Instrumentation and Engineering Services VFR 1 User manual

Instrumentation and

Engineering

Services, Inc.

VFR 1 Recorder

USER MANUAL

Tel. 850-244-2128 151 Mary Esther Blvd., Suite 311

Fax 850-244-7979 Mary Esther, FL 32569

Tel: 1-850-515-1244

Fax: 1-850-515-1245

IES, Inc.

7552 Navarre Parkway Suite 42

Navarre FL 32566

VFR 1............................................................................................................................... 1

Overview...................................................................................................................... 1

Specifications............................................................................................................... 1

Electrical .................................................................................................................. 1

Power ....................................................................................................................... 2

Physical.................................................................................................................... 2

Operational Theory ...................................................................................................... 2

Control Logic........................................................................................................... 2

Analog-to-Digital (A/D) Converter ......................................................................... 3

Memory.................................................................................................................... 3

Micro-controller....................................................................................................... 3

Oscillator Speed....................................................................................................... 4

Amplifier Gains ....................................................................................................... 4

Amplifier Bias.......................................................................................................... 4

Triggering Modes..................................................................................................... 4

Recorder Operational Modes ....................................................................................... 5

Sleeping.................................................................................................................... 5

Standby .................................................................................................................... 5

Recording................................................................................................................. 5

Awaiting T1 ............................................................................................................. 5

Data Downloading ................................................................................................... 5

Interface Signals Location and Description............................................................. 5

Operational Software ....................................................................................................... 9

VFR Software Program – Main Menu......................................................................... 9

Page 1 of the Main Menu......................................................................................... 9

Page 2 of the Main Menu....................................................................................... 20

Page 3 of the Main Menu....................................................................................... 31

VFR Software Program – Display Data..................................................................... 35

Encapsulation................................................................................................................. 47

Epoxy-Casting............................................................................................................ 47

Compound Formulation......................................................................................... 47

Mold Preparation ................................................................................................... 47

Container Preparation ............................................................................................ 47

Compound Preparation .......................................................................................... 48

Compound De-aeration.......................................................................................... 48

Compound Application.......................................................................................... 48

Compound Cure..................................................................................................... 48

Recorder Packaging ................................................................................................... 49

Epoxy Encapsulation ............................................................................................. 49

Glass Bead Encapsulation...................................................................................... 49

Paraffin Encapsulation........................................................................................... 49

Appendix A.................................................................................................................... 51

Example VFR Settings............................................................................................... 51

Appendix B .................................................................................................................... 56

VFR 1 Signal Locations............................................................................................. 56

VFR 1

Overview

The VFR1 is a reusable, compact, high shock, solid-state, recorder designed to acquire

data in hostile test environments. The epoxy-encapsulated unit was designed to fit inside

of a general-purpose bomb fuze booster cup. By installing the recorder in the place of the

fuze booster and lead, the user is able to record the impact acceleration event as well as

several analog and eight digital events.

The VFR1 can be programmed for various trigger modes, filter frequencies, sample rates,

amplifier gain, and amplifier bias. All of the programmable features are available to the

user through a menu-driven computer operating system (operating in a Windows

environment). On-line computer aided assistance is available to the user when setting-up

the amplifier gain and bias. The user has a visual display of the recorder range and zero

settings rather than relying on calculations.

Low power consumption allows the test instrumentation to be built weeks before the test

and extends the time for data retrieval. After a test, the recorder data is retrieved using a

personal computer and the same computer operating system that is used to program the

recorder.

Specifications

Electrical

Number of Programmable Analog Channels.......................................................................1

Number of Buffered Analog Channels ................................................................................2

Number of Digital Channels ................................................................................................8

Analog Channel Sample Rate (High Speed)...........................................................57.8 kHz

Analog Channel Sample Rate (Low Speed 0) ........................................................28.9 kHz

Analog Channel Sample Rate (Low Speed 1) ..........................................................7.2 kHz

Analog Channel Sample Rate (Low Speed 2) ..........................................................1.8 kHz

Analog Channel Sample Rate (Low Speed 3) ...........................................................451 Hz

Analog Channel Sample Rate (Low Speed 4) ...........................................................112 Hz

Analog Channel Sample Rate (Low Speed 5) .............................................................28 Hz

Analog Channel Sample Rate (Low Speed 6) ...............................................................7 Hz

Analog Channel Sample Rate (Low Speed 7) ............................................................1.8 Hz

Analog Channel Signal Bandwidth......................................... Selectable 2.3kHz or 9.3kHz

Analog Channel Amplitude Resolution ..................................................... 256 digital steps

Analog Channel (Programmable) .......................................... Filter8-pole elliptic low-pass

Total Storage Capacity.........................................................524,288 data words (512K x 8)

External Trigger 1 Signal.................................................................... 3.0 to 10.0-volt pulse

External Trigger 2 Signal...................................................................... 2.3 to 3.3-volt pulse

External Trigger 2 Input Impedance.................................................................10,000 ohms

Internal Trigger ...................................................................................Slope Programmable

Internal Trigger ................................................................................... Level Programmable

1

Power

Supply Voltage...................................................................................................6 to 15 volts

Standby Current ............................................................................ 450 micro amps (typical)

Operating Current ..............................................................................10 milliamps (typical)

Data Retention Current ................................................................. 450 micro amps (typical)

Sensor Reference Voltage........................................................................................3.3 volts

Sensor Supply Current (Per Channel)...........................................20 milliamps (maximum)

Physical

Shock Survivability................................................................................................100,000 g

Temperature Range.........................................................................................32oF to 160oF

Temperature Range (With Screening) .......................................................... -65oF to 160oF

Encapsulation.............................................................................................................. Epoxy

Size (VFR #1) ........................................................................................See Figure 1 Below

Figure 1. VFR 1 Size

Operational Theory

Figure 2 shows a simplified block diagram of the VFR1. The major components of the

recorder are the control logic, the memory, the analog-to-digital (A/D) converter, and the

micro-controller. Following is a description of each functional block.

