Inta ZERO114 User manual

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: [email protected]

web: www.intatec.co.uk

In this procedure document we have endeavoured to make the informa-

tion as accurate as possible.

We cannot accept any responsibility should it be found that in any

respect the information is inaccurate or incomplete or becomes so as a

result of further developments or otherwise.

© Intatec Ltd 2023

Zero Anti-Freeze Valve

ZERO001, ZERO114 & ZERO28

Installation and Maintenance Instructions

© Intatec Ltd 2023 1

Introduction

The Inta Zero is a unique anti-freeze valve designed to protect heat pump systems operating

with water.

Designed to discharge when the system water temperature goes down to 3˚C preventing ice

from forming in the heat pump circuit that could cause breakdown or costly damage to the

system.

The Inta Zero has been designed and engineered to avoid negative influences from low

ambient temperatures by directly positioning the element in the system water flow, permitting

accurate system discharge only when its truly needed.

A protective ring has been included in the construction to prevent system debris clogging the

operation of the valve.

Double O-rings and reduced surface friction treatment on the operating member also ensure

correct operation and reliability time after time.

These instructions cover the installation, operation and maintenance. Please read the enclosed

instructions before commencing the installation of this product, please note;

We recommend that the installation of any Inta product is carried out by an

approved installer.

It is recommended, especially in hard water areas, that a water softener such as the ActivFlo or

ActivFlo lite be fitted to reduce the risk of calcium deposits forming.

Products

Zero anti-freeze valve 1" M x M connections ZERO001

Zero anti-freeze valve 1¼" M x M connections ZERO114

Zero anti-freeze valve 28mm ZERO28

Technical Specification

Max. inlet pressure - static: 10 bar

Medium: Water

Sensitivity: ±1˚C

Opening temperature: 3˚C

Closing temperature: 4˚C

Threaded connections: BS EN ISO 228

Compression connections: BS EN 1254-2

Materials

Valve body: Brass BS EN 12165 CW617N

Spring: Stainless steel

Temperature element: Wax

Internal seals: EPDM peroxide

Internal parts: Brass BS EN 12164 CW617N

© Intatec Ltd 2023 2

Dimensions

Check Components

Before commencing remove all components from packaging and check each component with

the contents list.

Ensure all parts are present, before discarding any packaging. If any parts are missing, do not

attempt to install your Inta Zero anti-freeze valve until the missing parts have been obtained.

58

82 41

G1 or G1¼

Ø28

76

ZERO001- ZERO114 ZERO28

Olive

Compression

nut

Vaccum breaker

Temperature

cartridge

ZERO001,

ZERO114

or valve for

ZERO28

© Intatec Ltd 2023 3

Preparation for installation

Flush the water supply pipes thoroughly prior to installation. Do not allow debris, PTFE tape or

any metal particles to enter the system.

Important: All plumbing is to be installed in accordance with applicable codes and

regulations.

Important: When fitting/installing a heat pump system or components it is essential that the

correct insulation is used and properly sealed to reduce the heat loss from the system,

maintaining the system efficiency.

Installation

The Zero anti-freeze valve must only be installed in a vertical position, with the outlet facing

downwards, to allow the draining water to flow out free from obstructions.

The Zero antifreeze valves must be installed outdoors, where the lowest temperatures can be

reached if the heat pump is not operating.

The Zero anti-freeze valve should be properly insulated and sealed to reduce heat loss. Only

the vacuum breaker and discharge point should be exposed.

The valve(s) must also not be placed close to heat sources which could interfere with their

function.

For the valve(s) to work properly, keep the system under pressure at all times.

Most installations only require one anti-freeze valve, located outside and at the lowest point in

the system.

We recommend at least 15cm clearance between the valve and the

ground as discharged water could freeze and hinder the operation of

the valve.

The discharge from anti-freeze valves must be collected in a suitable

drain and routed to a suitable collection point.

If a second valve is required, Inta recommend leaving at least 10 cm

between the valves to avoid water discharging onto the lower valve.

>1

5cm

© Intatec Ltd 2023 4

Installation Continued

When installed outdoors, the Zero antifreeze valve must be protected from rain, snow and

direct sunlight.

Inta recommend placing a small cover / hood with 1 open face over the vacuum break. This

should prevent interference or debris while still permitting air flow.

Do not make any trap connections.

If the shape of the connection pipes has the potential to create a trap effect (as shown below),

part of the pipe will not be able to drain and frost protection will no longer be ensured.

Where the heat pump is elevated so the pipework goes down into a U shape (as shown below),

this would then require 2 anti-freeze valves to completely drain all the pipework and system.

ûûûû

© Intatec Ltd 2023 5

Maintenance

Vacuum Breaker Replacement

In the event of a malfunction, the vacuum

breaker can be removed.

Checking the Vacuum Breaker

In the event of a malfunction, or as part of a

planned maintenance programme the vacuum

breaker can be removed.

Using a 20mm A/F spanner remove the

vacuum breaker from the anti-freeze valve

body.

Using a suitable sized spanner remove the

cover from the vacuum breaker body.

Remove the sealing washer.

Invert the vacuum breaker body and the

plastic vacuum cap should fall out.

If it does not fall out it indicates that the

vacuum breaker has not been operating

correctly and the vacuum breaker needs to be

replaced.

If the plastic vacuum cap does fall out check it

and the sealing washer for damage and

inside the body for debris, if present wash

away with clean water.

Re-assemble and refit into the anti-freeze

valve.

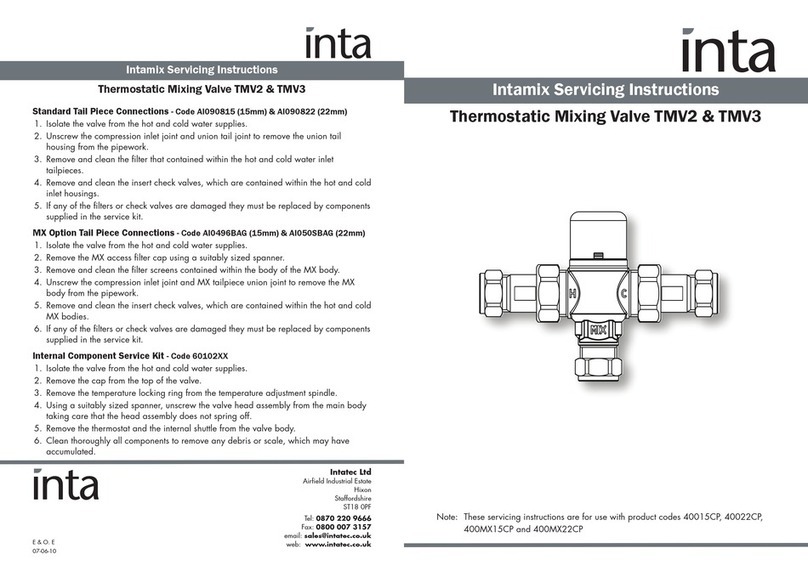

Thermostatic Cartridge Replacement

In the event of a malfunction, the thermostatic

cartridge can be replaced.

Using a 26mm A/F spanner remove the

cartridge from the body and replace with a

new one.

Replacement Components

Replacement components are available from

Inta.

Fit only genuine Inta replacement components.

Body

Sealing washer

Plastic vacuum cap

Cover

© Intatec Ltd 2023 6

Notes:

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: [email protected]

web: www.intatec.co.uk

E & O.E

© Intatec Ltd 2023 14-02-23

Please leave this Manual for the User

To activate your product warranty please visit

www.intatec.co.uk

and click on Product Registration

This manual suits for next models

2

Table of contents

Other Inta Control Unit manuals

Popular Control Unit manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley Kinetix 5700 Series installation instructions

EOS

EOS ECON H2 Assembly and operating instruction

Samson

Samson 2422 series Mounting and operating instructions

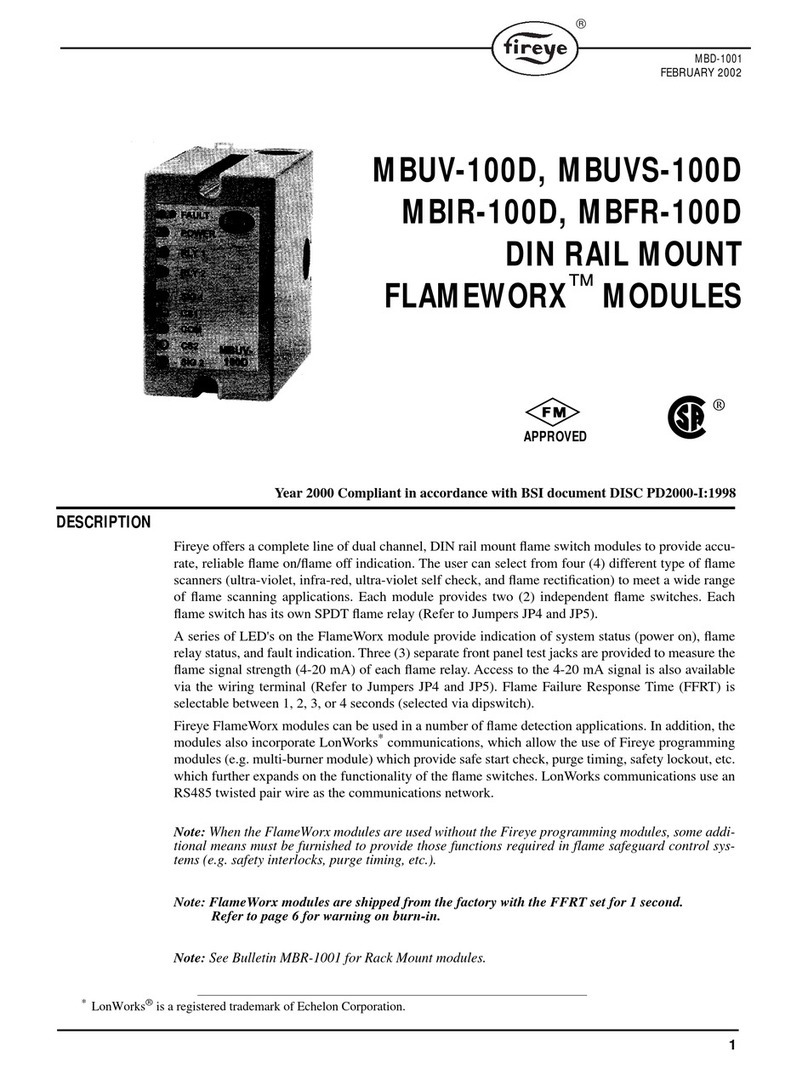

Fireye

Fireye FlameWorx MBUV-100D manual

FEAS

FEAS SSE10 operating instructions

Ross

Ross CrossMirror 77 Series operating instructions

Alutech

Alutech CU-TR230-868 Installation and operation manual

Honeywell

Honeywell VS8421 installation instructions

Transient Modules

Transient Modules u2X Build manual

Afag

Afag GMQ 32 Series Assembly and operating instructions

Balluff

Balluff MICROPULSE BTM-AR2-001 user guide

Jafar

Jafar 8890 Operation & maintenance manual