Integrity NexPore CF 7.2 User manual

科百特CF–7.2 完整性测试仪使用指南

!

Integrity Tester CF 7.2

Instruction Manual

CF 7.2IntegrityTester Instruction Manual

Integrity Test Instruments

CF 7.2 Integrity Test

All Integrity Test Methods Are Present: Basic Bubble Point, Enhance Bubble Point,

Diffusion Flow Test, Water Intrusion Test, Pressure Decay Test, and Manual Bubble Point

HD 7” Color Touchscreen Allow for Easy Selection of Testing Parameters

Testing Accuracy Has Been Significantly Improved By Using Advanced Digital

Sensors and Brand New Hardware Design

Dual Core CPU Features Include High Speed and Stability Which Ensure the Efficiency,

Safety, and Stability of the Device While in Use

Detailed Testing Data and Integral Testing Curve Provide An Objective Analysis Report

User-friendly Display Design Make it Easy to Use

Electronic Signature and User Classification Managing

Function Help to Eliminate Erroneous Operation

Optional Data Interface Includes Standard RS232/USB

Port and Simulation Control Port

Customized Communication Protocol Provides Automatic

Centralized Management for Customers

Features and Benets

- 1 -

Important Notice

Important Notice

Please read this user manual carefully before

starting CF7.2 Integrity Tester.

Failure to do so may result in product damage

and/or bodily harm.

NexPore SHALL NOT be held responsible for any

damage caused by failure to comply with this

instruction manual.

For additional information, please contact your

NexPore Sales Engineer.

CF 7.2IntegrityTester Instruction Manual

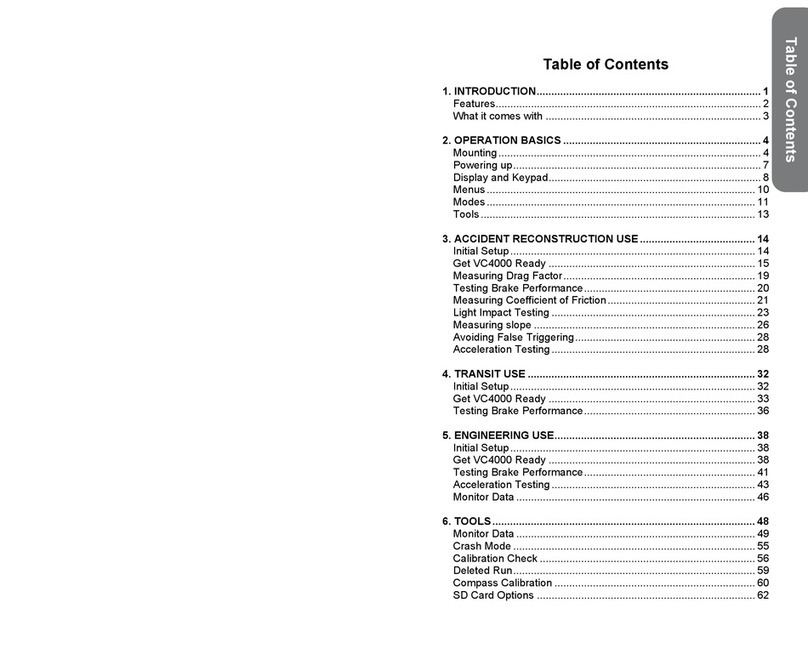

Table of Contents

Table of Contents

- 2 - - 3 -

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

1. CF 7.2 Integrity Tester Safety Instructions

1.1 Electrical

1.2 Compressed Air Use

1.3 Installation and Testing

1.4 Filter Installation

2. CF 7.2 Integrity Test System

2.1 Basic Characteristics

2.2 Standard Features

3. Test Principle Integrity Testing

4. Instrument Functions and Test Procedures

4.1 Instrument Test Functions

4.2 Introduction to Instrument Interface and Test Process

4.2.1 User Login Interface

4.2.2 Test Program

4.2.3 Self Test

4.2.4 Test

5. System Configuration

5.1 System Parameter

5.2 Date/Time

5.3 Communication Setting

5.4 Battery

5.5 Touchscreen

5.6 User Management

5.7 Audit Trail

6. History

7. Data Printing

8. Printer Installation and Maintenance

8.1 Installing/Replacing Paper

8.2 Installing/Replacing Ribbons

9. Replacing the Main Fuse

10. Instrument Calibration

11. Common Faults and Troubleshooting

1.1 Electrical

1. CF7.2 Integrity Tester Safety Instructions

a. Important Notice: Avoid touching the circuit interface

located at the back of the tester with water or other

liquids.

b. When replacing the fuse, the power plug must be

unplugged from the power supply.

c. All repairs must be completed by maintenance

personnel authorized by NexPore.

d. DO NOT OPEN the Integrity Tester Housing when the

power is turned on.

e. Please make sure that the power cord is connected

before turning the Integrity Tester on.

f. Due to GMP Regulations, NexPore advises customers

to calibrate the Integrity Tester once a year

1.2 Compressed Air Use

a. The operator is responsible for providing clean and dry

compressed air to the Integrity Tester

b. Maximum inlet pressure of the instrument is 8000mbar

c. Pressure resistance on the pressure pipe used must be

≥ 8000mbar

d. Operator MUST carefully check the pressure pipe and

fittings before use.

1.3 Installation and Testing

a. This Integrity Tester is a highly sensitive device. Please

be careful when in use.

b. When installing the Integrity Tester, please ensure that

no test solution accidentally pours into the instrument

c. When using chemicals or performing compressed air

tests, take all necessary precautions.

1.4 Filter Installation

a. The pressure range MUST NOT exceed the normal

working pressure range of the filter housing or capsule

filter.

b. Prior to disassembling, ENSURE that the instrument and

filter pressure have returned to normal.

c. Remove the air line on the high pressure line carefully.

1. When powering the Integrity Tester on, first connect

the power cord to the Integrity Tester first and then to

the external power supply.

2. The power supply MUST be grounded

3. NexPore SHALL NOT repair the Integrity Tester due

to damage caused by dismantling it.

