Integrity I Fuse 105 User manual

Pag. 1/50

I Fuse 105

I Fuse 60

Multipurpose Electrofusion Control Unit (ECU)

Soldadora multifunciόn - Unidad de control de la soldadura

USER MANUAL

MANUAL DEL USUARIO

Number of document IO0001 Edition 01 of 16/10/2014 Revision 03 of 22/02/2019

Pag. 2/50

This equipment has been manufactured according to the following documents:

Este Equipo cumple con los siguientes documentos:

Directives (Europe)

Standards

IEC EN

(Harmonized)

ISO

UNI EN ISO

IEC

other

DIRECTIVE 2006/95/EC OF THE EUROPEAN PARLIAMENT AND

OF THE COUNCIL of 12 December 2006

61000 – 6 – 2

12176 – 2

17050 – 1

DVS 2208 – 1

61000 – 6 – 3

12176 – 3

17050 – 2

UNI 10566

DIRECTIVE 2002/95/EC OF THE EUROPEAN PARLIAMENT AND

OF THE COUNCIL of 27 January 2003

61000 – 6 – 4

12176 – 4

60335 – 1

60335 – 2 – 45

13950

DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND

OF THE COUNCIL of 15 December 2004

61558-1

61558-2-6

WE REMIND YOU THAT THE DESCRIPTION OF ALL ADVANCED FEATURES OF THIS EQUIPMENT ARE STORED IN THE PROVIDED

DIGITAL SUPPORT (MEMORY STICK OR CD).

RECORDAMOS QUE LA DESCRIPCIÓN DE TODO EL USO AVANZADO DE ESTE EQUIPO ES EN DIGITAL MEDIA (MEMORY STICK O CD)

SUMINISTRADO.

Pag. 3/50

i) Introduction

Integrity Fusion Products, Inc. is free to modify the features of the control unit described in this user manual and the information

contained in it without any notice. Updates of this manual are available on www.integrityfusion.com

All rights reserved, it is strictly prohibited to reproduce this document or part of it in any form whatsoever.

Dear Customer,

Thank you for choosing an electrofusion control unit (ECU) from the range of products. This manual is designed to inform and

illustrate the features and operating on the correct methods of your new electrofusion control box I Fuse 60 and 105. It contains all

the technical information and documentation for correct and safe use of the equipment by qualified operators. Please read all parts

of the manual carefully and keep it in a safe place for future consultation of the ECU. The manual is designed to allow an easy and

immediate use of the ECU and for this reason it is divided into two parts. The first, which describes the basic functions for the

welding of electrofusion fittings and the second part - included into the memory stick - showing all the complex and advanced

functions that this new and unique electrofusion control unit is able to perform simplifying your work.

We are confident that you will enjoy getting to know your new Electrofusion Control Unit and will be able to use it profitably for

many years to come.

All the best from,

Integrity Fusion Products, Inc.