Control Logic

The control logic provides the control logic that enables data collection when the recorder

is triggered, places the recorder in a data retention mode when the incoming data has

filled the memory, and enables an external computer to interrogate the memory to extract

the data. The control logic also provides correct timing for writing the data into memory

and sequentially addresses all available memory locations.

2

Figure 2. Block Diagram of VFR 1

Analog-to-Digital (A/D) Converter

The recorder utilizes a CMOS 8-bit A/D converter for digitizing data. The control logic

selects the sampling rate. The A/D contains a multiplexer that is controlled by the control

logic. The multiplexer sequentially switches the A/D input through all of the available

channels, samples the channel output, digitizes the sampled level, and then places the 8-

bit digital word on the data bus for transfer to memory.

Memory

The data storage device used is a CMOS low-power static, random access memory. The

recorder storage capacity is 524,288 data words (512K x 8 bits). Each sample digitized

by the A/D is an eight-bit word and is stored as a data word in the memory. The A/D

sequentially samples each analog channel, generating a data word for each and writing it

in memory. Once all of the analog channels have been sampled, an addition eight-bit

data word is written in memory. This data word contains the information from the eight

digital channels.

Micro-controller

The micro-controller is the brain that enables the recorder flexibility. The laboratory

computer communicates with the recorder through the micro-controller. The micro-

controller accepts recorder configuration data from the laboratory computer through an

RS-232 serial link. The configuration data contains instructions for oscillator speed,

amplifier gains, amplifier bias, and triggering modes.

3

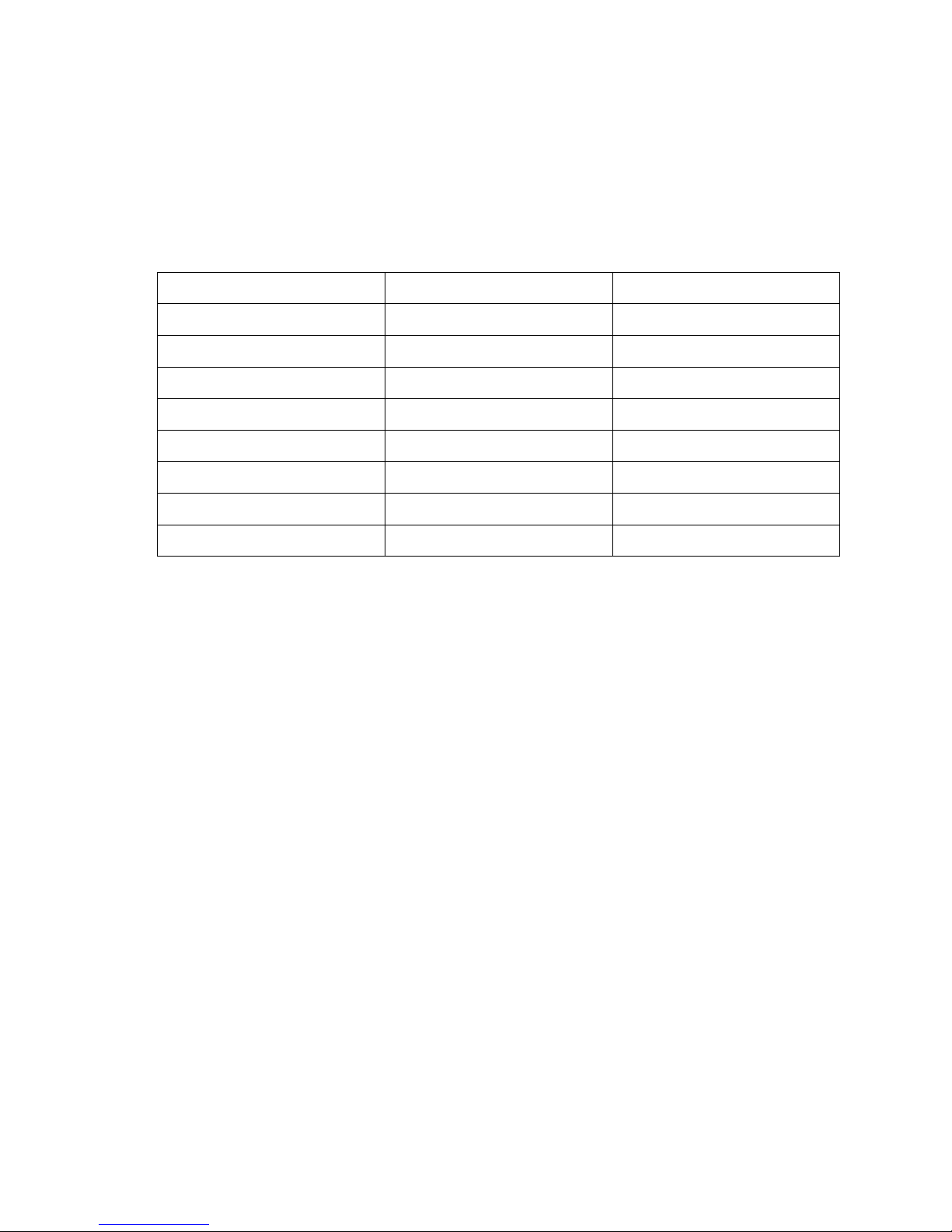

Oscillator Speed

The oscillator speed controls the recorder sample rate. The VFR1 has one high speed and

eight low speed options for the oscillator. The low speed is programmable and can be

changed between tests. Table 3-1 lists all of the available sample rates, the sample

periods, and the recording time available at that rate.