4. Please follow all instructions when testing the

equipment

Additional Remarks

Safety Instructions

- 4 - - 5 -

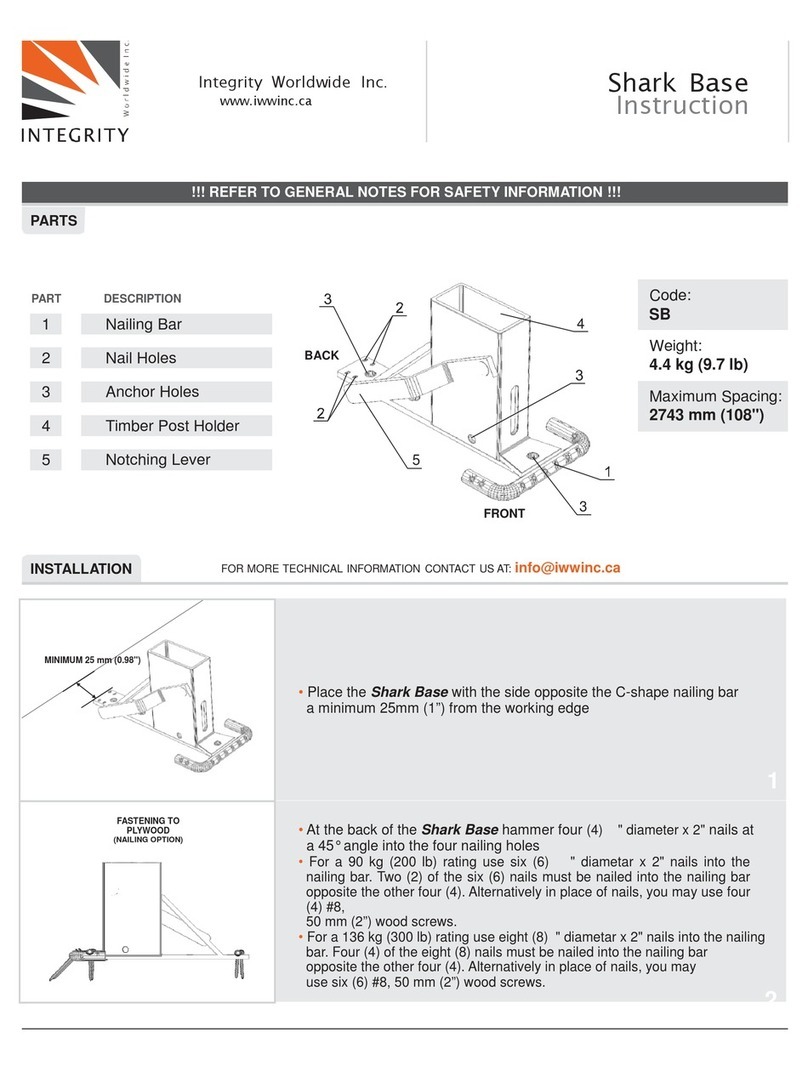

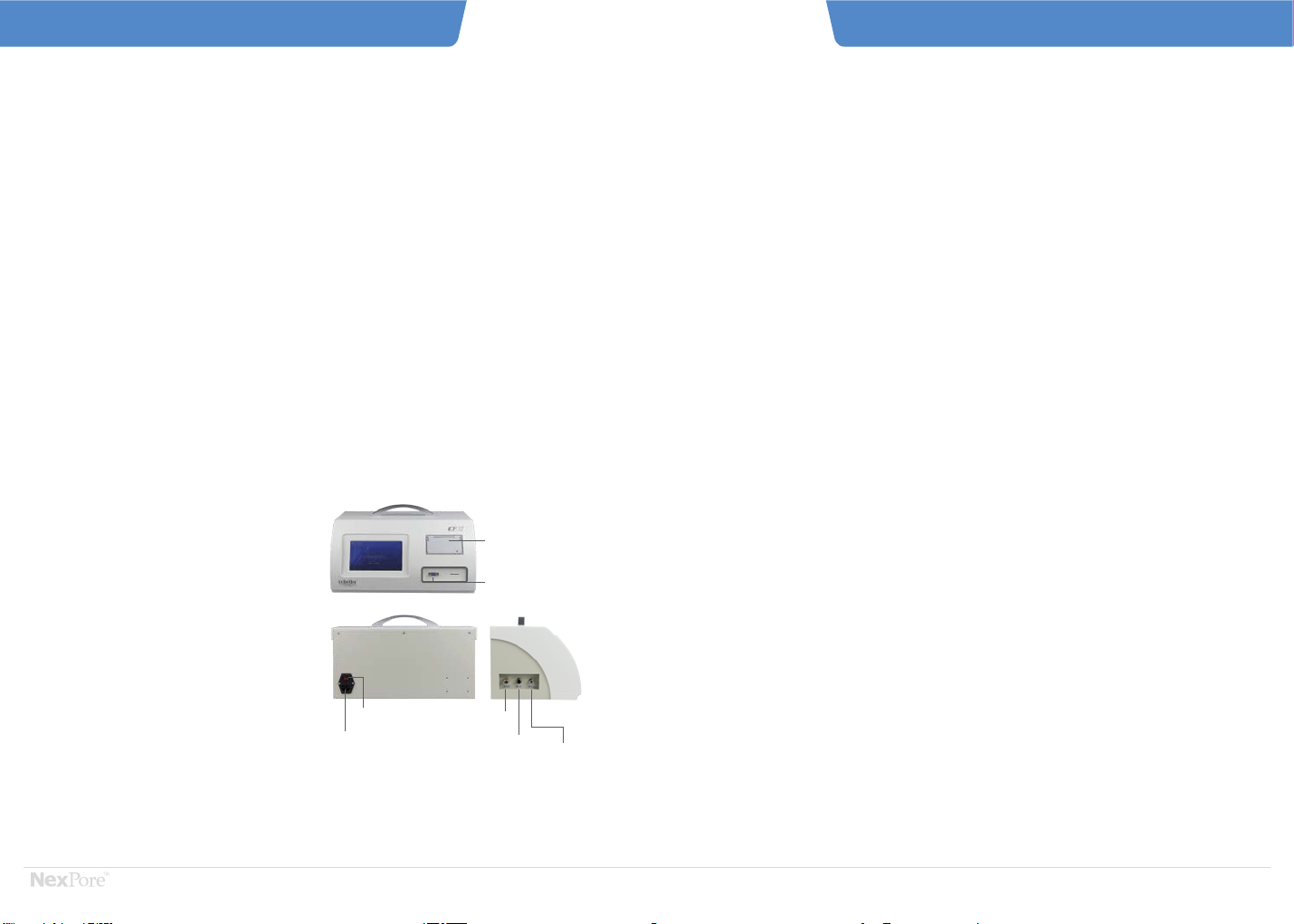

AIR

OUTLET

PRINTER

POWER(ON/OFF)

PLUG EHXHAUST

OUTLET AIR

INLET

EXPORT OUTLET

2.1 Basic Characteristics

2. CF 7.2 Integrity Test System

The instrument includes standard digital and analog

interface (RS232/USB) and customized industrial bus

and analog control ports according to customer needs.

Powerful PC software and customizable communication

protocols provide users with a guarantee of automated

centralized control management.

The R&D team can design specific solutions based upon

customer requirements. With years of on-site experience

and strong professional services, it ensures that the

customers can use the instrument with confidence, and

also provide technical support for the design and

configuration of the customer's filtration system.

CF7.2 Integrity Tester is a compact, light bench-top

instrument weighing 8.2 kg.

User-friendly interface design and modular settings

are easy to use and operate.

Upgrades include new hardware circuit design and

advanced digital sensor technology for accurate and

consistent test results.

The instrument's CPU has industrial-grade dual-core

design. Its high speed and stability ensure the safety,

reliability and speed of the instrument during use, and

solve the instability caused by the operating system. A

high-definition, large-size color touch screen allows

for richer test input data that can be based on different

test parameters including automatic selection and

matching detection program that best fits the current

filter.

The simple and convenient "pre-determined" design

not only improves the integrity of the test parameters,

but also greatly simplifies the user's operation. As a

program, it allows the real implementation of

"one-click completion". Electronic signature and user

hierarchical management facilitate the division of

responsibilities and prevent misuse.

Detailed test data and complete test curves enable

users to comprehensively and accurately analyze

various the performance indicators of the filter under

test to provide users with objective analysis reports.

