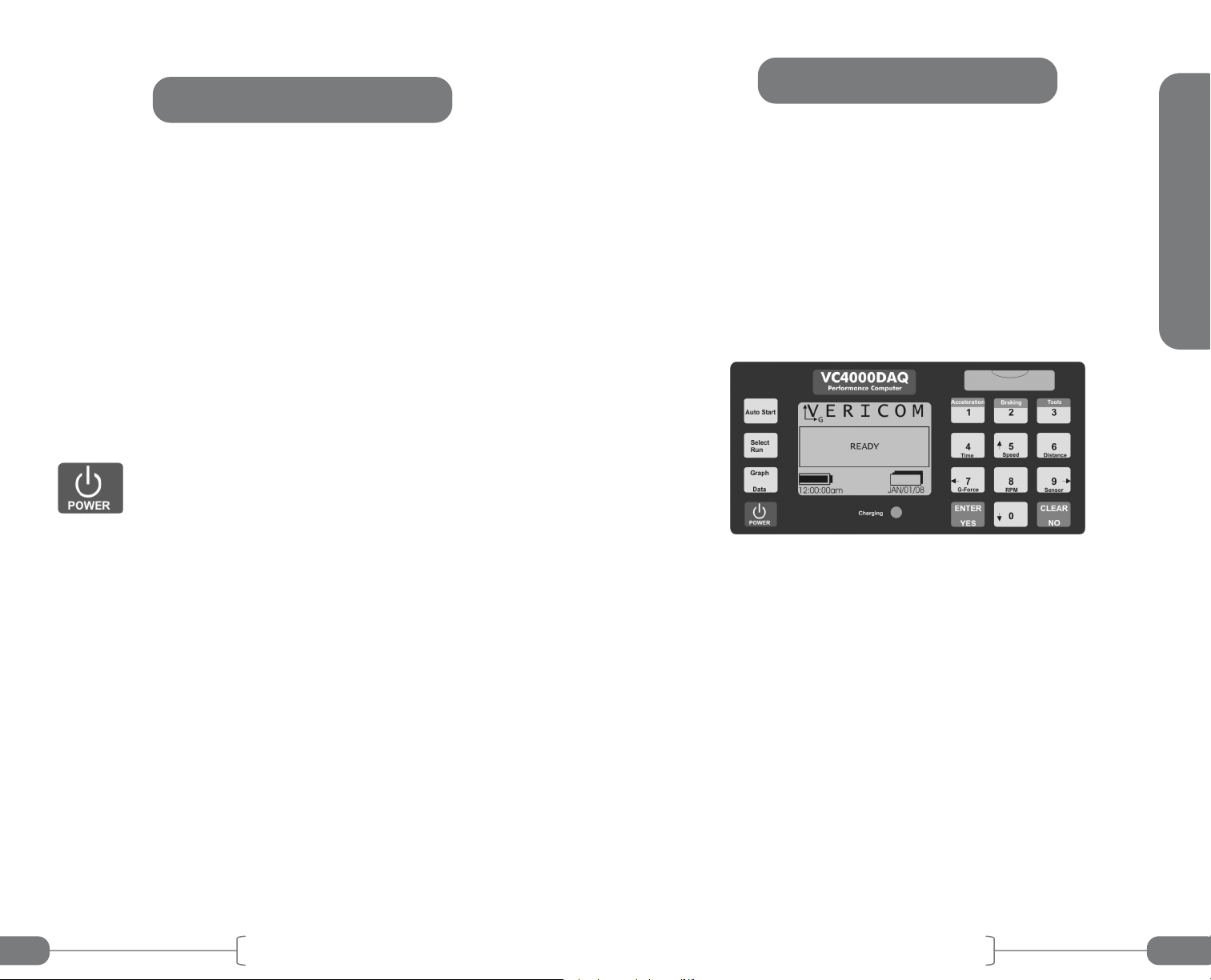

7. VC4000 SETUP ........................................................................... 65

Setup Flowchart............................................................................ 67

G-Threshold.................................................................................. 69

Vehicle ID ..................................................................................... 69

Set Defaults .................................................................................. 70

Date/Time ..................................................................................... 71

Pitch/Roll Factors ......................................................................... 71

User Type ..................................................................................... 73

Imerial/Metric ................................................................................ 75

RS232 Port ................................................................................... 76

Brake MPH ................................................................................... 77

Sensors Setup .............................................................................. 77

Internal Sensors........................................................................ 78

Analog Sensors......................................................................... 81

OBDII Sensors .......................................................................... 82

Tach On/Off .............................................................................. 83

Tach Factors ............................................................................. 83

Analog Out ................................................................................ 84

GPS Sensors ............................................................................ 84

Accelerometer Setup .................................................................... 86

G Summation ............................................................................ 86

G Smoothing ............................................................................. 88

Zeroing On/Off .......................................................................... 89

Accelerometer Range ............................................................... 89

G Adjust .................................................................................... 89

Graph Range ............................................................................ 90

Alarm Threshold........................................................................ 90

Sample Rate ............................................................................. 91

Performance Setup....................................................................... 91

Vehicle Weight .......................................................................... 91

Countdown On/Off .................................................................... 92

Tachometer On/Off ................................................................... 92

Tach Factors ............................................................................. 92

Maintenance ................................................................................. 93

Unit Information......................................................................... 93

Run Tests.................................................................................. 93

Discharge Battery ..................................................................... 93

8. SENSOR INPUT .......................................................................... 94

Internal Sensors ........................................................................... 95

Compass................................................................................... 95

Rate Gyro.................................................................................. 95

Tachometers ............................................................................. 95

Digital IN 1 and 2 ...................................................................... 96

Analog Sensor Input ..................................................................... 98

Sensor Requirements ............................................................... 98

Table of Contents

Junction Box ............................................................................. 99

OBDII Input................................................................................... 99

Tachometer Input ....................................................................... 101

Analog Output............................................................................. 102

GPS Input ................................................................................... 103

External Activation...................................................................... 105

9. REVIEW - PRINT DATA ............................................................ 108

Display a Run ............................................................................. 108

Print Runs................................................................................... 109

Store to SD Flash drive .............................................................. 109

10. PC INTERFACE....................................................................... 110

RS232 Ports ............................................................................... 111

USB Port..................................................................................... 112

Bluetooth..................................................................................... 113

11. UPDATING FIRMWARE.......................................................... 115

12. CHARGING THE BATTERY ................................................... 117

13. CUSTOMER SERVICE............................................................ 118

Warranty ..................................................................................... 118

Repairs ....................................................................................... 118

Options, Upgrades and Accessories .......................................... 119

14. TROUBLESHOOTING............................................................. 121

15. SPECIFICATIONS ................................................................... 123