installationmanual

1.PRECAUTIONS

The saftyprecautionslistedhere are divided intotwo categories.

After completing the installation,makesure thatthe unitoperates

properlyduring the start-upoperation.Pleaseinstructthe customer

onhowtooperatetheunitand keepitmaintained.Also,inform

customersthattheyshouldstore thisinstallation manualalong with

the owner's manualfor future reference.

Be sureonlytrainedand qualifiedservice personnelto

install,repairor servicetheequipment.

Improperinstallation,repair,and maintenancemayresultin

electricshocks,short-circuit,leaks,fire orotherdamageto

the equipment.

Ifyou do notfollow theseinstrutionsexactly,the unitmay

causepropertydamage,personalinjuryor loss oflife.

Ifyou do notfollow theseinstrutionsexactly,theunitmay

causeminorormoderatepropertydamage,personal

injury.

CONTENTS PAGE

Installaccording tothisinstallation instructionsstrictly.

Ifinstallation isdefective,itwill causewaterleakage,

electricalshockand fire.

Wheninstalling theunitinasmallroom, takemeasures

against tokeeprefrigerantconcentration fromexceeding

allowablesafety limits intheeventofrefrigerantleakage.

Contact theplaceofpurchaseformoreinformation.

Excessiverefrigerantinaclosed ambientcanlead tooxygen

deficiency.

Use theattachedaccessories parts and specifiedparts

for installation.

otherwise,itwillcausethe settofall,waterleakage,

electricalshockand fire.

Installatastrong and firmlocation whichisableto

withstandtheset'sweight.

Ifthe strengthisnotenough or installation isnotproperly

done,the setwill droptocauseinjury.

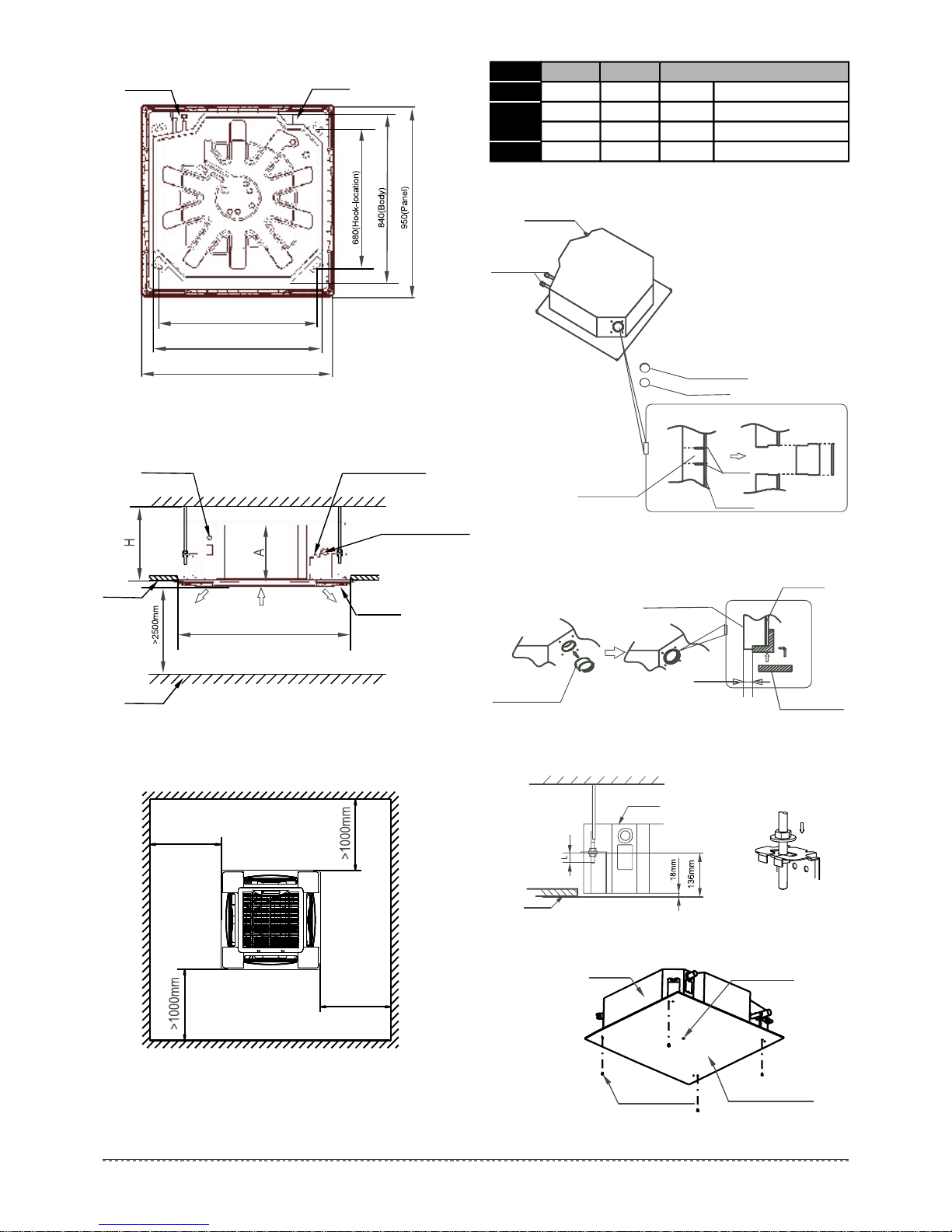

Theappliancemust beinstalled2.5mabove floor.