2.2 Standard Features

a. Basic Bubble Point Test

b. Manual Bubble Point Test

c. Pressure Decay Test

d. Diffusion Flow Test (including microfiltration and ultra-filtration)

e. Enhanced Bubble Point Test (Combination of Diffusion Flow and Basic Bubble Point)

f. Water Flow Test (WFT)

g. Self Test

h. Verification

i. Supports up to 80 Test Plans

j. User Management Hierarchy

k. Print using the Built-in Printer

l. Up to 5000 Test Results can be Stored

m. Display Time and Date

n. Support English and Chinese Input

Test Supplements

a. Support online and offline testing without affecting results

b. System presses the pressure compensation, so the environmental

pressure difference does not affect test results

c. In-line testing only contacts the upstream of the filter and does not

contaminate the downstream of the filter

d. The test results can be generated by the host computer software.

Basic Functions

a. Each test procedure supports pre-pressurization

b. Stored test results can be read and saved by SD card and USB

c. Check reminder

d. Support 4 levels of multiple users

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

Basic Characteristics Standard Features

Pressure Decay Test is also known as the pressure hold

test. During the test, a high-precision pressure gauge or

sensor is used to monitor the pressure change caused

by the diffusion of gas leaking or passing through the

filter. This test has two main uses:

1. to measure the tightness of the filtration system

2. detect filter integrity

3.Tests Principle Integrity Testing

Tests principle Integrity testing methods including diffusion flow test, bubble point test, pressure hold

test, water flow test and enhanced bubble point test in accordance with 21 CFR Part 11. The Integrity

Tester is also complied with the standard requirements of Pharmaceutical Industry.

Tests Principle Integrity Testing

At a certain temperature, the minimum pressure difference

required to vent the largest hole in the wetted filter

membrane is forced by gas.

Bubble Point Test

a. Bubble Point Test

b. Bubble Point Definition

D:

θ:

γ:

the diameter of the largest pores

the contact (“wetting”) angle between the liquid and

the membrane

the surface tension of the wetting liquid

k:correction factor for the shape of the largest pores

P = 4× kcos

D

γ

θ

Pressure

Bubble point

Membrane Membrane MembraneMembrane

× ×

b. Diffusion Flow Definition

Diffusion Flow Test

a. Diffusion Flow Principle

Diffusion Flow refers to the flow of gas through the

pores of the membrane hole driven by a pressure

difference between compressed air and nitrogen on

both sides of the membrane at a pressure below the

bubble point.

The bubble point test is a non-destructive test method

based on the principle of surface tension and capillary

phenomena of liquid in the pores of the filter membrane.

The bubble point detects the minimum pressure

required to overcome these forces and expel the liquid

in the pores of the membrane.

Q = K×H(P1-P2)×R

L

Pressure

Gas molecule

Diffusion

Membrane

Q:

K:

H:

Diffusion Flow (throughput per unit time)

membrane-specific correction factor

Henry's law coefficient 1

P1:

R:

L:

inlet side pressure

ideal gas constant

length of diffusion path

P2:outlet side pressure

- 6 - - 7 -

Water Flow Test

a. Water Flow Principle

The water flow method complies with the FDA's

integrity testing requirements for sterilizing grade

filters. It can be associated with bacterial challenge

experiments. The water flow test is a highly sensitive

method of performing hydrophobic membrane

integrity testing based on water flow without alcohol.

Since the filter is not wetted and is almost dry, it can be

blown (baked) after the integrity test is completed and

put into use.

Pressure Decay Test

a. Pressure Decay Principle

The diffusion flow test can also be approximated by

measuring the pressure decay of the filter. After a

certain period of time, the attenuation value can be

measured to determine the integrity of the filter.

Calculated as follows:

b.Water Flow Definition

The minimum pressure difference between the

maximum pores of the hydrophobic membrane.

(In general, the water flow value is tested by

means of constant pressure water flow, similar

to the diffusion flow test),

△P × V

DF = Pa × T

Pressure

Water molecule

Hydrophobic membrane

DF:diffusion flow (ml/min)

pressure decay (mbar)

upstream volume (cm³)

atmospheric pressure (1013 mbar)

test time (min)

△P:

Pa:

T:

V:

△P × V

WFT = Pa × T

WFT:water flow test (ml/min)

pressure decay (mbar)

upstream volume (cm³)

atmospheric pressure (1013 mbar)

test time (min)

△P:

Pa:

T:

V:

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

Recommend temperature: 20+/- 5 oC.

Temperature shifts must be avoided during the measurement.

Recommend temperature: 20+/- 5 oC.

Temperature shifts must be avoided during the measurement. Recommend temperature: 20+/- 5 oC.

Temperature shifts must be avoided during the measurement.

Recommend temperature: 20+/- 5 oC.

Temperature shifts must be avoided during the measurement.

4.Instrument Functions and Test Procedures

CF 7.2 Integrity Tester tests are automated. The operator

only need to prepare for the test as the instrument will run

the test and provide results.

This function is used to test the system seal and

ensure the accuracy of test results. The outlet

pipe does not need to be connected during this

self-test. Please see below for the Self-test Method.

1. Click/Select "ICALIBRATION".

2. Click/Select “Self-Test” to enter the pressure and

time required for the self-test. Click/Select "NEXT"

3. After confirming that the instrument's inlet and

outlet air pipes are properly connected, press

"START” and the button will turn green which

means the system will enter the running state.

The gas in the pipeline begins to flow, and the current

system pressure, time, and test duration are displayed

on the interface.

CF 7.2 Integrity Tester uses electronic signatures and user

hierarchical management, so users must log in and then

select the appropriate action based on their level.