Amplifier Gains

SAMPLE RATE SAMPLE PERIOD RECORDING TIME

57.8 kHz .017 mSeconds 2.268 Seconds

28.9 kHz .035 mSeconds 4.535 Seconds

7.2 kHz .138 mSeconds 18.141 Seconds

1.8 kHz .553 mSeconds 72.566 Seconds

450 Hz 2.215 mSeconds 4.838 Minutes

112 Hz 8.858 mSeconds 19.351 Minutes

28 Hz 35.433 mSeconds 77.404 Minutes

7 Hz 141.730 mSeconds 5.160 Hours

Table 1. Oscillator Sample Rates and Recording Times

The amplifier gain sets the full-scale level of the data window. It is similar to setting the

volts/division on a laboratory oscilloscope. The gain adjustment allows the user to

reconfigure the recorder for different test requirements and different sensors. Unlike

other commercially available recorders requiring gain calculations using complex

formulas followed by gain settings through the installation of a calculated resistor value,

the VFR1 is programmable using a laboratory computer.

Amplifier Bias

The amplifier bias adjustment is similar to adjusting the vertical position control of a

laboratory oscilloscope. The bias adjustment allows the user to select the zero location of

the data amplitude. The bias adjustment allows the user to reconfigure the recorder for

different test requirements and different sensors.

Triggering Modes

The user is able to program the recorder, for either the standard G-switch triggering

and/or an auto-triggering mode. In the auto-trigger mode, the micro controller monitors

the recorder channel zero output and generate a trigger 2 signal when the signal crosses a

bit threshold. The bit level selection for triggering the recorder when in the auto-trigger

mode is programmable by the user so the level can be changed between tests or it can be

disabled. The auto-trigger allows the recorder to be triggered in the same manner that a

laboratory oscilloscope is triggered. If a G-switch is attached to the normal trigger pads,

4

the recorder is triggered by the first signal generated, either the G-switch or the au

trigger. The G-switch ca

to-

nnot be disabled; it must be removed to prevent it from

gering the recorder.

ecorder Operational Modes

ta downloaded while the

rial link is connected, but the analog section remains off.

the

ctive, so signals can be connected to the recorder to test/calibrate the analog section.

d

not filled up), the “Stop” button

ust be pressed before the data can be downloaded.

rify

status indicates it is “Awaiting External T1”, the

rial connection can be removed.

rd

nd with a cross hair, obtain timing and amplitude information and print the display.

ll of the VFR1 signal locations. Following is a description of each

al.

trig

R

Sleeping

Sleeping indicates the recorder is in the low current mode. It draws 10-14 mA while the

serial link is connected. When the serial is disconnected, the recorder draws under 500

uA and is dormant. The recorder can be programmed, and da

se

Standby

Standby indicates the analog section of the recorder is powered, but data is not being

stored into memory. This mode is useful for measuring the data collection current of

recorder because the sensors are powered in this mode. Also, the analog outputs are

a

Recording

Recording data indicates the analog section is on and the recorder is actually storing data

into memory. When the memory is full, the recorder will automatically turn itself off and

go into the “Sleep” mode to conserve power. If the recorder is recovered after a test, an

it is still in the “Recording” data mode (memory was

m

Awaiting T1

Awaiting External T1 indicates the recorder is in the “Sleep” mode, waiting for the

correct external 3.3-volt pulse on the T1 pin of the recorder to wake it. The external pulse

is ignored when the serial link is on. When T1 occurs, the recorder will automatically go

into the “Recording” mode, sampling at the slow sampling rate. Note: If there is a sensor

error, the recorder will be shut down into the “Standby” mode. So it is recommended that

the recorder be put into the “Recording” data mode on the bench, before the test, to ve

proper operation. After the recorder

se

Data Downloading

Data transfer for the VFR recorder is accomplished using the same menu-driven

computer operating system that is used to program the recorder. The software is a user

friendly, menu driven program that allows the user to retrieve, display, and store data

records. In addition, the software enables the user to magnify portions of the data reco

a

Interface Signals Location and Description

Figure 3 illustrates a

input/output sign

5

DIG 0 to DIG 7

Digital channel inputs with CMOS inputs impedance. Do not apply a voltage greater

than Vcc or less than 0 volts to these inputs.

amplifier. Do not apply a voltage

reater than Vref or less than 0 volts to this input.

al amplifier. Do not apply a voltage greater than Vref

or less than 0 volts to this input.

CH 0 +

Non-inverting input to the channel 0 differential amplifier. This signal is connected

directly to the non-inverting input of an operational

g

CH 0 –

Inverting input to the channel 0 differential amplifier. This signal is connected directly to

the inverting input of an operation

Figure 3. VFR 1 Input / Output Signal Location

CH 1 IN

Non-inverting input to the channel 1 operational amplifier. This signal is connected

directly to the non-inverting input of an operational amplifier. Do not apply a voltage

greater than Vref or less than 0 volts to this input.

