iNO DOMINATOR User manual

2

CONTENT

1. General information………………………………………………… 4

1.1 Purpose of use…………….………………………………………….. 4

1.2 Warranty……………………………………………………………… 5

1.3 Identification of the machine..……………………………………… 6

2. Technical data…..……………………………………………………. 7

2.1 Noise.. ………………………………………………………………… 7

2.2 Technical specification ……………………………………………… 8

2.3 Optional equipment……………………………………………….… 8

3. Safety….……………………………………………………………… 9

3.1 General safety rules………………………………………………….. 9

3.2 Attachment on the tractor and transport…………………………. 10

3.3 PTO drive……………………..………………………………….…. 10

3.4 Hydraulic system...……………………………………………..…... 11

3.5 Safety rules during use, maintenance and servicing……………... 12

3.6 Warning decals……………………………………………………... 13

3.7 List of guards…..………………………………………………….... 14

4. Description and operating of the machine………………………… 15

5. Transport and attachment of the machine……………………….. 16

5.1 Transport to the customer..………………………………………... 16

5.2 Attachment and detachment from the tractor…………………... 16

5.3 Fitting the PTO shaft………………………..……………………... 17

5.4 Stability of the tractor…………………………………………….. 18

6. Adjustment ……………………………………………………….. 19

6.1 Support roller adjustment………………………………………. 20

6.2 Roller setup…………………….……………………………………… 21

6.3 Offsetting……………………………………………….. 22

6.4 Belt tension adjustment………..…………………………………… 23

7. Operating….….……………………………………………………. 24

8. After the job is done..………………………………………………… 26

8.1 Cleaning…………………………………………………………….. 26

9. Maintenance……………………………………………………….. 27

9.1 Oil control in the gearbox ………..……………………………….. 27

Greasing ……..…………………………………………………….. 28

9.2 Plan of maintenance jobs ……….…………………………………. 29

9.3 Replacement of working tools……………………………………... 29

9.4 At the end of the season …………………………………………… 30

9.5 Demolition when out of order ………………...…………………… 30

10. Trouble shooting …..……………………………………………….. 31

3

Dear Customer!

We are grateful that you decided to buy our product.We would like to

thank you for your trust. We are sure that you won't be disappointed with

your choice. A quality of the material, appropriate technical characteristics

and after sales services go together with your choice. For eventual

questions our stuff is always at your disposal.

We will specially respect your suggestions and observations that can be

of a great help for future development of the machine Through all the past

of our company experiances from the praxis represent a basement of de-

velopment and innovations.

INO Brežice d.o.o.

4

1. General information

This operation and maintenance manual is intented to the operator. It

consists of operating instructions, maintenance part and spare parts list for

the machine.

It is mandatory to follow these instructions in order to prevent events

which could endanger the operator's, other people's and animal's safety,

apart from the correct functioning of the machine. In case of doubt do not

experiment, call INO after-sales service instead, or a specialized INO dealer.

It is mandatory to read these instructions to understand the

operating of the machine!

In the case of re-sale of the machine it is necessary to give

these instructions to the new owner!

A meaning of decals in this book

Very important information!

Technical warning!

Safety warning!

5

Purpose of use

Flail mower DOMINATOR is a heavy duty professional machine, purpo-

sed for use on large agriculture and green areas, for mulching maize and

other crop residues, grass and bushes on green and abandoned areas. This

machine is very rigid and made for use in hard working conditions.

Warranty

Warranty period for the machine is 24 months.

WE DECLARE WITH FULL RESPONSIBILITY THAT THIS TYPE OF THE PRO-

DUCT FULFILLS ALL THE RELEVANT PROVISIONS OF THE FOLLOWING DI-

RECTIVES:

DIRECTIVE MACHINE 2006/42/EC

AND FOLLOWING ADDITIONS:

91/368/CEE, 93/44/CEE, 93/68/CEE

HARMONISED STANDARDS APPLIED IN ORDER TO VERIFY COMPLIANCE

WITH DIRECTIVES:

SIST-EN 292-1, SIST-EN 292-2, SIST EN ISO 4254-12:2012

A producer can ensure normal operating of the machine only

with use of original spare parts!

INO is not responsible for any damage or injuries, if the user

doesn't consider the rules in this book!