Theapplianceshall notbeinstalledinthelaundry.

Beforeobtaining accesstoterminals,allsupplycircuits

must bedisconnected.

Theappliancemust bepositionedsothat theplugis

accessible.

Theenclosureoftheappliance shallbemarkedbyword,

or bysymbols,withthedirection ofthefluidflow.

For electricalwork,followthelocalnationalwiring

standard,regulation and thisinstallation instructions.An

independentcircuitand singleoutlet must beused.

Ifelectricalcircuitcapacityisnotenoughordefect in

electricalwork,itwill causeelectricalshock or fire.

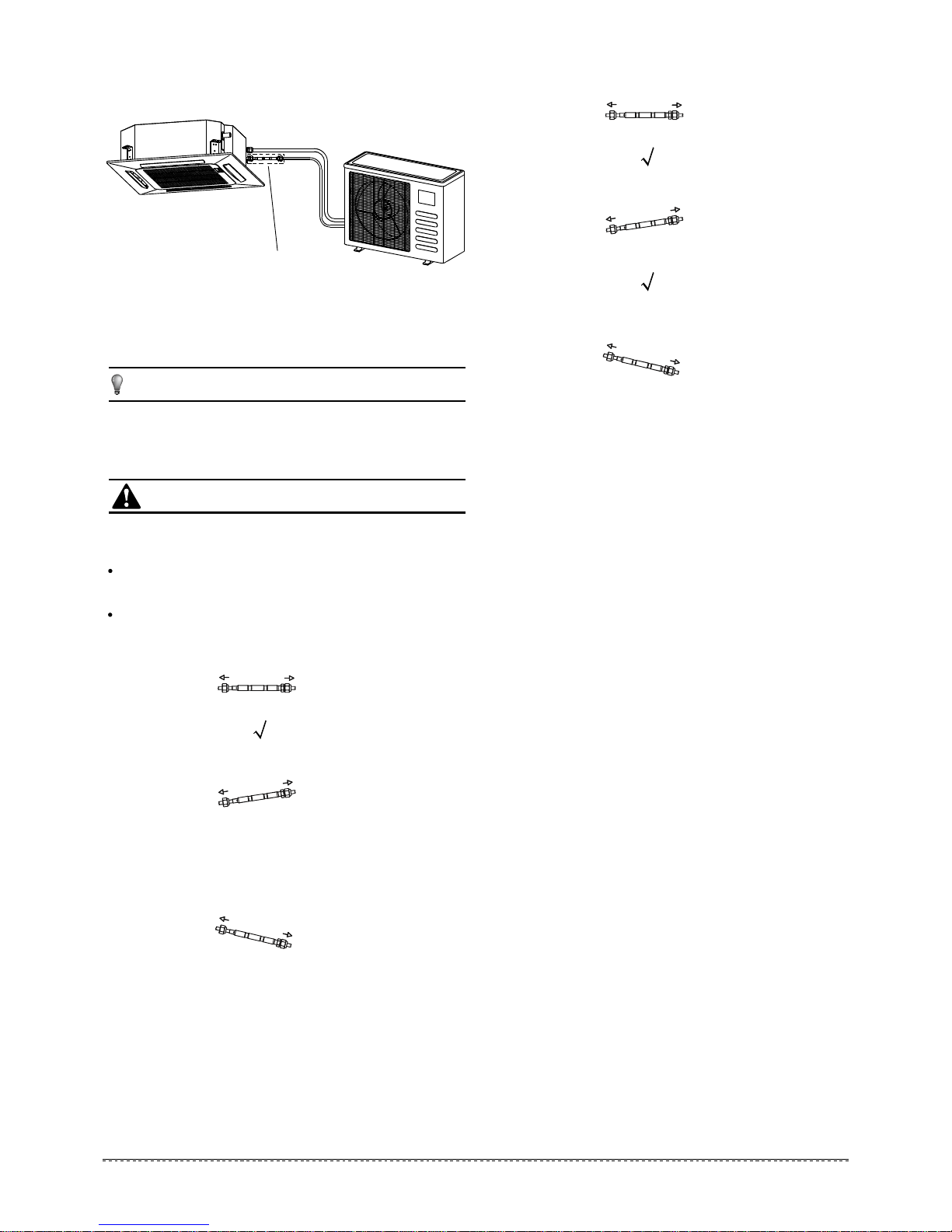

Use thespecifiedcableand connecttightlyandclamp

thecablesothatno externalforce willbeactedon the

terminal.

Ifconnection or fixing isnotperfect,itwill causeheat-up or

fireatthe connection.

Wiring routingmust beproperlyarrangedsothatcontrol

boardcoverisfixedproperly.

If controlboardcoverisnotfixedperfectly,itwill cause

heat-upatconnectionpointofterminal,fireorelectrical

shock.

Ifthesupplycord isdamaged,itmustbereplacedbythe

manufactureor its service agentor asimilarlyqualified

personinordertoavoidahazard.

Anall-poledisconnectionswitchhaving acontact

separationofatleast3mminallpolesshouldbe

connectedinfixedwiring.

