Intec Controls AirSense I-310en User manual

AirSense

Model I-310en

Infrared Environmental CO2 Sensor

Operator's manual

12700 Stowe Dr., Ste 110

Poway, CA 92064

Ph: 858-578-7887

Fx: 858-578-4633

Email: [email protected]

www.inteccontrols.com

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 1of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: i

Date

10/11/11

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 2of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: ii

Table of Contents

Preface ............................................................................

............. 1

Model Identification.........

..................................................... 1

Introduction ....................................................................

............. 1

Displays and Indicators ..................................................

............. 2

Specifications .................................................................

............. 3

Installation ......................................................................

............. 4

Cover Removal ................

..................................................... 4

Mounting..................................................................

............. 4

Wiring ................................................................................... 5

Power Supply ..............

..................................................... 5

Signal Output ..............

..................................................... 6

Cover Replacement............

................................................... 7

Field Adjustments...........................................................

............. 7

High CO2 Limit Adjustment .................

................................ 7

High CO2 Limit Hysteresis Adjustment...................

............. 8

Analog Top-of-Scale Adjustment ..........................

............... 9

Altitude Correction Considerations .....................

............... 10

Altitude Correction Procedure ........................

............... 10

Calibration ....................................................................

............. 11

Verification Procedure .........................................

............... 11

Optional High Limit Contact Relay .........................

................. 13

Setting High Limit Contact Polarity ....................

............... 13

Disclaimers and Notices .............................................

............... 14

Operational Limitations ...........................................

........... 14

Safety Critical Applications.....................................

........... 14

4

4

4

5

6

7

7

7

8

8

9

10

10

10

11

12

13

13

14

14

16

16

17

17

17

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 3of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 1

Preface

This manual describes the Model I-310en of the AirSense I-310

Carbon Dioxide sensor family. The I-310en, while similar in

external appearance and operation to previous 310e models,

has a slightly modified feature set and differences in the

location and operation of the user interface.

Model Identification

Because of its similarity to previous models, the Model

I-310en is most easily identified by the prefix “M310en” on

the unit’s serial number tag visible on the sensor circuit

board when the cover is removed.

All other AirSense I-310e series sensors are covered in the

AirSense Model I-310e Operator’s Manual.

Introduction

The AirSense Model I-310en is a non-dispersive infrared

analyzer for measuring environmental CO2 concentration in

ventilation systems and indoor living spaces. Its default

measurement range of 0 - 2000 ppm (parts per million; 1000

ppm = 0.1%) covers the range required to monitor

compliance with ASHRAE or other ventilation efficiency

standards. For specialty applications the measurement range

can be easily increased up to 5000 ppm.

Packaged in a compact, distinctively styled enclosure, the

Model I-310en can be discreetly installed anywhere from the

board room to the boiler room. Standard center wiring

access, fully floating outputs and power/signal mis-wiring

protection make installation a snap.

The Model I-310en provides several output alternatives. A

voltage or 4 - 20 mA current output is standard. An optional

LCD readout is available. An optional relay contact can be

configured to open or close above a user-adjustable setpoint.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 4of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 2

Displays and Indicators

The Model I-310en has a single green LED on the front panel

which illuminates whenever the unit is operating. This LED

is on steadily when the measured concentration is below the

high CO2 limit, and blinks whenever the concentration is

above the limit.

The standard factory high CO2 limit is 1000 ppm, but can be

adjusted in the field. The procedure for adjusting the high

CO2 limit is described on page 7.

The display option adds a 4 digit liquid crystal display

(LCD) to the front panel. The display shows the measured

CO2 concentration in parts per million (ppm). 1000 parts

per million equals 0.1%.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 5of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 3

Specifications

Operating principle Non-dispersive infrared (NDIR)

Gas sampling method Diffusion or sample draw

Measurement range 400 - 2000 ppm CO2 (standard)

Field adjustable to 5000 ppm

Typical drift (per year) ±75 ppm (@ 1200ppm)

Accuracy ±5% of reading or ±75 ppm,

whichever is greater

Repeatability ±20 ppm

Recommended Calibration Interval Five Years

Response time Less than 1 minute

Operating temperature range 0 to 50 ° C

Operating humidity range 0 - 90% RH (non condensing)

