INSBUD IB-TRON 4000 SOL User manual

Multisystem solar controller

With support for additional devices, two collectors areas,

for central and water heating.

IB – Tron 4000 SOL

www.insbud.net 3

English

InsBud company supports policy of development. Rights to making changes and

improvements in products and manuals without prior notice reserved!

The contents of this manual - the text and graphics are owned by InsBud company

or its subcontractors, and is legally protected.

Products is marked

and has been produced in accordance with ISO 9001 standard

v1.22

Contents

iB-TROn 4000 sOl

Basic information __________________ 4

Features _________________________ 4

Available Models __________________ 5

Technical data_____________________ 5

Supply___________________________ 5

General Remarks __________________ 5

Construction______________________ 6

Wiring ___________________________ 6

Display __________________________ 7

Temperature sensors _______________ 7

Calibration _______________________ 8

Temperatures overview _____________ 9

Basic settings _____________________ 9

Fresh water circulation pump ________ 10

Bacteriological protection ___________ 11

Hysteresis ________________________ 11

Extra heating busters _______________ 11

Frost protection ___________________ 13

High temperature protection ________ 13

Choice of tank_____________________ 14

Loading pumps ___________________ 14

P0 and P1 pump speed _____________ 15

SMART START _____________________ 17

GUARD __________________________ 17

Holidays _________________________ 17

Additional functions setting _________ 18

Keyboard lock_____________________ 18

Factory settings ___________________ 18

Test functions _____________________ 18

Temperature units _________________ 19

Network _________________________ 19

Software version___________________ 19

Errors____________________________ 20

Short manual _____________________ 20

Warranty _________________________ 22

„INSBUD”

ul. Niepodległości 16a

32-300 Olkusz

Poland

sales department: +48 (32) 626 18 00

sales department: +48 (32) 626 18 18

technical department: +48 (32) 626 18 07

technical department: +48 (32) 626 18 08

fax: +48 (32) 626 18 19

e-mail: insbud@insbud.net

www.insbud.netwww.insbud.net 54

English

English

Basic infORmaTiOn

fEaTuREs

fEaTuREs fEaTuREs

TEchnical daTa

supply

gEnERal REmaRks

availaBlE mOdEls

IB-Tron 4000SOL controller are used for con-

trol solar systems or any other heating sys-

tem, which control is based on measuring

dierence of temperature in dierent places

of system. IB-Tron 4000SOL controller ena-

bles full automation of these systems in a

comfortable way and it ensures high ecien-

cy of whole system.

eControl of 4 dierent expanded heating

systems

eIndependent control of two areas of so-

lar collectors

eLoading of two tanks (eg fresh water

tank and storage tank, fresh water tank

and a swimming pool etc.)

eAbility to connect 7 temperature sen-

sors (all sensors included)

eAbility to control 7 various devices

(pumps, heaters, valves, boilers, etc.)

eLoading pumps of collectors with auto-

matic dull range speed control for incre-

asing eciency of whole system. Speed

of pumps is calculated in two ways (de-

pends of user setting):

» according to optimum temperature

dierence

» according to optimal operating tem-

perature of collector

eFull adjustable hysteresis for all

parameters

eAnti-frost protection function for

collectors

eProtection against high temperature of

tanks (against overheating)

eAbsolute protection against excessively

high temperatures in system

eLegibly, large (4 „), backlit blue LCD di-

splay that shows all the necessary in-

formation (temperature, pumps, valves,

heaters status etc.) and the current ide-

ological view of instalation

ePower supply from building network -

does not require batteries to operate

eBattery memory backup in the case of

break of power supply.

eExtra heating busters independently for

each tank

eControls fresh water circulation pump

by modes:

» by temperature of circulation

» by time program of work and break

time

eHoliday function in two modes (de-

pends of user setting):

» Winter (heating building only,Fresh

water tank is not heated at all by so-

lar and other heating busters)

» Summer (cooling tanks and extra

heating busters not working at all)

eBacteriological protection of fresh wa-

ter tank

eGUARD function - protection devices

from damage

eReloading heat between tanks

eSMART START function, controller in-

telligently consider delay between real

temperature and sensor measuring

eIndependent calibration of each sensor

eChoice of how to load tanks:

» Highest eciency (system tries to

collect as much energy as possible,

both tanks are equivalent)

» Fresh water tank prioryty (Fresh wa-

ter tank is rst loaded to the optimum

temperature as priority and after that

both tanks are loaded according to

highest eciency method)

eManual test of all relays

eThe ability to verify operation of the lo-

gic by temperature readings overwrite

eMounting on DIN rail (10 modules) or

on-wall mounting

eEasy and intuitive handling

eAesthetic and modern look

eNetwork RS485 or Ethernet communi-

cation (optional)

ePower consumption: <5W

ePower supply: 230V AC

eAccuracy: ±1 ºC

eStorage temperature: -10÷50 ºC

eMax load:

» P0, P1: 1,5A (~300W)

» P2, P3: 3A (~600W)

» R1: 10A (~2000W)

» H1, H2: 16A (~3500W)

ePlastic cover: ABS

eDisplay: LCD (4”)

eHumidity: 5±90%

eClock accuracy: ±100 s/month

e1x Controller

e2x Sensor PT1000

e5x Sensor NTC10kOhm

e1x This instruction

e1x Instructions for network (only with

NW model NW)

HDuring the installation of controller po-

wer supply should be cut o. This pro-

duct should be installed by a qualied

electrician.

HController should be placed away from

showers, bathtubs, washbasins, etc. to

prevent direct ooding of controller.

HController is designed for installation in

electric distribution box with standard

DIN rails. It can be also mounted on-

wall by special mounting holes.

eBL - blue backlight (backlight is activa-

ted when pressing any button and it is

turned o after some delay)

eNW - controller for network (communi-

cation by RS - 485 or Ethernet)