INO is not responsible for any damage or injuries due to impro-

per use of the machine!

After receiving the machine it is necessary to check that the machine

has not been injured during transport and that it is equipped with all basic

and additional equipment ( if ordered). A customer can claim any missing

or damaged part in the period of 8 days after receiving the machine.

6

INO does not accept any responsibility in the case of:

•Improper maneuvring the machine,

•Improper maintenance,

•Unauthorized repairing ormodifications on the machine or use

of non-genuine spare parts,

•Non-respecting these rules,

•Overloading of the machine (see Table nr.1 –limited values)

Identification of the machine

Each machine is fitted with an identification plate with the following

data: producer and address, CE sign, name of the machine, type, weight,

identification number and year of production.

Fig. 1

MULCER

DOMINATOR

1093 kg

2019

123

7

2. Technical data

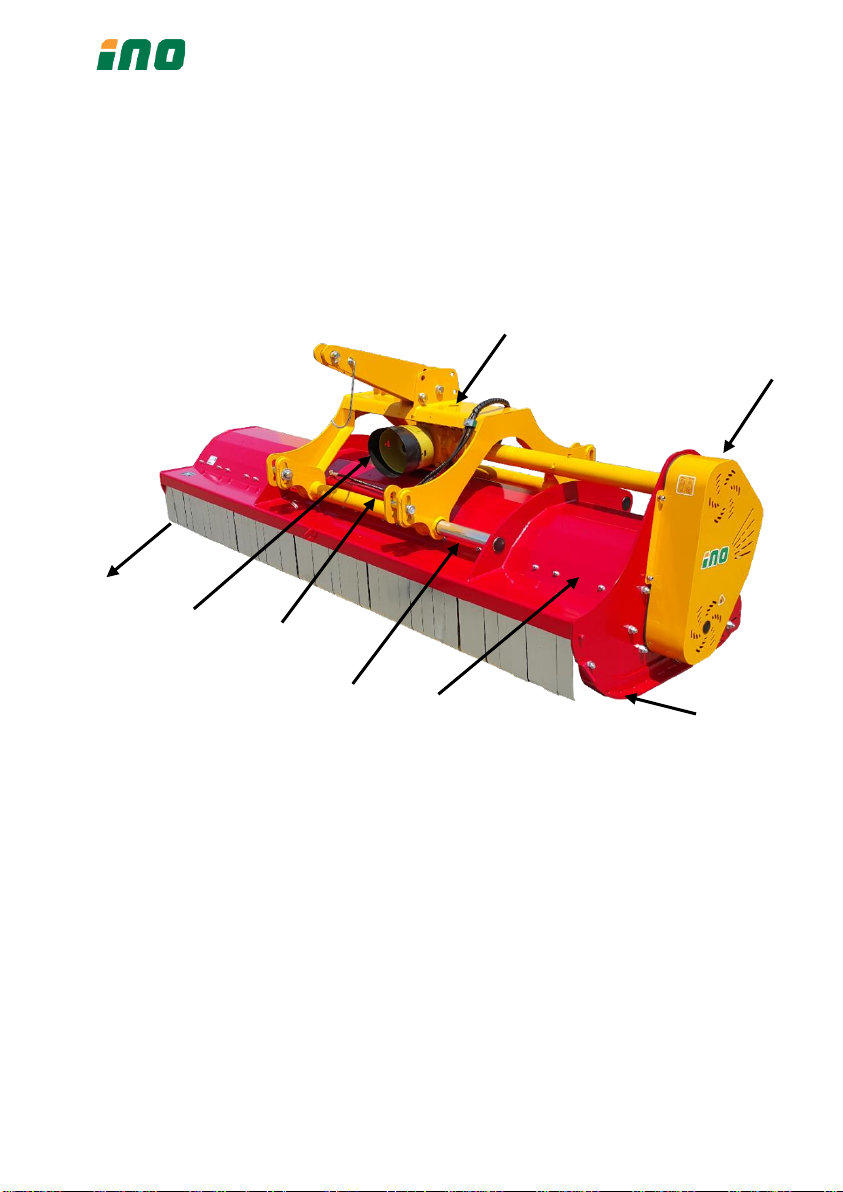

Fig. 2

1. frame

2. gearbox

3. belt drive

4. linkage

5. flaps

6. hydraulic cylinder

7. skids

8. sliding tubes

Noise

The sound level of this machine, as measured at the operator's ear,

ranges from 70 to 90 dB when the rear window of tractor is open. We

recommend the use of ear protectors

1

2

3

1

5

4

7

6

8

8

Optional equipment

According to the working requirements we recommend the following

additional equipment:

•Y-blades

•Double skin

•Reversible gearbox

•Gearbox 540 rpm

•INO VIBRATION CONTROL

Technical specification

Table. 1: Technical data

Type

Unit

DOMINATOR

250

DOMINATOR

270

DOMINATOR

300

Working width

cm

244

277

312

Min.tract.power

HP

65

75

90

Max.tract.power

HP

110

110

130

RPM

min-1

540/1000

540/1000

540/1000

Y blades

nr.

84

96

108

Hammers

nr.

28

32

36

Weight

kg

971

1023

1093

Offsetting

cm

50

50

50

Linkage

cat.

II

II

II

Total width

cm

267

300

333

9

3. Safety

General safety rules

1. Before starting the machine, functionality, road safety and acci-

dent prevention rules must be checked.

2. Together with the operating and maintenance rules for the ma-

chine it is necessary to consider general health and security rules

and warnings.

3. Before starting it is mandatory to know everything regarding the

equipment and operating of the machine. Reading instructions

when operating is too late.

4. Security and warning decals on the machine are very important.

Respect them always.

5. Even when using the machine correctly, stones or other objects

may accindentally fly a long distance. Therefore everybody must

stand out of the danger area. Special attention must be paid when

working near roads or buildings.

6. Use tractor with the cabin.

7. Whenever using public roads, respect traffic rules.

8. Never wear loose or fluttering clothes.

9. Keep the machine clean to avoid fire danger.

10. Before starting check the surrounding area for the likely presence

of children and/or animals.

11. Never carry passengers on the machine.

12. Never overload the machine and the tractor. Use the ballast if ne-

cessary.

13. Start the machine only if all guards of the machine are fit on proper

places .

14. It is forbidden to stand in the range of operating of the machine.

15. Do not enter the working zone of the PTO shaft. It is dangerous to

approach the rotating parts of the machine.

16. Keep a safety distance from drive parts outside the machine (PTO

shaft, hydraulic pipes).

17. Before leaving the tractor with the machine attached disconnect

the tractor, put the machine steadily on the ground (with the

10

hydraulic lift), apply the hand brake and if the ground is steeply

slooping, wedge the tractor.Take out the starting key.

18. Do not enter the zone between the tractor and the machine. It is

strongly forbidden to be in this zone if the tractor is not properly

disconnected, hand brake applied and starting key taken out.

Attachment to the tractor and transport

1. Before attaching the machine or detaching it of the tractor be sure

that hydraulic lift system is in a neutral position.

2. Check that a category of 3-point linkage on the tractor corresponds

to that one on the machine.

3. Be careful! There is a danger of injuries when working near or with

3-point linkage.

4. It is forbidden to be in the zone between the tractor and the ma-

chine while working with the hydraulics.

5. Put the 3-point linkage into the position that makes the moving of

the machine impossible.

6. During transport secure the lever of hydralic lift to avoid any

unplanned moving of the machine.

7. ever leave the tractor cab when the tractor is working.

8. Adjust driving speed to the road conditions.

PTO drive

1. Use only PTO shafts with all guards, as directed by the producer.

2. All guards on PTO shaft must be in good order .

3. Take care that all guards on the PTO shaft are in proper position

during transport or operating. Respect the producer's instructions.

4. The PTO shaft must be assembled or diassambled only with the

engine stopped and the starting key removed.

5. The guards of the PTO shaft must be fixed to the machine and to

the tractor with chains to prevent rotation.

6. Before starting always check that the speed and the rotational di-

rection correspond to those on the machine.

11

7. With some tractors a number of rotations depends on the speed

and a direction of rotating depends on the direction of driving.

Take care about that.

8. Before starting the PTO shaft be sure, that noone is in the danger

area.

9. Never try to start the PTO shaft when the tractor engine is discon-

nected.

