intatec Intamix Pro V 61022CPB User manual

Thermostatic Mixing Valves

61022CPB & 61028CPB

Intamix Pro V

Installation and Maintenance Instructions

In this procedure document we have endeavoured to make the

information as accurate as possible.

We cannot accept any responsibility should it be found that in

any respect the information is inaccurate or incomplete or

becomes so as a result of further developments or otherwise.

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: [email protected]

web: www.intatec.co.uk

© Intatec Ltd. 2021

© Intatec Ltd 2021 1

Introduction

A thermostatic mixing valve (TMV) is used in domestic hot water systems.

It’s function is to maintain the temperature of the mixed water, supplied to the user, constant at

the set value when there are variations in the supply pressure and temperature of the incoming

hot and cold water or in the flow rate.

The Intamix Pro V TMV has been designed specifically for systems requiring high flow rates,

for example group showing.

Systems of this nature require precise, stable temperature control, especially when there are

variations in the flow rates drawn off by the users.

It is recommended, especially in hard water areas, that a water softener such as the ActivFlo or

ActivFlo lite be fitted to reduce the risk of calcium deposits forming.

Products

Intamix Pro V 22mm with isolating unions 61022CPB

Intamix Pro V 28mm with isolating unions 61028CPB

Technical Data

Temperature range: 30 to 65˚C

Max. working pressure: 14 bar - Static

5 bar - Dynamic

Min. working pressure: 0.2 bar

Max. inlet temperature: 85˚C

Max. inlet ratio (H/C or C/H): 2:1

Min. temperature differential to ensure

failsafe between hot and mixed supplies: 10˚C

Accuracy: ±2%

Minimum flow rate required to maintain

stable temperature: 61022CPB 8.3 l/min

61028CPB 13.0 l/min

Kv value: 61022CPB 4.0 m3/hr

61028CPB 4.5 m3/hr

Connections: 22mm & 28mm compression for copper pipe

Note: Use BS EN 1057 R250 (half hard) copper pipe with compression joints to BS EN 1254-2

© Intatec Ltd 2021 2

Dimensions

Safety

If the thermostatic mixing valve is not installed, commissioned and maintained properly,

according to the instructions contained in this manual, it may not operate correctly and could

endanger the user.

Make sure the connecting pipework to the TMV is not mechanically over-stressed, appropriate

support/fixing should be used. Over time this could cause a fracture, with consequential water

loss which, in turn, could cause harm to property or people.

Water temperatures higher than 50˚C can cause serious scalding.

During installation, commissioning and maintenance take the necessary precautions to

ensure that such temperatures do not endanger people.

In the case of highly aggressive water, arrangements must be made to treat the water

before it enters the thermostatic mixing valve, in accordance with current legislation.

Otherwise, the TMV may become damaged and not operate correctly.

