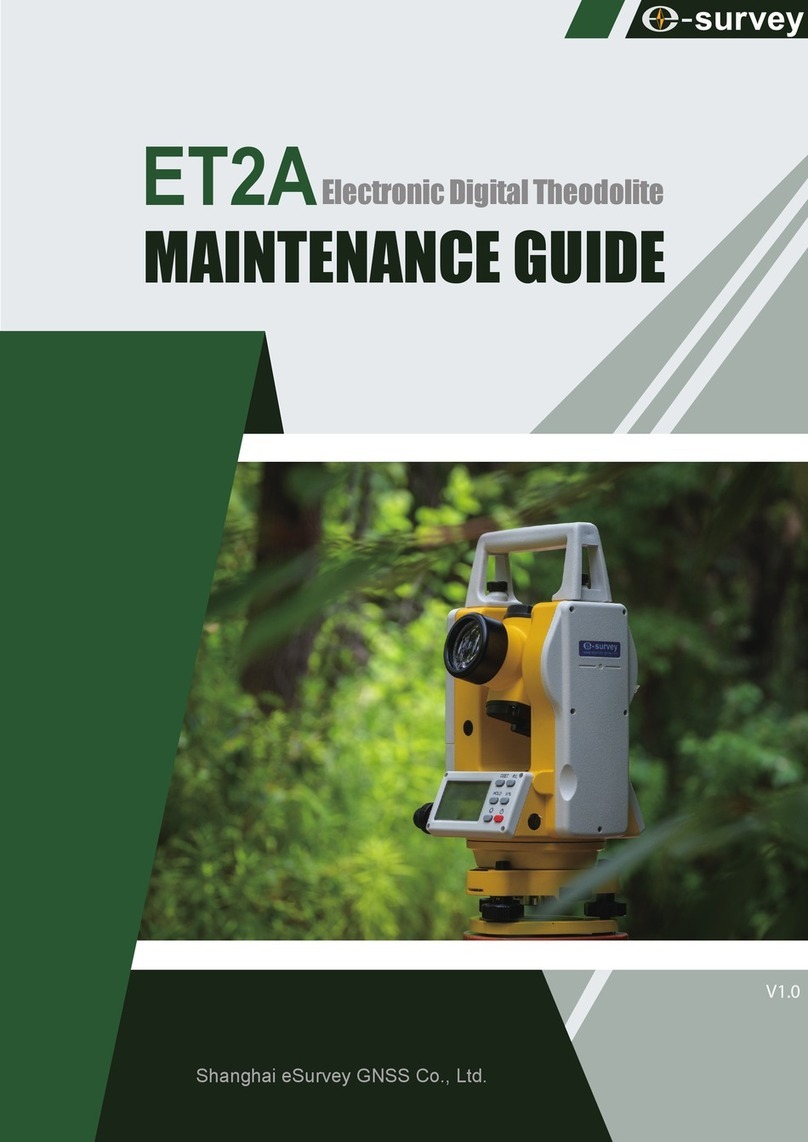

HOW TO REMOVE AND REINSTALL THE FRONT COVER

Remote indicator’s installation requires the device’s top cover to be removed from the its bottom (see picture 3):

1) Screw the grain inwards until it stops

2) Press the tab shown in the picture and gently and carefully remove the cover

Reinstalling the cover consists in performing the operation portrayed in picture 3.

TAMPER DETECTION FEATURE

The opening of the wireless remote indicator’s case is signaled by the control panel as a tampering attempt; the device’s PCB is equipped with

a spring-tactile switch assembly: if the case is closed this spring is kept pressed, but when released (and this occurs if the case is opened) the

remote indicator sends a tamper attempt message to the control panel which provides the signalization of such event.

The signalization of this event is automatically revoked a short time after the case is properly closed again.

RESET

To reset the wireless remote indicator from alarm it is necessary to reset the system from the control panel: alarm indication will deactivate.

Picture 2

Picture 3

INIM ELECTRONICS S.R.L. VIA DEI LAVORATORI 10, FRAZIONE CENTOBUCHI, 63076 MONTEPRANDONE, ITALY www.inim.biz

3

Install and fix the device’s rear cover in the selected position using

the screws provided in the product’s packaging. Fixing holes are

indicated in picture 2.

Press here

to remove

Grub screw

TESTING

In order to test the functionality of the installed wireless indicator proceed as follows:

activate an alarm condition on the control panel (by a call-point or sensor in the in-

stalled system): the control panel will lit the alarm indicator.

After each test the device must be reset from the control panel (see the RESET paragraph).

If the test fails check whether the batteries are charged, if mistakes were done previously or even if the system is activated. If the remote

indicator’s functionality is hopeless, send back the device to your distributor for repair or substitution.

All devices must be tested after installation and, successively, on a periodic basis.

BATTERY FAULTS AND BATTERY SUBSTITUTION PROCEDURE

When one or both batteries are low in charge, a specific fault message is routed to the

control panel. This condition is locally signaled by the module’s status indicator LED

(check table 1).If such event occurs:

1) Remove the front cover.

2) Extract both batteries.

3) Insert both new batteries into their holders, oriented as per polarity marks.

See POWERING UP - DEVICE LINKED TO THE SYSTEM.

4) Reinstall the front cover.

TECHNICAL SPECIFICATION

BATTERY SPECIFICATION

*Battery lifespan depends by environmental conditions, default monitor settings and link quality.

Local safety standards may require you

to test these devices on a regular basis.

When a low battery condition is indicat-

ed, both batteries must be changed

altogether.

Batteries must be brand new.

Do not touch the Link / program switch.

Ensure that the batteries are installed properly,

with their polarities matching the indications on

the device.

WARNINGS AND LIMITATIONS

Our devices use high quality electronic components and plastic materials that are highly resistant to environmental deterioration. However,

after 10 years of continuous operation, it is advisable to replace the devices in order to minimize the risk of reduced performance caused by

external factors. Ensure that this device is only used with compatible control panels.

Detection systems must be checked, serviced and maintained on a regular basis to confirm correct operation. Smoke sensors may respond

differently to various kinds of smoke particles, thus application advice should be sought for special risks. Sensors cannot respond correctly if

barriers exist between them and the fire location and may be affected by special environmental conditions. Refer to and follow national codes

of practice and other internationally recognized fire engineering standards.

Appropriate risk assessment should be carried out initially to determine correct design criteria and updated periodically.

Use only in FireVibes fire detection and alarm systems.

WARRANTY

All devices are supplied with the benefit of a limited 5 years warranty relating to faulty materials or manufacturing defects , effective from the

production date indicated on each product. This warranty is invalidated by mechanical or electrical damage caused in the field by incorrect

handling or usage. Product must be returned via your authorized supplier for repair or replacement together with full information on any prob-

lem identified. Full details on our warranty and product’s returns policy can be obtained upon request.

Specification Value

Communication range with EWT100, IWT100 or XWT100 network

devices 200 m (in open space)

Wireless frequency band(s) of operation 868-868.6 MHz, 868.7-869.2 MHz, 869.4-869.65 MHz, 869.7-870.0 MHz

Number of wireless channels 66

RF output power (max) 14 dBm (25 mW) e.r.p.

Operating temperature range -10 °C to 55 °C

Maximum humidity (non condensing) 95% RH

Environmental application Indoors

Dimensions 80 mm x 80 mm x 32 mm

Weight 60 grams (without batteries)

Table 3

Specification Value

Battery type CR123A (3 V, 1.25 Ah)

Battery lifespan * 5 years

Low battery threshold value (nominal) 2.850 V

Table 2

DCMIINE0WIL0010-110