10. It is forbidden to be in the zone of drive axle exit, when it is enga-

ged.

11. After the drive is disconnected wait that the drive axle stops to ro-

tate completely. Never approach before it stops.

12. Never carry out maintenance of a machine or tractor while the en-

gine is running. The engine should be switched off and the key re-

moved.

13. If the PTO shaft is damaged, immediately stop with any operating.

Hydraulic system

1. Take care! Hydraulics is under very high pressure.

2. When connecting the pipes on the tractor check that the pressure

is not too low.

3. We recommend that an official service tests the pipes before ope-

rating and than at least ones per year. Damaged or worn outpipes

should be replaced immediately with others of the same specifica-

tion.

4. When checking pipes it is necessary to wear protection clothes and

gloves to avoid injuries.

5. The oil under high pressure may sweep into the skin causing seri-

ous infections. In this case contact a doctor immediately.

6. Before working on the hydraulic system lower the machine, take

pressure out and stop the tractor.

7. Approximate using period of the pipes is 6 years. After that the

pipes should be replaced to avoid any damage.

8. Used oils and greases must be stored and disposed according to

antipollution rules.

9.

12

Safety rules during use, maintenance and servicing

1. Never start or continue to work with the machine if the tractor or

the drive axles are engaged

2. Always remove the starting key after you stopped the tractor.

3. Periodically check that bolts and nuts are tighten properly.

4. When maintaining it is sometimes necessary to lift the machine. It

is mandatory to put under the machine an appropriate support to

avoid falling the machine at eventual damage on hydraulics.

5. Use the gloves and appropriate tools at changing sharp parts of the

machine to avoid injuries.

6. Used oils and greases should be removed according to the rules.

7. Always disconnect electric cables on the tractor before any wel-

ding or other operation when using electricity is necessary.

8. Only original spare parts should be installed

13

Warning decals

1. Always turn off the machine of the tractor and

read the instructions carefully before starting

servicing and/or lubrification operations.

2. Keep at a safety distance from the machine to

avoid the risk of flying objects.

3. Never remove the guards while the parts of

the machine are moving. It can injure the

hands.

4. Keep at a safety distance from the machine to

avoid the risk of injuring the feet.

5. It is forbidden to stand on the machine be-

cause of the risk of fall!

