Frequency

Division

Coecient

DIP Switch

Filtering

Function

Frequency Division Coecient

Setting Switch

Filtering

Function

Selection

Switch

12345678

No output 0 0 0 0 0 0

0 0

Non-

adaptive

ltering

1 frequency

division output 100000

2 frequency

division output 010000

1 0 Adaptive

ltering

3 frequency

division output 110000

. ......0 1 Fixed

interlock

. ......

. ......

1 1 Automatic

interlock

63 frequency

division output 111111

◆ Non-adaptive ltering: The lter coecient of the PG card is

xed to a small value. This function is suitable for applications

without signal interference, with small signal interference, or

where the motor runs at high speed.

◆ Adaptive ltering: The lter coecient of the PG card is

adjusted automatically, and the PG card has a strong anti-

interference capability, especially when the encoder feedback

speed is smaller than 60 kHz. This function which is enabled

by default is suitable for applications with strong signal

interference.

◆Fixed interlock: Add the function of eliminating the edge jitter

of the encoder feedback signal compared to the adaptive

ltering. This function is suitable for applications where the

edge jitter of the encoder feedback signal exists.

◆ Automatic interlock: Compared to the xed interlock, add

the automatic switchover between the adaptive ltering

and the xed interlock to adapt to zero-speed and non-zero-

speed working conditions, preventing the problem that useful

signals are eliminated mistakenly as edge jitter in zero-speed

condition.

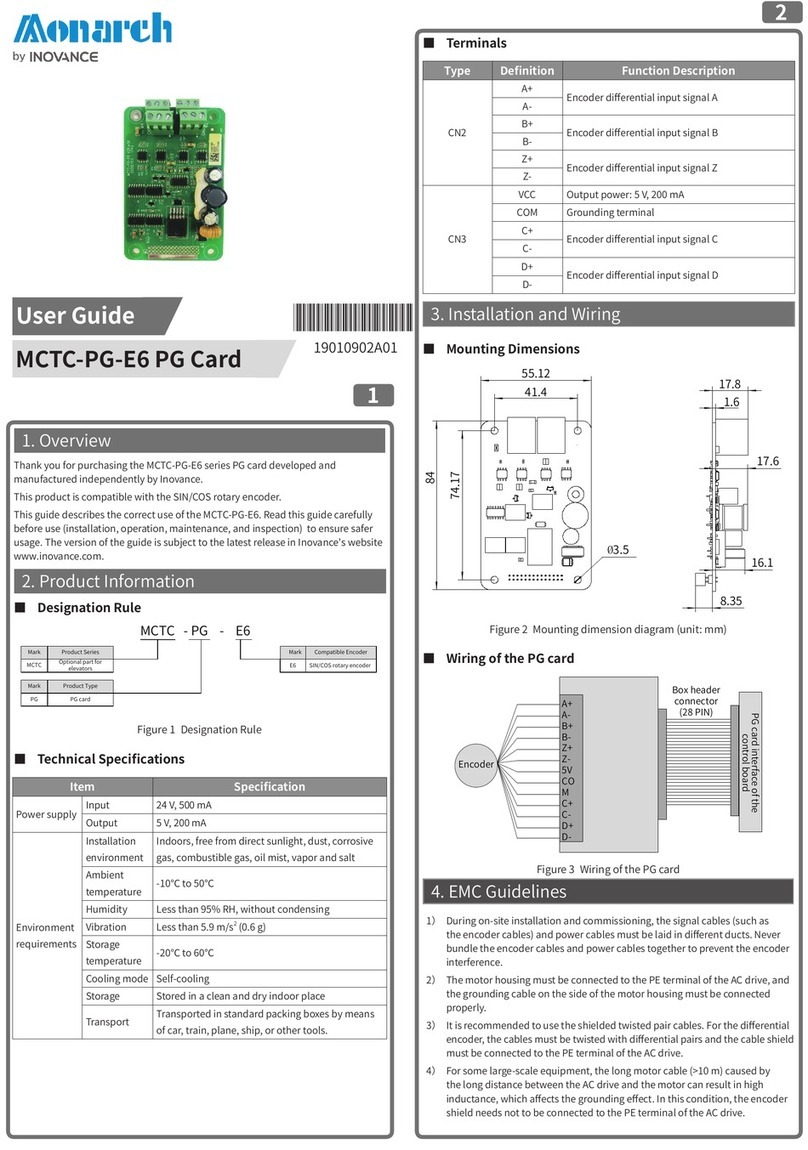

3. Wiring

■Instructions for Collector Input Wiring

1 ) Connect the encoder output phase A and phase B to the PGA and PGB

terminals of the PG card, respectively, and connect the power cable of the

encoder to the +15PG and COM terminals.