6

CH 2 IN

Non-inverting input to the channel 2 operational amplifier. This signal is connected

directly to the non-inverting input of an operational amplifier. Do not apply a voltage

greater than Vref or less than 0 volts to this input.

CH 0 OUT

CH O OUT is the recorder channel 0 amplifier output. This signal is also the input for

the analog multiplexer. Use only high impedance instruments to measure this signal.

OSC OUT

OSC OUT is the output signal of the internal recorder oscillator. The frequency of the

oscillator out signal is the sampling rate of each channel. This output is not active when

the recorder in a sleep mode.

Vcc

Vcc is the regulated power supply output. This output will source 10 milliamps for an

external load.

Vref

Vref is the regulated power supply for powering sensors. This power supply is only

active while the recorder is acquiring data. This output will source 30 milliamps.

GND

GND is the power and signal ground.

SW GND

This signal is a switched ground. When the recorder is collecting data, the SW GND is at

ground potential. When the recorder is in the sleep mode, the SW GND is at Vcc level.

This single can only source/sink 1 milliamp.

BATT

BATT is a connection for an external battery. This input is not diode-coupled to any of

the other battery connections and should not be used in conjunction with any other

battery. This connection is intended to power the recorder when only one battery is used.

Use of this connection for powering the recorder eliminates the diode voltage drop that

the other battery connections have.

BATT 1

BATT 1 is a connection for an external battery. This input is diode-coupled to Battery 2

and External Power Input.

BATT 2

BATT 2 is a connection for an external battery. This input is diode-coupled to Battery 1

and External Power Input.

7

EXTERNAL POWER INPUT

EXTERNAL POWER INPUT is a connection for an external battery. This input is

diode-coupled to Battery 1 and Battery 2 inputs. This input is used by the interface box

for application of external power during the recorder programming and data retrieval.

TRIG 1

TRIG 1 is a latched input signal that provides a method of initiating the recorder data

collection operation. This trigger signal is a positive pulse that can be between the

voltage range of 3.0 to 10-volts.

TRIG 2

TRIG 2 is a latched input signal that provides a method of initiating the recorder high-

speed data collection operation. This is a CMOS input with a 10K ohm pull-down

resistor. Do not apply input signals greater than 3.3-volts to this input.

RS232-TX

RS232-TX is an RS232 level signal used for communications between the recorder and

the laboratory computer.

8

Operational Software

The operational software was written as a menu-driven computer operating

system utilizing the LabView programming language. This chapter is intended as

a user manual for the operating system. A graphics approach has been taken to

describe the operating system. Below is a display of each of the screen menu

followed by a description of each item on that menu.

VFR Software Program – Main Menu

Page 1 of the Main Menu.

This is the opening menu of the VFR program. It shows the current status

of the recorder, allows the control of the recorder, and download and display of

the data.