14

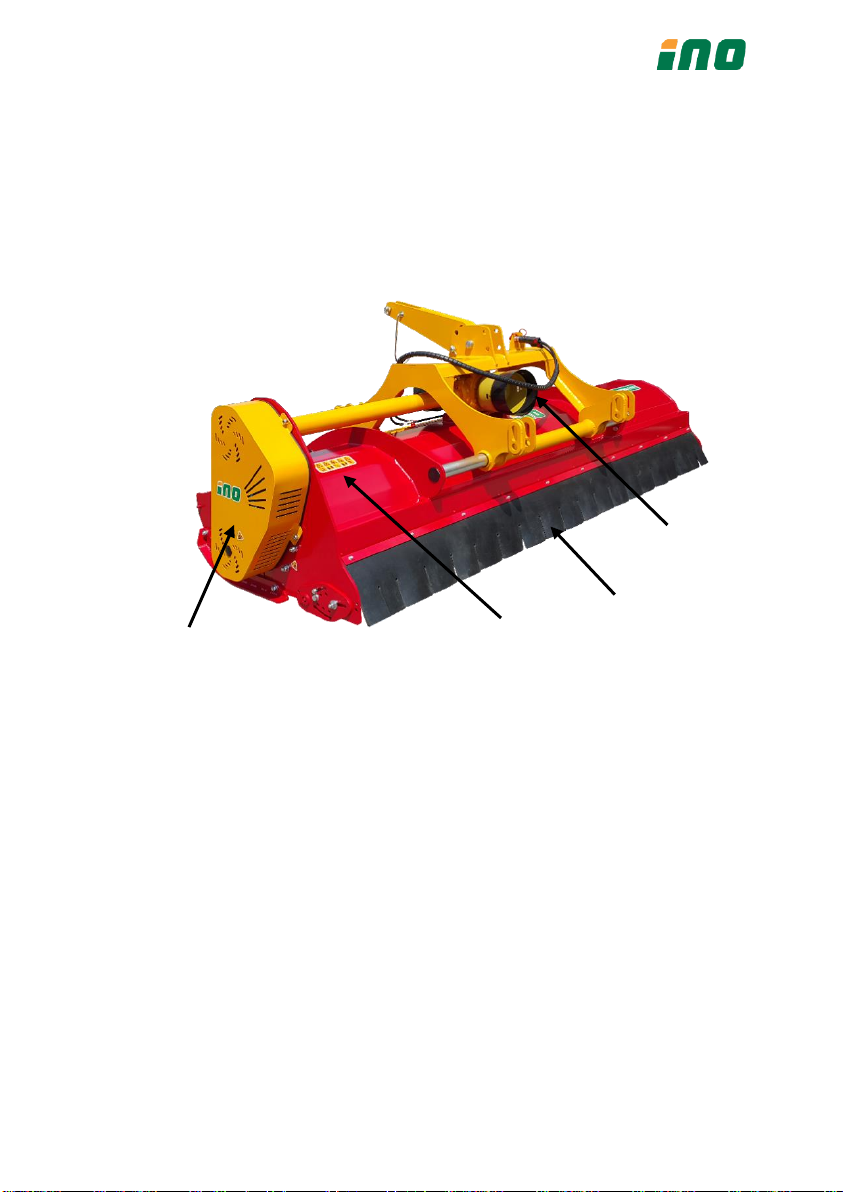

List of guards

Fig. 3

1. PTO shaft shield PVC

2. belt shield

3. warning decals

4. rubber guard

1

2

3

4

15

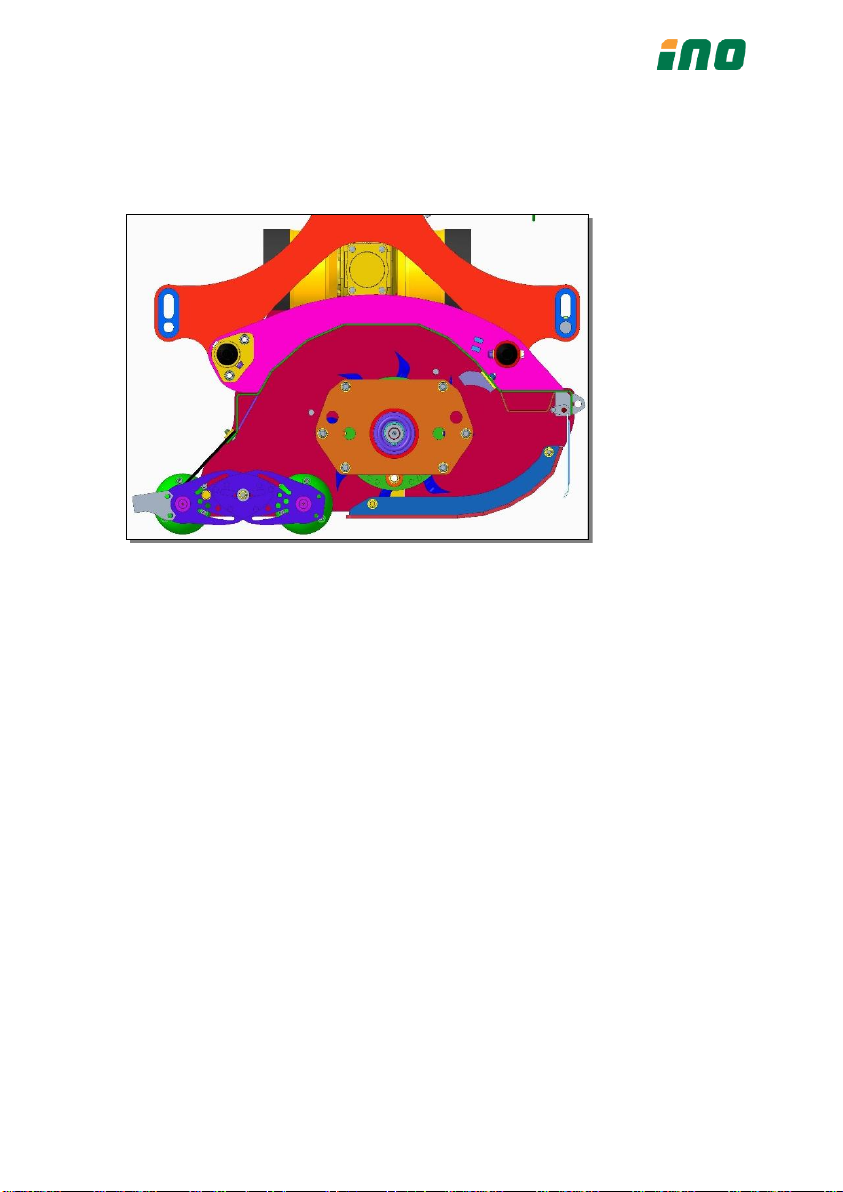

4. Description and operating of the machine

The machine is equipped with hammers on the rotor shaft. Hammers

are used for material with diameter with diameter Ø 6 cm. Optional wor-

king tools Y-blades are used for cutting material with diameter Ø 3

cm.While rotating working tools cut the material and lift it under the top of

the frame. Falling material is again cut several times by rotating hammers.

Maximal thickness of the material depends on the sort and

hardness of the wood. Up-mentioned diameters are valid for

the fresh wood only.

Fig. 4

Fig. 5

16

5. Transport and attachment of the machine

Transport to the customer

Unload the machine with special care to avoid any damage. Check that

all nuts and bolts are fixed and tightened. Specially check the bolts and nuts

for the working blades.

Attachment and detachment from the tractor

Before any operation check:

•That the machine is in good condition,

•That all guards are in proper places and in good condition,

•That working blades are complete and undamaged,

•That all greasing points are greased well and that in gearbox is

enough oil,

•Appropriate tensioned belts,

•That rpm and direction of rotation on the drive axle correspond

to those on the machine.

When you attach the machine to the tractor, bring the tractor lower

lines near the machine, to the points corresponding to the pins. Insert the

pins and secure them with the spring clips. Fit the top link, raise the ma-

chine to a perpendicular position to the ground. Adjust the two tractor

lower linkage stabilizers thus fixing the machine to the tractor in a central

position. Connect the hydraulic cylinders and check if it works.

3-point hitch of the machine must be in a simetrical position

with the tractor.

Top linkage point has two working modes: floating and fixed linkage.

Use floating position whenever working on hilly, uneven terrain to avoid

damaging the machine or linkage. To get floating position just remove the