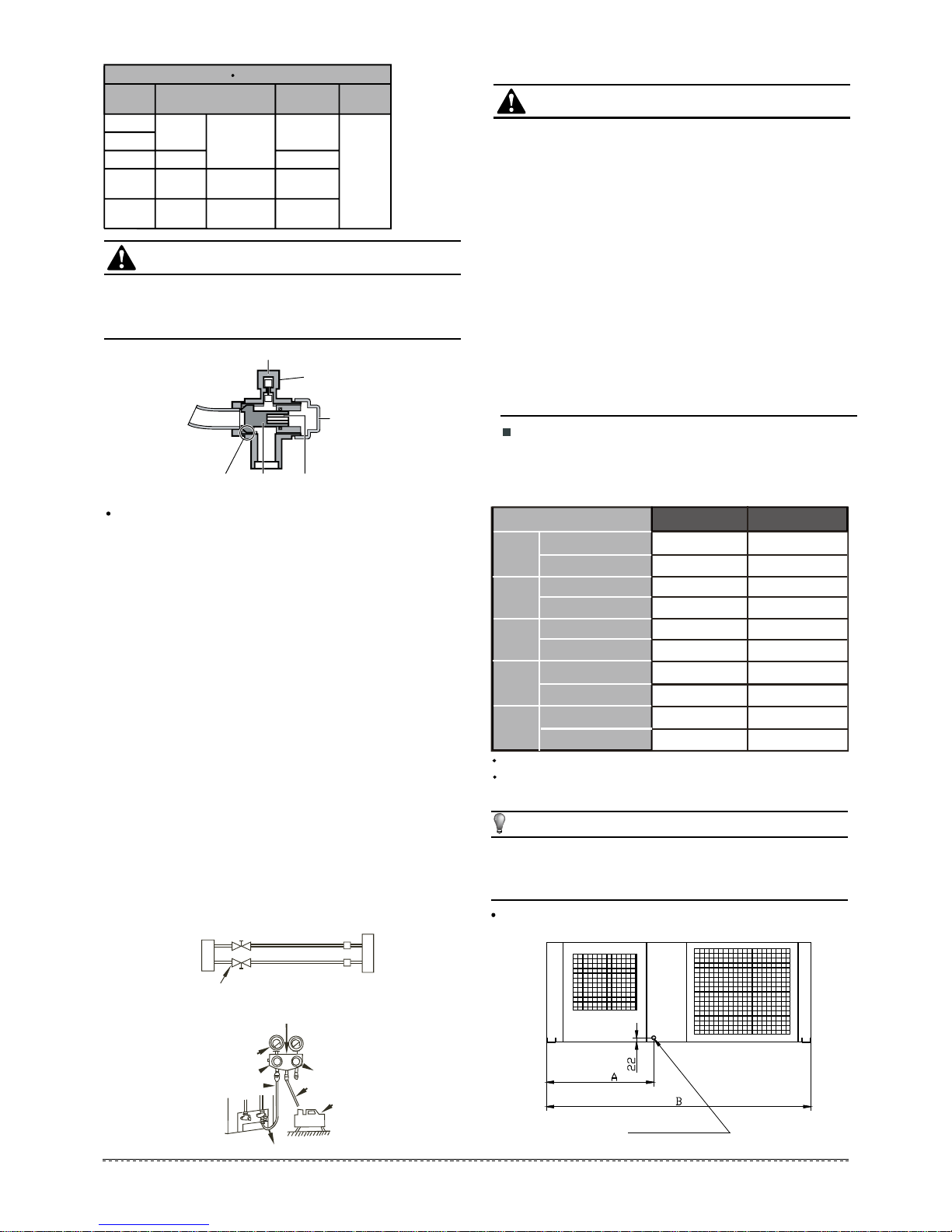

Whencarryingoutpiping connection,take carenottolet

airsubstances go intorefrigeration cycle.

Otherwise,itwillcauselowercapacity,abnormalhigh

pressure inthe refrigeration cycle,explosion and injury.

Donotmodify thelengthofthepowersupplycordor use

ofextensioncord,and donotsharethesingleoutlet with

otherelectricalappliances.

Otherwise,itwill causefire or electricalshock.

Carryoutthespecifiedinstallationworkaftertaking into

accountstrong winds,typhoonsor earthquakes.

Improperinstallationworkmayresultinthe equipmentfalling

and causingaccidents.