2 ) Connect the shield of the encoder cable to the PE terminal of the PG card.

3 ) Select the ltering function according to the applications (The ltering

function is selected by numbers 7 and 8 of the DIP switch. For details, see

section 2).

Because the electrical characteristics of the collector can lead to slow rising edge

of signals, the signal transmission distance of the collector encoder does not

exceed 50 m. Therefore, for applications with cable length greater than 50 m, it

is recommended not to use the collector encoder, but to use the push-pull or

dierential encoders.

■Instructions for Collector Frequency Division Output

Wiring

1 ) Connect the frequency division output cable to the OUT-A/OUT-B/COM

frequency division output terminals of the PG card.

2 ) Set the frequency division coecient by numbers 1 to 6 of the DIP switch. For

the specic settings, see section 2. The default is 32 frequency division output.

3 ) Connect the shield of the frequency division output cable to the PE terminal of

the device receiving the frequency division signal.

The allowable maximum sink current and maximum pull-up voltage of the collector

frequency division output of the PG card are 300 mA and 30 V, respectively. The

output cannot be directly connected to a 24 V power supply. Otherwise, the PG card

output component will be damaged.

4

■Wiring of the PG card

Encoder

+15V

PGM

A

B

PE

OUTA

OUTB

COM

MCTC-PG-A5

Control board

Figure 3 Wiring of the PG card

◆The cable from the encoder to the PG card must be separated

from the cables of the control circuit and the main circuit.

Parallel cabling with close distance is forbidden.

◆The cable from the encoder to the PG card must be a shielded

cable, with the shield connected to the PE terminal on the AC

drive side (only one end is grounded to prevent interference).

◆The cable from the encoder to the PG card must run through a

separate duct, and the metal shell is reliably grounded.

4. EMC Guidelines

1 ) During on-site installation and commissioning, the signal cables (such as

the encoder cables) and power cables must be laid in dierent ducts. Never

bundle the encoder cables and power cables together to prevent the encoder

interference.

2 ) The motor housing must be connected to the PE terminal of the AC drive, and

the grounding cable on the side of the motor housing must be connected

properly.

3 ) It is recommended to use the shielded twisted pair cables. For the dierential

encoder, the cables must be twisted with dierential pairs and the cable shield

must be connected to the PE terminal of the AC drive.

4 ) For some large-scale equipment, the long motor cable (>10 m) caused by

the long distance between the AC drive and the motor can result in high

inductance, which aects the grounding eect. In this condition, the encoder

shield needs not to be connected to the PE terminal of the AC drive.

5 ) LED1 on the PG card is used to judge whether interference exists in the

encoder input signal. For details, see the table“Denition of Signal Indicators”

in section 2.

Warranty Agreement

1) Inovance provides an 18-month free warranty to the equipment itself from the

date of manufacturing for the failure or damage under normal use conditions.

2 ) Within the warranty period, maintenance will be charged for the damage

caused by the following reasons:

a. Improper use or repair/modication without prior permission

b. Fire, ood, abnormal voltage, natural disasters and secondary disasters

c. Hardware damage caused by dropping or transportation after

procurement

d. Operations not following the user instructions

e. Damage out of the equipment (for example, external device factors)

3 ) The maintenance fee is charged according to the latest Maintenance Price List

of Inovance.

4 ) If there is any problem during the service, contact Inovance’s agent or

Inovance directly.

5 ) Inovance reserves the rights for explanation of this agreement.

Suzhou Inovance Technology Co., Ltd.

Address: No.16, Youxiang Road, Yuexi Town, Wuzhong District, Suzhou 215104, P.R. China

Website: http://www.inovance.com

3