270 Parkade Court

Peachtree City, GA 30269 USA

P +1 770 632 7530

F +1 770 632 7540

www.integrityfusion.com

Pag. 4/50

Index

i) Introduction pag. 3

1) Graphic signs used in this manual pag. 6

2) Product description pag. 6

3) General warnings pag. 6

3.1) Workplace warnings pag. 6

3.2) Electric current warning pag. 6

3.3) Personal safety pag. 7

3.4) Operating and care of the electrofusion control unit pag. 7

3.5) Authorization and operators pag. 7

3.5.1) Fusion process preparation pag. 7

3.5.2) Fusion process control pag. 8

3.5.3) Safety distances during the fusion process pag. 8

4) Technical data and dimensions pag. 9

5) Technical file according to ISO 12176-2 pag. 11

6) Technical information pag. 12

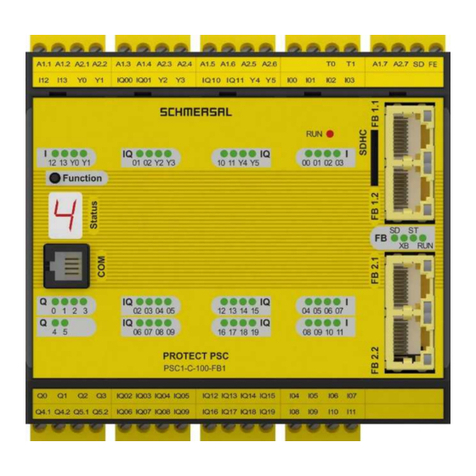

6.1) Function keys pag. 12

6.2) Front display panel pag. 12

6.3) Connections pag. 12

6.4) Accessories pag. 13

6.4.1) Optical wand pag. 13

6.4.2) USB Memory Drive pag. 13

7) Transporting and handling pag. 13

8) Storage pag. 13

9) Disposal pag. 13

10) Functioning and use pag. 13

10.1) Intended and non-intended use pag. 13

10.2) Range of applications pag. 14

10.3) Limits pag. 14

10.3.1) Operating limits pag. 14

10.3.2) Power supply pag. 14

10.3.3) Extension power supply cable pag. 14

Pag. 5/50

10.3.4) Environmental limits pag. 15

11) Hazards pag. 15

12) Training of personnel pag. 15

13) Instructions pag. 15

13.1) Start-up, Emergency Stop, Reset pag. 15

13.1.1) Start-up pag. 15

13.1.2) Emergency Stop pag. 17

13.1.3) Reset pag. 17

13.2) Fusion start-up pag. 17

13.2.1) Automatic fusion by Bar Code reading pag. 17

13.2.1.1) Scanner usage pag. 18

13.2.1.2) Verify data transferred and fusion start-up pag. 18

13.2.2) Fusion by manual introduction of Bar Code pag. 19

13.2.3) Fusion by manual introduction of Voltage and Fusion Time pag. 21

13.2.4) Fusion cycle’s Emergency stop pag. 22

13.2.5) Fusion cycle’s Reset pag. 23

14) Fusion Procedure pag. 23

15) Maintenance pag. 23

16) Error Messages pag. 24

17) Information on generators pag. 26

18) Warning on generators use pag. 26

Pag. 6/50

1) Graphic signs used in this manual

1.1) general hazard

1.2) electric shock risk

1.3) prohibition

1.4) obligation

1.5) using face protection

2) Product description

I Fuse 60 or 105 is a Multipurpose Electrofusion Control Unit (ECU) capable of delivering to electrofusion fittings the energy

required to carry out the fusion. This device controls with a frequency of 4 times per second, that all the electrical parameters are

in agreement between themselves and coherent with those indicated by the manufacturer of electrofusion fittings. I Fuse 60 or 105

works with fusion fittings like "electrofusion" made of polyethylene, PE80, PE100, PE-X and PP. I Fuse 60 or 105 can be used at

ambient temperature within the range -10; + 45 °C / 14; 113 °F. Utilization beyond these limits must be agreed in advance with our

technical department.

ECU automatically sets correct fusion parameters by Scanner/Optical Wand reading or manual introduction of Bar Code visible on

the couplers (according to ISO13950 ). In case couplers do not show Bar Code, it is possible to manually introduce Voltage and

Fusion Time recommended by fitting’s manufacturer.

I Fuse 60 or 105 has an internal memory for storage of fusion parameters (electrical parameters, time, fittings features, etc.). It is

also possible to print out Fusion Data and download them to a PC for further processing and/or integration in proper Data Base.

Any use not mentioned in this manual is not allowed.

3) General warnings

Read all warnings and technical information. Otherwise you can being involved in accidents at the workplace. Follow all indications

for health and safety at work.

3.1) Workplace warnings

a) Keep the workplace clean and well lighted. Untidiness and darkness increase the possibility of accidents.

b) Do not use machine in explosive atmosphere, such as in the presence of flammable liquids, gases or dusts. Under

certain conditions, ECU may produce an electrical arc which could cause a fire.

c) Keep children and unauthorized people away.

3.2) Electric current warning

a) Electrical tools’ plugs should be placed properly into the sockets. Never modify plug on this ECU. Unmodified plugs and

sockets reduce the risk of electrical shock.

b) Avoid contact between people and pipes, radiators, ovens and refrigerators. There is a high risk of electrical shock if

your body is in close contact with the elements mentioned before.

c) Avoid exposing to rain and water in general ECU. Contact with water increases risk of electrical shock.

Pag. 7/50

d) Do not abuse electrical cables. Do not use electrical cables to carry out ECU. Do not unplug by pulling on electrical

cable. Keep electrical cables away from heat, oil, sharp blades and moving parts. Damaged or twisted electrical cables

increase the risk of electrical shock.

e) Use an extension cable suitable for outdoor use. This reduces the risk of electrical shock.

f) Prevent unintentional ignition of ECU. Make sure the switch is turned OFF before plugging in power, lifting or carrying

the machine. Transportation when ECU’s switch is turned ON increases the risk of accidents.