Storage temperature -30 to + 60 ° C

Power requirements 20 - 28 VRMS AC, 18 - 30 VDC

Power consumption Less than 2W @ 24 VAC

Calibration verification time 10 minutes typical

Dimensions 5.2" x 3.2" x 1.4"

Voltage output (linear) 0 - 10 volts DC

Current output (linear) 4 - 20 mA (RL ≤ 500Ω)

Warm-up time 3 minutes

Weight 6.5 Oz. (.35 Kg)

Optional Digital Display 4 digit, .35" LCD

Optional setpoint range 0 to full scale

High

Limit contact polarity jumper selectable

Contact contact rating 2A @ 24 VAC

Operating life expectancy 10 years typical

Warranty 18 months, parts and labor through

repair or exchange

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 6of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 4

Installation

Cover Removal

To open the Model I-310en use a coin in the slot on the

bottom to release the snap. Lift the cover up slightly to

disengage the closure and remove cover with a downward

motion to clear the catch at the top of the unit.

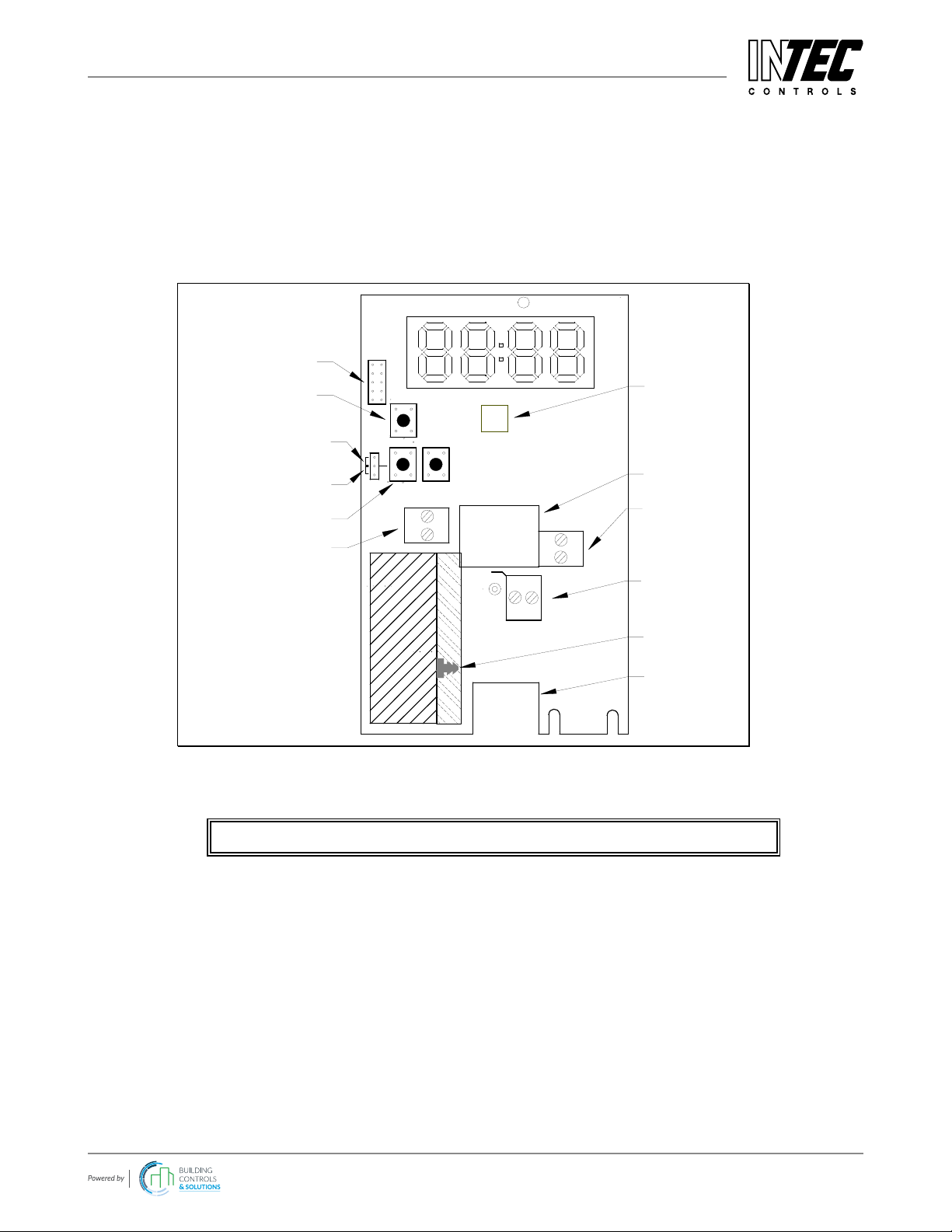

The locations of controls and terminals on the main circuit

board are shown in the Figure 2 on page 5.