www.insbud.netwww.insbud.net 76

English

English

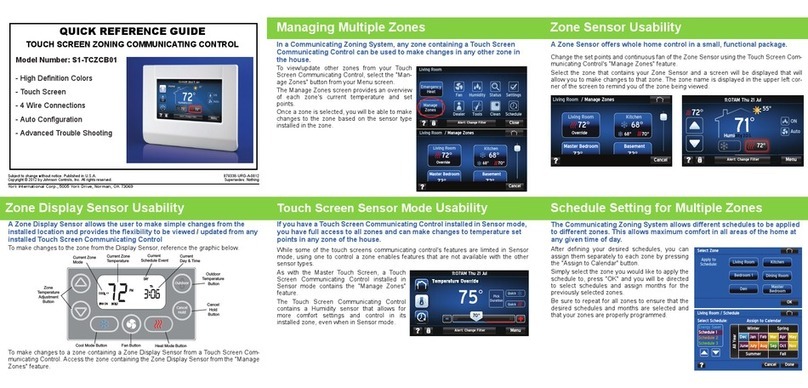

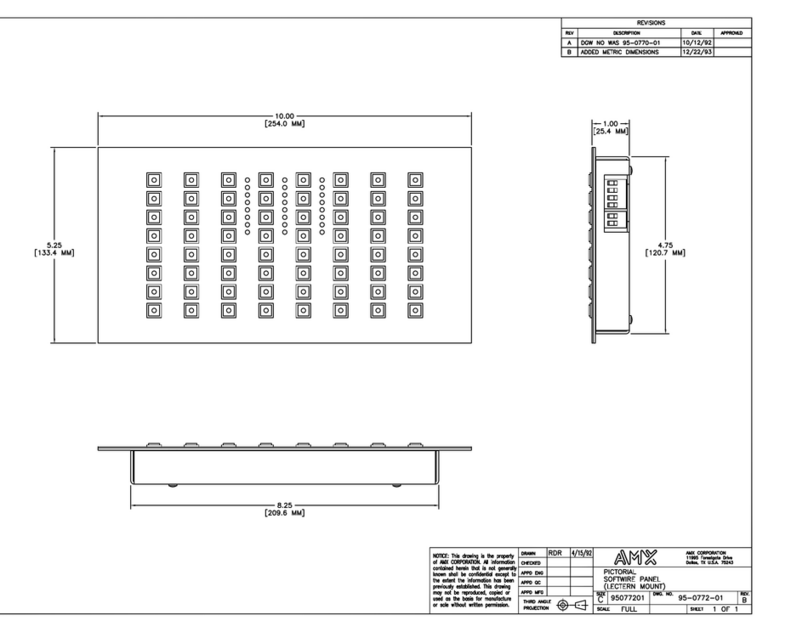

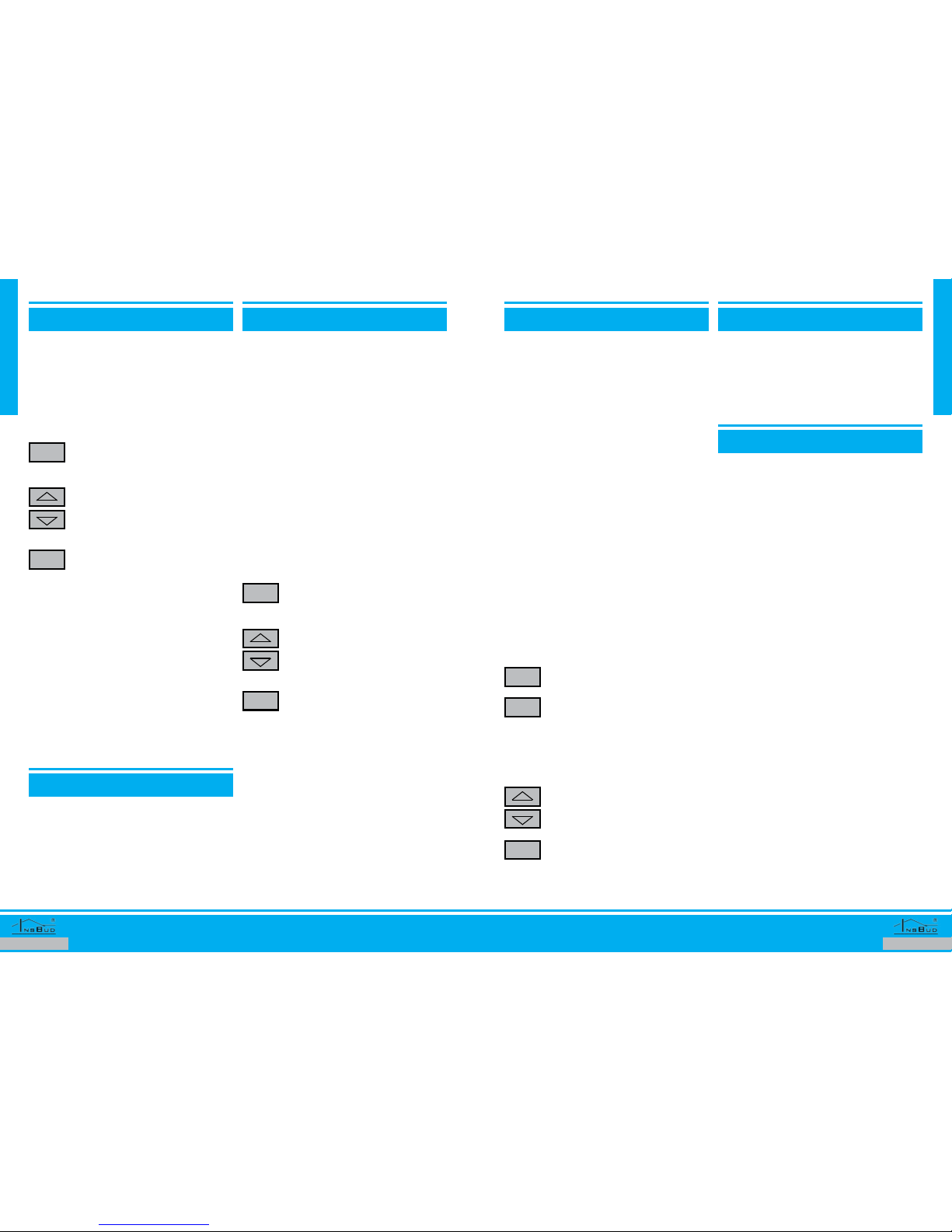

cOnsTRucTiOn

WiRing

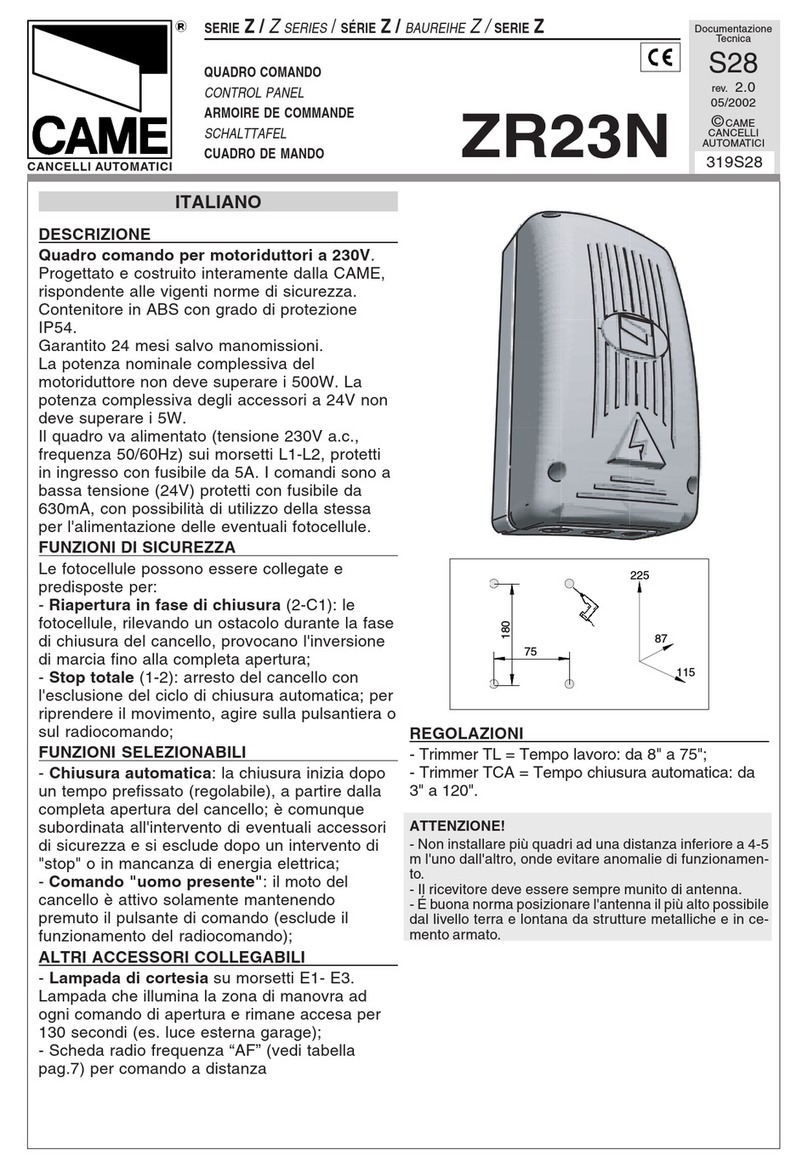

display

TEmpERaTuRE sEnsORs

159

159

94

59

49

30

3335

88

47

61

77

18

POWER R1H1 H2 P0 P1 P2 P3

NONN N N N N NL OFFL L L L L L N

T0 T1 T2 T3 T4 T5 T6

eConnection terminals are located under

front panel. To connect wiring please re-

move front panel and disconnect wiring

cable from main board.

ePOWER - Power supply

eConnection various devices and sen-

sors depends of chosen system of

work. Some devices or sensors may be

not connected. All connected devices

must have the same power supply like

controller.

eR1 - Controlling terminal of 3-way valve.

Controller gives voltage at ON output

when it want to load tank 2 (buer), and

gives the voltage at OFF output when it

want to load tank 1 (fresh water tank)

Day

T1

T3

T6

T5

T2

H1

T4

T0

1

P

System

2

H2

P0 P2 P3

R1

P1

eThe appearance of display depending

of chosen system of work. Some items

may not be visible.

eFlashing pump symbol means that this

pump works at the moment. If the sym-

bol is not ashing means that pump

does not work now.

IWith controller are provided follow

sensors:

» 2x PT1000 Sensors (connected to T0

and T1)

» 5x NTC10kOhm Sensors (connected

to T2, T3, T4, T5 i T6)

IThe sensors can be extended to any

length, but it must be remembered that

the extension above 10m may cause de-

viation of temperature measurement,

so for a distance above 10m controller

should be calibrated. Sensor wires must

be extended by cables:

» to 50m 2x 0,75 mm2

» above 50m 2x 1,50 mm2

eController is compatible with NTC 10kΏ

sensors witch follow characteristic:

Temperature

[ºC]

Resistance

[Ώ]

-50 687 803

-40 346 405

-30 181 628

-20 99 084

-10 56 140

0 32 960

10 20 000

20 12 510

25 10 000

30 8 047

40 5 310

50 3 588

60 2 476

70 1 743

80 1 249

90 911

100 647

AH

Tmin Tmax

∆T OK

www.insbud.netwww.insbud.net 98

English

English

TEmpERaTuRE sEnsORs TEmpERaTuREs OvERviEW

Basic sETTings

Basic sETTingsTEmpERaTuRE sEnsORs

eSensors cables are low-voltage, so as

not to interfere with the measurements,

sensor wires should not be conducted

in the vicinity of high voltage cables (the

distance of at least 100mm).

eThe sensors can operate in all weather

conditions.