pin, fixing the top linkage bracket, on the opposite site of the linkage

bracket (see Fig.6).

17

Fig 6

It is mandatory to use floating linkage on hilly or sloping ter-

rain!

Before any change af attachment (front, rear) it is mandatory to

check that rpm and direction of rotation on the drive axle correspond

to those on the machine.

Fitting the PTO shaft

Attach the machine on the tractor. Split the tubes into both parts and

put one part on the tractor and another on the machine. At the machine

laying on the ground, minimum overlapping of the tubes mustn't be less

than 1/3 of total length. Cut too long part of the tube and clean the edges.

Cut on the proper length also the guard as on fig. 13. Measure the length

when the PTO shaft is in horisontal position. Grease before putting them

together.

Too long PTO shaft can seriously damage tractor or flail

mower.

Never put PTO shaft on the tractor without all guards and cha-

ins fitted properly.

18

Fig. 7: Appropriate length of PTO shaft at the machine on the ground

Fig. 8: Appropriate length of the guard when machine is lifted.

Stability of the tractor

At attachment of the machine on the tractor always take care

about allowed weight of the attachment and axle load. First

axle of the tractor should always be loaded with min.20% of

the weight of the tractor itself. This is very important specially

on this machine because of its distance between the tractor

and working part of the machine!

Fig. 9

1/3 shaft

19

6. Adjustment

Working height adjustment

Height of cut depends on working conditions and volume of the mate-

rial. The height of cut can be regulated with the hydraulic system on the

tractor or/and with adjusted rear roller of the machine (Fig. 13). The min.

height of cut should be between 1-3 cm. The machine always run on the

rear roller and not on the skids.

Working tools should never touch the ground. The skids are

only the protection against injures.

20

Support roller adjustment

You can set the roller in two positions depending how you want to dis-

perse the material and working conditions and volume of the material.

Fig. 12

Table of contents

Other iNO Lawn Mower manuals