Mounting

The Model I-310en is designed for flush mounting with two

fasteners. The locations of the mounting points (shown in

Figure 1) allow direct mounting on a standard simplex

(single circuit) junction box. There is a wiring cutout in the

center of the unit near the terminal strips.

3.20"

1.60"

0.00"

2.10"

1.10"

0.00"

2.00"

2.75"

5.20"

3.50"

0.42"

Figure 1: AirSense Model I-310en Mounting Dimensions

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 7of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 5

The Model I-310en will operate from an AC or DC input

voltage between the values called out in the specifications on

page 3. The power supply leads are connected to the two-

terminal power connector. shown in Figure 2.

The Model I-310en must never be connected directly to

line power. Operation at voltages higher than specified will

damage the unit and void the warranty.

When operating from DC power, the polarity of the power

leads must be as shown in Figure 2. Reversed polarity

UP

button

User

Jumpers

Shorting block here

for current output.

Shorting block here

for voltage output.

Analog Output Selector

DOWN

button

Analog

Output

Upper Mountinhg

Screw Access

Wiring Access

+

-

C DCS 2010

32-0310-30

4-20mA

OUT

RLY

POWER

V

I

DN

-+

0-10V

UP

SEL

SW3

J4

SW1

SW2

JP4

JP1

JP3

JP5

JP2

Lower Mounting

Screw Access

Calibration Nipple

(Under sensor

electronics)

CO2 SENSOR

Power In

20 - 28 VAC

18 - 30 VDC

(Polarity matters

for DC only)

Optional

Relay Contact

Output

Figure 2:

M

odel I-310en Component Locations

Wiring

This section describes the external connections to the Model

I-310en. Figure 2 shows the location of the components

described in the following sections.

Power Supply

The Model I-310en is not a loop powered device

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 8of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 6

connection will not damage the unit, but will make it

inoperable until the connection is reversed.

Signal Output

The Model I-310en provides either a 0 - 10 volt or a 4 - 20 mA

current loop output at the two terminals of the analog output

connector. The type of analog output is determined by the

setting of the analog output selector.

The unit is shipped from the factory with the top-of-scale set

to 2000 ppm. See the Analog Top-of-Scale Adjustment

section on page 9 to change the analog output range limits.

The analog output of the Model I-310en is completely isolated

from the power supply. The common outputs of multiple

units can be connected together with no interaction

regardless of power supply hook-up.

Voltage

When the two bottom pins of the analog output selector are

connected with the shorting block, a voltage output appears

at the terminals marked ANALOG OUTPUT. The output

voltage increases linearly with CO2 concentration from 0

volts at 0 ppm to 10 volts at the top-of-scale concentration.

Current

When the two top pins of the analog output selector are

connected with the shorting block, a current output appears

between the two terminals marked ANALOG OUTPUT.

The output current increases linearly from 4 mA at 0 ppm to

20 mA at the top-of-scale concentration. The unit is shipped

from the factory with the top-of-scale set to 2000 ppm. See

the Analog Top-of-Scale Adjustment section on page 9 to

change the top-of-scale value.

If the total resistance between the two terminals exceeds the

specified maximum loop resistance, the output current may

be erroneously low at high concentrations.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 9of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 7

Cover Replacement

Engage the top center of the cover under the latch at the top

of the base, then press the bottom of the cover onto the base

until it latches.

Field Adjustments

This section describes the features that can be field

configured and the procedures to make these changes. All

these procedures require the closing of one and sometimes

two jumpers.

When making adjustments to units without displays, the

current setting of the value being adjusted is reported by the

analog output. If there is no display, the procedures below

assume that the unit is set to voltage output and only a volt

meter is connected to the analog output terminal.