CAUTION

WARNING

WARNING

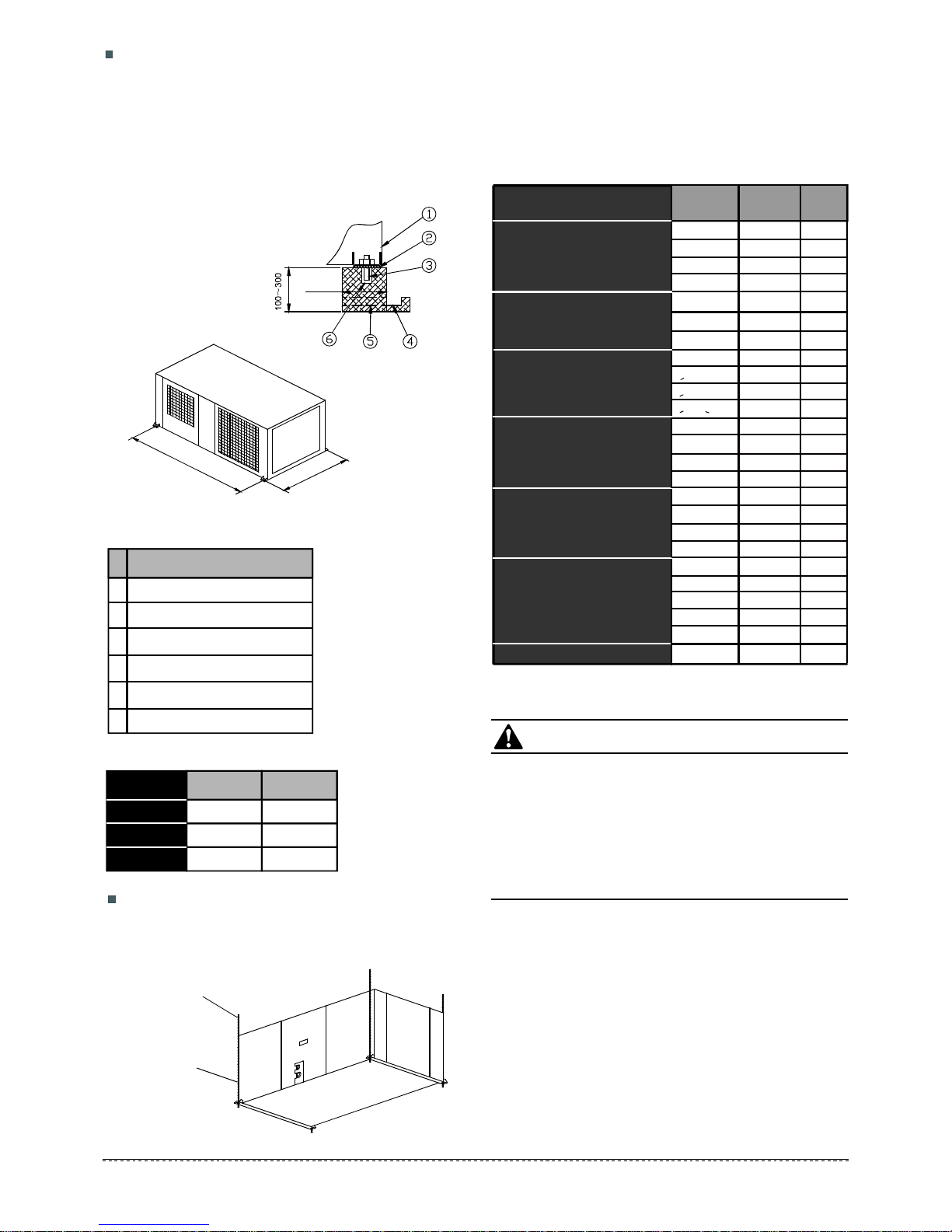

PRECAUTIONS......................................................................

INSTALLATIONINFORMATION.............................................

ATTACHEDFITTINGS............................................................

