Inland SCOREONE User manual

Rev 2 / Stock No. 97866520 Page 1 of 2 Document No. 3000/QF/621

SCOREONE™ GLASS CUTTER

User Instructions

Safety

It is extremely important to wear proper eye protection when scoring or breaking any material. We highly

recommend that you wear safety goggles rather than safety glasses.

Place your ScoreOne™ on a sturdy, level surface at a comfortable height.

You can use your ScoreOne on a grid cutting surface by removing the four rubber feet from the corners of the

base and then reinsert two of them into the two holes found between the screws centered on the base bottom.

Assembly

Your ScoreOne™ comes fully assembled and ready for use. Use the

diagram to reference parts while operating.

1 - Drive Roller

2 - Cutter Head

3 - Pressure Adjustment Knob (red)

4 - Height Adjustment Knob (white)

5 - Lift Lever

6 - Hand Wheel

Scoring Glass

1. You insert glass under the cutter by depressing the lift lever (5) on the machine right. This raises and lowers the

cutting head. CAUTION: It is important that the cutter head is raised before inserting the glass. Forcing the

glass under the wheel will damage the drive tread.

2. Raise the cutting head and place the glass on the rubber drive roller (1) so that the cutting wheel is close to the

edge of the glass. Gently release the lever bringing the cutting head down onto the glass.

3. Now rotate the hand wheel (6) with one hand to feed the glass under the scoring wheel while your other hand

guides it along the pattern line. You can go as fast or slow as need be, even stopping in mid score. Unlike hand

held cutters, the head will stay exactly where you stopped and then continue the score.

Adjusting for Proper Score

It’s a good idea to run a test score or two on scrap glass when starting or changing glass types. A good score is a

continuous light scratch on the glass surface. Once adjusted, you will be able to cut all your pieces from the same glass

type with confidence.

1. First, adjust for the glass texture and thickness and check cutting wheel contact and scoring pressure. If the head

is too high it can skip over spots, especially on textured glasses, and make an uneven score. If it’s set too low, you

will make a heavy score with chips and slivers. When properly adjusted, the cutting wheel should sit firmly

against the glass surface without digging into it.

Turn the white knob (4) clockwise to raise the cutting head position

Turn the white knob counterclockwise to lower the head position.

2. Fine tune the pressure applied to the cutter head using the red pressure adjustment knob (3).

Turning the knob clockwise increases pressure, creating a deeper score.

Turning counterclockwise decreases the pressure applied, lightening the score.

That is all there is to operating your ScoreOne™. With a little practice you’ll find scoring fast and easy!

Maintenance

Rev 2 Page 2 of 2 Document No. 3000/QF/620

Cutting Head: The cutter head is designed with a hole that a simple (smokers, not craft) pipe cleaner can be inserted into

for removing accumulated glass chips and cutting debris. This keeps the wheel rotating freely. Keep corrosive materials

like soldering flux away from your ScoreOne™.

Lubrication: You periodically need to lubricate the axle the carbide wheel rotates on. Using a

cutting fluid like Inland RinsesOff™ or plain mineral oil, take a short 3/4" length of pipe cleaner, dip

it in lubricant and then insert it into the hole in the head and bend it back out of your line of site. This

acts as a wick to keep the wheel oiled.

Cutter Head Replacement: The cutter head supplied with your machine will eventually wear and

need replacement. When simple scores don’t break easily or the head appears to "skip" when making a score it is probably

time to replace the head.

1. Partially remove the Phillips screw holding the hand knob (6) in place. Give the knob a light tap to loosen, then

remove the screw and pull the knob off.

2. Pull the drive roller (1) forward out of the body about 2 inches.

3. Insert a small nail or wire into the hole in the cutter head and force downward to remove.

4. Replace with the new cutter head.

5. Push the drive wheel back in place.

6. Refasten the hand wheel (6).

Rubber Drive Treads: Clean treads with a little acetone (non-oily nail polish remover). Be careful not to get it on the

body, it will stain the surface. You can also remove the tread and turn it inside out for a second life span. Replace the tread

by lifting an edge with your fingernail and peel it off the hub (1). The replacement just stretches back in place.