Note that the scaling of the analog output is not always the

same.

High CO2 Limit Adjustment

An adjustable high CO2 limit is a standard feature of the

Model I-310en. The front panel LED changes from steady to

blinking when the indicated concentration is above the high

CO2 limit value. An optional contact closure is available

which actuates when the high limit is exceeded.

The High CO2 Limit value is adjusted as follows:

1. Note whether the shorting block at jumper JP5 is

covering both pins or only a single pin, then

borrow the shorting block and slide it over the two

pins of jumper JP3 (see Figure 2 on page 5).

2. If the display is present when JP3 is closed it will

show the current high limit setpoint in ppm CO2.

If there is no display the current value of the high

CO2 limit is reported by the analog output scaled at

500 ppm/Volt. A high CO2 limit of 1000 ppm is

indicated by and output voltage of 2.0 volts.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 10 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 8

3. The high CO

2

limit value is adjusted with the ‘UP’

and ‘DOWN’ buttons while JP3 is closed. When

JP3 is opened, the new relay setpoint takes effect

and is stored in non-volatile memory.

4. Remove the shorting block from JP3 to save the

value, and restore the shorting block to its original

position on JP5.

High CO2 Limit Hysteresis Adjustment

The default high CO2 limit hysteresis is approximately 40

ppm and can be inspected and adjusted between 0 and 200

ppm as follows:

1. Note whether the shorting block at jumper JP5 is

covering both pins or only a single pin, then

borrow the shorting block and slide it over the two

pins of jumper JP3 (see Figure 2 on page 5). Use a

narrow-bladed screwdriver or the like to

momentarily connect the two pins of JP1 while JP3

is closed.

2. If the display is present it will show the current high

CO2 limit hysteresis value in ppm CO2.

If there is no display the current value of the high

CO2 limit hysteresis is reported by the analog output

scaled at 20 ppm/Volt. A high CO2 limit hysteresis

of 40 ppm is indicated by and output voltage of 2.0

volts.

3. The high CO2 limit hysteresis value is adjusted with

the ‘UP’ and ‘DOWN’ buttons while JP3 is closed.

4. Remove the shorting block from JP3 and return it to

its previous position over one or both pins of jumper

JP5. When the jumper is opened, the new High

CO2 Limit Hysteresis setpoint takes effect and is

stored in non-volatile memory.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 11 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 9

Analog Top-of-Scale Adjustment

This section refers to advanced features of the Model I-310en.

2000 ppm full scale users need not perform this adjustment.

Unless explicitly ordered otherwise, the Model I-310en ships

from the factory set for an analog output range of 0 to 2000

ppm.

The top-of-scale concentration (i.e. the concentration at

which the analog output is at its maximum value) can be

adjusted between 500 and 5000 ppm.

To change the top-of-scale value use the following

procedure:

1. Record whether the shorting block at jumper JP5

is covering both pins or only a single pin, then

borrow the shorting block and slide it over the two

pins of jumper JP4 (see Figure 2 on page 5).

2. If the display is present it will show the current top-

of-scale value in ppm.

If there is no display the current top-of-scale value is

indicated by the analog output at a scaling of 500

ppm/volt.

3. Use the ‘UP’ and ‘DOWN’ buttons to adjust the top-

of-scale to the desired value. A top-of-scale setting

of 5000 ppm corresponds to an output voltage of 10

volts.

4. Remove the shorting block from JP4 to save the

value, and restore the shorting block to its original

position on JP5.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 12 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 10

Altitude Correction Considerations

The Model I-310en is factory-

calibrated for operation at sea

level. When operated at higher

elevations, the calibration will

correct for altitude as the unit

detects outside air concentration

In applications where the detected

CO2 concentration does not

routinely fall close to outside-air

levels, the procedure below can be

used to set the operating elevation.

Beware that this procedure

works only on units that are

calibrated for sea level

operation.

Altitude Correction Procedure

To adjust the calibration of a unit

currently calibrated for sea level

operation to a new altitude proceed as follows:

1. Let the Model I-310en stabilize to the ambient CO2

concentration, and record the reading in ppm. If the

reading is greater than 1500 ppm, wait for a lower

reading before performing this procedure.

2. Multiply the reading by the scale factor corresponding to

the operating altitude in the altitude correction table.