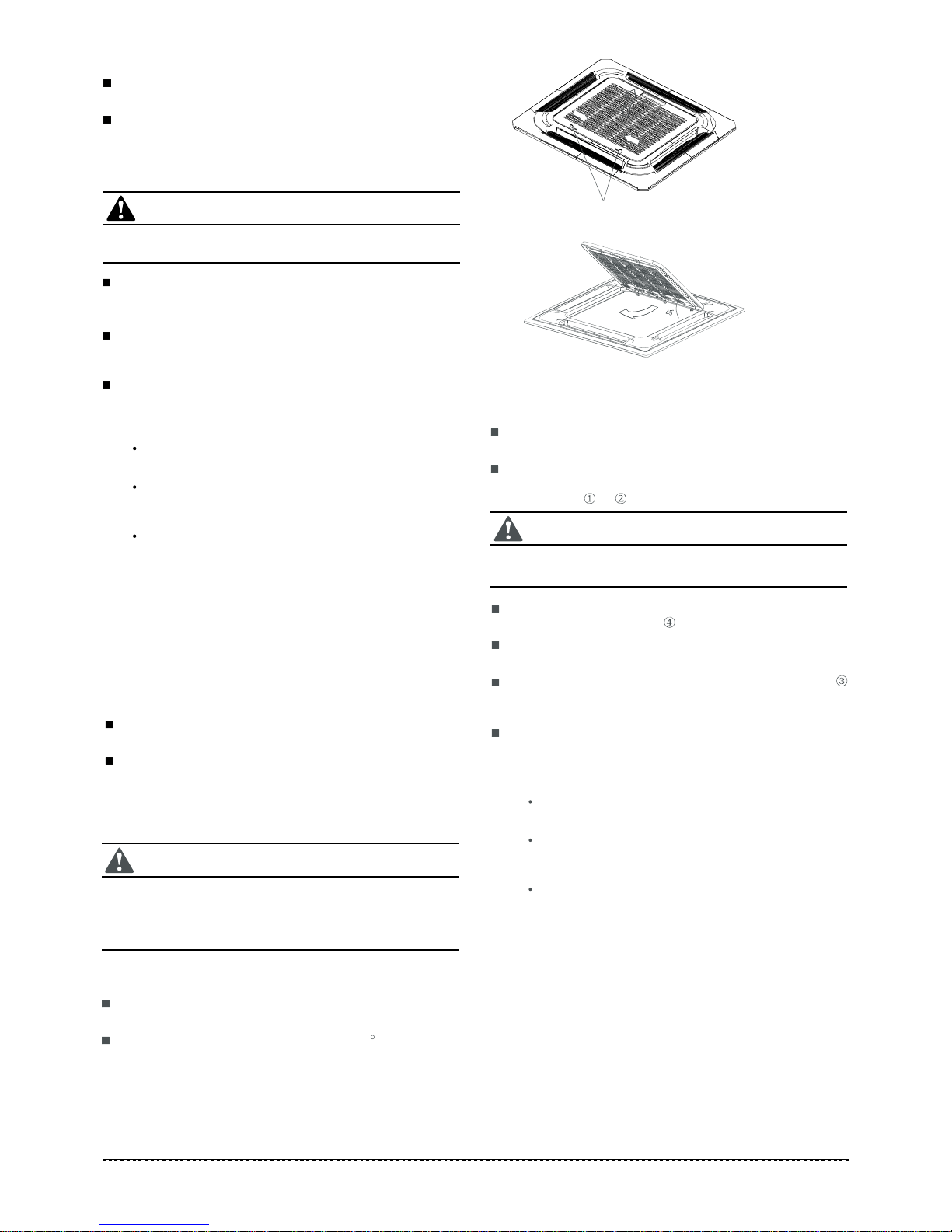

INSPECTINGAND HANDLINGTHEUNIT.............................