» Sensors cables are resistant to tem-

perature:

» PT1000: -50÷140 ºC, temporary to

200 ºC

» NTC 10kΏ: -50÷100 ºC, temporary to

120 ºC

eIf sensor is not connected or damaged

and it is not important for controller

operation on display you can see „- - -”

value

IIf sensor is not connected or damaged

and it is important for controller ope-

ration on display you can see warning

symbol

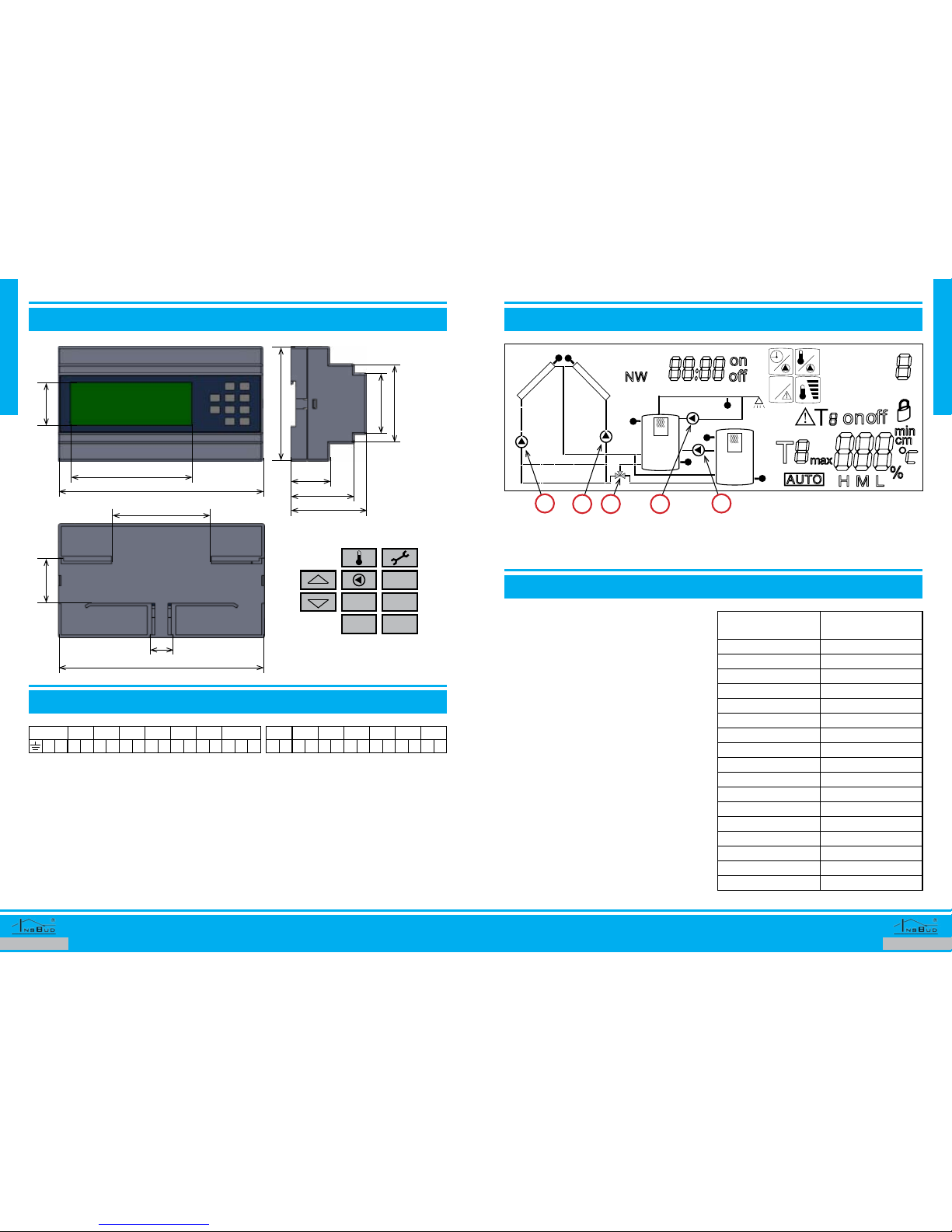

First of all you need to set an appropriate sys-

tem of work, which will correspond to actual

installation of hydraulic connecting.

Controller supports 4 heating systems:

1. One collector area and one tank

2. Two collector areas and one tank

3. One collector area and two tanks

4. Two collector areas and two tanks

IIn fact, areas of collectors may be any

other device that generates heat in a

similar way to a collector (eg, heating

replace). A similar situation is with the

tank, which in fact may be, for example

swimming pool.

To select an appropriate system please:

eController is compatible with PT1000

sensors witch follow characteristic:

Temperature

[ºC]

Resistance

[Ώ]

-30 862

-20 902

-10 944

0 1 000

10 1 057

20 1 097

30 1 136

40 1 175

50 1 215

60 1 254

70 1 292

80 1 331

90 1 370

100 1 408

110 1 447

120 1 485

130 1 523

140 1 561

150 1 599

160 1 597

170 1 645

180 1 712

190 1 750

200 1 787

210 1 774

220 1 810

230 1 847

240 1 875

250 1 912

260 2 008

270 2 045

280 2 081

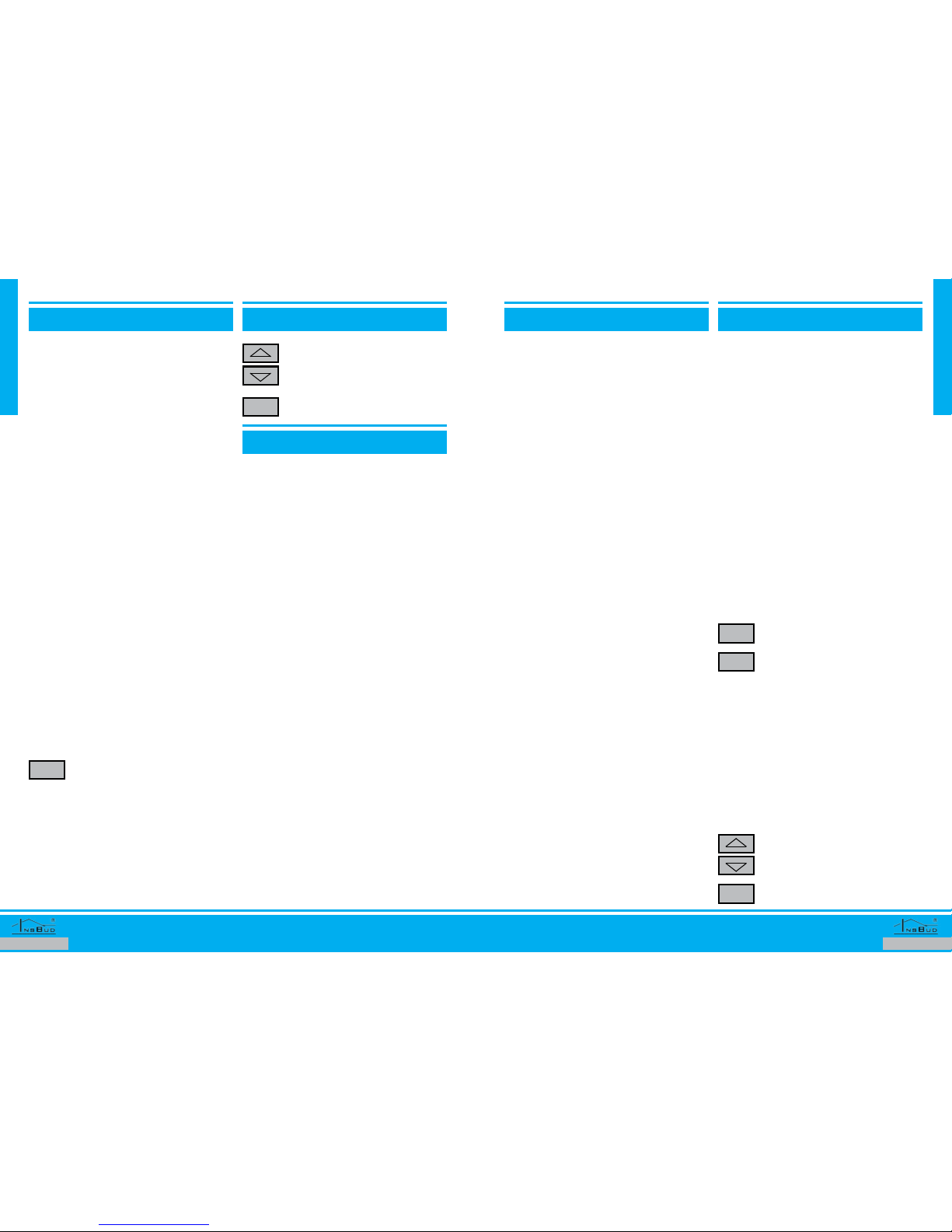

caliBRaTiOn

After properly connecting controller is ready

to work. Controller is factory-calibrated to

work with standard sensors. However after

extension temperature displayed by control-

ler may be dierent from actual.

In that case, you can calibrate the device.

Each sensor is calibrated separately:

Press and hold two buttons simul-

taneously. On display start ashing

current calibration settings and

number of sensor.

Press the button. On display there

will be ashing system number in

the right upper corner.

Press the button. On display there

will be ashing hour.

Press the button. On display the-

re will be ashing day of the week

(number 1÷7).

To see a specic temperature sen-

sor, press button. Repeated pres-

sing of this button will switch to the

next sensor indications. If current

temperature sensor is last available

sensor, another button press will

switch to the rst available sensor.

To be able to easily nd out where

specic sensor is located, all sen-

sors have been symbolically mar-

ked on the display and next to it is

number of sensor.

Calibrate sensor by setting the ap-

propriate value settings.

Select desired system (during the

selection display will be updated

automatically).

Set current hour. Longer holding

the button will change settings

faster.

Set current day of the week.

By repeatedly pressing button you

can change calibrated sensor.

Conrm set data.