For instance if the unit is operating at an altitude of 4000

ft, the scale factor from the table is 1.14. If the

concentration reads 420 ppm, multiply 420 times 1.14

giving 478 ppm. Adjust the display to read 480.

3. Remove the Model I-310en’s cover (see cover removal

procedure on page 4).

4. Note whether the shorting block at jumper JP5 is

covering both pins or only a single pin, then borrow the

shorting block and slide it over the two pins of jumper

JP2 (see Figure 2 on page 5). Use the 'UP' and 'DOWN'

ALTITUDE

CORRECTION TABLE

Altitude

[feet]

Multiplication

Factor

0 1.0

500 1.02

1000 1.03

1500 1.05

2000 1.07

2500 1.08

3000 1.10

3500 1.12

4000 1.14

4500 1.16

5000 1.18

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 13 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 11

buttons to change the indicated concentration to the value

just calculated.

If there is no display the indicated concentration is

reported by the analog output with a scaling of 200

ppm/volt.

5. Remove the shorting block from jumper JP2 and return it

to its previous position over one or both pins of jumper

JP5.

6. Replace the cover (see procedure on page 7).

Calibration

This section describes the calibration verification procedure

and calibration adjustment procedures.

Verification Procedure

A quick but approximate calibration verification can be done

by supplying the unit with outside air and letting the reading

stabilize. CO2 concentrations in outside air are typically

between 375 and 450 ppm.

A more accurate calibration check requires the use of

calibration gas of known concentration. 2000 ppm

calibration gas is recommended A calibration kit that

includes a digital display is available from the factory.

To verify the Model I-310en's calibration, proceed as follows:

1. Remove the front cover of the unit (see procedure on

page 4).

2. If there is no display on the unit being calibrated, connect

a meter to the analog output terminals. Check the setting

of the analog output selector (see Figure 2 on page 5) to

determine whether the unit is set for voltage or current

output.

3. Locate the calibration nipple under the sensor’s circuit

board as shown in Figure 3.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 14 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 12

4. Remove the dust

cover from the

barbed calibration

nipple by grasping

its top with a pair of

needle-nose pliers

and pulling straight

back.

5. Attach a 1/8 “ ID

flexible tube to the

nipple and establish

a flow of between

50 and 100 cc/min

(0.002 to 0.004

SCFM) of 2000

ppm or or lower

concentration

calibration gas through the sensor. Allow approximately

two minutes for the reading to stabilize.

6. If the reading differs by less than ± 50 ppm from the

known concentration of the calibration gas, no adjustment

is recommended; proceed directly to step 9.

Otherwise note whether the shorting block at jumper

JP5 is covering both pins or only a single pin, then

borrow the shorting block and slide it over both pins of

jumper JP2 (see Figure 2 on page 5).

7. Use the 'UP' and 'DOWN' buttons (see Figure 2 on page

5) to adjust the reading.

8. When the reading agrees with the concentration of the

calibration gas, remove the shorting block on jumper JP2,

and replace in its original position at jumper JP5.

9. Turn off the calibration gas flow, disconnect the gas

tubing from the calibration nipple and replace its dust

cover. Remove the meter leads from the terminal strip

and replace the front cover (see procedure on page 7).

Figure 3: Showing location of

calibration nipple

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 15 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 13

Optional High Limit Contact Relay

The high CO2 limit relay option provides a dry (i.e.

unpowered) contact closure that activates when the detected

concentration rises above the high CO2 limit. The high limit

is adjustable from 0 to 5000 ppm.

Setting High Limit Contact Polarity

The polarity of the high limit contact is set with jumper JP5

as shown in the table below.

Jumper JP5 Relay Operation

CLOSED

(factory default)

normally open

closes above setpoint

OPEN normally closed

opens above setpoint

To open jumper JP5 remove the shorting block from the two

pins, and replace it so that it engages only a single pin of the

jumper. The shorting block should not be discarded; it is

required for all field calibration procedures.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 16 of 17

I-310eN – UserManual

AirSense Model I-310en Operator’s Manual

10/16/11 Page: 14

Disclaimers and Notices

Operational Limitations

The standard Model I-310en has the following operational

limitations:

1. The unit is not intended for routine operation at CO2

concentrations below 400 ppm.

