M

EZTV3-UG-EN-V01 Feb 2022

i

Table of Contents

1 SAFETY...................................................................................................................................... 1

Precautions .................................................................................................................................. 1

Warning and Caution Notices..................................................................................................... 1

Working with the Product .......................................................................................................... 2

Operating Personnel ................................................................................................................... 2

Repair and Maintenance.............................................................................................................. 2

General Cautions and Warnings ................................................................................................. 2

Intended Application............................................................................................................... 2

What to Do if Equipment Malfunctions ................................................................................. 3

Five Safety Rules ..................................................................................................................... 3

Important Safety Advisory Note - When Working With Hv Surge Generator / Thumper ... 4

Requirements for Safe High Voltage Work Environment ...................................................... 4

2 TECHNICAL DESCRIPTION ................................................................................................. 6

System Description ..................................................................................................................... 6

Functional Description............................................................................................................ 6

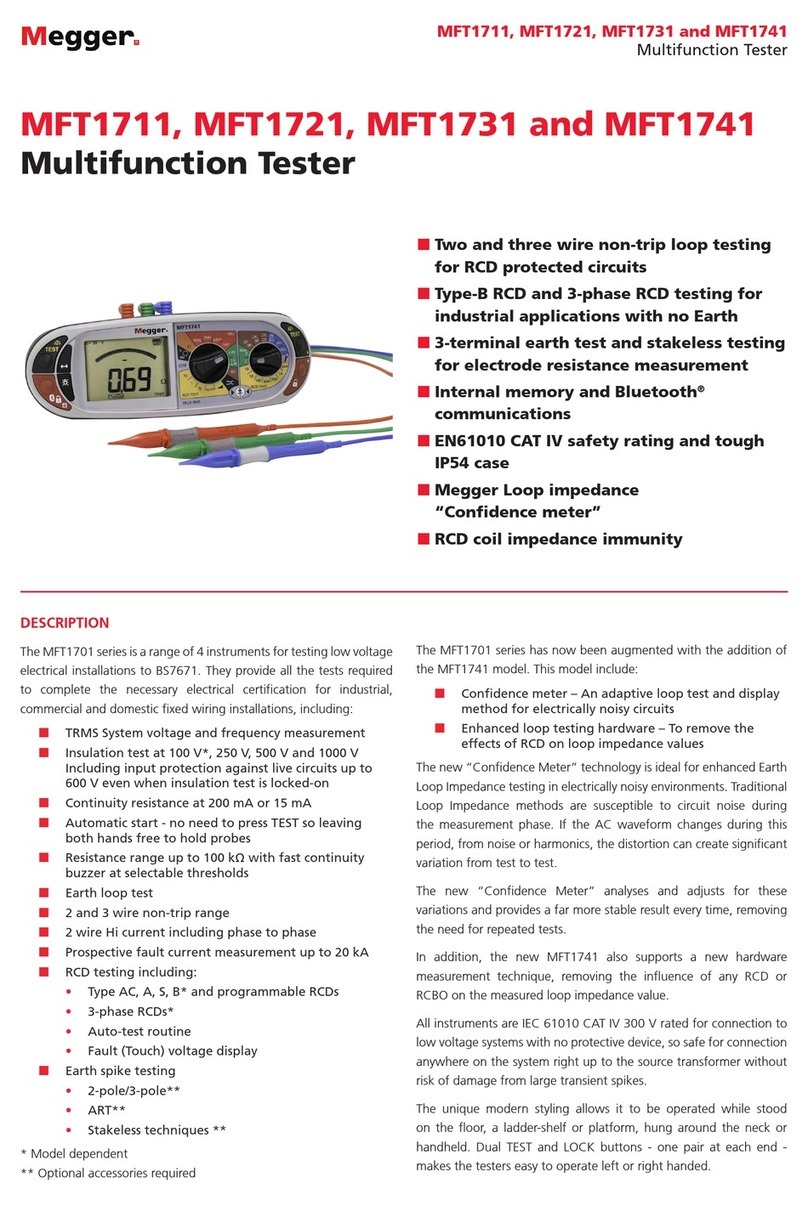

Product Models ....................................................................................................................... 7

Features ................................................................................................................................... 7

Scope of Delivery .................................................................................................................... 8

Available Accessories............................................................................................................... 8

Technical Data ............................................................................................................................ 9

Control Elements, Indicators and Connectors...........................................................................10

Power Supply .............................................................................................................................11

Battery Operation ..................................................................................................................11

Introduction .......................................................................................................................11

Battery Status and Automatic Shutoff ................................................................................11

Charging .............................................................................................................................12

120/230V AC Line Operation................................................................................................13

3 SETTING UP THE SYSTEM...................................................................................................14

Connection Diagram..................................................................................................................15

Connection Sequence .................................................................................................................15

4 OPERATING INSTRUCTIONS.............................................................................................16

Power on the System..................................................................................................................16

Basics of Operation ....................................................................................................................16

Operation with Rotary Knob.................................................................................................16

High Voltage Control ............................................................................................................17

Safety Circuit .............................................................................................................................17

Introduction ...........................................................................................................................17

Conditions of the Safety Circuit ............................................................................................18