Tmin

OK

∆T

www.insbud.netwww.insbud.net 1110

English

English

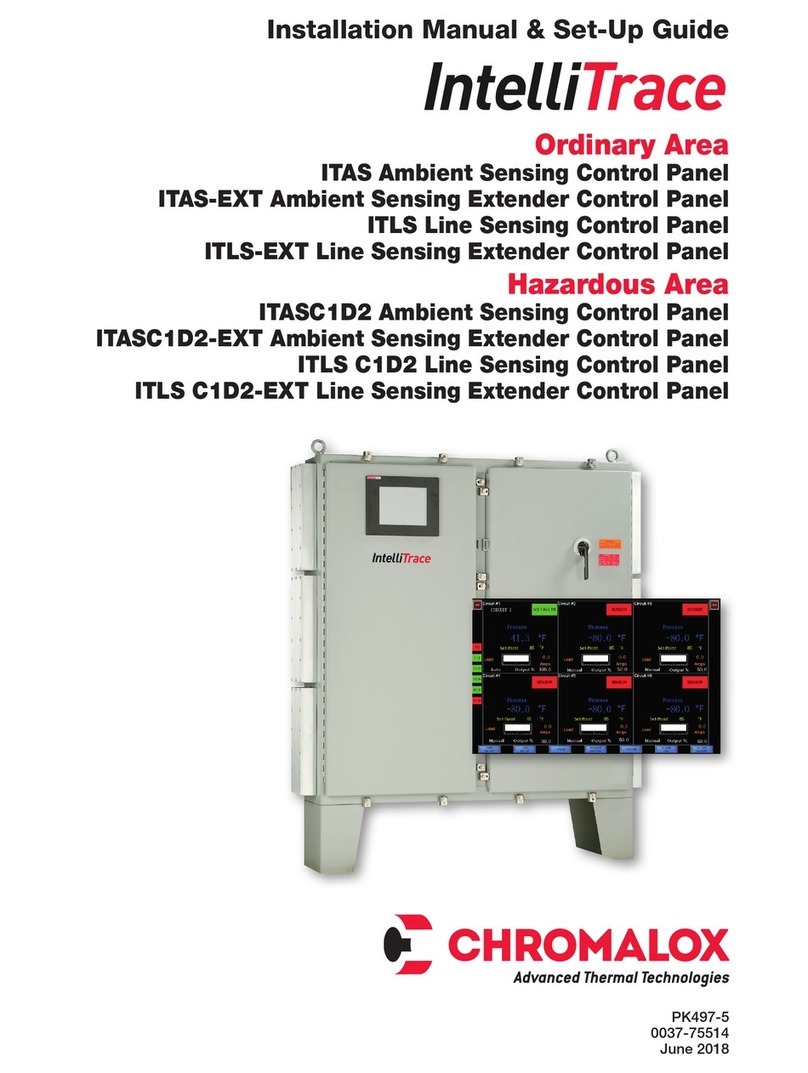

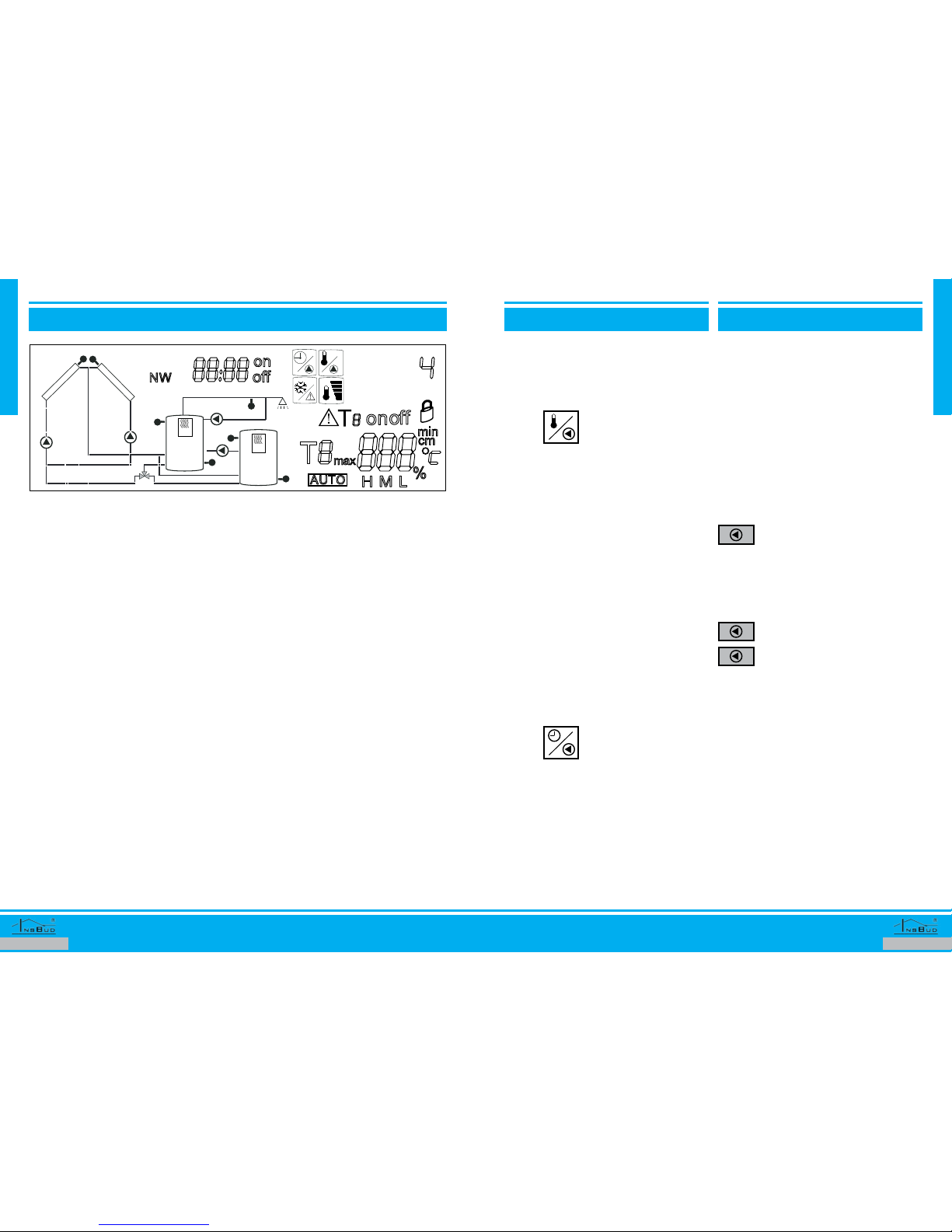

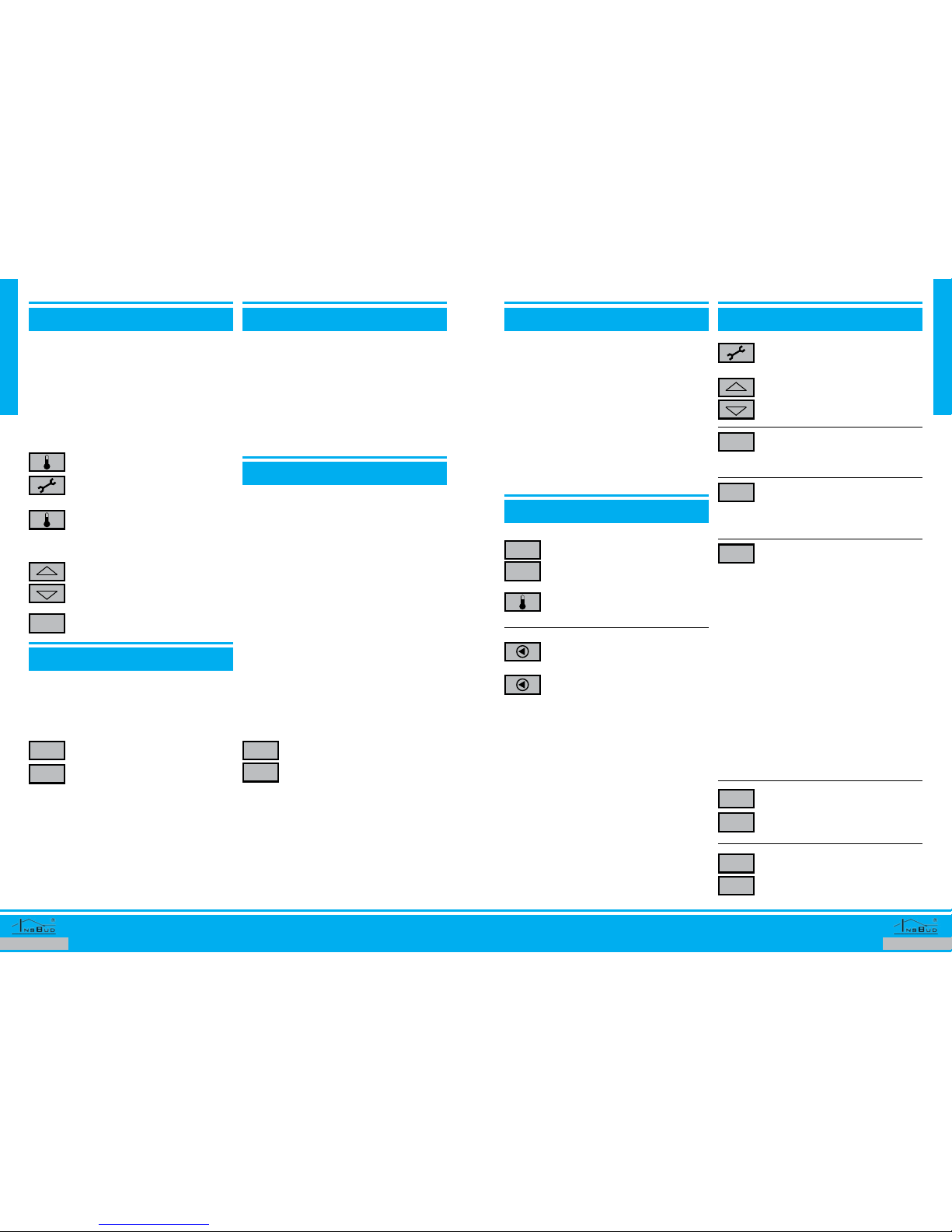

fiRsT sysTEm - OnE cOllEcTORs aREa and OnE Tank

sEcOnd sysTEm - TWO cOllEcTORs aREa and OnE Tank

The circulation pump of collectors area (P1) is

started when temperature dierence of col-

lectors area (T1) and tank temperature (T2)

reaches the set value of switching on. The

pump is turned o when temperature die-

rence of T1 and T2 falls below the set value of

switching o or temperature in the tank (T2)

reaches the set maximum value. The pump

of the collectors is controlled with continu-

ously speed adjustment.