3.3) Personal safety

a) Stay alert, it is important to use care with ECU. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A single moment of inattention while operating power tools may result in serious personal

injury.

b) Use of personal safety equipment.

c) Do not underestimate ECU. Always keep a good balance. This can help to get more control in unexpected situations.

d) Dress properly. Do not wear loose clothing and jewellery. Keep hair, clothes and gloves away from electrically live

parts. Loose clothing, jewellery or long hair may touch electrically active components.

3.4) Operating and care of the electrofusion control unit

a) Do not force ECU. Use it properly for the application to be performed. Its proper use allows to make it work in the best

manner and with greater safety.

b) Do not use ECU if power switch does not work. Any power tool which cannot be controlled with the switch is

dangerous and must be replaced.

c) Keep ECU out of reach of children and do not allow persons unfamiliar with the electrofusion machine to operate the

power tool. Power tools are dangerous in the hands of untrained users.

d) Maintenance. Visually inspect ECU. Any anomalous condition may affect the operations performed by the electrofusion

machine. If damaged, contact Integrity Fusion Products, Inc.

e) Use ECU and its accessories in accordance with these instructions and in the manner intended for the particular type of

machine, taking into account the working conditions and the work to be performed. Use of ECU for operations different

from those intended in this user manual is forbidden.

3.5) Authorization and operators

a) ECU must be used by trained and authorized operators in accordance with national and international standards.

b) The appliance is not intended for use by children, persons with limited physical or mental abilities or without

experience and knowledge of it, unless they are under the supervision of or instructed in its use by a person responsible

for their safety. Children must be supervised so that they do not play with the appliance.

3.5.1) Fusion process preparation

a) Read and follow the national and international regulations for the prevention of accidents related to welding on

construction sites.

b) Follow the installation instructions recommended by the manufacturer of the fittings.

c) Do not connect a fitting if its fusion parameters are not present in the ECU’s range.

d) Do not start the fusion process if the fusion parameters on the ECU’s screen do not correspond with those on the

fitting.

Pag. 8/50

3.5.2) Fusion process control

a) The operator must check ECU and the complete fusion process, including the cooling phase of the joint.

b) In case of smoke and/or loss of melted polyethylene must immediately stop the process by pressing the red STOP

button.

c) Be aware that the fusion of any material involves a risk of fire ignition. Inquire about how to alert the fire department

and/or providing a device for extinguishing of fires.

3.5.3) Safety distances during the fusion process

a) Avoid body contact with fittings or cables during fusion process. Keep a minimum safety distance of 1 meter / 3.28 ft.

Pag. 9/50

4) Technical data and dimensions

Technical data I Fuse 60 I Fuse 105

CEI EN 60335 – 1 Classification Electronic device in Class I

ISO 12176-2 Classification P2 3 U S2 V AK D X P24 U S2V AK D X

Max Working Range 400 mm / 16” IPS + DIPS 1.200 mm / 48” IPS

Fusable Materials PE / PEX / PP / PP-R

Transfer fusion parameters Scanner / Manual

Input Voltage 120 V AC, (102 V – 138 V) 230 V AC, (185 V – 260 V)

Input Current 32 A 16 A

Input frequency 50 Hz (40 – 70 Hz) 50 Hz (40 – 70 Hz)

Output Voltage 8 - 48 V AC

Output Current

100% = 50A

60% = 70A

30% = 90A

65 A >20000 sec. – 105 A max 1400 sec.

@ 20 °C / 68 °F

Output Peak 100 A (electronically limited) 120 A (electronically limited)

Nominal power 2500 W 3600 W

Working temperature range -10 °C + 50 °C / 14 °F to 113 °F

Protection IP54

Weight (cables included) 18 Kg / 40 lbs. 24 Kg / 53 lbs.