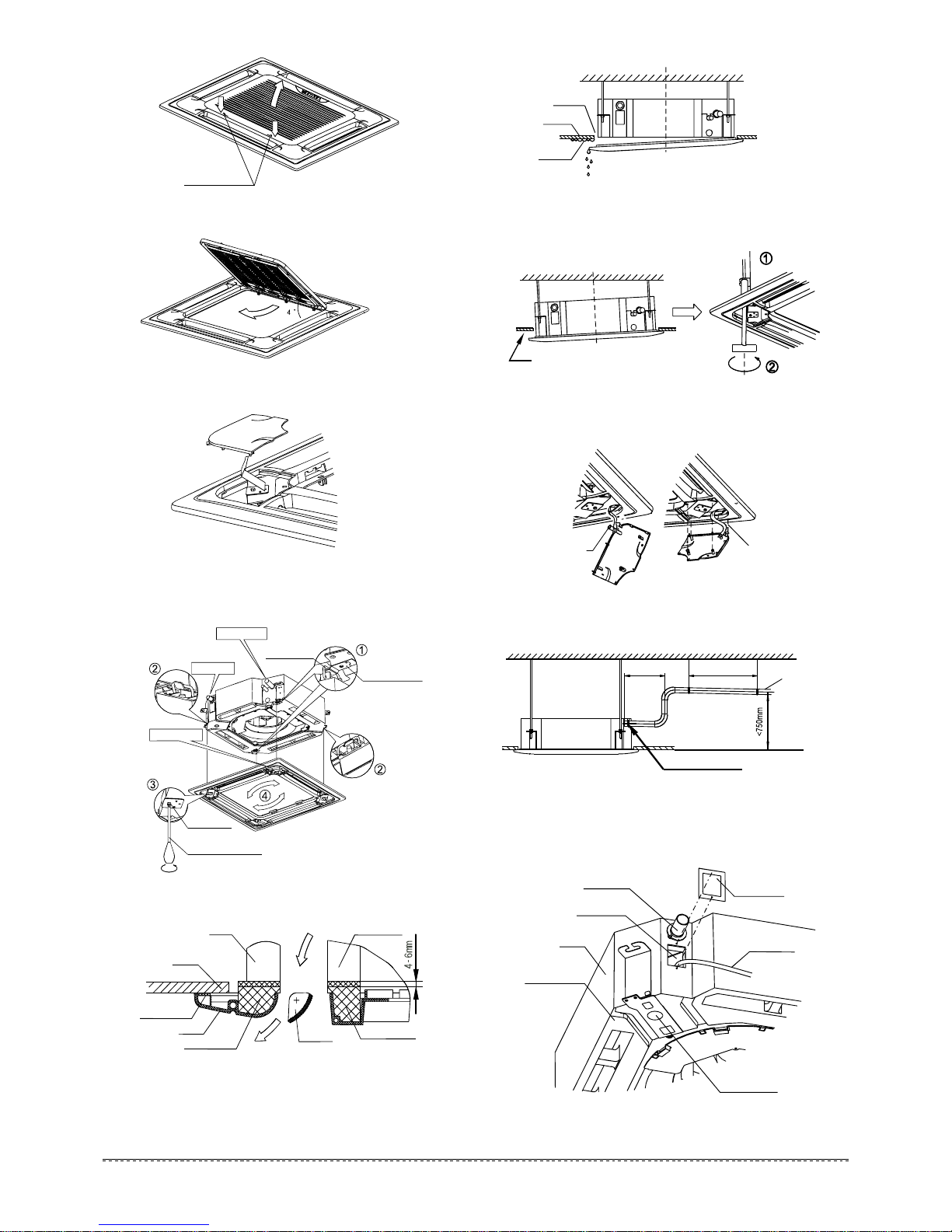

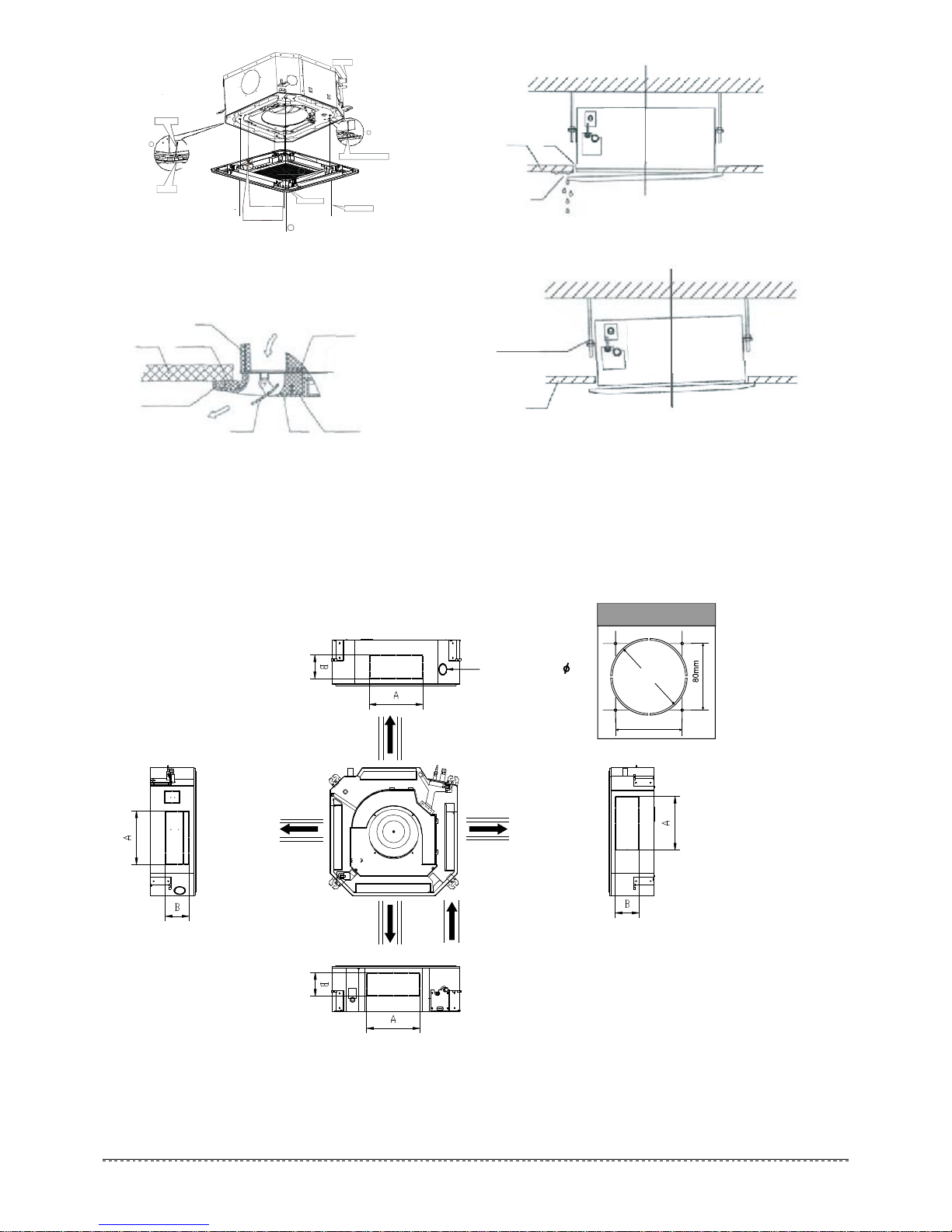