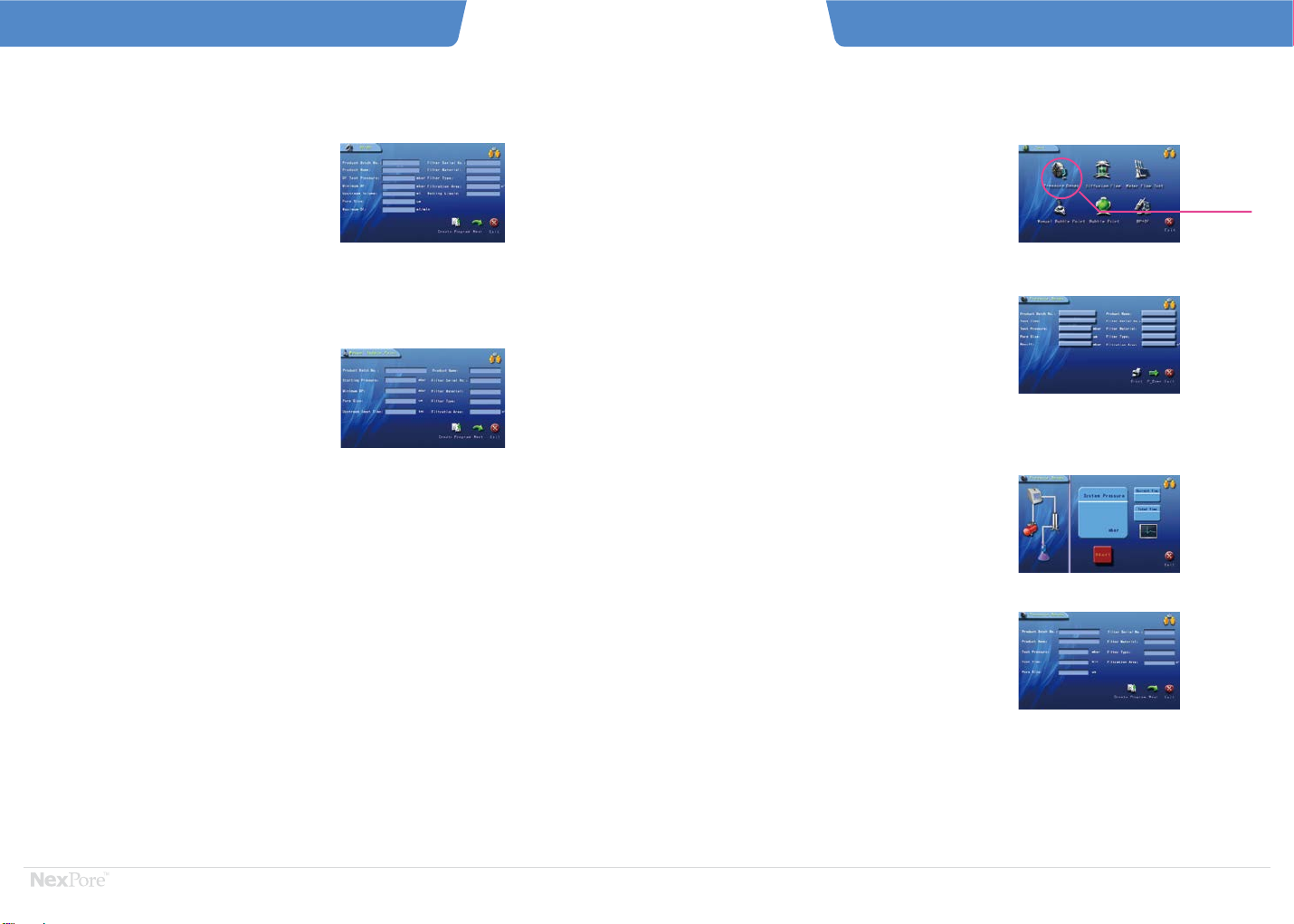

Program Edit:

1. Input the test parameter and click "Creat Program",

input the program name, click"Next" to save.

2. Choose the present program, click "Edit" to modify.

Choose Program:

When using the pre-determined test program, first

SELECT the test program needed in the program

name column, and then click “NEXT” to enter the

pre-determined test parameter interface. If there are

no modifications required, select “NEXT” until you

enter test mode.

Delete Program :

Choose the present program, click "Delete"

An Example of User Login Interface is shown below

ADMIN

Default Factory Username: ADMIN

Password: 123456 (also supports Chinese username)

The Default Username and Password can be changed after

users enter the system.

4.1 Instrument Test Functions

4.2 Instrument Interface and Test Process Introduction

4.2.1 User Login Interface

4.2.3 Self Test

4.2.2 Test Program

Click/Select to

enter the Test.

Enter requested data and

click/select "NEXT"

Click/Select "START" to

start the self-test

Test Results are

automatically displayed

once the test finishes.

1. Recommended parameters: 5000mbar pressure

and time of 3 minutes

2. During self-test, the instrument only needs to be

connected to a gas source. The pressure should

be kept 1000mbar higher than the self-test

pressure.

3. Outlet valves should be kept closed when the

filter is self-testing. Do not install the filter

element during this time

4. The self-test cannot be added to the test program

5. Self-test should be performed once per day the

Integrity Tester is turned on

Self-Test Method:

- 8 - - 9 -

Gas

In

Instrument Test Functions

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

CF 7.2IntegrityTester

System Self Test

Bubble Point Test Supplement

When the measured filter element is greater

than the set minimum bubble point value, the

interface will display “measure bubble point has

passed, whether to continue”. To continue, click

/select “OK”, otherwise click/ select “CANCEL” to

end the test and display Test Results and Curves.

When the bubble point appears, the instrument

ends the test. The Interface displays the bubble

point test results. To instantly print these results,

click/select “PRINT”.

Click/Select "EXIT" and the system automatically

saves the test results and returns to the parameter

settings page.

1. Quick test mode does not support pre-pressurization

2. The filter element for the second bubble point test must be re-soaked or rinsed

3. When the filter element is inputted, the data entered in the filter area column cannot differ significantly

from the actual filter element area. If you do not know the filter area, please confirm with the filter

manufacturer. If you enter “0” or “CLEAR”, the instrument will set the default value depending on filter

type. For a 10inch single core filter, the default is 0.6m²and for a capsule filter 0.04m². For Manual

Bubble Point Test, the recommended length of refueling is 0.1s

4. The starting pressure can be set to the diffusion test pressure of the filter element, or 80% of the basic

bubble point value.

1. Click/Select "Test"

2. Click/Select "Bubble Point "

3. According to filter specifications, enter in the following

details “Product Batch No.”“Filter Serial No.”“Product

Name”“Filter Material”“Starting Pressure”“Filter

Type” “Minimum BP”“Filtration Area” “Pore Size”and

“Wetting Liquid”

“Starting Pressure” enters the starting pressure on the

instrument. This option increases the speed of the Basic

Bubble Point Test.

Test data should be filled in/enter according to actual working

condition. Enter and click/select “NEXT” to enter Basic Bubble

Point Test Interface.

Confirm that the instrument is correctly connected and click/

select “Enter” to begin the test.

Click/Select “ ” to display the curve of Basic Bubble Point

Test in real time. The first page displays the “Time-Flow”

curve and the second page the “Time-Pressure” curve, which

allow the user to analyze the filter media characteristics.

Filter specifications include “CARTRIDGE”,

“PANEL”, “BAG” and “OTHER” filter types.

Fill in the information according to the filter

specifications.

Once the interface displays ""the Bubble Point Test

has passed". Continue testing?"

Click/Select "OK" to continue testing. Click/Select

"CANCEL" to end the test.

There are 4 different types of test liquids: “WATER”,

“ALCOHOL”, “ETHANOL” and “OTHER”.

Fill in the information according to the specific

test solution.

The test starts, click the real time first.

Test the pressure-to-time relationship of the filter

element.

Bubble Point Test Procedure

4.2.4 Test

4.2.4.1 Bubble Point Test

Click "PRINT" to print test results.

Click "OK" to save the results instantly.

The "preset test name" is filled in by the user.

Fill in all the requested information.

Click "Start" and the test starts.

- 10 - - 11 -

Upstream Valve

Closed

Outlet

Pressure Gauge

Wetted Filter

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

Gas

In

Out

CF 7.2IntegrityTester

Bubble Point Test

4.2.4.2 BP + DF Test

1. Select " Pressure Decay" in the "Test" interface

2. Input the parameters

3. After all test parameters are entered,click “Next”;

4. Click/Select “START” to start test after confirming that

the instrument's inlet and outlet air lines are properly

connected.

5. At the end of the test, the Interface displays the

Pressure Decay Test Results and Curves. To instantly

print these results, click/select “PRINT”.

6. Click/Select "EXIT" and the system automatically saves

the test results and returns to the parameter settings

page.