Input cable

Length 4,0 m / 13≅ft

NEMA L5-30 125V/ 30A Twist Lock Plug

Length 4,0 m / 13≅ft

NEMA L14-30 250V/ 30A Twist Lock Plug

Output cable 3,0 m / 10≅ft

Welding Terminals 4,0 mm (4,7 mm adapters)

Display graphic, 128x64 Characters ( alphanum.), background lighting

Monitoring Functions

Input

Voltage / Current / Frequency

Output Voltage / Resistance / Contact / Short Circuit / Current

Other Software / Working Temperature / Service

Error messages Plain Text / Acoustic Signals

Kit USB Memory Drive, Transport Case, User Manual

Pag. 10/50

MEMORY DATA

Memory

I Fuse 60

I Fuse 105

No. of reports 7500

Interface USB / RS232 USB / RS232 / RADIO

Data format CSV –TXT (changeable to any format)

Data Retrieval

Fusion data Voltage / Current / Nominal/Actual fusion time / Mode / Resistance / Error Messages

Data fitting Bar Code information (ISO 13950) / Type / Size / Manufacturer

Welding machine No. Series / No. Inventory / Last Service Date / Working Hours / Software

Welder

Bar Code (or ISO 12176-3) with functions control:

•identification

•manual setting

•system configuration

Traceability

No. work Max. 40-digits (alphanumeric) by Bar Code

Welder code ISO-12176-3

Weather conditions DVS 2207 / 2208

Fusion Bar Code ISO 13950

Traceability fitting code ISO 12176-4

1st pipe traceability code ISO 12176-4

2st pipe traceability code ISO 12176-4

3st pipe traceability code / Infotext ISO 12176-4

ACCESSORIES

Ancillaries (standard supply)

Manual scraper

Optionals I Fuse 60 / 105

Optical wand

DIMENSIONS (mm)

Code

I Fuse 60

I Fuse 105

A

329

329

B

233

233

C

252

252

D

309

309

E

165

165

Pag. 11/50

5) Technical file according to ISO 12176-2

Classification

Type

Classification

I Fuse 60

P23 U S2V AK D X

IFuse 105

P24 U S2V AK D X

Simulated curve 24V (output voltage)

Duty cycle

Additional information

Soft Start: adaptive

Soft End:

Ambient Temperature Compensation: according to ISO 13950

Fitting Temperature Compensation: No

Fusion stored: 7500 fusion cycles

Pag. 12/50

6) Technical information

6.1) Function keys

6.2) Front display panel

LED Voltage Indicator

LED Ready Indicator

LED Error Indicator

6.3) Connections

ECU is connectable to voltage by means of plugs. These last are conform to their specific standards and supplied as

normal equipment. Do NOT change/alter plugs without written authorization from Integrity Fusion Products, Inc.

The USB connector allow ECU’s connection to other equipment provided with equal connection system.

ECU is connectable to electrofusion fittings by means of the specific welding lead provided with welding terminals and

adapters . Do NOT replace welding terminals without written authorization from Integrity Fusion Products, Inc.

Power On / Off

Menu Button

Cancel or Back Button

Option Button

Start Button

Menu Button

Confirm Button

Option Button

Stop Button

GRAPHIC DISPLAY

System connection plug / generator

Pag. 13/50

6.4) Accessories

6.4.1) Optical wand

If looking for wand’s technical features usable on this electronic device, please contact Integrity Fusion Products, Inc.

service

6.4.2) USB Memory Drive

Can be used memory drive (USB key) normally present on the market. In order to work properly with our device,

technical requirements are:

• ≥ 1 Gbyte memory capacity

• Formatting FAT 16/32

7) Trasporting and handling

ECU shall be transported using the supplied box. Do not knock the machine and do not damage the body. In case of damage or

bruising, do not connect to the fusion power supply and contact the service center. Be very careful moving ECU. Switch off ECU

using the switch before disconnecting to the input voltage.

8) Storage

If possible, ECU have to be preserved in its supplied box. Avoid exposure to temperatures above 60 °C / 140 °F and lower than

- 20 °C / - 4 °F. The storage place should be dry, not humid.

9) Disposal

This ECU and its packaging should be recycled respecting the environment.

This symbol means: Do not throw the electrical tools in household waste.

According with the European Directives 2002/95/EC and 2002/96/EC - concerning the restriction of hazardous

substances (RoHS) and the treatment of electrical and electronic waste equipment (WEEE) and their application

to national rights - equipment and electrical tools that are no longer usable must be collected separately and

disposed respecting the environment. The owner of this machine must use the disposal method using in its

territory. Please note that there are the presence of aluminum (frame) and copper (transformer) between recyclable materials.

10) Functioning and use

10.1) Intended and non-intended use

This ECU is designed to operate in environmental and supply conditions indicated in the table showing technical data

(paragraph 4). It’s an electronic device which must be exclusively used to provide the required energy for electrofusion

fittings. The supply circuit must be connected to an electrical system with protection. The electrical circuit supplying

current to the fittings is a PELV (Protected extra low voltage) "safety low voltage" and it can be used in areas defined as

"restricted conductors" (e.g.: excavations with presence of humidity). Integrity Fusion Products, Inc. is not responsible for

any other use not covered in this handbook.