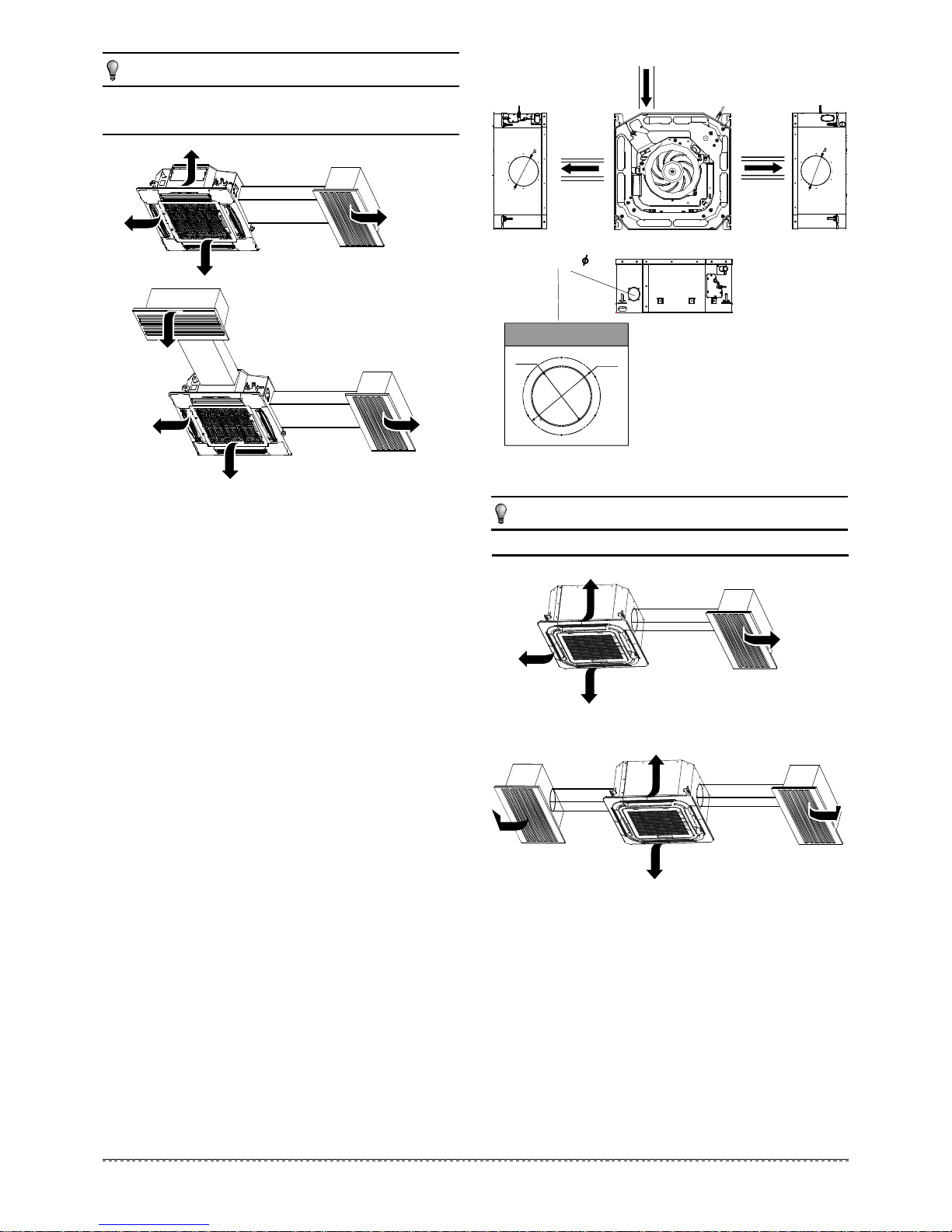

INDOORUNITINSTALLATION..............................................