Enter the “PRESSURE VALUE” of the dwell test

corresponding to the filter in the Hold Pressure

text box.

Click to enter the test and enter “PRODUCTION

LOT NUMBER”, “PRODUCT NUMBER” and

“FILTER SERIAL NUMBER”

4.2.4.4 Pressure Decay Test

Click/Select to enter

the Pressure Decay

Test

Enter “FILTER SPECIFICATIONS”, “APERTURE”,

and “FILTER AREA”

Click/Select “START” to start test

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

- 12 - - 13 - Bubble Point Test

It simplifies the operation and reduces the testing time to

test diffusion flow and bubble point simultaneously.

1. Select "BP+DF" on the "Test" interface;

2. After entering the test parameters, click "Next" to start.

4.2.4.3 Manual Bubble Point Test

The manual bubble point function can be used as a gas

source for manual test of the filter element, and the

operator needs to observe the bubble generation

downstream of the filter element in the meantime.

1. Select "Manual Bubble Point" on the "Test" interface;

2. After entering the test parameters, click "Next" to start;

Diffusion Flow Test Procedure

- 14 - - 15 -

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

1. Click/Select “DIFFUSION FLOW” in the “TEST”

selection inferface.

2. Click/Select “DIFFUSION FLOW”- (MICROFIL-

TRATION)” and follow the prompt to enter the

filter specifications. If the user does not know

"MAXIMUM DIFFUSION FLOW" or "UPSTREAM

VOLUME", click/select "OK" to start the

measurement. The default standard for the

maximum diffusion flow is the value in the

parameter settings and upstream volume is

automatically calculated

3. After the test parameters are entered, click/

select “NEXT” to enter the diffusion flow test

interface to start the test. View the curve in real

time with the bubble point.

4. At the end of the test, the Interface displays the

Test Results and Curves. To instantly print these

results, click/select “PRINT”.

5. Click/Select "EXIT" and the system automatically

saves the test results and returns to the parameter

settings page.

4.2.4.5 Diffusion Flow Test (microfiltration)

Click/Select to enter

Diffusion Flow Test

Click/Select "ULTRA-FILTRATION" in the test

category.

As above if the user does not know

"MAXIMUM DIFFUSION FLOW" or

"UPSTREAM VOLUME", click/select "OK" to

start the measurement.

Pressure Decay Test

Diffusion Flow - (ultra-filtration) Test Procedure is

the same as described above for Diffusion Flow -

(microfiltration).

4.2.4.6 Diffusion Flow Test (ultra-filtration)

Click/Select "DIFFUSION FLOW -

(ULTRA-FILTRATION)”

1. Click/Select “Test” in the “Main Menu”.

Click “Traffic Detection” in the system operation

selection interface to enter the “Traffic Detection”

interface.

2. Click/Select “Water Flow” and enter “Product batch

No.”, “Product name ” and “Filter Serial No.”. If the

user does not know "MAXIMUM FLOW", click/select

"Next" to start the measurement. The default

standard for the maximum diffusion flow is the

value in the parameter settings

3. View the curve in real time with Bubble Point

4. At the end of the test, the Interface displays the Test

Results and Curves. To instantly print these results,

click/select “PRINT”.

5. Click/Select "EXIT" and the system automatically

saves the test results and returns to the parameter

settings page.

If the user does not know the "MAXIMUM

FLOW", click/select "Next" to start the

measurement.

4.2.4.7 Water Flow Test

Click/Select to enter the

Water Instrusion Test.

Water

Upstream Valve

Closed Outlet

Gas

In

Out

CF 7.2IntegrityTester

Flow Test Supplement

1. If the upstream volume is entered during the Diffusion Test, the instrument will skip the

upstream volume test procedure.

2. The filter element used for diffusion flow testing can only be done once

3. As with bubble if the filter area is unknown the system defaults are 0.6m²for a 10inch

single core filter, and 0.04m²for a capsule filter

4. Water flow Test must be refilled with water before the second test

5. When performing the Water Flow Test, please input pressure according to the instructions

to avoid damage to the filter element

6. When testing for water flow, keep the instrument above the filter cartridge and connect the

tubing to the top of the filter cartridge to prevent back suction

7. The molecular cut-off weight for ultra-filtration parameters only calibrates filter

specification and is not a test results

5. Touchscreem

6. User Management

7. Audit Trail

8. About

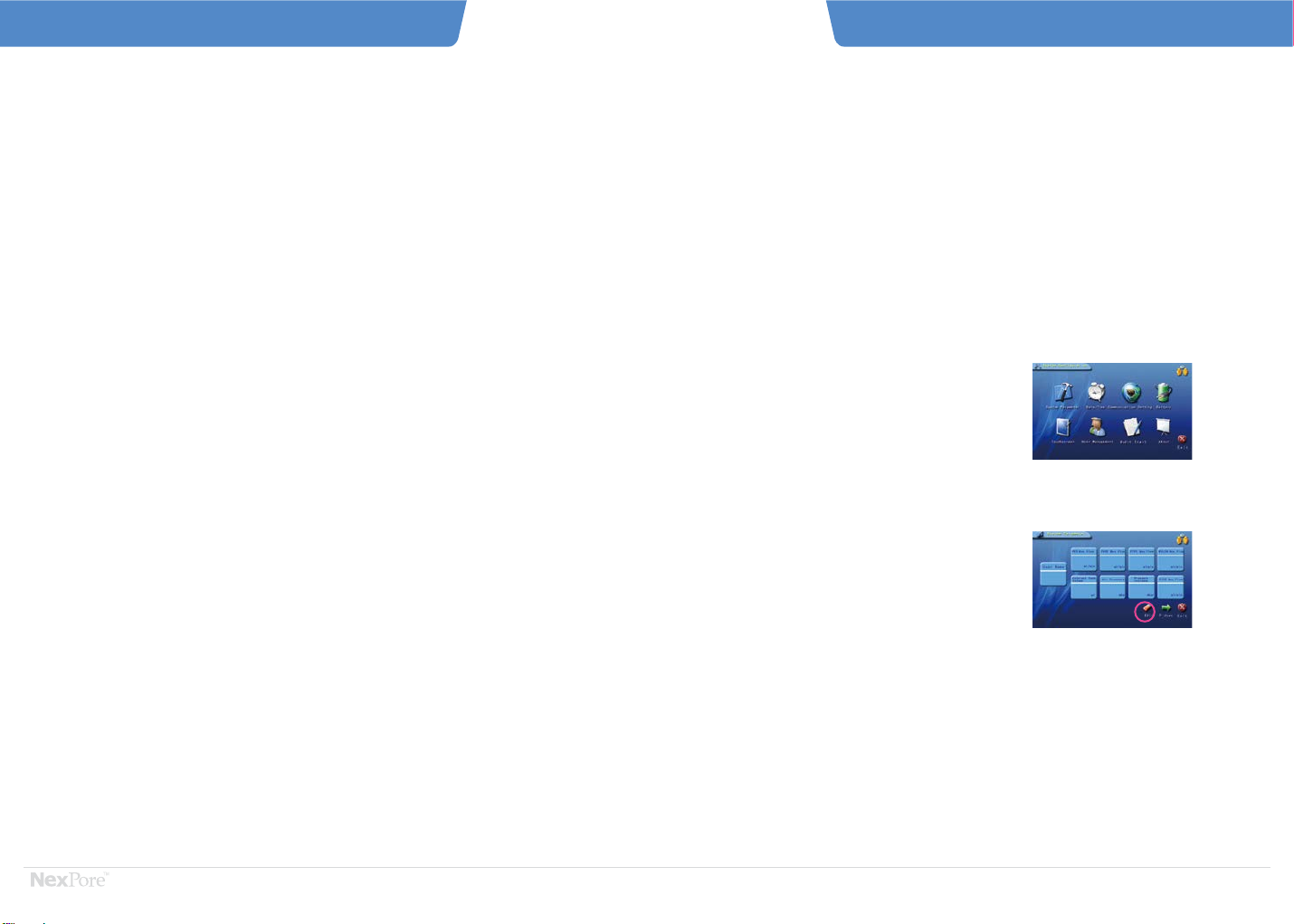

System parameter are further subdivided into two sections:

browsing and editing.

