Intelagard MERLIN User manual

MR012013.4

1

OPERATOR MANUAL

MERLIN® HANDCART

COMPRESSED AIR FOAM SYSTEM (CAFS)

Multi-Purpose, Portable Compressed Air Foam System

for

Fire Suppression, Decontamination & Spill Response

This document contains Intelagard proprietary information intended for use solely by the purchaser of this Intelagard

system. Reproduction is not authorized without the expressed written consent of Intelagard.

MR012013.4

2

MR012013.4

3

TABLE OF CONTENTS

TABLE OF CONTENTS.......................................................................................................................3

MERLIN QUICK START.......................................................................................................................5

SECTION 1 – FRONT MATTER.........................................................................................................6

WARNING SUMMARY.....................................................................................................................7

SECTION 2 - GENERAL INFORMATION.......................................................................................10

2.0 Scope of this Manual. ...........................................................................................................10

2.1 Equipment Model Number and Name...............................................................................10

2.2 Serial Number Locations.....................................................................................................10

2.3 List Of Abbreviations/Acronyms & Terms Used In This Manual...............................11

2.4 Purpose of Equipment..........................................................................................................12

2.5 Safety, Care, and Handling..................................................................................................12

2.6 Commercial Warranty Information....................................................................................13

SECTION 3- EQUIPMENT DATA AND DESCRIPTION...............................................................14

3.0 Merlin Characteristics, Capabilities and Features........................................................14

3.1 Merlin Physical Parameters.................................................................................................15

3.2 Merlin Operational Parameters...........................................................................................16

3.3 Location of Major Components..........................................................................................17

3.4 Description of Major Components....................................................................................18

3.5 Description of Merlin Controls and Indicators...............................................................22

3.7 Nozzle Options........................................................................................................................24

SECTION 4 – INSPECTION, PREPARATION & USE OF THE MERLIN .................................27

4.0 General......................................................................................................................................27

4.1 Uncrating..................................................................................................................................27

4.2 Inventory & Inspect - Standard Equipment Shipped with the Merlin.......................28

4.4 Operating the Merlin Handcart...........................................................................................31

4.6 Considerations for Spray Operations...............................................................................34

4.8 System Shut Down................................................................................................................37

4.9 System Venting Procedure..................................................................................................37

4.10 Storage Options....................................................................................................................38

4.11 Freeze Protecting the Merlin.............................................................................................39

SECTION 5 – PREVENTIVE MAINTENANCE CHECKS.............................................................41

5.0 General......................................................................................................................................41

5.1 Merlin Periodic Maintenance Checks...............................................................................45

SECTION 6 - TROUBLESHOOTING...............................................................................................46

SECTION 7 – SUPPORTING INFORMATION...............................................................................47

7.0 General......................................................................................................................................47

7.1 Using the Merlin with a Low-Pressure Air Source........................................................47

7.2 About Air Cylinder Recharging..........................................................................................48

7.3 Cylinder Compatibility Information...................................................................................49

7.4 Merlin Decontaminant Application Capability................................................................50

SECTION 8 – FREQUENTLY ASKED QUESTIONS....................................................................51

SECTION 9 – REPAIR PARTS, REPLACEMENTS & CONSUMABLES.................................52

MR012013.4

4

9.0 Repair Parts, Replacements, Consumables & Optional Items..................................52

9.1 Merlin System .........................................................................................................................52

9.2 Merlin Spares/Repairs...........................................................................................................53

9.3 Merlin Optional Accessories/Replacement Parts..........................................................53

9.4 Merlin Consumables .............................................................................................................54

REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR) ...........................55

