Inta Intamix Pro 60001CP User manual

This manual suits for next models

5

Table of contents

Other Inta Control Unit manuals

Popular Control Unit manuals by other brands

Kamstrup

Kamstrup OMNIGRID Connect installation guide

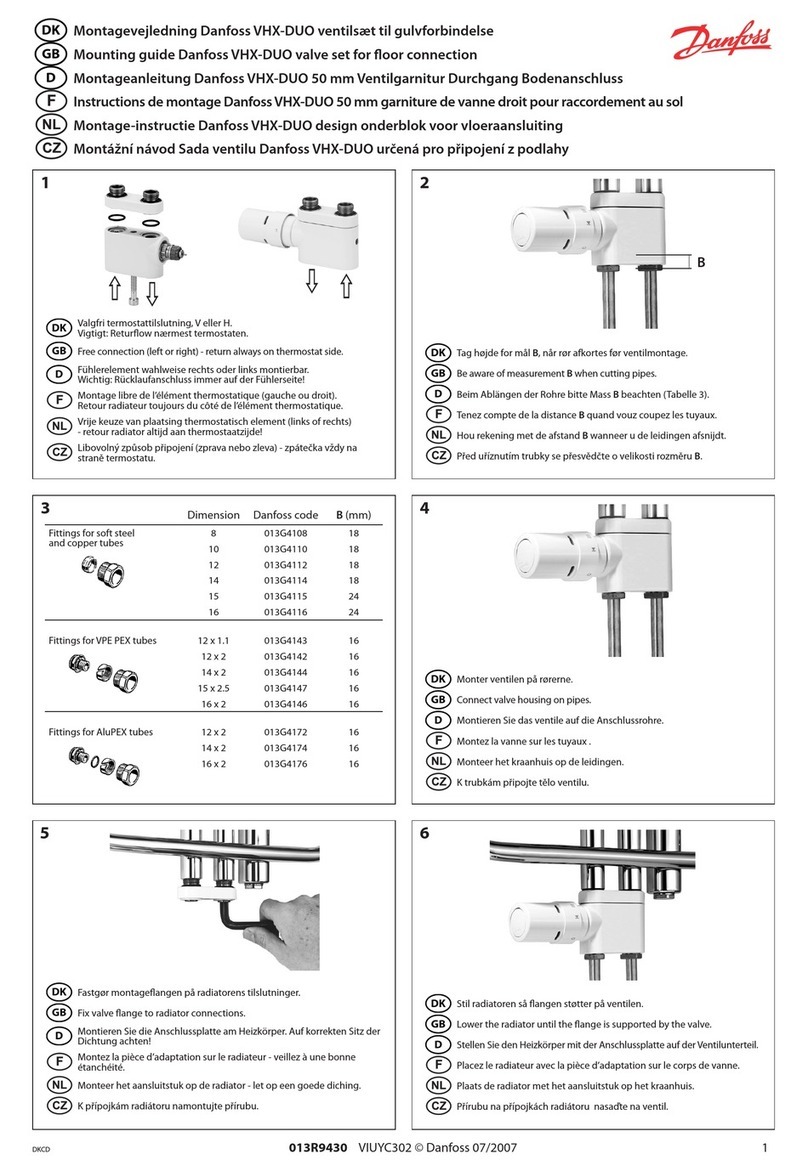

Danfoss

Danfoss VHX-DUO Mounting guide

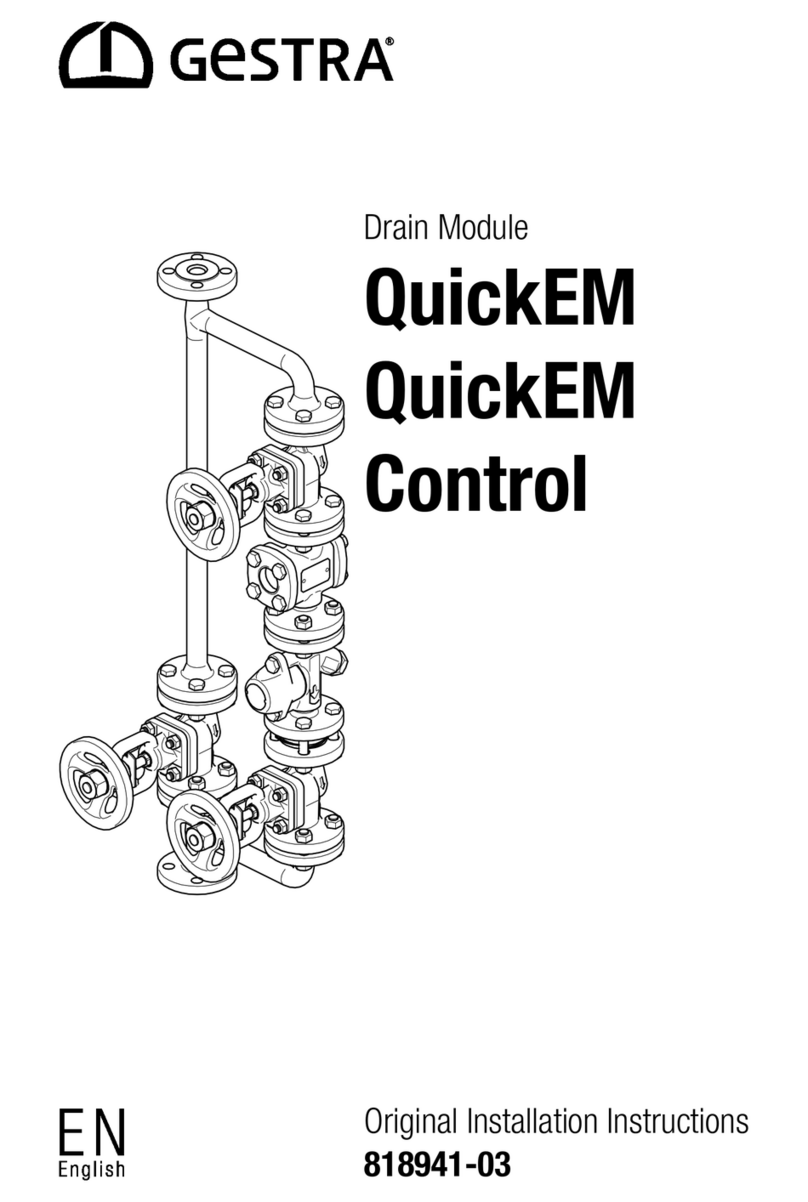

GESTRA

GESTRA QuickEM Original Installation Instructions

McIntosh

McIntosh C38 owner's manual

Texas Instruments

Texas Instruments TMS320C6A816 Series Technical reference manual

CKD

CKD MN3GD/E1 Series instruction manual

Eden

Eden C1P2FXBT Technical manual

elsner elektronik

elsner elektronik RF-MSG-DST Technical specifications and installation instructions

HEIDENHAIN

HEIDENHAIN TNC 426 PB/M Technical manual

VIPA

VIPA System 200V Series manual

Flomatic

Flomatic Miniair installation instructions

Siemens

Siemens XC1001-A Installation and maintenance manual

Warren rupp

Warren rupp Sandpiper HD20F Service & operating manual

KUGELHAHN MÜLLER

KUGELHAHN MÜLLER KM-O Series Operating and maintenance instructions

Laird

Laird SDC-SSD30AG Hardware integration guide

RabbitCore

RabbitCore RCM3100 Series Getting started manual

Laird

Laird MSD50NBT user guide

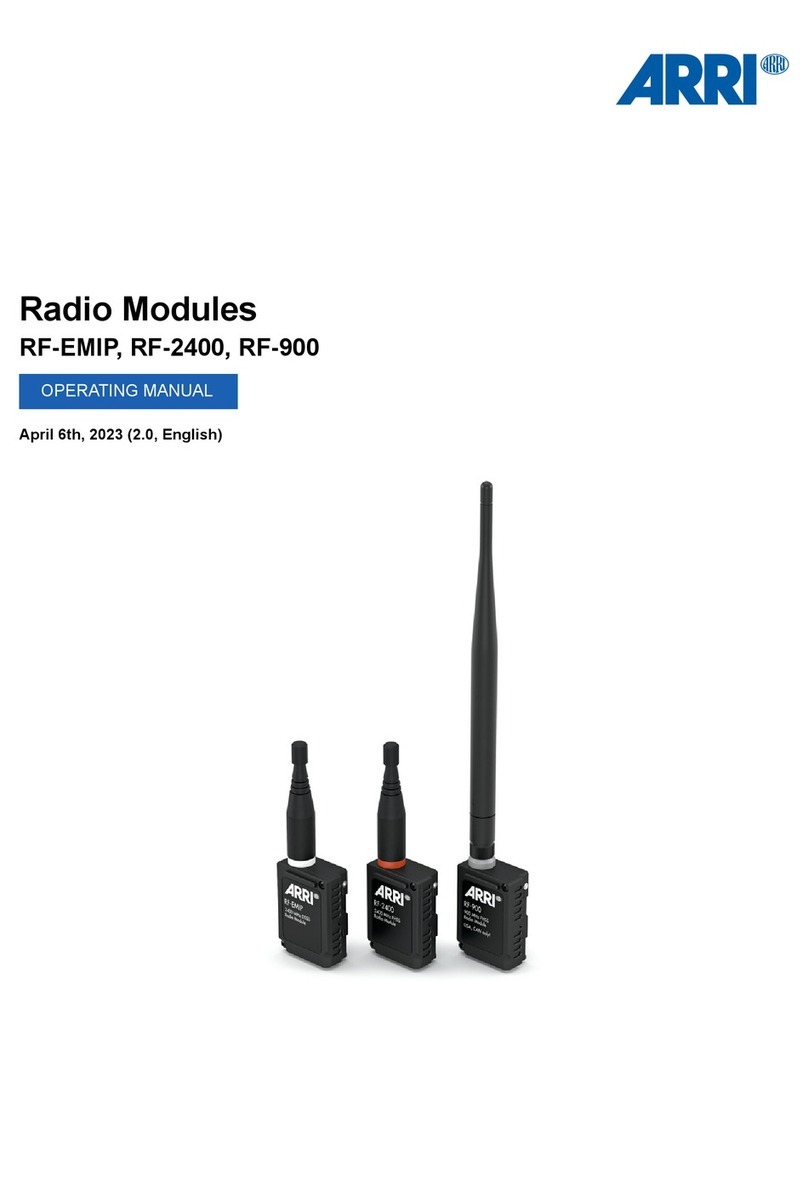

ARRI

ARRI RF-EMIP operating manual