9

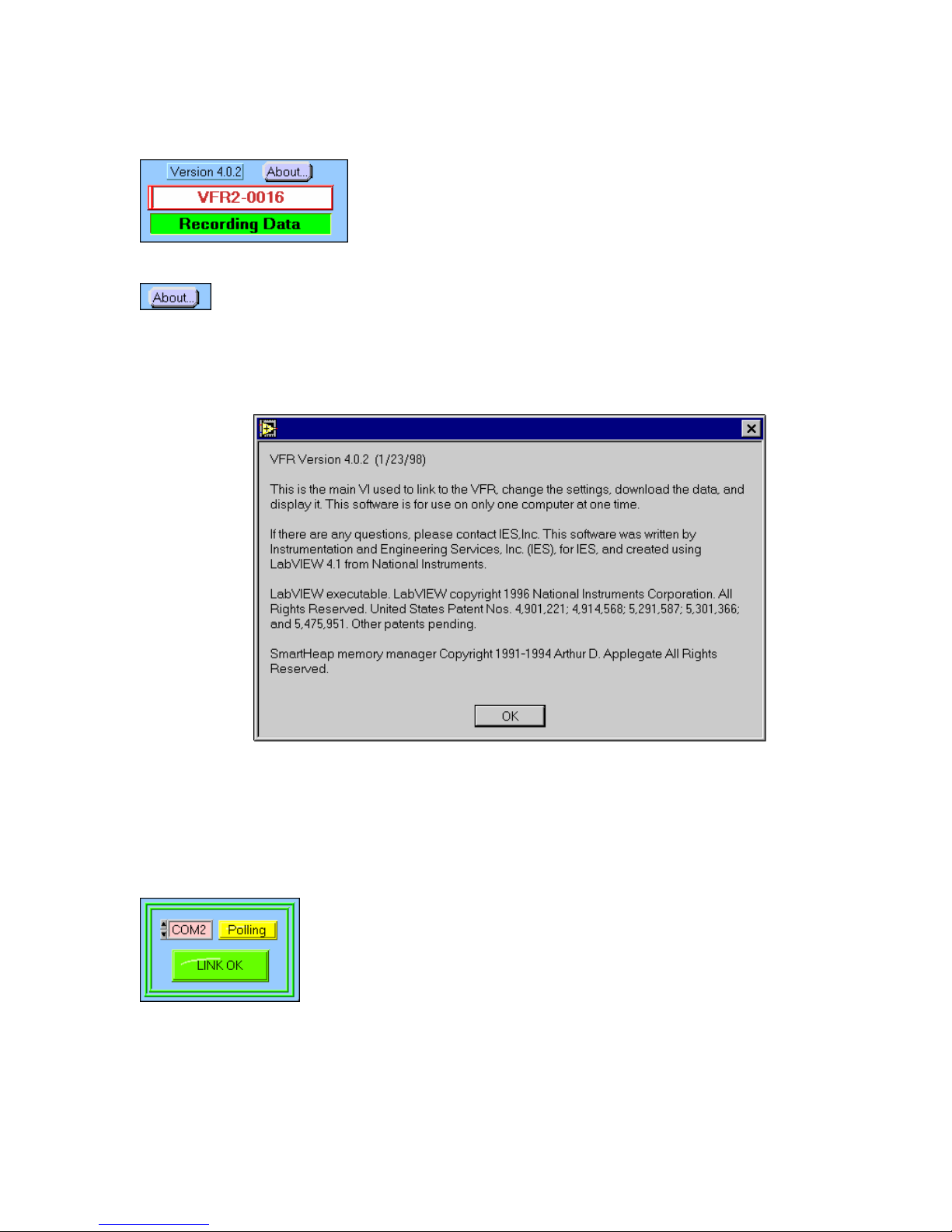

Displays the Serial Number and the current

operating status of the recorder.

Displays the program version and copyright

credits, shown below.

Allows the selection of the serial port for

communicating with the recorder. The choices

are COM1, COM2, COM3, and COM4. If the

proper port has been selected, and

communication has been established, the

“LINK OK” will turn on and the “Polling”

indicator will flash on and off.

10

The recorder cannot be found.

No serial link can be established. Possible

causes are no power to the recorder, a bad

cable connection, or the wrong serial com port

is selected.

Allows selection of different baud rates.

Note: This is the default value and should not

be changed.

Occasionally, when first connecting the

recorder to the serial port, a

“SERIAL ERROR” can occur. A beep will be

heard. This is OK, unless the recorder

continues to have error problems. It could

indicate more serious problems, such as loss

of serial link or a problem with the recorder.

Other errors can occur under “Error Status”. If

this occurs, there is a serious problem with the

recorder.

If a “Sensor Error” occurs, it means the

“Channel Auto Bias at Start” was enabled for

the channels displayed, and the recorder was

unable to set the Sensor bias when the

“START” button was pressed. The recorder will

not start recording data until the problem is

corrected. Possible solutions are disabling the

“Channel Auto Bias at Start” for that channel,

balancing the sensor, or reducing the gain for

that channel. This error could also indicate a

bad sensor or sensor wire.