MR012013.4

5

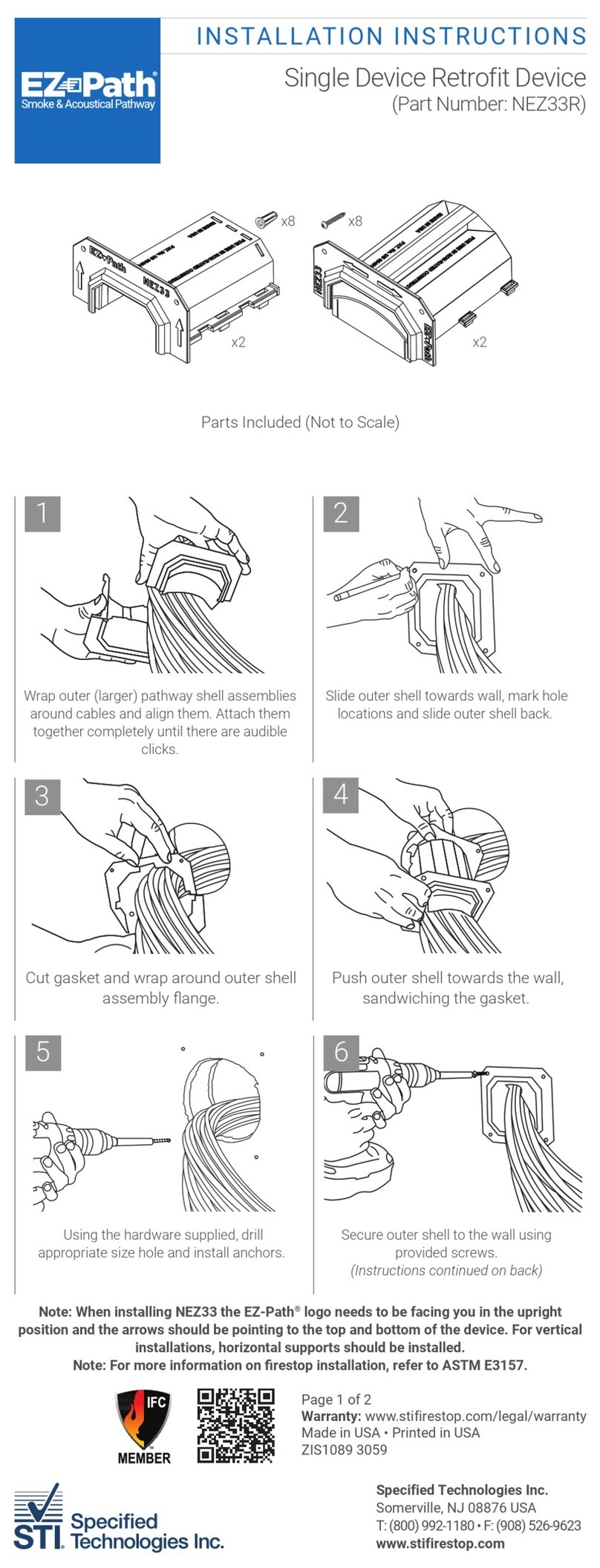

MERLIN QUICK START

1. Fill Fluid Tanks via Tank Ports. (See Foam Mixing and Nozzle Guidelines, Section 3

paragraph 3.8 for general mixing guidelines. Refer to solution manufacturer’s

recommendations whenever possible.)

2. Install fully charged air cylinder(s) into Cylinder Pouch. (One will operate the system;

the second can be stored there as back up.)

3. Buckle and tighten tank retention strap(s).

4. Connect Air Cylinder Coupler to Air Cylinder Valve and hand tighten clockwise. Do not

turn on air yet!

5. Ensure that push-to-connect fitting is securely attached to High Pressure Inlet fitting on

Equipment Case.

6. Unwind hose.

7. Securely attach hose to Fluid Outlet

8. Make sure that Handset with nozzle is securely attached to hose.

9. Ensure that Handset Valve is in closed position (clockwise to stop).

10.Turn on air by completely open Air Cylinder Valve by slowly turning knob counter-

clockwise to stop.

11.Briefly open the Handset Valve to allow pump to prime. Once liquid starts discharging

from nozzle, close handset by turning valve clockwise to stop.

12.Adjust Air Control Valve setting for WETTER or DRIER foam as needed.

13.Turn Flow Balancing Valve handles to desired settings.

Merlin is now ready to operate. Open Handset Valve to apply foam.

MR012013.4

6

SECTION 1 – FRONT MATTER

The Merlin Handcart provides the user with the ability to apply unexpanded (1:1) to highly

expanded (~35:1) compressed air foam that is generated from on-board liquid solution. The

Merlin is capable of creating and applying fire fighting foams, decontaminating foams and

many other foam products, without modification or performance degradation.

Used and maintained properly the Merlin is an extremely safe and effective system that

provides a single operator the ability to deploy up to ~490 gallons1of compressed air foam

from a single liquid tank fill.

The Merlin is a high pressure air unit. Although every effort has been taken to ensure the

Merlin is safe to operate, the operator MUST be aware that this system uses high-pressure

air to create and propel foam onto a target. Precautions MUST be taken to ensure operator

safety.

Operators must read this manual and be familiar with the safety considerations outlined

herein. Refer to the Warning Summary beginning on page 7 of this manual for an

explanation of potential risks.

Throughout this manual Important Procedures, Cautions and Warnings are identified by

the symbol below. Ensure the cautions, warnings and procedures specified herein are

closely followed. Doing so will help ensure your Merlin remains serviceable and can be

employed with maximum safety and effectiveness.

**NOTE**

This symbol is used throughout this manual to clearly indicate an

important procedural step or warning statement.

When accompanied with the word “WARNING” this symbol

indicates a strong possibility of severe personal injury or loss of life

if instructions are not followed.

When accompanied with the word “CAUTION” this symbol

indicates a possibility of personal injury or equipment damage if

instructions are not followed.

Heed all warnings and cautions!

1The Merlin has an operator adjustable air control valve that is used to control foam expansion, with the range

being unexpanded (1:1) up to ~35:1 expansion. Using the optional Mid-X air aspirating nozzle increases

achievable expansion up to ~70:1. The level of expansion achieved will vary based upon foam concentrate

used, quality of water supply, operator adjustment of the ‘Air Control Valve’ and foam concentrate viscosity and

quality.

MR012013.4

7

WARNING SUMMARY

This section contains general safety warnings and procedural cautions that must be

understood and consistently applied during operation and maintenance of this equipment.