External power supply (H1), which may be a

electric heater, gas stove or components of

automation (pump, valve) is controlled on

the basis of respectively set parameters of

the controller, which are described later in

this manual and temperature reading of sen-

sor (T3) in the upper part of the tank. Circu-

lation pump of hot water (P2) is controlled

on the basis of respectively set parameters

of the controller, which are described later in

this manual and temperature reading of sen-

sor (T4) of hot water circulation.

Above remarks connected with external heat

source and hot water circulation pump con-

cern to all supported systems.

Circulation pump of the rst collectors area

(P1) is started when temperature dierence

of the rst collectors area (T1) and tempe-

rature in the tank (T2) reaches the set value

of switching on. Similarly, circulation pump

of the second collectors area (P0) is started

sEcOnd sysTEm - TWO cOllEcTORs aREa and OnE Tank

ThiRd sysTEm - OnE cOllEcTORs aREa and TWO Tanks

adjustment.

This system is recommended when areas of

the collectors are working independently for

each other (east-west layout with a low slope,

there may be a case when two collectors are-

as are working simultaneously).

In fact, the second collectors area may be re-

spectively hydraulically connected another

device which produces thermal energy for

example: heating replace.

when temperature dierence of the second

collectors area (T0) and temperature in the

tank (T2) reaches the set value of switching

on. Circulation pumps (P1 and P0) are wor-

king independently from each other - the

pumps may work simultaneously, don’t work

at all or one pump works. Suitable pump is

turned o when temperature dierence be-

tween the suitable collectors area and the

tank falls below the set value of switching

o or temperature in the tank (T2) reaches

the set maximum value. Pumps of collec-

tors are controlled with continuously speed

The circulation pump of collectors area (P1) is

started when temperature dierence of col-

lectors area (T1) and temperature in the tar-

get tank (T2 or T5) reaches the set value of

switching on and three-way valve is set in the

position to load appropriate tank. Tanks are

loaded according to the selected priority (de-

scription is later in this manual). The loading

pump (P1) is turned o when temperature dif-

ference between collectors area and loaded

tank falls below the set value of switching o

or temperature in the tank (T2 or T5) reaches

the set maximum value. The pump of the col-

lectors is controlled with continuously speed

adjustment.

There is a posibility to pump heat between

tanks (description is later in this manual).

External power supply (H2), which may be

electric heater, gas stove or components of

automation (pump, valve) is controlled on

the basis of respectively set parameters of

the controller, which are described later in

this manual and temperature reading of sen-

sor (T6) in the upper part of the buer tank.

In fact, the second tank may be respectively

hydraulically connected swimming pool.

Day

T1

T3

T2

H1

T4

1

P2 P

P1

System

Day

T1

T3

T2

H1

T4

T0

1

P2 P

P1 P0

System

Day

T1

T3

T6

T5

T2

H1

T4

1

P2 P

P1

System

2

H2

www.insbud.netwww.insbud.net 1312

English

English

fREsh WaTER ciRculaTiOn pump fREsh WaTER ciRculaTiOn pump

Controller is equipped with a fresh water cir-

culating pump control function (P2 pump).

Control of fresh water circulating pump can

be done in two ways:

1. Control based on return

temperature of fresh water

circulation. If fresh water

pump control is by this me-

thod, special symbol is visible on di-

splay. T4 sensor must be connected to

use this control method. Fresh water

circulation pump is turned on when

temperature on T4 sensor drops be-

low set value. It is recommended that

T4 sensor be placed on return pipe of

fresh water circulation or just before

last fresh water receiver. To this place,

fresh hot water will be pushed and

then fresh water pump will be turned

o. Just as water pipe in the circula-

ting pump will cool down, fresh water

circulation pump will be turned on.

Attention. If the temperature in the

upper part of tank No 1 (T3) is too

low to warm T4 sensor to desired

temperature, the circulation pump

will not be turned on.

2. Control based on time pe-

riods. f fresh water pump

control is by this method,

special symbol is visible on

display. Controller controls fresh water

pump according to periods of time:

work time and break time. E.g. Cir-

culation pump is turned on every 20

min for 3 min. Both periods are

adjustable.

eIf on display is not showed any of above

symbols, this means that fresh water cir-

culation pump is not controlled by con-

troller at all.

eIf fresh water circulation pump is wor-

king P2 symbol on display is ashing.

eFresh water circulation pump is control-

led only in set daily periods of time (only

between beginning and end of the pe-

riod). Often there is no need for circula-

tion pump control during the night or

when no one is in the building. Apart

from these periods circulation pump

never turns on.

To choose method of control of fresh water

circulation pump please:

Repeatedly press the button.

Press and hold button.

Repeatedly press the button to set

further parameters:

T4on - Value of temperature [ºC]

below which fresh water circula-

tion pump is turned on (parameter

adjustment available only for rst

method of control)

T4o - Hysteresis between turning

on and turning o fresh water cir-

culation pump (parameter adju-

stment only for rst method of

control)

on - Work time period [min] - how

long the pump has to work in one

cycle (parameter adjustment ava-

ilable only for second method of

control)

After selecting control method, you can set

the parameters of control function. Depen-

ding on selected control method there are

dierent parameters settings. To adjust para-

meters of function please:

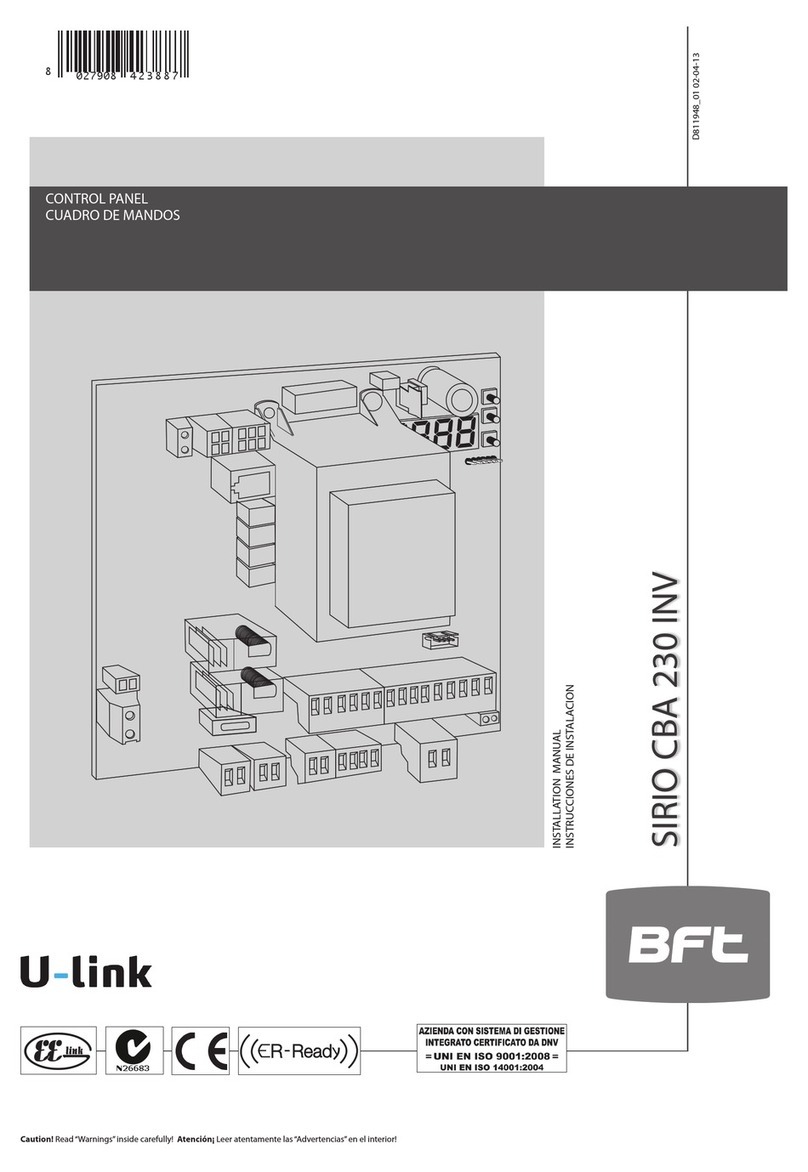

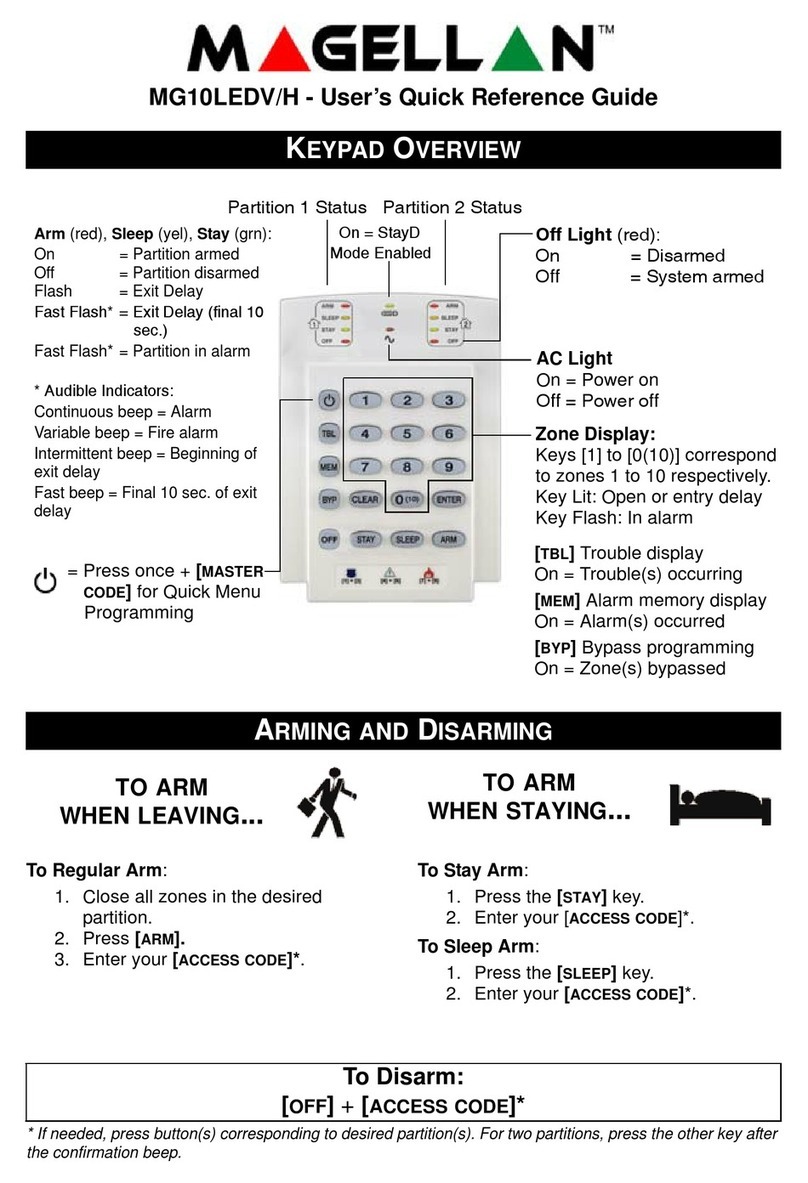

fOuRTh sysTEm - TWO cOllEcTORs aREas and TWO Tanks

Circulation pump of the rst collectors area

(P1) is started when temperature dierence

of the rst collectors area (T1) and tempera-

ture in the target tank (T2 or T5) reaches the

set value of switching on. Similarly, circula-

tion pump of the second collectors area (P0)

is started when temperature dierence of

the second collectors area (T0) and tempera-

ture in the target tank (T2 or T5) reaches the

set value of switching on. Circulation pumps

(P1 and P0) are working independently from

each other - the pumps may work simultane-

ously, don’t work at all or one pump works.

Three-way valve (R2) is set in the position to

load appropriate tank. Tanks are loaded ac-

cording to the selected priority (description

is later in this manual). Suitable loading pump

is turned o when temperature dierence

between the suitable collectors area and

the loaded tank falls below the set value of

switching o or temperature in the tank (T2

or T5) reaches the set maximum value. The

Pump of collectors is controlled with conti-

nuously speed adjustment.

There is a posibility to pump heat between

tanks (description is later in this manual).

This system is recommended when areas of

the collectors are working independently for

each other (east-west layout with a low slope,

there may be a case when two collectors are-

as are working simultaneously).

External power supply (H2) works as in the

third system.

In fact, the second collectors area may be re-

spectively hydraulically connected another

device which produces thermal energy for

example: heating replace.

In fact, the second tank may be respectively

hydraulically connected swimming pool.

Day

T1

T3

T6

T5

T2

H1

T4

T0

1

P2 P

P1 P0

System

2

H2

www.insbud.netwww.insbud.net 1514

English

English

Repeatedly press the button to set

further parameters:

T3 on - T3 comfortable tempera-

ture - up to this temperature rst

tank is heated by H1

T3o - Hysteresis for H1 - applica-

ble for T3

T3 P1 on - First period of H1: be-

ginning of period

T3 P1 o - First period of H1: end

of period

T3 P2 on - Second period of H1:

beginning of period

T3 P2 o - Second period of H1:

end of period

T6 on - T6 comfortable temperatu-

re - up to this temperature second

tank is heated by H2 (only for sys-

tems with two tanks)

T6 o - Hysteresis for H2 - appli-

cable for T6 (only for systems with

two tanks)

T6 P1 on - First period of H2: be-

ginning of period (only for systems

with two tanks)

T6 P1 o - First period of H2: end

of period (only for systems with

two tanks)

T6 P2 on - Second period of H2:

beginning of period (only for sys-

tems with two tanks)

T6 P2 o - Second period of H2:

end of period (only for systems

with two tanks)

ExTRa hEaTing BusTERs ExTRa hEaTing BusTERs

water in tanks (directly or by exchange coil),

etc.

Please note that the maximum load of H1

and H2 can not exceed values given in tech-

nical data of this manual. For bigger loads of

extra heating busters please use additional

external relays of adequate power.

Controller is designed for extra heating bu-

sters located in upper parts of tanks so that it

does not heat whole tank just top part of it.

If temperature in upper part of rst tank (T3)

drops below comfortable set value (for spe-

cic period of time) H1 device will be turned

on until it reach desired comfortable tempe-

rature (including hysteresis value).

Similarly H2 deviece is turned on when tem-

perature in upper part of second tank (T6)

drops below comfortable set value.

For each tank can be set two independent

periods of time (for a day) in which extra he-

ating busters are controlled (outside this pe-

riods extra heating busters are never turned

on).

To adjust parameters of the function please:

AH

Set desired value of the parameter.

Conrm set data.

OK

IIn some heating systems, it is desirable

that temperature at top of buer tank

(tank 2) was variable and dependent

on outside temperature (colder outside

- higher required temperature T6, war-

mer outside - lower required tempera-

ture T6). This eect can be achieved by

additional linear weather compensator.

Such controllers are available in our

oer.

fREsh WaTER ciRculaTiOn pump

BacTERiOlOgical pROTEcTiOn

BacTERiOlOgical pROTEcTiOn

ExTRa hEaTing BusTERs

o - Break time period [min] - ever

this time period circulation pump

will be turned on (parameter ad-

justment available only for second

method of control)

P1 on - Beginning of rst period of

work

P1 o - End of rst period of work

P2 on - Beginning of second pe-

riod of work

P2 o - End of second period of

work

Set desired value of the parameter. select temperature protection va-

lue (recommended value is 70 ºC)

or turn OFF protection function.

Conrm set data.

OK

Caring for health of user, the controller is

equipped with bacteriological protection of

fresh water tank, this feature prevents the

tank before legionell bacteria (legionnaires).

Optimal temperature for growth of the Le-

gionella pneumophila bacteria in the labo-

ratory is 37ºC. At higher temperatures these

micro-organisms proliferation decreases, at

46ºC it stops. Bacteria can survive at higher

temperatures, but decreases survival time of

several hours at 50ºC and of few minutes at

60ºC. At 70ºC bacteria is killed instantly.

Controller controls maximum temperature

which was in fresh water tank within 7 days. If

at that time temperature in fresh water tank

remained at low level there is a risk of bacte-

ria appearance. Therefore, if such a situation

occurs (temperature in fresh water tank for 7

days, will not increase above the set protect

value), controller is turning on an additional

source of heat (extra heating buster) H1 and

remains turned on until protection tempera-

ture will be achieved.

Bacteriological protection function is recom-

mended in all cases, but you can disable it if

necessary.

To enable / disable bacteriological protection

function please:

Controller is equipped with additional, inde-

pendent, strong relays H1 and H2, into which

you can connect an additional source of heat

(extra heating busters). This source of heat

may be e.g. electric heater, gas boiler heating

Press and hold button.

Conrm set data.

OK

hysTEREsis

Controller allows full adjustment of hystere-

sis for multiple functions.

Hysteresis is delay between turning on/o of

device Higher value of hysteresis means less

cycles of controlled device (e.g. pumps) and

thus increases the vitality of the device.

In normal conditions it is recommended to

set hysteresis value to 2 ºC (for liquid). Value

setting of hysteresis depends on where the

measurement is.

www.insbud.netwww.insbud.net 1716

English

English

IDisplay symbolically show valve posi-

tion and in addition some parts of in-

stallation are ashing. In this way, in

clear and unambiguous way user gets

information that what tank is being lo-

aded now.

lOading pumps

Generally speaking, controller loads tanks

where temperature is higher than in destina-

tion tank (with appropriate modications to

respective systems).

For all collectors areas (T0 or T1) you can set

turn on/o temperature dierence of pump

P0 or P1. Analyzed dierence refers to ap-

propriate collector area and destination tank

(This may be T2 or T5 depending on which

tank controller decides to load). Values of

these parameters should be set individually

to each installation.