11

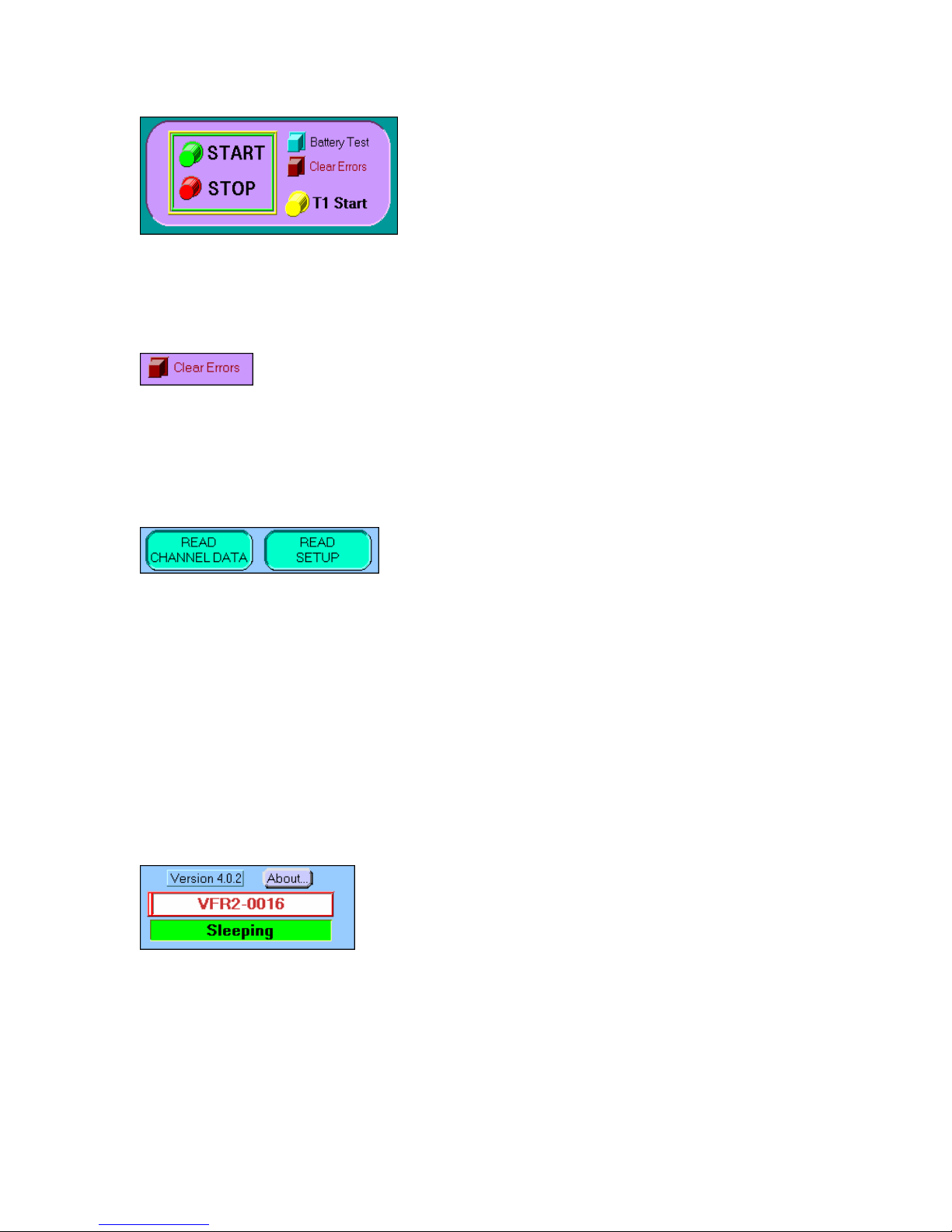

This is the main section for controlling the

recorder.

Clears any “Error Status” or “Sensor Error

Status” warnings and silences the beeping. If

the errors are not cleared with this button,

there is a more serious problem with the

recorder.

These indicators flash to remind the User to

“READ SETUP” on page 2 of the Main

program, and “READ CHANNEL DATA” on

page 3 of the Main program. This is VERY

important to do as soon as serial link has been

established with the recorder. This allows the

User to verify the current settings programmed

into the recorder’s EEPROM. These will

usually flash when the recorder is first

connected to the serial port.

Note: Data can still be downloaded even if the

“READ CHANNEL DATA” or “READ SETUP”

indicators are flashing.

“Sleeping” indicates the recorder in the low

current mode. It will draw 10-14 mA while the

serial link is connected. When the serial is

disconnected, the recorder will draw under 500

uA and will be dormant. The recorder can be

programmed, and data downloaded while the

serial link is connected, but the analog section

will remain off.

12

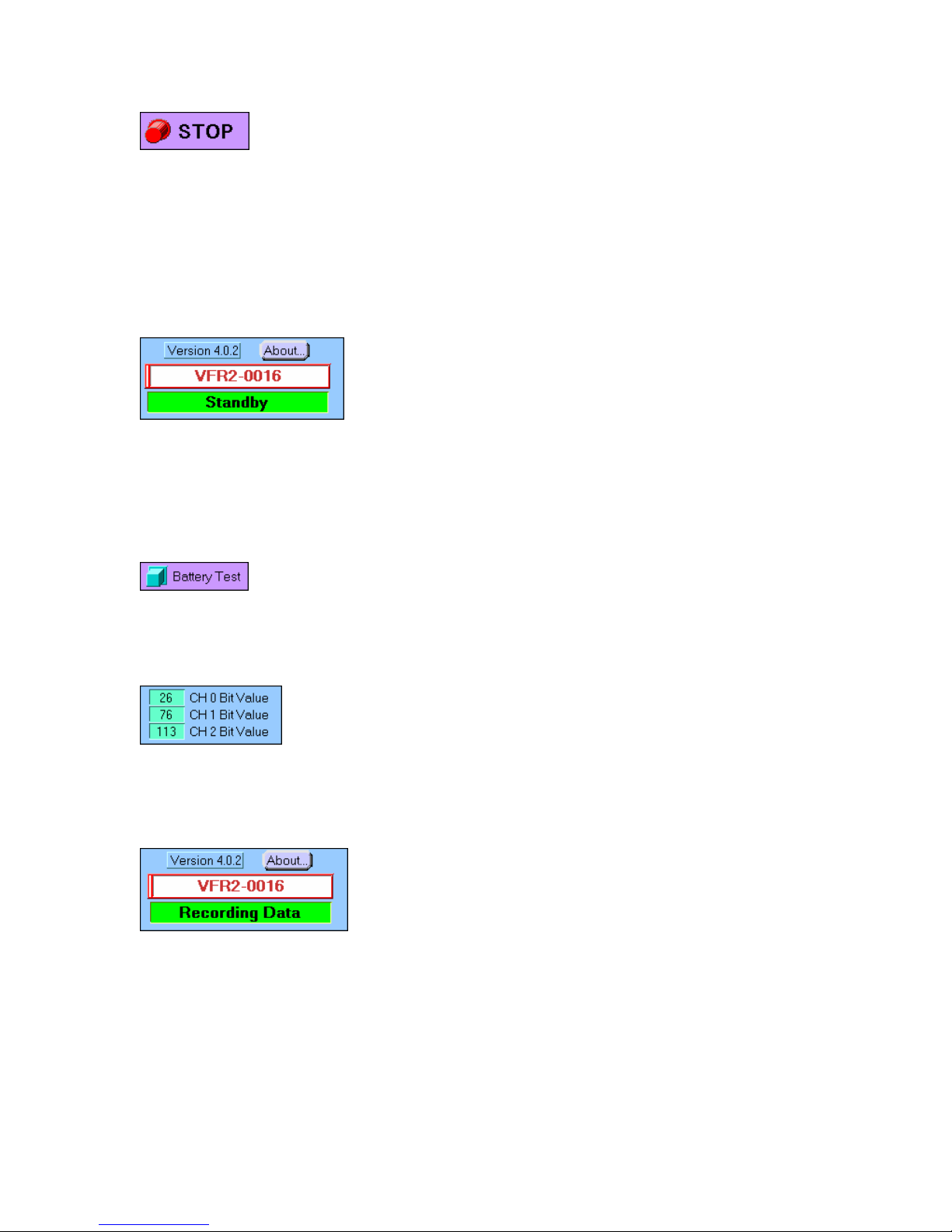

“STOP” will put the recorder into the “SLEEP”

mode if it is currently “RECORDING” data, in

“STANDBY”, or “AWAITING T1”. If the recorder

is already in the “SLEEP” mode, nothing will

happen. NOTE: If the recorder is currently

“RECORDING” data, the “STOP” button MUST

be pressed before any data can be

downloaded.

“Standby” indicates the analog section of the

recorder is powered, but data IS NOT being

stored into memory. This mode is useful for

measuring the data collection current of the

recorder, because the sensors are powered in

this mode. Also, the analog outputs are active,

so signals can be connected to the recorder to

test/calibrate the analog section.

Pressing this button will put the reocrder into

the “Standby” mode. If the recorder is in the

“Recording” data mode, this button is ignored.

When in the “Standby” or “Recording” modes,

these indicators display the analog outputs (0-

255 bits) of the amplified analog channels. In

the “Standby” mode, these values will float

towards zero.

“Recording” data indicates the analog section

is on and the recorder is actually storing data

into memory. When the memory is full, the

recorder will automatically turn itself off and go

into the “Sleep” mode to conserve power. If the

recorder is recovered after a test, and it is still

in the “Recording” data mode (memory was not

filled up), the “Stop” button must be pressed

before the data can be downloaded.

13

The “Start” button must be pressed to start

recording data. Data will start at the beginning

of the memory and sample at the “slow”

sampling rate and ALL previous data will be

erased. A message (shown below) will prompt

the User to be sure they are ready to start

recording data. Pressing “Stop” will turn off the

data recording. After the recorder is in the

“Recording Data” mode, the serial connection

can be removed.

Note: If there is a “Sensor Error”, the recorder

will put itself into the “Standby” mode, an error

will sound, and no data will be recorded. You

will need to correct the sensor problem before

recording data.

“Awaiting External T1” indicates the recorder is

in the “Sleep” mode, waiting for the correct

external 3.3-volt pulse on the T1 pin of the

recorder to wake it. The external pulse is

ignored when the serial link is on. When T1

occurs, the recorder will automatically go into

the “Recording” mode, sampling at the slow

sampling rate. Note: If there is a sensor error,

the recorder will be shut down into the

“Standby” mode. So it is recommended that the

recorder be put into the “Recording” data mode

on the bench, before the test, to verify proper

operation. After the recorder status indicates it

is “Awaiting External T1”, the serial connection

can be removed.

INFO: The recorder will start recording data

when the “START” button is pressed in the lab.

This will work in most test applications,

14

because the recorder is collecting data at a low

speed until an external T2 occurs, or the auto

trigger is activated. But certain tests require

low current and the recorder may remain

dormant for long periods of time, such as, a

sled track test. This requires the recorder to be

in the “SLEEP” mode until woken by an

external 3.3-volt signal, T1. The width of the T1

pulse required to wake the recorder can be

selected on Page 2.

The “T1 Start” button will put the recorder into

the “Awaiting External T1” mode. Pressing the

“Stop” button will turn this off and put the

recorder back into the “Sleep” mode.

Displays the current battery voltage. A good

way to determine the strength of the battery is

to apply a load to it. Pressing the “Battery Test”

button can do this. This turns on the analog

section the recorder and which loads down the

battery.

The “LOW BATT” indicator blinks when the

battery voltage is below 5.0 volts. It is highly

recommended that a new battery be used if

this occurs. The recorder monitors the battery

voltage during a test and if it falls below a safe

limit, the recorder is put into high speed and is

shut down to conserve battery voltage.

Note: If the battery voltage falls below ~5 volts

while the recorder is collecting data, the

recorder will automatically put itself into “High

Speed” until the memory is full, and shut itself

down to save battery energy and prevent data

loss.

The current recorder temperature is displayed

while the serial link is connected. Also, the

maximum temperature the recorder has seen

in its lifetime is displayed. The display can be

either in F or C.

15

After a test has been completed, the highest

and lowest temperature during that test is

displayed. These values are reset when the

“Start” button is pressed and the serial link is

disconnected.

After a test has been completed, the starting

and ending battery voltages are displayed. The

recorder starts monitoring the voltage only after

the serial link is disconnected. The voltage is

monitored about once a minute.

The current memory size. This can be selected

for 512K or 32K data points.

The memory size dedicated for each channel.

The value is determined by the mode (number

of analog channels activated) and the memory

size selected (32K or 512K data points).

The Channel mode is either “0” or “1” for the

VFR2 recorder. Mode 0 has 3 programmable

analog channels, only. Mode 1 has 3

programmable analog channels, and 4

buffered analog channels. The VFR2 recorder

has only Mode 0, which is 1 programmable

analog channel, and 2 buffered analog

channels.

Displays the current high speed and low speed

settings, which are programmed, into the

recorder.

16

Controls the downloading of the data after the

test. If the recorder is still in the “Recording

Data” mode, the “STOP” button must be

pressed first, to stop the data collection. This

will put the recorder into “High” speed until the

memory is full.

Note: The data will remain valid in memory

until either power is removed from the

recorder, or the “START” button is pressed.

Also, data can still be downloaded even if the

“READ CHANNEL DATA” or “READ SETUP”

indicators are flashing, and do not need to be

read before downloading the data.