Pag. 14/50

Methods of fusion data transfer of the fitting to I Fuse 60 or 105 are:

•Bar Code (ISO 13950, type 2/5i, 24 digits)

Bar Code contains all the instructions of the fitting’s manufacturer useful for a proper fusion. Bar Code contains,

among others, the following information: manufacturer, type, diameter, voltage, fusion time (with the relative

correction of the time according to the ambient temperature) resistance and its tolerance, etc.

•Manually selection of Bar Code numbers

In the case of the Bar Code cannot be read by the optical reader (defective scanner) it is possible to insert, either

manually, all numbers that compose it.

•Manually selection of fusion time and fusion voltage

Unlike what stated above, it is possible to directly insert the data relating to the fusion voltage and the fusion time

indicated on the fitting. The user must be aware that in this case ECU is unable to correct the fusion time

according to the ambient temperature.

10.2) Range of applications

I Fuse 60 or105 is a Multipourpose device able to weld all electrical fittings with an operating voltage (AC)

between 8 and 48 V and at maximum of 50 °C / 122 °F ambient temperature.

10.3) Limits

10.3.1) Operating limits

ECU(s) can operate within the following functional limitations:

Ambient T.

°C (Celsius) / °F (Fahrenheit)

Model of Control

Unit

Peak current

required by the

fitting

Average current Maximum fusion

time (minutes)*

20 °C / 68 °F

I Fuse 60

100 A

40 A

330

20 °C / 68 °F

100 A

60 A

40

20 °C / 68 °F

I Fuse 105

120 A

65 A

330

20 °C / 68 °F

120 A

105 A

23

* can vary according to environmental temperature

The cooling fan has an IP55 protection degree and it can operate in dusty and humid environments. Its

operation is due to the thermal load induced by the amount of energy required for the fitting and the ambient

temperature (it does not work with medium-small diameter fittings).

10.3.2) Power supply

Power supply shall be in accordance with the table in clause 4: “Technical Data and Dimensions” (pag. 9).

According to local regulations the ECU supply mains should be provided with: a protective earth circuit, a “slow”

fuse and a RCCB device (residual current-operated protective - circuit breaker).

Connect the ECU only to a good quality voltage.

In case of using a motor generator, its power must be adapted to the diameter of the fitting to be welded,

taking care to choose models with harmonic current distortions contained within 20%. If the generator is not in

double insulation, the connection to earth must be executed in accordance with the applicable regulations and

legislation.

10.3.3) Extension power supply cable

If necessary, use an extension cable having the following features:

Pag. 15/50

Model of control unit LENGTH CROSS SECTION

I Fuse 60

(110 V)

Up to 20 m

Up to 66 ft

3 x 4 mm2

3 x 11 AWG

From 20 to 50 m

From 66 to 164 ft

3 x 6 mm2

3 x 9 AWG

From 50 to 100 m

From 66 to 328 ft

3 x 10 mm2

3 x 7 AWG

I Fuse 105

(230 V)

Up to 20 m

Up to 66 ft

3 x 4 mm2

3 x 11 AWG

From 20 to 50 m

From 66 to 164 ft

3 x 6 mm2

3 x 9 AWG

From 50 to 100 m

From 66 to 328 ft

3 x 10 mm2

3 x 7 AWG

IT IS FORBIDDEN TO EXTEND FUSION WIRES !!!

10.3.4) Environmental limits

The electrofusion machine is NOT designed to operate in explosive atmospheres

Important note: welding can generate magnetic fields around the electrofusion fittings. Verify that the surrounding

environment would be compatible. When performing welds, by using electrofusion fittings that are requiring high

power (e.g.: more than 40 A), you are request to check that ferrous masses and/or electromagnetic fields generated

by high voltages aren’t present in the surrounding welding area (e.g.: high voltage grids)

11) Hazards

The safe use of this machine depends on reading general instruction and on its care and maintenance. Integrity Fusion

Products, Inc. has used all the known techniques to minimize any risk of electric shock providing by a commensurate insulation

with the conditions of use.