According to a simplied method turn on

temperature dierence should be:

Temperature losses arising on installation (in

standard conditions of heating) on distance

between the analyzed collector area and far-

thest tank and this value increased by 4 ºC.

Conversely, turn o temperature dierence

of the same collector area should not be less

than above temperature losses.

For example, losses between collector and

tank are 4 ºC. Turn on temperature dierence

should be 8ºC and turn o temperature die-

rence should be 4ºC.

Controller has been additionally equipped

with control of re-loating pump P3. This fe-

ature is very necessary in many cases, an

example of this may be the typical situation:

chOicE Of Tank chOicE Of Tank

The issue concerned for two tank systems (3

and 4).

Controller selects which tank is loaded in two

ways (method of selection is determined by

user choice):

1. First tank priority method. As long

as rst tank (sensor T2) did not reach

desired optimal temperature, second

tank is not loaded (exception is case

when controller determines that the-

re is no chance to load rst tank to

desired optimal temperature). When

rst tank is loaded to optimal tempe-

rature, both tanks are loaded by most

eciency method.

2. Most eciency method. First and

second tank have equal rights. Con-

troller loading tank which will provi-

de greatest yield of energy in whole

system (NOTE! Please do not confuse

energy with temperature!)

To adjust parameters of this function please:

Press and hold button.

Repeatedly press the button to set

further parameters:

1. Optimal T2 temperature (for

rst method of choice)

2. Method of tank choice (by

former description)

Set desired value of the parameter.

Conrm set data.

OK

AH

AH

high TEmpERaTuRE pROTEcTiOn

high TEmpERaTuRE pROTEcTiOnfROsT pROTEcTiOn

Controller is equipped with tanks and

entire system protection against high

temperatures.

If T0 or T1 temperature exceeds set safety

temperature, respectively, P0 or P1 pump is

turned o as priority, so high temperature,

which may appear don’t damaged compo-

nents mounted on installation. These values

should be set at level which instantaneous

resistance to high temperature has on the

weakest part of solar installation.

If T2 or T5 temperature exceeds set safety

temperature, the corresponding tank is not

loading anymore (until temperature drops)

because of safety. These values should be

lower than maximum allowable temperature

for tank (this information should be given by

manufacturer of tank).

All of these security features may be disabled.

However for safety reasons, it is strongly not

recommended.

To adjust this functions please:

If controller nds that temperature in the col-

lectors (T0 or T1) drops below safe frost limit,

it will turn on loading pump (P0 or P1) with

maximum speed, to protect collector from

damage.

To adjust this function please:

eSetting range of safe frost limit is 5 ÷

-30ºC

eSafe frost limit value should be respon-

sible for freezing level of used liquid

(e.g. if it is glycol of freeze level -15ºC,

safe frost limit value should be at this or

higher value).

eIf solar system uses completely non-fre-

eze liquid, you can disable this function

(for only one or two areas).

IIf frost protection function is current

activated on display warning symbol

appears.

Set desired protection value (safe

frost limit) or turn OFF protection

function.

Conrm set data.

OK

Tmin Repeatedly press the button to set

appropriate collectors area.

select temperature protection va-

lue or turn OFF protection function

for choosen senso.

Conrm set data.

OK

Repeatedly press the button to

choose temperature sensor for

protection function setting.

Tmax

IIf frost protection function is current

activated on display warning symbol

appears.

www.insbud.netwww.insbud.net 1918

English

English

p0 and p1 pump spEEd p0 and p1 pump spEEd

re (T0 or T1) was always at constant

optimal level (eg 80ºC)

2. Based on optimal temperature dif-

ference between supply and return.

Speed of the pump is calculated that

dierence of temperature at collector

(T0 or T1) and destination tank (T2

or T5) Was always at constant optimal

level (optimal growth of temperature

for example 20ºC)

To properly determine how speed should

be calculated please ask manufacturer of

collectors. At time of writing this manual,

InsBud vacuum tube collector (classic and

SHCMV) have optimal performance with

method 2 and value of dierence with

20ºC. These values are default settings of

controller.

IController controls of pump speed,

which only has an impact on ow spe-

ed. Therefore rst of all please set opti-

mal ow speed for 80% speed of pump

by suitable balance valve placed just

before pump.

IController has been designed to con-

trol classic pumps currently available

on market. Due to variety of available

pumps we recommend using original

IB-Pump xx-60. By using this pump we

guarantee valid proportional control

of speed. Using other pumps (eg with

dierent strength, dierent type of en-

gine), you must reckon with possibility

that pump will be regulated in steps (not

proportional) or not extent as provided

for in controller algorithm.

Controller allows to adjust minimal speed

of P0 i P1 pump. This means that a suitable

pump will never work with lower speed than

set value. Setting minimal value for 100%

means that pump is only turned on and o

(no speed control).

Minimal speed value of pump is default set

to 10%. This value should be changed only in

two cases:

ePump with minimal speed makes vi-

bration and loud voice in system (very

specic situation for hydraulic installa-

tion). Then gradually increase the mini-

mum speed of the pump until vibration

stops.

eControlled pump is an advanced elec-

tronic pump, dynamically changing its

own speed by its own built-in controller.

In this case, set minimum speed value

to 100% and for safety of pump and its

controller we recommend to connect to

it by separated external relay.

To adjust parameters of this function please:

Tmax

Tmax

Press and hold button.

Repeatedly press the button to set

further parameters:

1. Speed control method (me-

thod common to both lo-

ading pumps according to

above description)

2. Optimal operating tempe-

rature (for rst method)

3. Optimal temperature die-

rence (for second method)

4. Minimal speed for P0

5. Minimal speed for P1

Set desired value of the parameter.

Conrm set data.

OK

lOading pumps lOading pumps

Solar system for whole day heat both tanks

completely (1 and 2). First tank is fresh water

tank. At evening residents of building cool

rst tank (hey used hot water). Normally, at

this point extra heating buster should be

turned on to heat fresh water tank (such as

electric heater – extra heating buster feature

has been previously described in this manu-

al). However, when second tank is still collec-

ted by solar energy, this energy is re-loaded

from second tank to rst fresh water tank (for

example by upper coil exchanger in fresh wa-

ter tank or by external exchanger). This featu-

re allows maximum solar energy use in who-

le system. When re-loading process is active

H1 extra heating buster is turned o.

Control of P3 re-loading pump is in same

way like P0 and P1 pumps, but for calcula-

tion controller using temperatures in the up-

per parts of both tanks (dierence between

T6 and T3).

IP0 and P1 pump working with variable

speed. This speed is calculated by con-

troller (more details later in this manu-

al). P3 pump works as turn on/o with

constant speed.

IIf any pump is working its symbol on di-

splay is ashing.

To adjust parameters of this function please:

Repeatedly press the button to set

further parameters:

1. Turn on dierence for P0

2. Turn o dierence for P0

3. Turn on dierence for P1

4. Turn o dierence for P1

5. Turn on dierence for P3

6. Turn o dierence for P3

Set desired value of the parameter.

Conrm set data.

OK

∆T

p0 and p1 pump spEEd

As you know the speed of uid ow through

the collector is not neutral. If ow speed is too

high, the collector will not be operated with

maximum eciency. If too low, the collector

may fall within the zone of steam.Set of ow

speed at a constant level is only simple so-

lution because this ow speed is optimal for

conditions that were at the time of ow spe-

ed adjustment. If intensity of solar radiation

will change, collector return temperature will

changes automatically also other parameter

will change, after that optimal ow speed (at

which collector has highest eciency and

produces the most energy for current situ-

ation) is very dierent than one previously

set.

Only solution to this problem is automatic

control and ability to change ow speed of

liquid through collector. IB-Tron 4000SOL

controller it is equipped with such a possibi-

lity. Controller controls loading pumps speed

in proportional way so solar collectors are al-

ways working with its highest eciency.

In addition, due to fact that on market there

are many types of solar controllers (and other

equipment working on a similar principle)

calculation of optimal speed can be in two

methods:

1. Based on optimal operating tempe-

rature of collector. Speed of pump

is calculatet that supply temperatu-

www.insbud.netwww.insbud.net 2120

English

English

addiTiOnal funcTiOns sETTing

kEyBOaRd lOck

facTORy sETTings

TEsT funcTiOns

To adjust parameters of additional functions

(SMART START, GUARD, HOLIDAYS) please:

After properly setting of controller it is possi-

ble to lock keyboard to prevent setting mo-

dication. When controller is locked it does

not respond to keyboard pressing and on di-

splay is visible symbol of lock. To lock/unlock

keyboard please:

To reset controller and go back to factory set-

tings please:

Controller has a relays test function. Each re-

lay can be manually turned on/o and for P0

and P1 pump it is possible to set test speed.

To activate relay test function please:

∆T

∆T

Press and hold button.

Repeatedly press the button to set

further parameters:

1. SMART START for P0

2. SMART START for P1

3. GUARD function

4. HOLIDAY function (method

of work according to above

description).

By repeatedly pressing button you

can change testing relay.

Set desired value of the parameter.

Set relay status.

Conrm set data.

Conrm set data.

OK

OK

∆T

OK

Press and hold two buttons

simultaneously.

Press and hold two buttons

simultaneously.

Press and hold two buttons

simultaneously.

AH

hOlidays

P3 pump is turned on (to cool tanks)

2. Winter holidays. Excluded from ope-

ration is only the rst tank (fresh wa-

ter tank). It will be not heated by so-

lar system. Re-loading P3 pump and

fresh water circulation P2 pump ne-

ver turn on. The same with H1 extra

heating buster. Second tank (buer

tank) Works normally so solar energy

is available for use in central heating

process. H2 extra heating buster rów-

nież działa wg podstawowych kryte-

riów, Also works normally to not di-

srupt process of building heating .

p0 and p1 pump spEEd

ITo see current speed of the pump

please:

AH

Press and hold two buttons simul-

taneously. On display you will see

current speed of P0 pump.

Press and hold two buttons simul-

taneously. On display you will see

current speed of P1 pump.

smaRT sTaRT

Distribution of temperature in collector is

not linear and also sensor in collector is not

physically placed in theoretical ideal place.

Therefore in fact often happens that collec-

tor, could start work earlier few minutes than

this happened in practice. While in days with

high solar radiation this energy losses arising

from this delay is negligible, but in winter

days with lower solar radiation there is quite

a lot of this energy losses.

To solve this problem and increase energy

output IB-Tron 4000SOL controller is equip-

ped with a special algorithm which analyze

in dynamic, long term way behavior of indi-

vidual collectors areas. If controller comes to

conclusion that above situation may occurred

following several attempts to „push” heat to

sensor (with minimum speed loading pump

is turned on for short period of time), each

reaction is further studied by controller. If ac-

tion do not occur valid result (which means

that there is no conditions for load heat) con-

troller cease testing for other period of time

(this period is dynamic changeable).

Thanks to SMART START function signi-

cantly increases system eciency. For each

collector area this function is implemented

smaRT sTaRT

separately.

SMART START function May be disabled if

needed.

guaRd

Some of devices in whole system does not

work all year round. If the valve or pump is

not working for a long period of time it may

be damaged. Therefore it is important that

each device was periodically turned on even

when there is no need of it by logic of whole

system point of view.

This protective function of the fully is GUARD

function. It monitors work of all devices

connected to the controller.If any device was

not turned on for two weeks GUARD function

turn it on for one minute (in case of valve is a

full cycle of closing and opening).

GUARD function May be disabled if needed.

hOlidays

In case of leaving building for a longer period

oftime,itisdesirabletosetcontrollerinspecial

holiday mode, which modies principle of

system operation. Holiday function starts

and stops in manual way (after arrival from

holidays this function must be manually

disable). If you enable holiday function you

can see information about this on display.

Controller is equipped with two holiday

function methods, which can be selected

depending on situation:

1. Summer holidays. Extra heating bu-

sters H1 and H2 are strictly turned o

(never will be turned on). If tempera-

ture in any tank exceeds 40ºC P2 and

www.insbud.netwww.insbud.net 2322

English

English

ERRORs

On display may appear such symbols that’s

means:

eLO -temperature at current sensor is be-

low lowest measuring range.

eHI - temperature at current sensor is

above highest measuring range.

e--- - current sensor is not connected or

is damaged.

IIn an error occurs on display you will

warning sign.

shORT manual

shORT manual

Calibration. Press and hold two

buttons simultaneously.

By repeatedly pressing button you

can change calibrated sensor.

Tmin

Fresh water circulation pump pa-

rameters. Press and hold button.

Repeatedly press the button to set

further parameters:

1. Circulation pump turn on

temperature (method 1)

2. Work time for P2 [min] (me-

thod 2)

3. Break time for P2 [min] (me-

thod 2)

4. Beginning of rst period of

work

5. End of rst period of work

6. Beginning of second period

of work

7. End of second period of

work

Extra heating busters. Repeate-

dly press the button to set further

parameters:

1. Comfortable temp. T3

2. Hysteresis for H1

3. 1-st period H1: beginning

4. 1-st period H1: end

5. 2-nd period H1: beginning

6. 2-nd period H1: end

7. Comfortable temp. T6

8. Hysteresis for H2

9. 1-st period H2: beginning

10. 1-st period H2: end

11. 2-nd period H2: beginning

12. 2-nd period H2: end

AH

Select temperature protection

value.

Bacteriological protection. Press

and hold button.

Tmin Frost protection. Repeatedly

press the button to set appropriate

collectors area.

High temperature protection.

Repeatedly press the button to

choose temperature sensor for

protection function setting.

Tmax

Temperature units. Press and

hold two buttons simultaneously.

Tmin

Tmax

Software version. Press and hold

two buttons simultaneously.

Tmax

OK

∆T

TEsT funcTiOns

In addition, there is possible to test logic of

system work by sensor test function. When

this function is on, sensors no longer making

real measurement user are able to simulate

absolute values from controller keyboard

controller (simulate value of sensor).

To activate sensor test function please:

Press and hold two buttons

simultaneously.

By repeatedly pressing button you

can change testing sensor.

Set sensor status.

Conrm set data.

OK

nETWORk

TEmpERaTuRE uniTs

Controller is also available in versions desi-

gned to work in network.

There are versions based on RS-485 or Ether-

net communication.

Issues relating to network communication

are contained in separate manual for IBS

system.

Controller supports two temperature units:

ºC and ºF.

To change temperature units please:

Press and hold two buttons

simultaneously.

Tmin

Tmax

If you want update your controller to ne-

wer version please contact us or one of our

partners.

sOfTWaRE vERsiOn

InsBud company supports policy of develop-

ment. Thats why rights to making changes

and improvements in products and manuals

without prior notice reserved!

Our company is open to all suggestions to

improve our controllers. If you have any idea

to add new features or require unusual solu-

tions, please contact us.

This manual applies to controller with so-

ftware version number

011

If your controller has other software version in

operation and functionality may be dierent

from information contained in this manual.

To check software version please:

Press and hold two buttons

simultaneously.

Tmax

OK

www.insbud.netwww.insbud.net 2524

English

English

WaRRanTy

eWarranty is given for 24 months from

date of purchase of goods.

eAny defect disclosed in warranty period

will be removed within 21 working days,

counting from date of adoption of go-

ods for service.

eIn need of import goods or parts from

abroad, repair time is extended by time

required for their transportation.

eCustomer provides product to service at

their own cost.

eAt time of repair service will not provide

buyer replacement product

eWarranty repairs will be made upon pre-

sentation of properly and legibly lled

your hardware warranty card, signed by

guarantor and with sale document

eWarranty covers only defects arising

from causes inherent in goods. They

are not covered damage resulting from

external causes such as: mechanical in-

jury, pollution, ooding, weather, impro-

per installation or improper wiring and

operations. Warranty does not apply in

case customer’s unauthorized repairs,

changes in software (rmware) and de-

vice formatting.

eDue to natural material use, some of

them are not covered by warranty (for

example: cables, battery, charger, micro

switches, buttons).

eIn event of unjustied claims for warran-

ty repair, all additional cost are on custo-

mer’s side.

eService has right to refuse to perform

warranty repairs for following: dieren-

ces between documents and goods

marks, make repairs on their own by

customer, changes in product construc-

tion without authorization. This case

warranty is not valid anymore.

eIf it is not possible to test product be-

WaRRanTy

fore its purchase (sale at distance), it is

possible to return goods within 10 days.

Returned goods cannot bear signs of

exploitation, it must contain all elements

with which it was delivered.

eIn the case of return of purchased go-

ods all shipping costs are on buyer side.

Before return of goods please contact

with seller.

eTerms of warranty may be changed by

local InsBud company partner.

shORT manual

Choice of tank. Press and hold

button.

Repeatedly press the button to set

further parameters:

eoptimal T2 temperature (for 1

method)

eMethod of choice:

1. 1-st tank priority

2. Most eciency

shORT manual

Loading pumps. Repeatedly

press the button to set further

parameters:

1. Turn on dierence for P0

2. Turn o dierence for P0

3. Turn on dierence for P1

4. Turn o dierence for P1

5. Turn on dierence for P3

6. Turn o dierence for P3

∆T

Tmax

Tmax

Pump speed. Press and hold

button.

Repeatedly press the button to set

further parameters:

1. Method of speed control

(1 - based on optimal work

temperature; 2 – based

on optimal temperature

dierence)

2. Optimal work temperature

(1-th method)

3. Optimal temperature die-

rence (2-nd method)

4. Minimal P0 speed

5. Minimal P1 speed

AH

P0 P1

Pump speed view:

∆T

∆T

Additional functions. Press and

hold button.

Repeatedly press the button to set

further parameters

1. SMART START for P0

2. SMART START for P1

3. GUARD

4. HOLIDAY (1 – summer holi-

days; 2 – winter holidays)

∆T

OK

Keyboard lock. Press and hold

two buttons simultaneously.

Factory settings. Press and hold

two buttons simultaneously.

By repeatedly pressing button you

can change testing relay.

Relay test. Press and hold two

buttons simultaneously.

AH

Logic test. Press and hold two but-

tons simultaneously.

By repeatedly pressing button you

can change testing sensor.

AH

AH

ul. Niepodlegości 16a

32-300 Olkusz, POLAND

tel/fax +48 (32) 643-26-87

e-mail: insbud@insbud.net

Table of contents

Popular Control Panel manuals by other brands

Magellan

Magellan MG10LEDV User quick reference guide

AEG

AEG S 64.9 L Instructions for use

Steamist

Steamist TC-135 Installation and operating instructions

Menvier Security

Menvier Security TS2500 Operator's manual

EasiWise

EasiWise Standard Quick start user guide

Rosslare

Rosslare HLX-40 Installation and programming manual