Table of Contents

Introduction.............................................................................................................................................1

Principles of Operation ...........................................................................................................................2

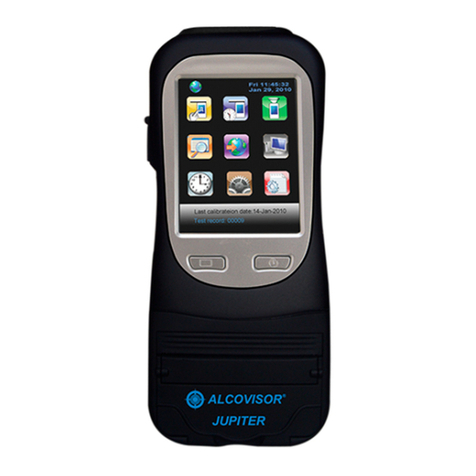

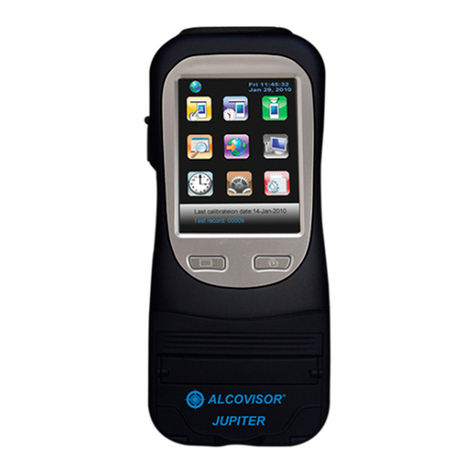

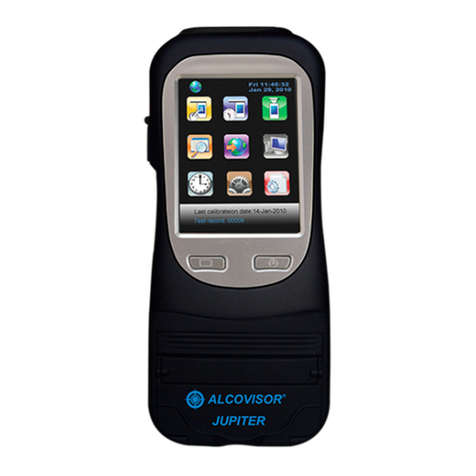

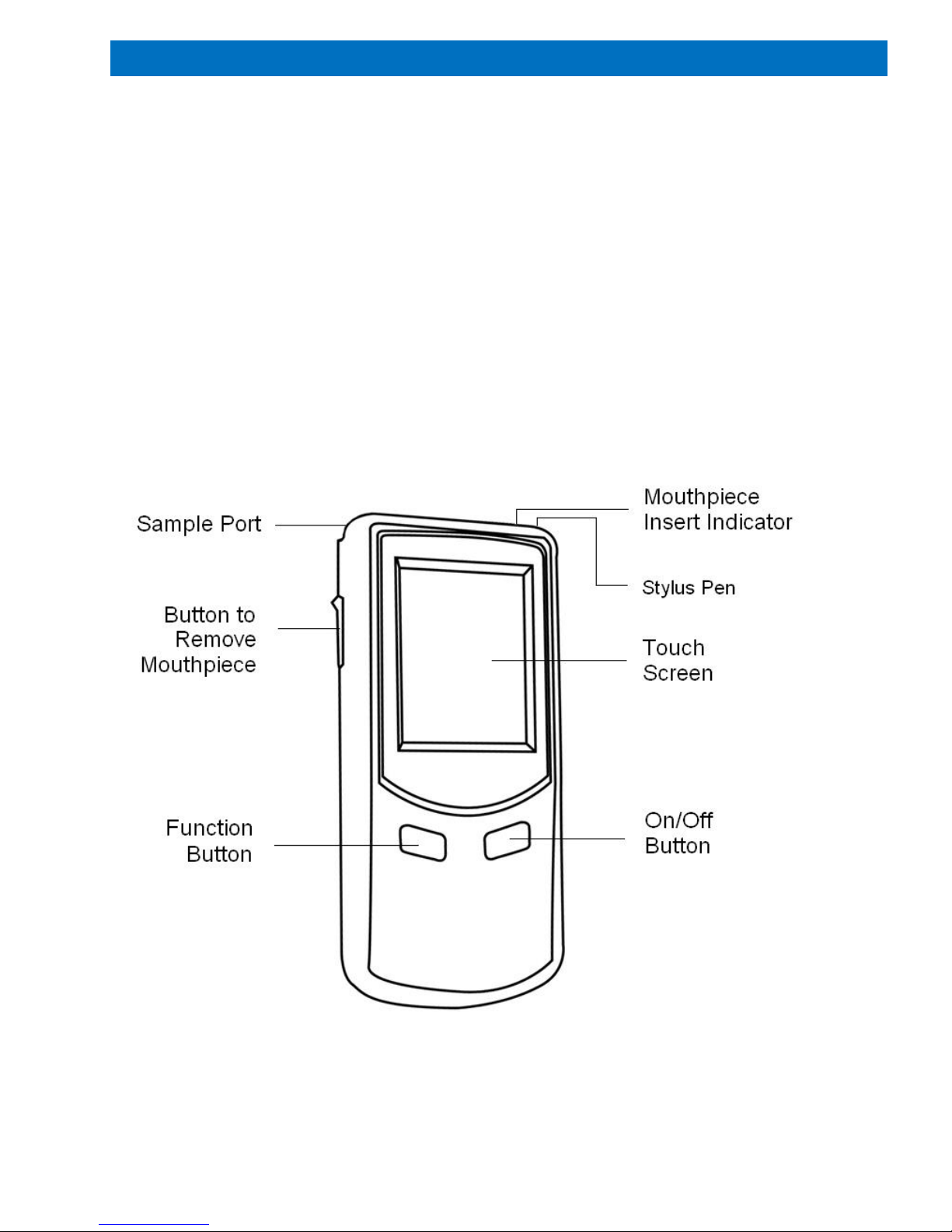

Instrument Features................................................................................................................................2

Preparing the Mercury............................................................................................................................3

Installing the Batteries.........................................................................................................................3

Turning On & Off .................................................................................................................................3

Touch-Screen Calibration.......................................................................................................................3

Icon Descriptions....................................................................................................................................4

Performing a Breath Test........................................................................................................................5

Conditions for Test Site.......................................................................................................................5

Conditions for Test Subject .................................................................................................................5

Attaching a Mouthpiece.......................................................................................................................5

Performing an Air Blank Test...............................................................................................................6

Measuring BrAC/BAC.............................................................................................................................6

Passive Test........................................................................................................................................6

Standard Test......................................................................................................................................7

Manual Override Test..........................................................................................................................8

Test Records..........................................................................................................................................8

Settings...................................................................................................................................................9

Printer...................................................................................................................................................10

Accuracy Checking and Calibration......................................................................................................12

Wet Bath Accuracy Checking...............................................................................................................12

Dry Gas Accuracy Checking.................................................................................................................13

Dry Gas at High Altitude....................................................................................................................14

High Altitude Correction Chart..............................................................................................................14

Quality Assurance Plan ........................................................................................................................15

Troubleshooting....................................................................................................................................16

Technical Specifications.......................................................................................................................17

Safety, Maintenance & Warranty..........................................................................................................18