SAFETY 7

DURINGOPERATION

•Childrenshouldnotbeallowedontheproduct.

•Clear the area of small children and bystanders before

movingtheequipment.

•Securely aach feeder to towing unit, using a hardened

3/4” pin, a metal retainer, and safety chains if required.

Shitowingunittoalowergearbeforegoingdownsteep

downgrades, thus using the engine as a retarding force.

Keep towing vehicle in gear at all mes. Slow down for

cornersandroughterrain.

•Makesureyouareincompliancewithalllocalandstate

regulaonsregardingtransporngequipmentonpublic

roadsandhighways.Lightsandslowmovingsignsmustbe

cleanandvisiblebyovertakingoroncomingtrafficwhen

feederistransported.

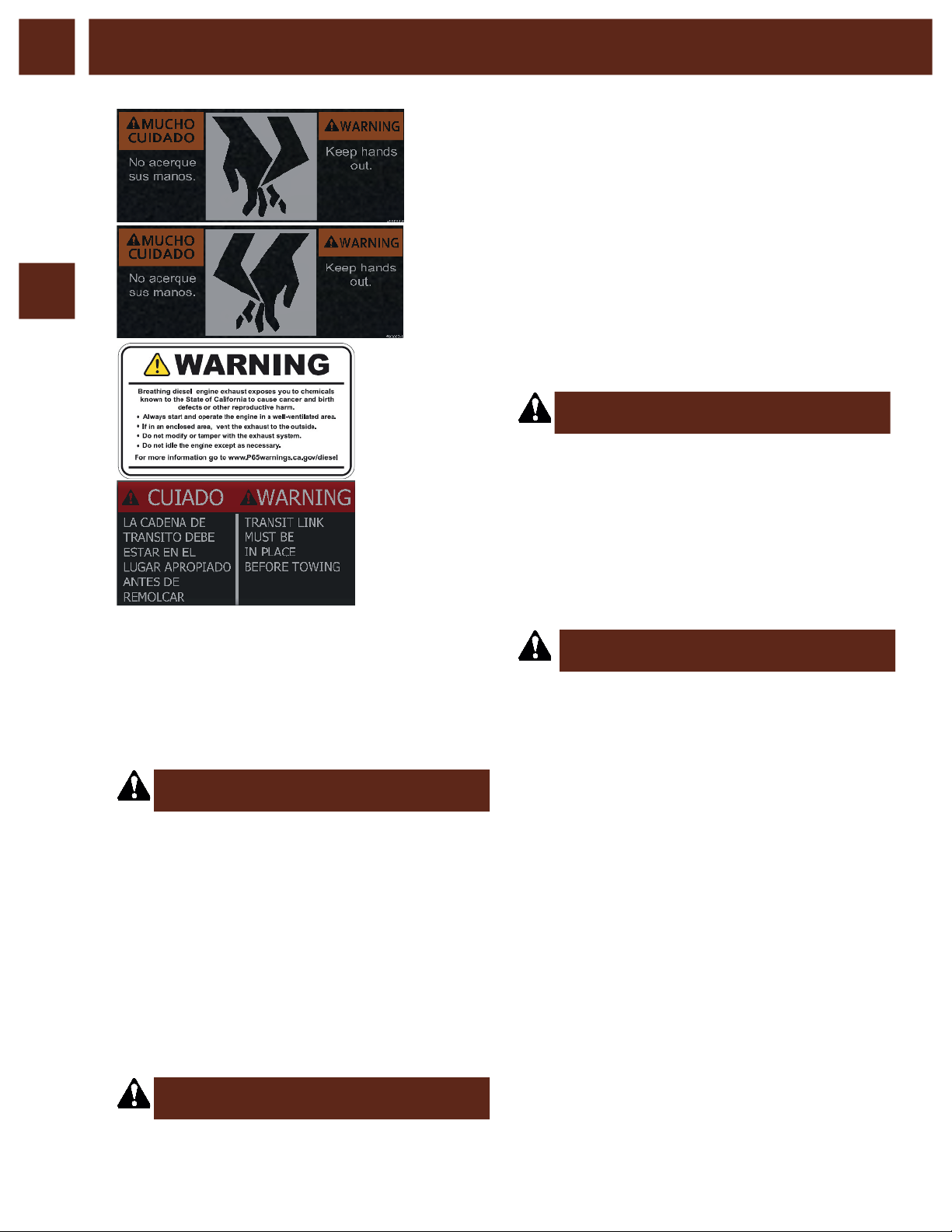

•SAFETYCHAIN‐ifequipmentisgoingtobetransported

onapublichighway,asafetychainshouldbeobtained

andinstalled.Alwaysfollowstateandlocalregulaons

regardingasafetychainandauxiliarylighngwhen

towingfarmequipmentonapublichighway.Besureto

checkwithlocallawenforcementagenciesforyourown

parcularregulaons.Onlyasafetychain(notanelasc

ornylon/plasctowstrap)shouldbeusedtoretainthe

conneconbetweenthetowingandtowedmachinesin

theeventofseparaonoftheprimaryaachingsystem.