2. The unit expects to see outside-air CO2 concentrations

for at least a few hours every few weeks.

For CO2 sensing applications where these two limitations

can not be met, contact the factory for guidance

on achieving maximum accuracy under these conditions.

Safety Critical Applications

These products are not designed, intended or authorized for

use in life safety systems or devices where failure of the

Model I-310en to perform to specification may be reasonably

expected to result in significant risk of injury or death.

INTEC Controls | 12700 Stowe Drive, Suite 100, Poway, CA 92064 | Ph: (858) 578.7887 & (888) GO.INTEC | inteccontrols.com

Specifications subject to change without notice. | 111011 | PRE 200217 | Page 17 of 17

I-310eN – UserManual

Table of contents

Popular Accessories manuals by other brands

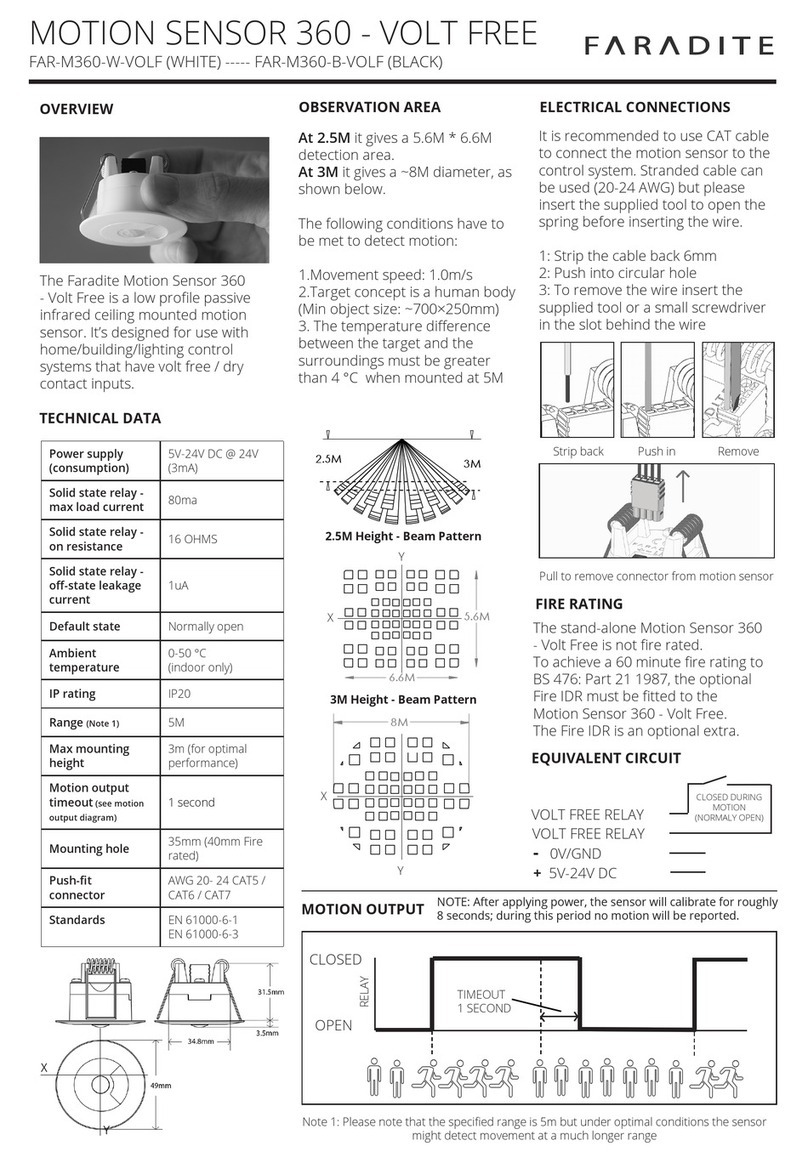

Faradite

Faradite FAR-M360-*-VOLF Series quick start guide

Siensor

Siensor D100 Series Passport

S+S Regeltechnik

S+S Regeltechnik AERASGARD RFTM-LQ-CO2 Operating Instructions, Mounting & Installation

SkyBound

SkyBound 2 ARCH TRAMPOLINE NET Assembly and installation manual

Nortel

Nortel 1000BASE-XD Using

Anritsu

Anritsu MA24 A Series Operation manual