Product Code A B C D E

61022CPB 22 200 300 74 98

61028CPB 28 200 304 74 99

ØA

ØA

B

C

DE

2

MAX

MIN

7

1

© Intatec Ltd 2021 3

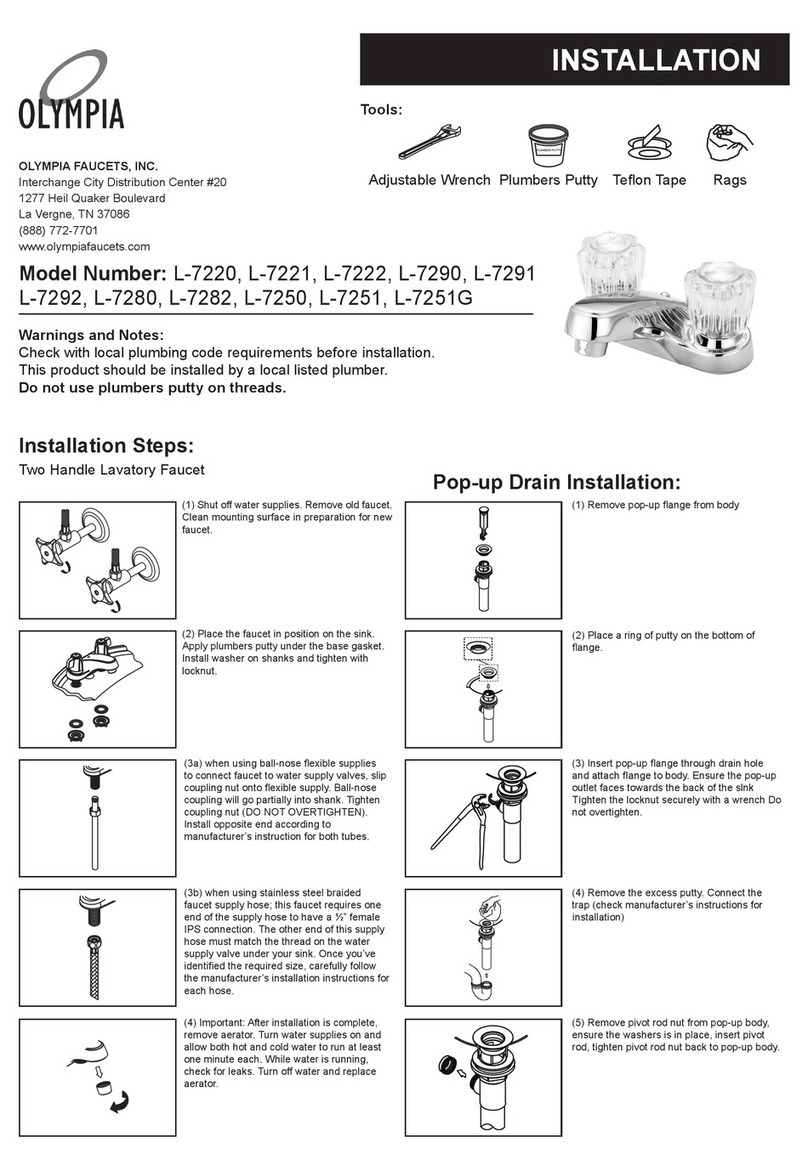

Installation

If the thermostatic mixing valve is not installed, commissioned and maintained properly,

according to the instructions contained in this manual, it may not operate correctly and may

endanger the user.

Before installation the system must be thoroughly flushed and checked to ensure that it’s

operating conditions are within the range of the valve; eg the supply temperatures, pressures

and flow rates.

Systems must be flushed to remove any dirt or debris, which may have accumulated during

installation, which may affect its performance and the manufacturer’s product guarantee.

The installation of filters, of appropriate capacity, at the inlet from the mains supply is always

advisable.

In the case of highly aggressive water, arrangements must be made to treat the water

before it enters the thermostatic mixing valve, in accordance with current legislation.

Intamix Pro V TMV must be installed strictly in accordance with the Water Supply (Water Fitting)

Regulations 1999, any local authority regulations and the diagrams in this manual.

They can be installed in any orientation, either vertically or horizontally.

The following are shown on the mixer body:

~ hot water inlet, denoted by the letter ‘H’.

~ cold water inlet, denoted by the letter ‘C’.

It is essential that access to the valve or connections is totally unobstructed for any maintenance

which may be required.

The pipework to or from the valve must not be used to support the valve unless adequately

supported.

© Intatec Ltd 2021 4

Commissioning

After installation, the valve must be tested and commissioned in accordance with the

instructions given below, taking into account current applicable standards and Codes of

Practice.

1. Ensure that the system is clean and free from any dirt or debris before commissioning.

2. It is recommended that the temperature is set using a suitable calibrated digital

thermometer. The valve is commissioned by measuring the temperature of the mixed water

emerging at the point of use.

3. The maximum discharge temperature from the valve must be set to take account of

fluctuations due to simultaneous use.

Allow conditions to stabilise before measuring the temperature and commissioning

4. Adjust the temperature using the adjusting knob on the valve.

5. This valve setting is only applicable to current site conditions at the current location in the

system.

Setting the Temperature

The temperature is set to the required value by means of the adjusting knob with the

graduated scale located at the top of the valve.

1. Using a suitably sized screwdrive unscrew the knob retaining screw.

2. Note the position of the lug on the body and the corresponding recess inside the knob.

Application

Hot Water

Mixed

Water

Cold Water

2

MAX

MIN

7

1

© Intatec Ltd 2021 5

Setting the Temperature Continued

3. Temporarily refit the knob onto the splined section of

the stem and rotate the stem to alter the mixed water

temperature.

To increase the temperature, rotate the spindle

anti-clockwise.

To decrease the temperature, rotate the spindle

clockwise.

4. Allow the outlet temperature to stabilize for 60

seconds and once again take a temperature

reading. Repeat the procedure until the desired

temperature has been reached.