Replacement Parts

Cutter Head: Inland no. 50051

3/8"Drive Tread: Inland no. 50053

Accessories

ScoreOne™ Circle / Strip Accessory:Use your ScoreOne to make circles, from 1 ½" to 13" in diameter, and

strips, as narrow as 3/8" and up to 3" wide, without interfering with its normal operation. This accessory is

included with the ScoreOne Plus and available as an add-on for the ScoreOne. Inland no. 50056

RinsesOff™:Our water soluble cutting fluid will help to properly lubricate and maintain the carbide cutting

wheel for longer head life and better breaking scores. Inland no. 50057

Service

If you have any questions or comments regarding the use of this or any Inland product please call Inland Customer

Service at 1-800-521-8428 9 AM to 5 PM EST, email us at helpdesk@inlandcraft.com, or write us at:

Inland Craft Products, Co.

32052 Edward Dr.

Madison Heights, MI 48071

www.inlandcraft.com

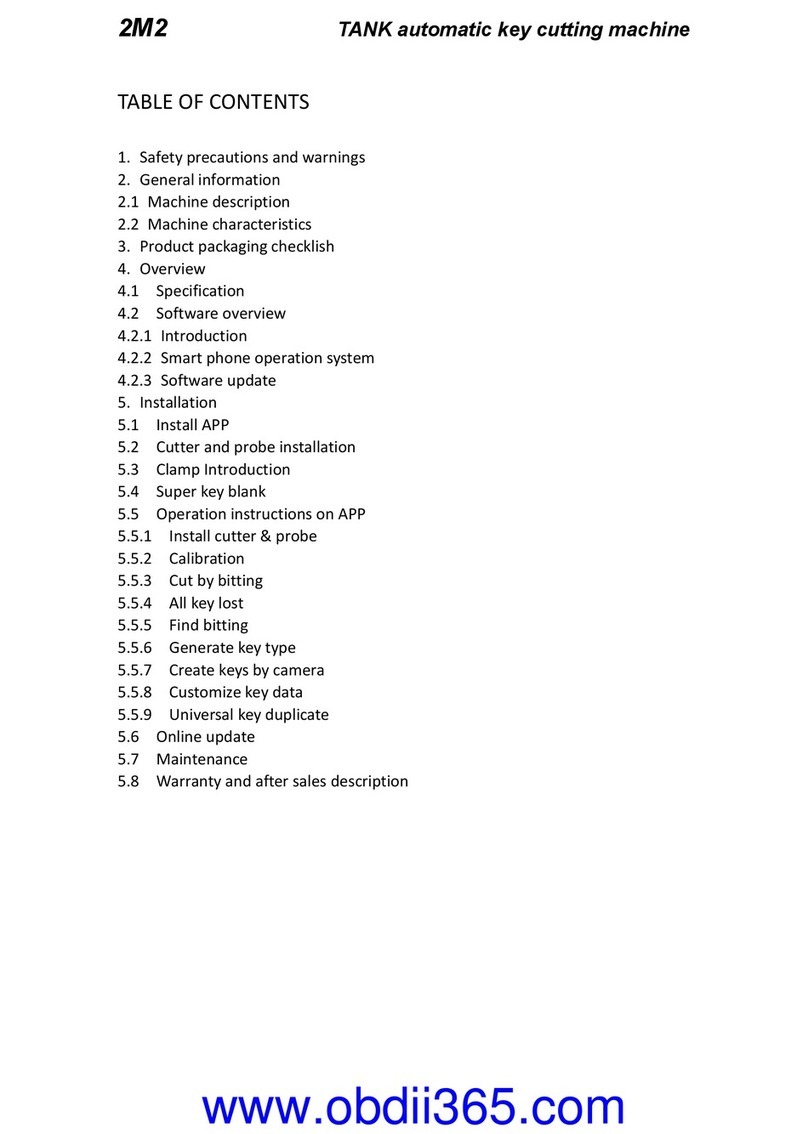

Table of contents