12) Training of personnel

Reading the technical information of this manual provide the necessary knowledge for a safe use of I Fuse 105. Integrity Fusion

Products Inc. has a training center (tel. +1 770 632 7530) from which you can schedule a training course. The presence of

qualified technicians to perform the fusions activity is a further guarantee of reliability.

13) Instructions

13.1) Start-up, Emergency Stop, Reset

13.1.1 ) Start-up

Before turning on the ECU do the following actions:

• Check the equipment, cables, plugs and adapters. Replace damaged parts;

• Fully unwind supply and fusion cables (including extension);

• Verify that the switch is OFF;

• Place the machine close to the joint to be fused so that it is firmly installed and staying securely on it’s

rubber feet. Carefully choose the control box place;

• If using a generator, start before connecting the ECU, if necessary, adjust the output voltage and wait

until it is stabilized.

• Connect the control box to the generator (or mains voltage);

• Press the switch on the ON position to start ECU

Pag. 16/50

•After you have pressed the on / off button the display shows the following message

•In succession messages of start-up including prohibition of use in environments with explosive

atmosphere.

•Pressing the < > buttons you can select the operations to be done:

proceed with the welding

displays memory data

system edit (see instructions in the USB memory drive)

provides information related to the control unit

fusion data export (see instructions in the USB memory drive)

go back to the switch on

Press OK button to confirm the choice. Press the Cbutton to go back to the previous view.

Power on/off switch in OFF

position

PRESS START

WELD! 10,48

Pag. 17/50

13.1.2) Emergency Stop

If necessary, at any time during use you can cause an emergency stop by pressing the on / off button to the OFF

position, or by pressing the STOP button.

Having pressed the on / off button to the OFF position (in any case after disconnecting the control unit from the

power source) after the following restart you will see this message: "Warning, Error, Power interrupted before

the end of the work". Press OK button to proceed and the display shows:

Having pressed the STOP button, you will see this message: "Error, STOP command! Welding Failed ". Press the

OK button to proceed and the display shows:

13.1.3) Reset

Reset Procedure to do after pressing the on / off button in the OFF position

•Unplug the fitting from the control box terminals (change or wait until the fitting is cool before

another fusion cycle; let pass the cooling time indicated on the fitting)

•Press START to activate the main screen

Reset Procedure to do after pressing the STOP button

•Unplug the fitting from the control box terminals (change or wait until the fitting is cool before

another fusion cycle; let pass the cooling time indicated on the fitting)

13.2) Fusion start-up

13.2.1) Automatic fusion by Bar Code reading

The display shows the highlighted icon COD:

Press the OK button and the display changes

Read the fitting bar code with the scanner

WELD ! 10,48

Pag. 18/50

13.2.1.1) Scanner usage

•put the scanner on the barcode so that the reader is aligned with the bar code;

•press the button in the scanner handle for reading

Correct Way

Wrong Way

Wrong Way

13.2.1.2) Check data transferred and start welding

After reading the fitting bar code through the scanner, press OK button

The display shows the following warning:

Press OK button and you get two views in series:

Press the START button to get the fusion cycle start and the display shows:

Pag. 19/50

The passing of time is indicated by the large and highlighted number. The graduated scale is an indicator of

ambient temperature. Once the cycle is complete the display shows the following screen, then press the OK

button to confirm the end of the fusion cycle:

The display shows the request to disconnect the fitting:

The control unit go back to the first screen for a new fusion cycle:

13.2.2) Fusion by manual introduction of Bar Code

If the automatic reading system - scanner or optical pen - is defected, the control unit will switch to manual

mode.

NOTE: You can switch to manual mode in the presence of scanners working properly. In "Waiting for Scan"

position (page 17), press > button to highlight the bar code icon and then OK button.

Through the use of arrows <and >choose the option to manually enter the entire number code of

fusion fitting and the display shows:

WELD ! 11,48

Pag. 20/50

Use the choice/option buttons +and –to increase or decrease the value to be inserted as the first digit. When

you reach the required value, press the button >to move to the next digit and continuing till the inclusion of all

fitting code digits. After the last digit, press the OK button and the display shows:

The display shows the following warning:

Press OK button and you get two views in series:

Press the START button to get the fusion cycle start and the display shows:

The passing of time is indicated by the large and highlighted number. The graduated scale is an indicator of

ambient temperature. Once the cycle is complete the display shows the following screen, then press the OK

button to confirm the end of the fusion cycle:

The display shows the request to disconnect the fitting:

This manual suits for next models

1

Table of contents

Languages: