3. MAINS CONNECTION

The mains supply should be exclusive to the fire alarm as detailed in BS 5839 pt. 1. A plug and socket is not satisfactory.

We recommend that a switched double pole fused spur unit is used and marked FIRE ALARM DO NOT SWITCH OFF, and this

should be solely for the use of the fire alarm. This also provides a method of isolating the supply for maintenance purposes.

The mains supply should only be connected to the terminal block marked MAINS.

4. BATTERY CONNECTION

Connect the red battery wire to the red battery terminal (+), connect the black battery wire to the black battery terminal (-).

5. CLASS CHANGE

The sounder circuits can be operated by an external volt free contact. A short circuit at this terminal will activate non-latching

sounders, (no indication will show on the fire alarm panel) This is sometimes used for schools at Class Change times.

6. OUTPUTS

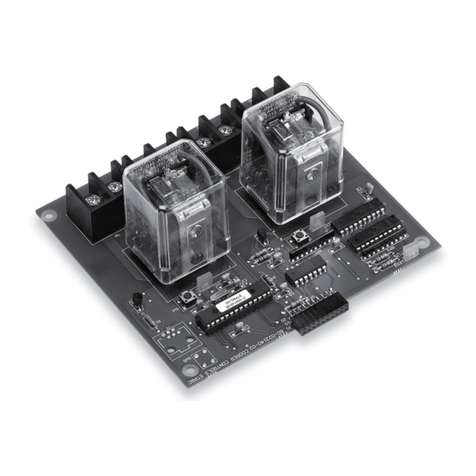

6.1. FAULT RELAY

The fault relay provides a set of fused volt free changeover contacts, which operate in the event of a fault condition occurring,

these contacts are not monitored.

For connection details refer to connection diagram on page 2 or refer to PCB.

6.2. FIRE RELAY

The fire relay provides a set of fused volt free changeover contacts, which operate in the event of a fire condition occurring,

these contacts are not monitored.

For connection details refer to connection diagram on page 2 or refer to PCB.

7. RECOMMENDED CABLE TYPE AND SIZE

Mains Wiring:

1.0mm2- 1.5mm2Mineral insulated or similar fire proof cable.

Zone Wiring:

1.0mm2- 1.5mm2Mineral Insulated or similar fire proof cable.

Sounder Wiring:

1.0mm2- 2.5mm2Mineral Insulated or similar fire proof cable.

INSTALLATION GUIDE

DO NOT USE A HIGH VOLTAGE INSULATION TESTER WHEN WIRING IS CONNECTED TO ANY ELECTRONIC

EQUIPMENT.

Do not use excessive force when tightening the screws on the terminal blocks.

8. INSTALLATION CHECK

Panel: With EOLM-1 fitted in the panel, connect the mains and battery and check that the green power on indicator is lit and

no other indicators are showing.

Check that the panel operates correctly by entering the correct access code, then silence, then reset, check that all the indicators

show momentarily.

Zone circuits: Disconnect the mains and battery. Wire in the zone circuits one at a time, with the EOLM-1 transferred to the

end of the zone (check polarity) but with no sensors plugged in.

Power up the panel by connecting the mains and battery. Check that the panel indicates a zone fault. Check that the furthest

call point operates correctly by using one of the plastic test keys provided. (ie. the fire alarm goes into the fire condition).

Reset the panel. Complete all zone circuits as above.

Fit all detectors and check that the panel shows healthy (ie. No faults showing). If there is a problem, check the faulty circuit

for continuity, correct polarity and the polarity of the EOLM-1. DO NOT USE A HIGH VOLTAGE INSULATION TESTER.

Sounder circuits: Disconnect the mains and battery. Wire in one of the sounder circuits transferring the end of line resistor,

to the end sounder in that circuit.

Power up the panel as before and verify that no fault shows. If there is a fault, check the circuit for continuity and polarity.

DO NOT USE A HIGH VOLTAGE INSULATION TESTER.

Repeat as above for next sounder circuit.

Momentarily operate a call point using one of the plastic test keys provided, and check that all the sounders operate, and the

fire indicator shows on the fire alarm control panel. Reset the panel.

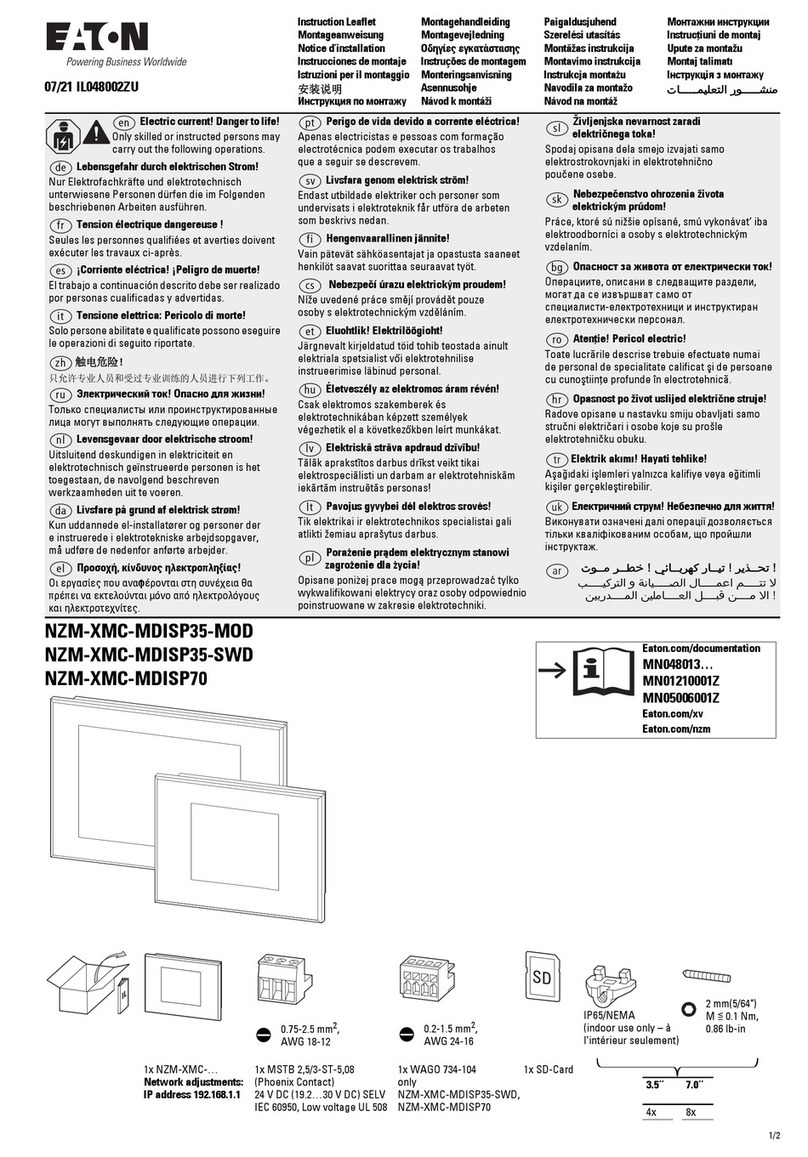

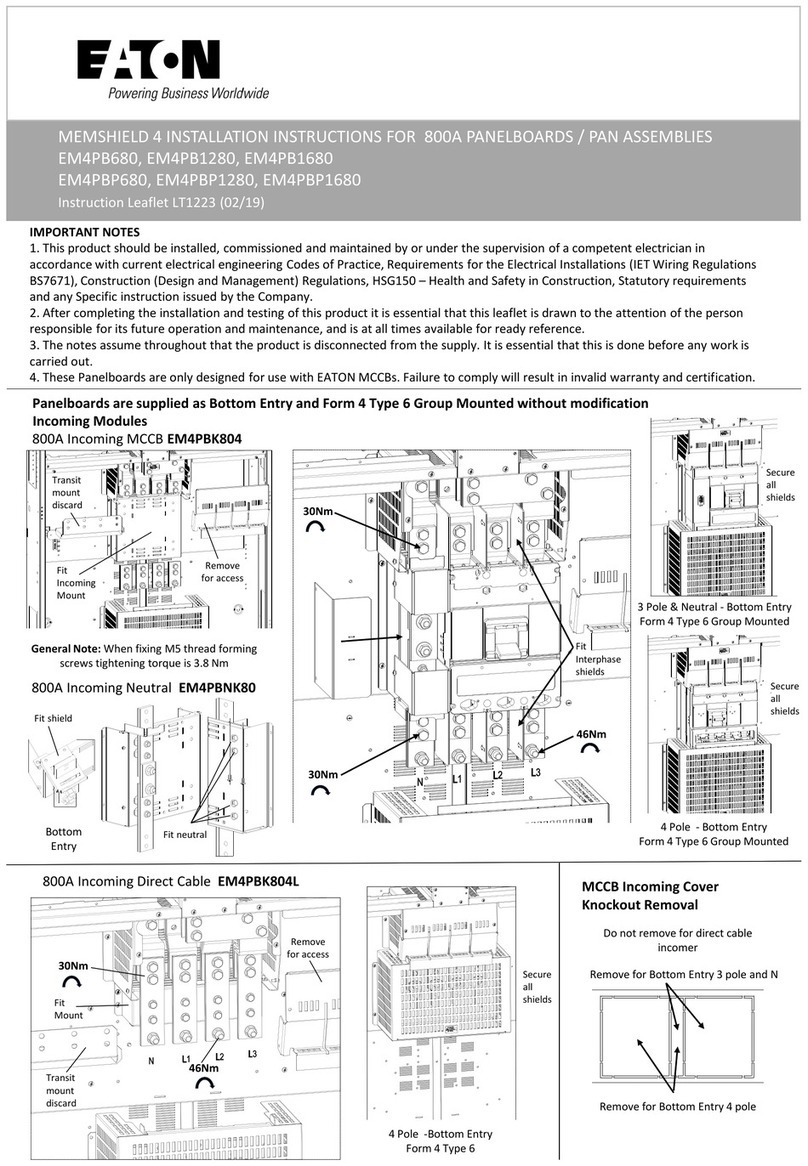

2. WIRING INSTRUCTIONS

Refer to diagram below for connection of external circuits to fire panel.

For individual components such as detectors, callpoints and sounders, refer to the instructions supplied with the components.

2.1. ZONE WIRING

The zone circuit must be terminated with the EOLM-1 (supplied with panel connected to zone terminals), taking care to observe

the correct polarity. Do not fit any other component such as an end of line resistor to the zone circuit, The EOLM-1 should be

removed from the panel and fitted to the furthest component on each zone, it is used to monitor the zone wiring for open or

short circuits and to detect removal of detectors.

The EOLM-1 works in conjunction with a diode fitted in each sensor base, so that all call points continue to operate, even if all

sensor heads have been removed.

Zones can be wired with detectors and callpoints wired in any order, the EOLM-1 can be sited in a break glass call point or in a

detector base.

Wiring for each zone should be a single continuous radial circuit, spurs and tees are not permitted.

If any zones are to be unused, the EOLM -1 end of line device should be left in place in the panel otherwise a zone fault will be

indicated. Perform installation check on panel before connecting zone circuits. See section 8.

2.2. SOUNDER WIRING

Each sounder circuit is monitored for open/short circuit and terminated with a 6800 ohm resistor (supplied with panel

connected to sounder terminals.)

This resistor should be removed from the panel and fitted to the final sounder in the circuit, it is used to monitor the integrity

of the external wiring.

The 4200 series fire alarm control panels have two separately protected, monitored sounder circuits for use with polarised and

suppressed bells or sounders, suppressed relays and suppressed strobes.

Electrical insulation tests should not be carried out if the cables are connected to the fire alarm panel, detectors, callpoints, bells,

sounders or strobes.

The wiring for each sounder circuit is to be a radial circuit with the end of line resistor fitted at the end of that circuit, no spurs

or tees are permitted. (Refer to wiring diagrams and instructions enclosed with sounders, for details of connection).

Perform installation check before connecting sounder circuits. See section 8.