Click/Select “PARAMETER SETTINGS” to enter browse. In

this section, you can check the current system user name,

test pressure increase, default maximum diffusion flow, and

maximum flow and pressure of the hydrophobic filter PTFE.

When "Edit" is clicked / selected and if the user level is

appropriate, then you enter “EDIT” interface. After setting

each parameter, click/select “SAVE” to return to the previous

page (Browse)

For Hydrophobic PTFE: view current system

user name, test pressure increase, default

maximum diffusion flow, and maximum flow

and air pressure.

For advanced user level, click/select ‘Edit’ to

enter the parameter setting edit status.

5. System Configuration

5.1 System Parameter

CF7.2 Parameters

1. System Parameter

2. Date/Time

3. Communication Setting

4. Battery

Diffusion Flow Test Procedure

- 16 - - 17 -

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

Water Flow Test

- 18 - - 19 -

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

System Parameter Settings

Maximum Diffusion Flow:

The maximum diffusion flow value allowed by the filter

element in the corresponding diffusion flow measurement

pressure. It is necessary to set the maximum diffusion flow

of the four filter elements: 10-inch asymmetric membrane

filter (PES), 10-inch symmetric membrane filter (PVDF,

Nylon), and 10-inch air filter (PTFE).

Maximum Flow Rate:

The maximum flow rate of the aqueous solution immersed in

the filter at the specified test pressure and unit time during

the water flow test. It is necessary to set the maximum flow

of the 10-inch PTFE filter.

Air Source Pressure: recommended to be set at 1000 mbar

less than the actual air source.

Coefficient:

PES / PVDF / CN-CA / PTFE / NYLON coefficients should

retain factory settings

Internal Volume / External Tank : Capacity should retain

factory settings

Pressure Increase: refers to the amount of gas in one

intake. The larger the value, the larger the amount of

intake air, the faster the test speed, but the lower the

accuracy. This value can be set according to customer

specifications/needs.

If the test time exceeds 25 minutes, causing the

instrument to report an error, it is recommended to

increase the pressure increase.

Examples :

a. maximum diffusion flow of a 10-inch PES filter is

30.0 ml/min

b. maximum flow rate of the 10-inch PTFE filter is

0.75 ml/min when using the water flow test.

Flow Test Supplement

For advanced user level, click/select ‘ALT’ to

enter the parameter setting edit status.

“MANUAL” the user must manually click/select “PRINT”

to print test results after the test is completed. “AUTO”

the test results will automatically print

Click/Select "Date / Time" to enter the "Date / Time"

interface, as shown

For advanced user level, click/select “EDIT” to enter “EDIT

PARAMETER SETTINGS”.

Supplement:

In order to ensure correct and reliable measurement results,

a user password needs to be setup, and only relevant

personnel can change these measurement parameters.

Each machine has a factory default password. To facilitate

production management, the password can be changed in

the user management interface.

Printing Settings

To reduce user's test time in production and extend the

service life of the filter element, the instrument provides

two options after the bubble point is tested. Option 1: to

ask the user whether to continue the operation, if the user

clicks/selects "OK" the actual bubble point will always be

tested. If the user clicks/selects “CANCEL” the test will

end and results provided. Option 2: terminate the test

directly and get the test results. Users can select either

option based on their specific requirements/needs

Load Default/Initial Test Parameters:

The system's default parameters include test

pressure increase, default maximum diffusion

flow, air supply pressure, and test parameters

loaded or reverted to factory settings.

Use this feature with caution.

Interchanging between Chinese and English still

under development

End Mode Language Selection

5.2 Date / Time

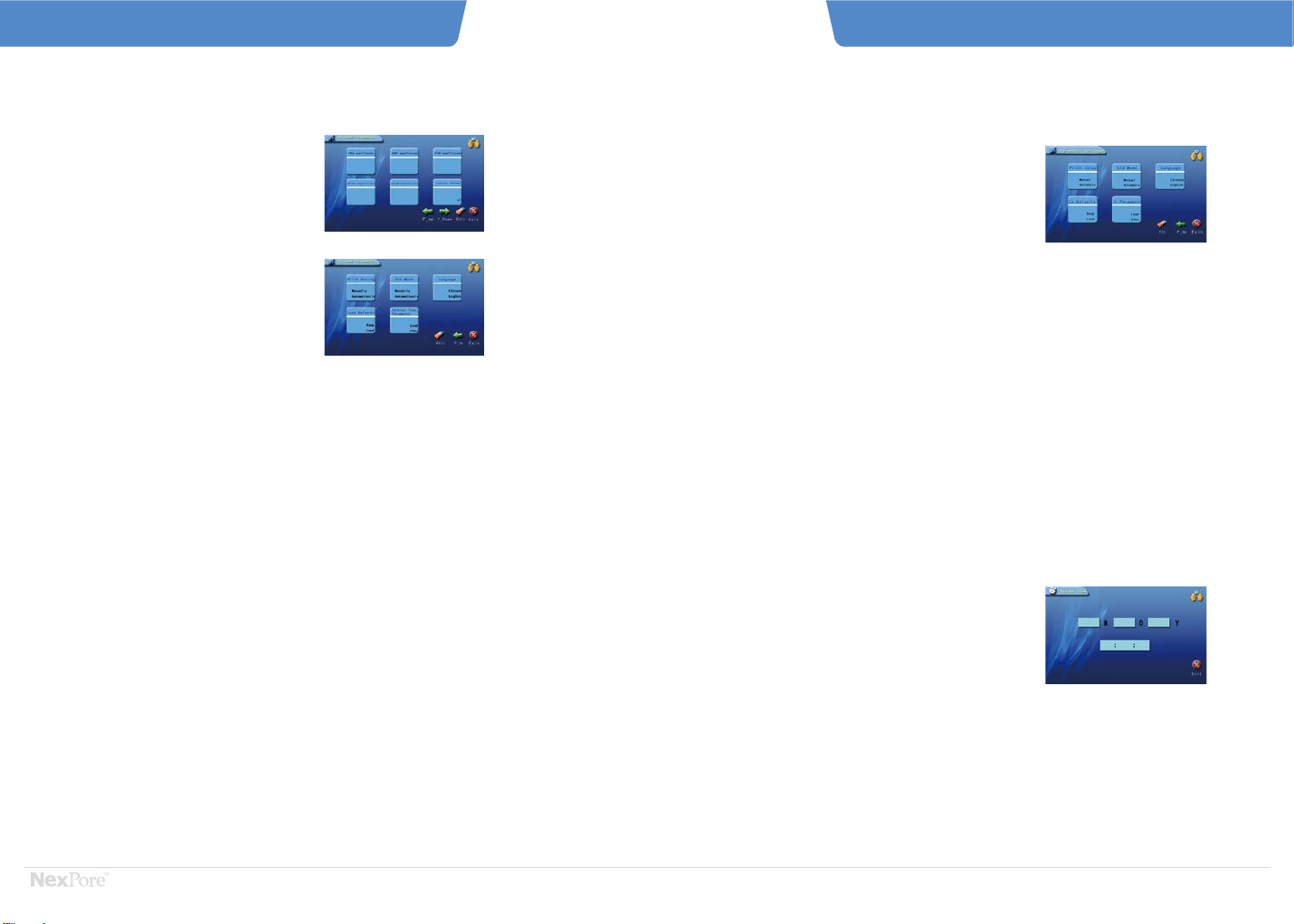

Click/Select "PROJECT" and then click/select

"ALT".

Click/Select "ADD" and follow the prompts to

add users and passwords.

Click/Select "SAVE"

In the system settings interface, click/select "USER

MANAGEMENT" to enter the user management

interface.

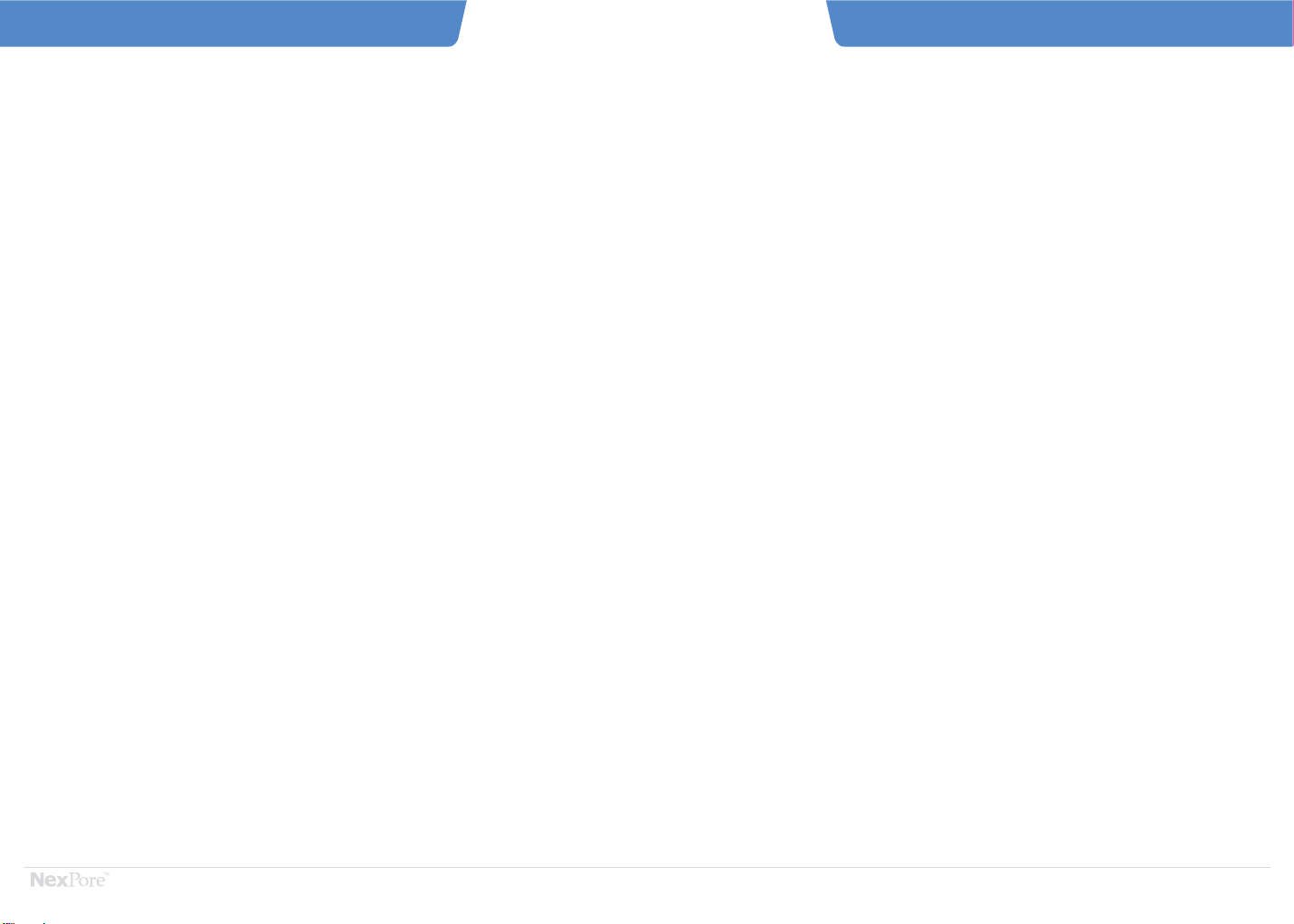

In the system settings interface, click/select "AUDIT

TRAIL" to enter “AUDIT TRAIL”. Users can browse

historical records.

To modify or delete, first select the item, then

click/select “EDIT” to change the user name or user

password or click/select "DELETE" to delete the

user.

Users cannot modify or delete user that are either

higher than them or at the same level than them in

the hierarchy management.

Click/Select "ADD" and follow the prompts to add a

user and create username/password/save.

Currently CF7.2 Integrity Tester supports 4 levels

of user.

5.6 User Management

5.7 Audit Trail

“COMMUNICATION SETTINGS” is mainly used to

communicate with the host computer. CF 7.2 Integrity Tester automatically saves the last

12,000 test data records (including test curves and

complete test conditions). At this point, the earliest

test data is automatically overwritten.

Historical records include: Bubble Point, Manual Bubble

Point, BP+DF, Pressure Decay, Diffusion Flow, and water

flow Test Results.

When CF 7.2 Normal Test is finished, the test result

interface will pop up. At this time, after pressing “EXIT”,

the system automatically saves the data.

History is stored in the recording unit inside the

instrument according to production lot number.

The history query is also based on the production

lot number. The history interface is shown below:

To ensure the safety and integrity of the

history, the CF 7.2 Integrity Tester can export

the historical data via USB, SD card and data

port and be saved separately.

“POWER MANAGEMENT” is mainly used when the

instrument works in different power supply

environments. For some parameters of the

instrument power mode, including battery power,

the instrument will automatically reduce power

consumption.

Temporarily unavailable

In the Instrument Standby Interface, click/select “Test

Results” to enter “Test Results” interface.

Click/Select “EXPORT” and “EXPORT MEDIA” interface

will be displayed.

Select the media to export data, and determine whether to

clear the history.

After confirming the error, click/select “OK” to export the

data.

Please export and then delete data if you so choose.

The exported format is a .dat file, which can be opened by

using the matching PC software.

When exiting, click/select “EXIT” continuously to return to

“SYSTEM OPERATION SELECTION INTERFACE.”

6. Test Results

- 20 - - 21 -

Please export and then delete data if you so choose.

Click/Select "EXPORT" and select the appropriate

export data media to export.

Record Saving View History

Test Results Exporting Process

5.3 Communication Settings 5.4 Power Management

5.5 Touch Management

System Parameter Settings

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

User Management

The system supports two print modes.

1. Click/select "PRINT" to instantly print the current test results whenever this interface appears

2. In “Test Results”, click/select the Test Option and then click/select “PRINT”.

There will be a lag between clicking/selecting print and the results printing.

CF 7.2 Integrity Tester has a built-in printer and the following sections describe how to replace the paper

and ribbon.

7. Data Printing

1. Important Notice - paper specifications are: outer

diameter 20mm, inner diameter 11mm, paper width 47mm

2. Turn on the power switch

3. Press the elastic plastic on both ends of the printer panel

toward the center and pull up to open the printer panel.

4. Pull the plastic plate at the upper end of the card slot

outward, and then rotate the center roller in the card slot

to the center line in a vertical state, and pull out the empty

paper roll.

5. Insert the center roller into the new paper roll and reinstall

the card slot. Note that the installed paper slot should be

below the card slot.

6. Pull the paper out and place it in the first slot on the card

slot, and open the paper feed button (green cylindrical at

the bottom right of the paper card slot) and feed the

paper until the paper exits.

7. Close the printer panel.

1. Open the printer panel as described in the above

8.1 section

2. Pull the plastic assembly on the top of the printer out.

3. Hold the ribbon on both sides and pull it up.

4. Pass the new ribbon through the printer, snap the

holes in the ribbon to the gears on the printer,

press the flat ribbon, and then flatten the ribbon

inward.

5. Flatten the plastic components inward and close

the printer panel.

8. Printer Installation and Maintenance

- 22 - - 23 -

8.1 Installing/Replacing Paper 8.2 Installing/Replacing Ribbons

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

History Record Data Printing

If the working fuse is damaged, it can be replaced with

a spare fuse. The replacement steps are as follows:

1. Unplug the power cord

2. In the middle of the switch and socket, find the cover

with the fuse pattern and use a flat-blade screwdriver

to pry open the cover

3. Pull out the working fuse in the card slot and load it

with the spare fuse in the cylinder

4. Reload the entire card slot into its original position

Due to GMP regulations, NexPore advises customers

to calibrate the tester once a year.

10. Instrument Calibration

9. Replacing the Main Fuse

During instrument use, there may be issues/problems with the CF 7.2 Integrity Tester. If the following problems

occur, please solve per the methods described below. If the problems/issues cannot be solved by the methods

below, please contact your NexPore Sales Engineer immediately.

Printer cannot print the test

results

Qualified filter elements are

determined by other means,

but cannot pass when tested

with CF7.2 Integrity Tester

a. test environment is below

0°C

b. out of paper

c. paper is not in place

d. incidental failure

a. The test environment temperature should be

between 0°C to 40°C; test must be performed

in a location with this range of temperature

b. Check to see if the printer is out of paper and if

it is replace per the Instructions illustrated in

this Manual

c. For other issues, shutdown and restart the

system but wait at least 5 seconds before

restarting.

a. Filter is not thoroughly

immersed

b. System leak

c. Tested filter temperature is

too high

d. Immersion liquid is

unreasonable

a. Thoroughly immerse the filter element to be

tested

b. Remover the filter and perform system self-test

c. As previously explained, Integrity Testing should

be performed at room temperature. When the

filter element temperature is too high, the

integrity test should be performed after the filter

element has naturally cooled.

d. Different filter materials need different immersion

liquids. Immersion liquid should be selected

according to factory report provided by the filter

manufacturer.

11. Common Problems

- 24 - - 25 -

CF 7.2IntegrityTester Instruction ManualCF 7.2IntegrityTester Instruction Manual

Common Problems

Problem Causes Solutions to Problem

1 .

2 .

Pre-pressurization failure

during testing

a. Filter is not thoroughly

immersed

b. System leak

c. The instrument fills with

liquid

a. Thoroughly immerse the filter element to be

tested

b. Remover the filter and perform system

self-test

c. Check to see if there is any liquid outflow in

the exhaust port during testing. If there is,

please return the CF7.2 to the factory for

repairs.

3 .

Screen drifts/shifts Click/Select “LOGIN INTERFACE” until the

“VERIFICATION PAGE” appears. Click/Select

“+” on the page with the touch pen until

verification is over.

4 .

Diffusion Flow and Water

Flow Values are too large

a. In parameters initialization,

the buffer tank volume does

not match the actual buffer

tank

b. The internal pipeline has a

leak and the upstream

volume is calculated as too

large

c. Influent, resulting in a buffer

tank volume smaller than the

set buffer tank volume

d. No instrument issues but

there are leaks in the external

pipeline

e. The instrument needs to be

verified.

a. Check that the parameters are correct

b. Have the instrument check to see if the filter

is in the liquid

c. Have the instrument check for leaks.

d. Performa self-test with a filter to detect

whether there is a leak in the external

pipeline

e. Calibrate the instrument and observation

coefficient.

7 .

Outlet quick connector and

unable to plug in the air inlet

connector

Outlet corrosion place the outlet quick connect in alcohol8 .

a. The air source pressure

setting of the internal

parameters of the instrument

is too low

b. The source pressure is lower

than the bubble point value

c. The instrument or filter has

a leak

d. Sensor failure

a. Check that the parameters are correct

b. Verify that the gas source is up to standard

c. Check if there is a leak in the tester or

external equipment

d. Sensor Verification.

9 .

A small amount of liquid

discharges

place the CF7.2 in an upright position with the

outlet facing up. Perform a self-test. As the

self-test ends, the moisture in the chamber will

be discharged with the gas.

10.

The printer won’t release

the paper

Open the flip cover of the printer and with a

screwdriver slightly loosen the left and right

screws.

5 .

The start screen is either

a blue screen, flower

screen or black screen

Check that the power supply and screen

connection are normal and then place the

CF7.2 in a dry and ventilated environment for

a short period of time. If it has not been

released, contact the factory for repair.

6 .

Problem Causes Solutions to Problem

™

Global

Headquarters,

Netherlands

R&D,

Lab,

Facility,

Marketing,

Sales

Taiwan Headquarters

Lab, Facility, Marketing, Sales

World Wide Offices, California, Singapore, Korea, Japan, Hangzhou

Lab,

Marketing,

Sales

Manufacturing Site, Ireland

Facility, Lab, Sales

Contact Information

Vrijheidweg 57, 1526 RS, Wormerveer

Amsterdam, Netherlands

Tel: +31 75 2014000

Fax: +31 75 2014020

Web: www.nexpore.com

Email: [email protected]

Planing

Germany Office

Switzerland Office

Table of contents

Other Integrity Test Equipment manuals

Popular Test Equipment manuals by other brands

Elenco Electronics

Elenco Electronics S-3000 user guide

Agilent Technologies

Agilent Technologies 100 Operator's manual

Megger

Megger EZ-ThumpV3 user manual

WT

WT PH 2066UK Installation operation & maintenance

Keysight Technologies

Keysight Technologies U3022AM06 User's and service guide

Keithley

Keithley System SourceMeter 2602B quick start guide