•Installthesafetychainbycrossingthechainsunderthe

tongueandsecuretothedrawbarcageorhitchor

bumperframe.

•Bewareofbystanders,parcularlychildren!Alwayslook

aroundtomakesurethatitissafetostarttheengineof

thetowingvehicleormovetheunit.Thisisparcularly

importantwithhighernoiselevelsandquietcabs,asyou

maynothearpeopleshoung.

•NOPASSENGERSALLOWED‐donotcarrypassengers

anywhereon,orin,thetractororequipment,exceptas

requiredforoperaon.

•Keephandsandclothingclearofmovingparts.

•Donotclean,lubricateoradjustyourequipmentwhileit

ismoving.

•Whenhalngoperaon,evenperiodically,setthe

vehiclebrakes,shutofftheengineandremovethe

ignionkey.

HIGHWAYOPERATION

•Adoptsafedrivingpracces:

•Keepthebrakepedalslatchedtogetheratallmes.

NEVER USE INDEPENDENT BRAKING WITH MACHINE IN

TOWASLOSSOFCONTROLAND/ORUPSETOFUNITCAN

RESULT.

•Always drive at a safe speed relave to local condions

and ensure that your speed is low enough for an

emergency stop to be safe and secure. Keep speed to a

minimum.

•Reduce speed prior to turns to avoid the risk of

overturning.

•Avoidsuddenuphillturnsonsteepslopes.

•Always keep the tractor or towing vehicle in gear to

provide engine braking when going downhill. Do not

coast.

•Comply with state and local laws governing highway

safetyandmovementoffarmmachineryonpublicroads.

•Use approved accessory lighng flags and necessary

warningdevicestoprotectoperatorsofothervehicleson

thehighwayduringdaylightandnighmetransport.

•Varioussafetylightsanddevicesareavailablefromyour

dealerordirectfromJackrabbit.

•The use of flashing amber lights is acceptable in most

localies. However, some localies prohibit their use.

Locallawsshouldbechecked forallhighwaylighngand

markingrequirements.

•Whendrivingthetractorandequipmenton theroador

highway under 35 kph (20 mph) at night or during the

day,useflashingamberwarninglightsandaslow‐moving

vehicle(smv)idenficaonemblem.

•Planyourroutetoavoidheavytraffic.

•Beasafeandcourteousdriver.Alwaysyieldtooncoming

traffic in all situaons, including narrow bridges,

intersecons,etc.

•Be observant of bridge loading rangs. Do not cross

bridges rated lower than the gross weight as which you

areoperang.

•Watch for obstrucons overhead and to the side while

transporng.

•Always operate equipment in a posion to provide

maximumvisibilityatallmes.

•Makeallowancesforincreasedlengthand weightofthe

equipmentwhenmakingturns,stoppingtheunit,etc.

•Pickthemostlevelroutewhentransporngacrossfields.

Avoidtheedgesofditchesorgulliesandsteephillsides.

(CONTINUEDONNEXTPAGE)

•Beespeciallyobservantoftheoperangareaandterrain

‐watchforholes,rocksorotherhiddenhazards.Always

inspecttheareapriortooperaon.

•DONOToperateneartheedgeofdrop‐offsorbanks.

•DONOToperateonsteepslopesasoverturnmayresult.

•OPERATEupanddown(notacross)intermediateslopes.

Avoidsuddenstartsandstops.

•Donotdrinkanddrive!

•Themanufacturerdoesnotrecommendusageoftractor

withROPSremoved.

•Move tractor wheels to the widest recommended

sengstoincreasestability.

•Securely aach to towing unit. Use a high strength,

appropriately‐sized hitch pin with a mechanical retainer

andaachsafetychain.

•Do not allow anyone to stand between the tongue or

hitch and the towing vehicle when backing up to the

equipment

•EnsureDisconnectswitchisonpriortostarngignion.