5. Check the circulating water temperature is stable.

Preset Locking

Position the adjusting knob to the temperature required.

Unscrew the retaining screw.

Remove the knob by pulling away from the valve and reposition on the splined shaft so

that the internal slot locates on the position indicator on the knob frame.

Re fit and tighten the retaining screw.

Maintenance

In service, tests should be carried out regularly to monitor the TMV’s performance, as

deterioration could indicate that the valve and/or the system require maintenance.

If during these tests, the temperature of the mixed water has changed significantly when

compared with the previous test, the details given in the Installation and Commissioning

sections should be checked and maintenance carried out.

The following should be checked regularly to ensure that the optimum performance levels of the

valve are maintained.

Every 12 months or more often if necessary.

1. Check and clean the system filters.

2. Check that any non-return valves positioned upstream of the TMV are operating correctly

and free from debris.

3. Limescale can be removed from internal components by immersion in a suitable

de-scaling fluid.

4. When the components have been checked and maintained, the mixed water outlet

temperature should be checked using a thermometer following the procedure detailed in

the Commissioning section.

M

I

N

M

A

X

© Intatec Ltd 2021 6

Problem Solving

The following details are supplied for on site queries, should you require any further assistance

our Technical Department can be contacted directly on 01889 272 199.

1 Hot water at cold outlet

i. Operation of the insert check valves is hindered, check the valve is seated correctly.

ii. Check Valves not fitted.

iii. Unbalanced hot/cold supply pressure.

2Fluctuating mixed water temperature

i. Erratic supply temperatures at the inlets of the valve.

ii. Starvation of the water supplied at the inlets of the valve.

iii. Incorrect commissioning of the valve.

3 Erratic flow

i. Insufficient water supplies.

ii. Fluctuations in the supply pressures/temperatures.

iii. Adverse effect created by other draw off points on the system.

4 No flow/reduced flow from valve

i. In line filters are blocked.

ii. Insufficient supply pressure.

iii. Debris obstructing valve operation.

iv. Valve requires servicing.

© Intatec Ltd 2021

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: [email protected]

web: www.intatec.co.uk

E & O.E

26-04-21

Notes

To activate your product warranty please visit

www.intatec.co.uk

and click on Product Registration

Please leave this Manual for the User

This manual suits for next models

1

Table of contents

Popular Plumbing Product manuals by other brands

Hans Grohe

Hans Grohe Vivenis 75445 7 Series Instructions for use/assembly instructions

AbodeFit

AbodeFit Zen Ultimate Far user manual

Helvex

Helvex EP-95 installation guide

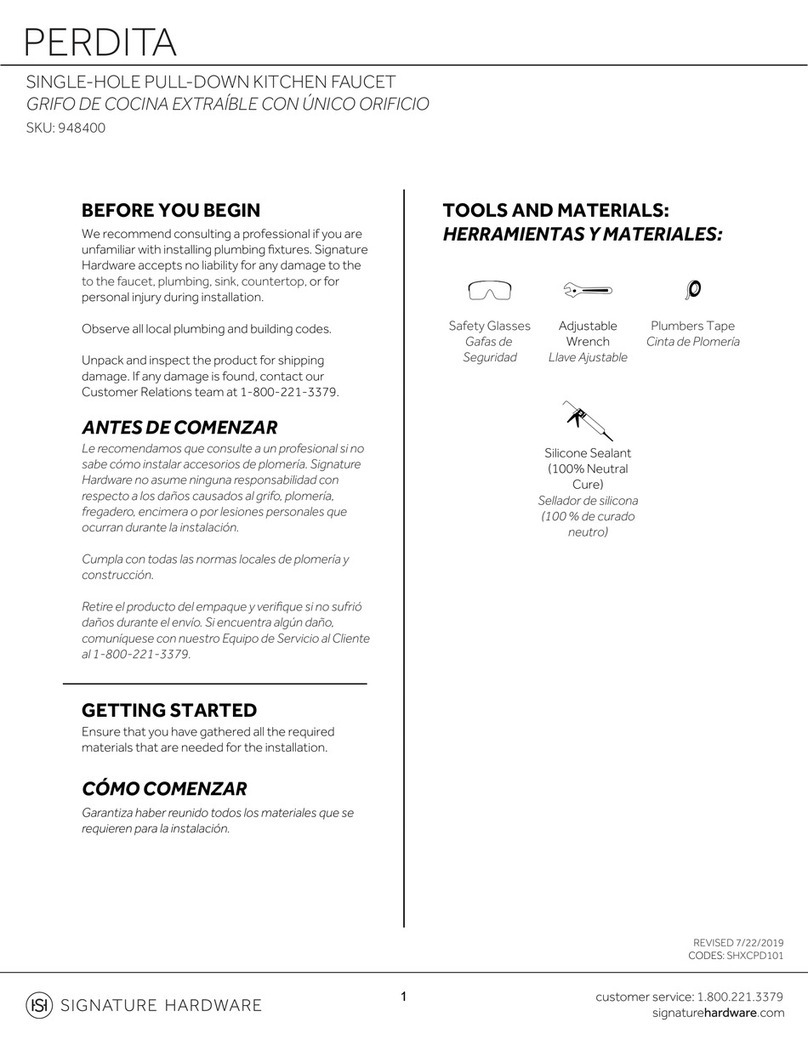

Signature Hardware

Signature Hardware PERDITA 948400 manual

Allen + Roth

Allen + Roth WSWS-PB1C manual

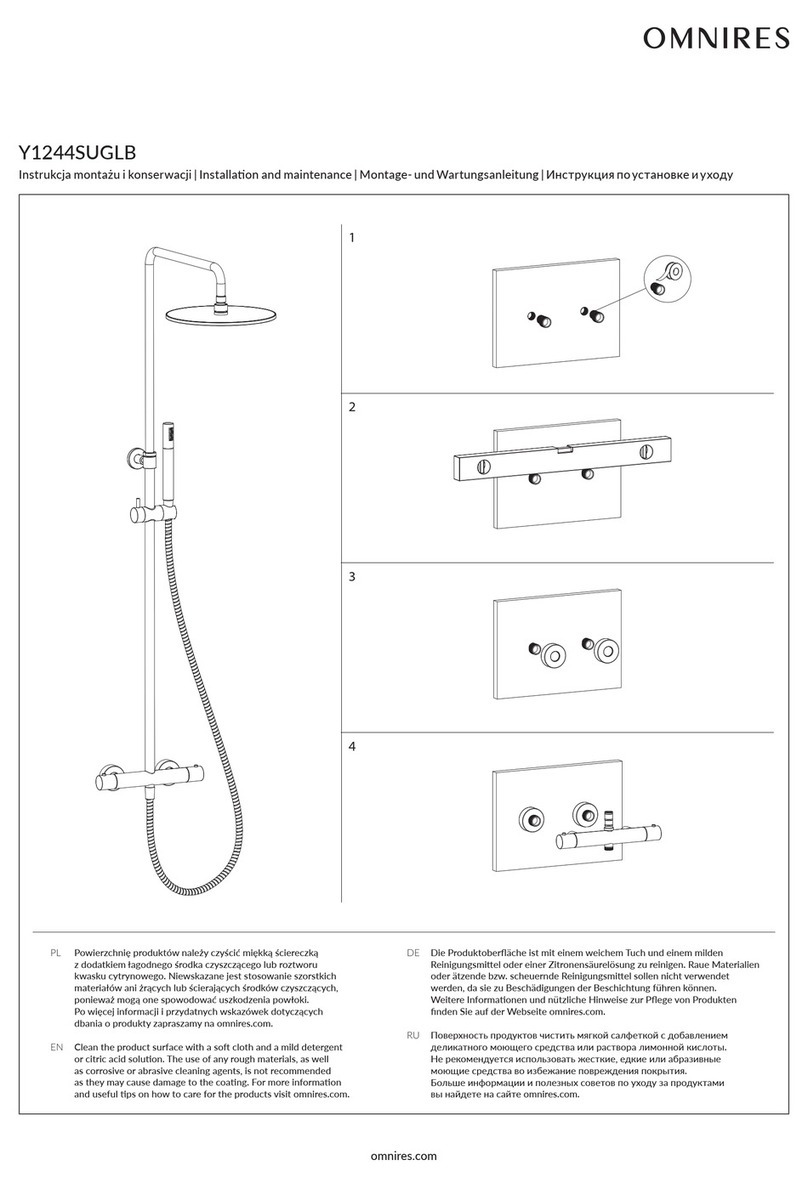

Omnires

Omnires Y1244SUGLB Installation and Maintenance