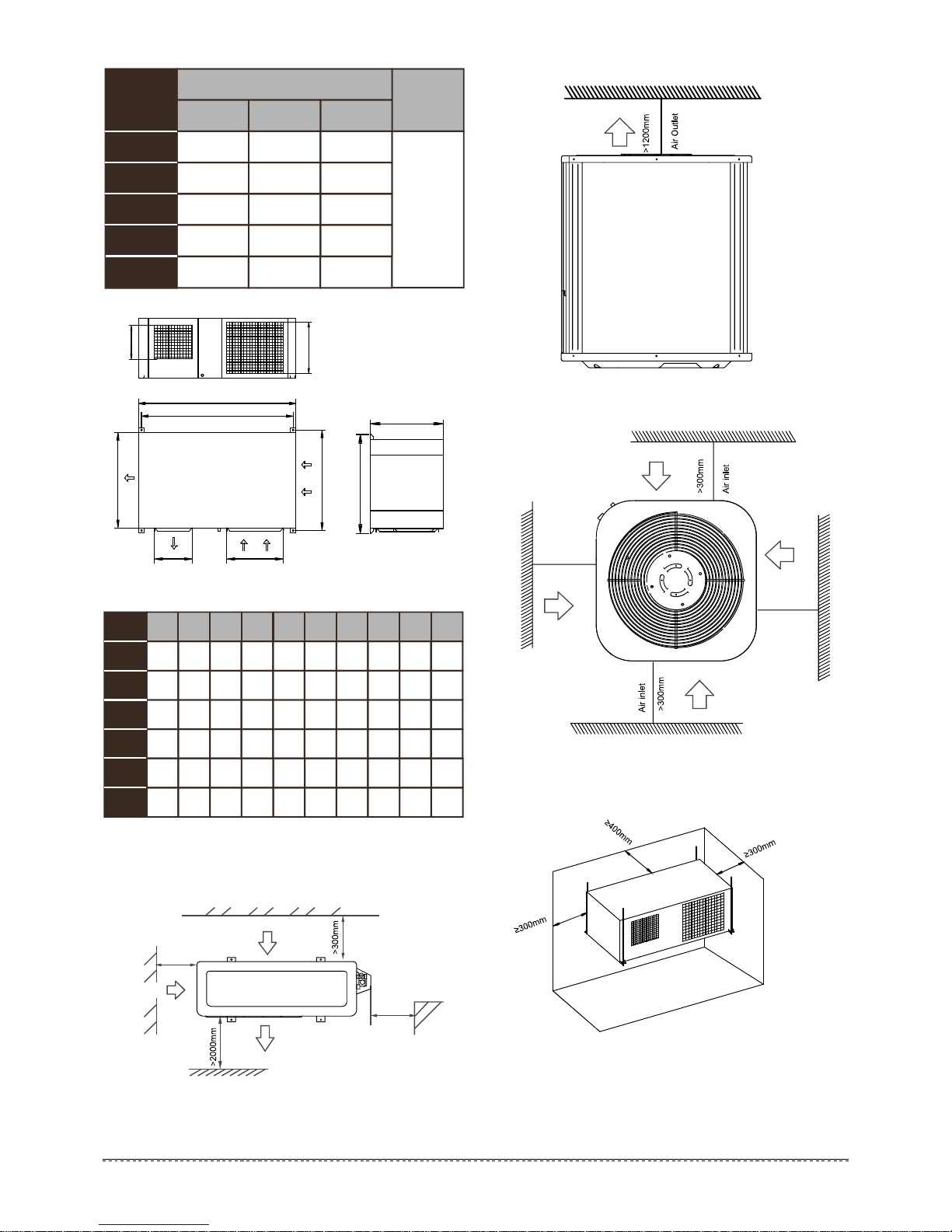

OUTDOORUNITINSTALLATION..........................................

INSTALLTHECONNECTINGPIPE.......................................

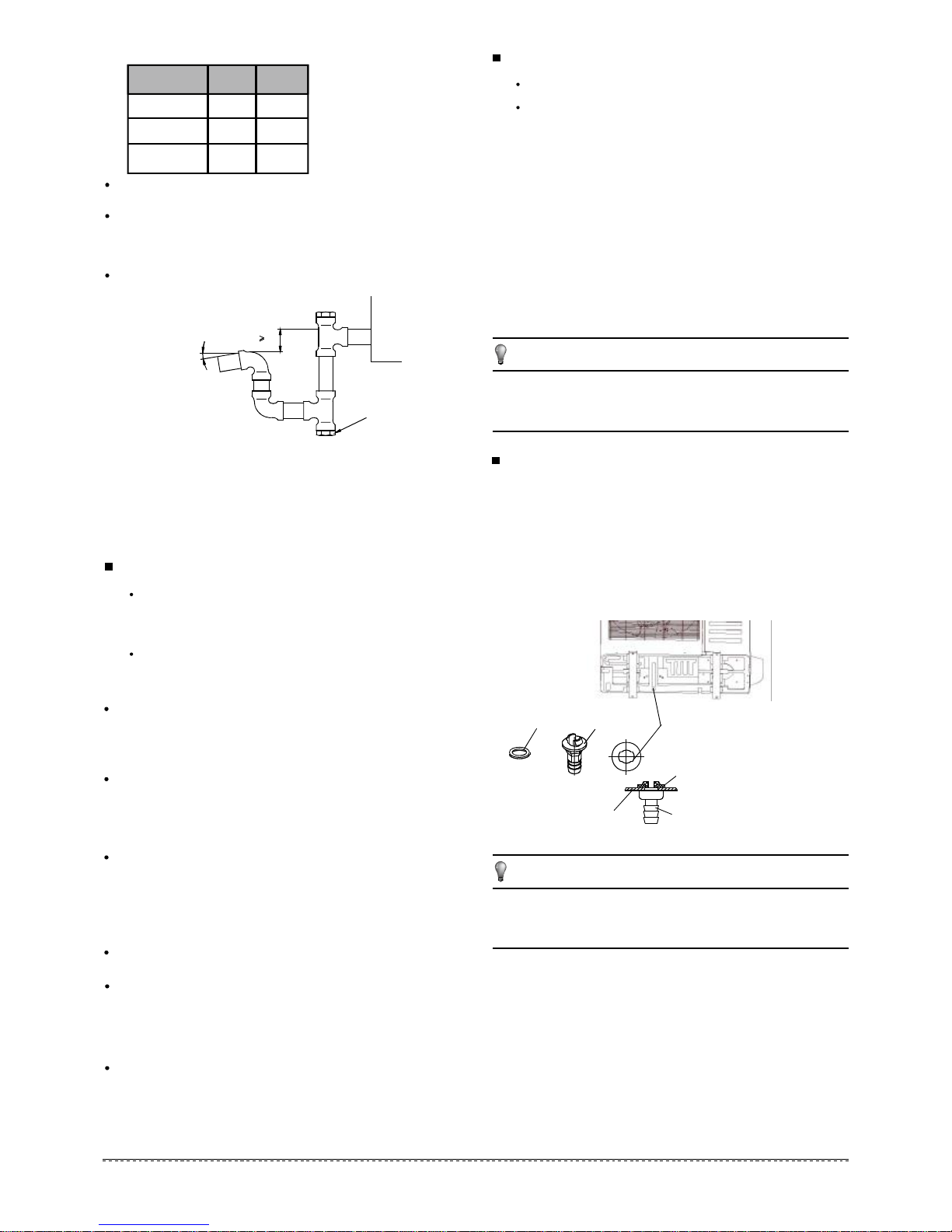

CONNECTTHEDRAINPIPE................................................

CONNECTIVEDIAGRAM.....................................................

WIRING...................................................................................

TESTOPERATION.................................................................

1

2

3

4

4

11

15

18

19

20

21

CONTENTS PAGE

Keepthismanual wheretheoperator caneasilyfind them.

Readthismanual attentivelybeforestarting uptheunits.

For safety reasontheoperator mustreadthefollowing

cautionscarefully.

IfusedasMULTIunit,pleaserefertotheInstallation &

operation manualspackedwithoutdoor unit.