Downloads ALL the data in the recorder. Either

32K or 512K data points, depending on how

the recorder was programmed. When

downloading, this operation can be canceled. If

there is a problem while downloading, such as,

a parity error, the User will be warned, and the

data can be downloaded again.

Sometimes when data from a test is written

into memory, not all the memory is used. In

that case, the recorder indicates the “Valid

Memory Size”. By pressing the “Quick

Download” button, only the memory, which was

used during the test, is downloaded. This

reduces the time required for downloading. If

there are any uncertainties, the User can

simply download ALL the data by pressing the

“Download ALL Data” button.

17

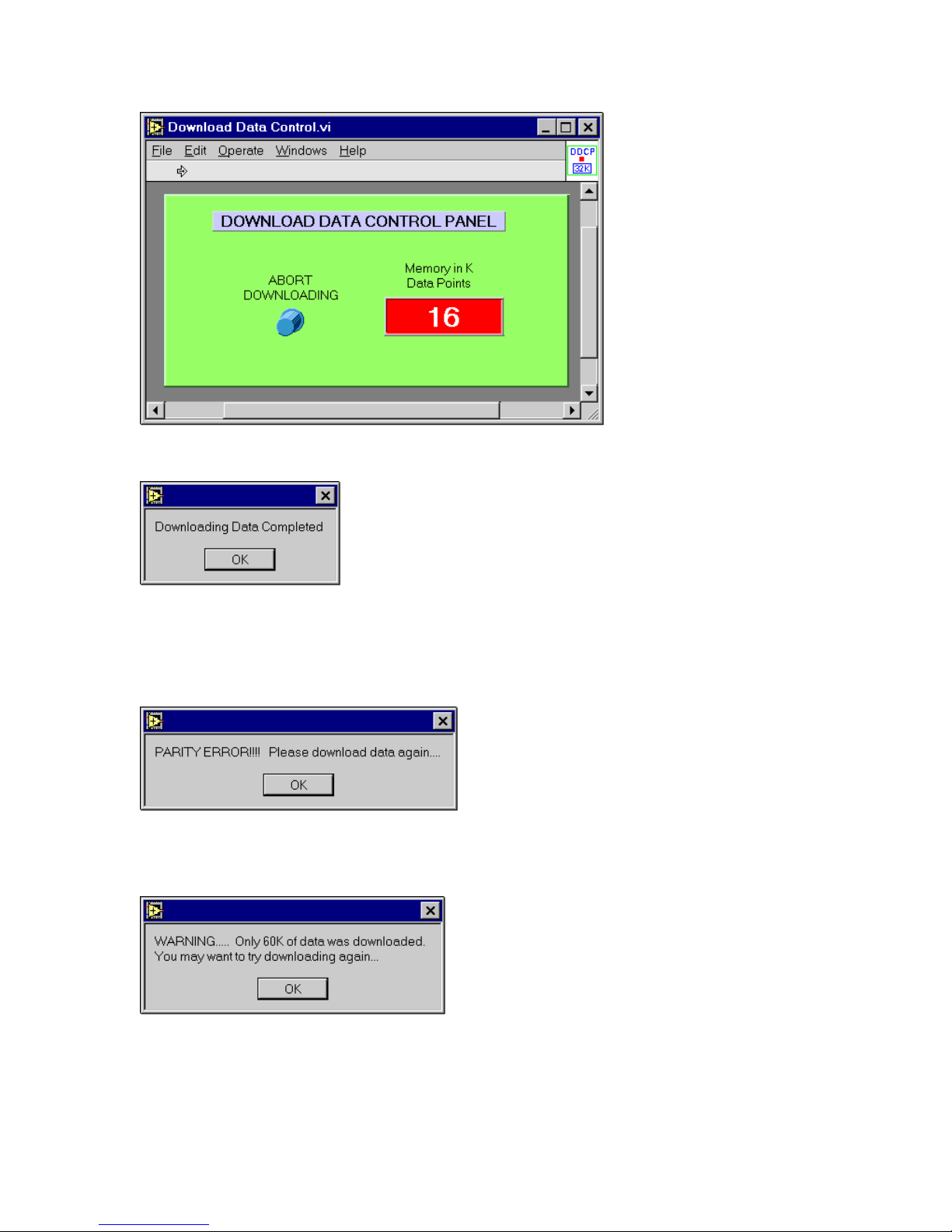

This screen pops

up when

downloading data.

The User can stop

the downloading

process by pressing

the “ABORT

DOWNLOADING”

button. It is Normal

for the memory

counter to go

slightly past the

memory size and

stop for a short

period of time.

This message is displayed when ALL the data

has been successfully downloaded from the

recorder’s memory. The data can be

downloaded as many times as the Users

wants, but it will be erased if power is removed

from the recorder, or the “START” button is

pressed.

If this message appears, there was

a problem downloading the data.

Either there was a bad connection,

or the User aborted the download

process. Simply try downloading

the data again.

This message appears if not all the

data was downloaded, indicating

how much was actually received.

18

Table of contents

Popular Recording Equipment manuals by other brands

Stereoping

Stereoping synth programmer Owner's handbook

National Instruments

National Instruments PC/104-GPIB Getting started

Mitsubishi Electric

Mitsubishi Electric DX-NT400E Operation manual

Vimar

Vimar By-alarm 01729 manual

Citronic

Citronic DSM2-6mkII manual

Siemens

Siemens XTRI-S installation instructions