FAILURE TO OBSERVE THESE WARNINGS AND CAUTIONS COULD RESULT IN

SEVERE PERSONAL INJURY OR LOSS OF LIFE AND/OR DAMAGE TO YOUR

EQUIPMENT!

WARNING! Personnel using the Merlin to respond to a fire emergency

must be educated in the basic principles of fire fighting to mitigate the risk

of performing these inherently dangerous operations.

WARNING! Before operation, ALWAYS verify that all hoses and

accessories are properly connected. Further, ALWAYS inspect the unit to

ensure the integrity of the air cylinder is not compromised and that all

lines are serviceable.

WARNING! NEVER operate a unit that has an identified air leak or worn

or damaged air lines/discharge hose. Once pressurized, a

loose/leaking/damaged connection may disconnect or rupture, potentially

causing injury.

WARNING! After operation, ALWAYS turn off the air supply and bleed

the handset hose to relieve the system of pressure. Failure to do so could

result in injury and /or system damage.

WARNING! To enhance the service life of your Merlin system, we

recommend only filtered/breathing quality air be used to charge the

Merlin's air cylinder. NOTE: This cylinder is not certified/authorized for

use as a breathing air cylinder - DO NOT USE Merlin cylinders with

breathing systems!

WARNING! NEVER deploy liquid or foam onto a charged electrical fire.

Foam, like water, is a conductive medium. Deployment of foam onto an

electrically charged fire can result in electrocution!

WARNING! ALWAYS wear eye protection while operating any

compressed air foam system!

MR012013.4

8

WARNING SUMMARY - Continued

WARNING! The Merlin Handcart is capable of deploying chemical and/or

biological decontaminating foams without modification. Personnel

performing this operation must be properly trained. Standard protective

ensemble (MOPP gear) is required at all times prior, during and after

decontamination operations.

WARNING! ALWAYS treat the Merlin as though the discharge hose is

energized. Once a system is pressurized it will remain so until the air

supply is turned off and the handset is activated to release pressure in the

lines.

WARNING! ALWAYS point the discharge device of the Merlin in a safe

direction and activate the handset to verify the system is not pressurized.

CAUTION! NEVER transport unrestrained/unsecured air cylinders. Doing

so could result in cylinder damage, potentially rupturing the high pressure

vessel. Always protect the air cylinder valve from impact, especially when

transporting and/or filling cylinder.

WARNING! NEVER fill pressure air cylinders that are out of hydrostatic

testing period. Refer to DOT regulations at all times.

WARNING! NEVER fill an air cylinder that has visible damage, unraveling

or charring of composite fiber.

WARNING! ALWAYS retest air cylinders every 5 years per DOT OFFC &

DOT-SP11194 and per TC-SU5303.

CAUTION! Open the air cylinder valve slowly to reduce impact on the

pressure regulation system! Rinse and inspect the cylinder periodically to

insure material integrity!

WARNING! NEVER use high and low pressure sources to power the

system at the same time! Doing so will result in severe damage to system!

MR012013.4

9

REVISION TRANSMITTAL PAGE

MERLIN HANDCART COMPRESSED AIR FOAM SYSTEM (CAFS)

OPERATOR MANUAL

Call, contact us through our website (www.intelagard.com) or mail questions to:

Intelagard,Inc.

Attn: Project Manager, Merlin

1275 Rock Creek Circle

Lafayette, CO 80026

TEL: 303.309.6309

DATE OF REVISION

SUMMARY OF CHANGE

PAGES CHANGED

Feb2013Majorstructureandcontentchanges Multiple

MR012013.4

10

SECTION 2 - GENERAL INFORMATION

2.0 Scope of this Manual.

This manual fully explains receiving, preparing for use, using and maintaining your Merlin

Handcart. The manual is broken down into the sections below:

Table of Contents

Merlin Quick Start

Section 1 – Front Matter: Warning Summary, Revision Transmittal Page

Section 2 – General Information

Section 3 – Equipment Data and Description

Section 4 – Inspection, Preparation & Use of the Merlin

Section 5 – Preventive Maintenance Checks

Section 6 – Troubleshooting

Section 7 – Supporting Information

Section 8 – Frequently Asked Questions

Section 9 – Repair Parts, Replacements & Consumables

Reporting Equipment Improvement Recommendations (EIR)

Type of Manual

Operator’s Manual; Provides instructions for operating and maintaining the Merlin Handcart

CAFS. (Compressed Air Foam System)

2.1 Equipment Model Number and Name

Merlin Handcart CAFS can be ordered with or without an air cylinder. (Specific model and

part numbers are included in Section 9 of this manual.)

2.2 Serial Number Locations. The serial number is located on the back of the Power

Module, centered above the mounting bracket as shown in Figure 2.1. Take the time to

write down your new system’s information here. The air cylinder serial number is located

on the data label affixed to the cylinder.

1. Merlin Serial No.

_______________________

2. Air Cylinder Serial No. (if ordered)

It is located on air cylinder, not shown

_______________________

Figure 2.1 – Merlin Serial Number Location

MR012013.4

11

2.3 List Of Abbreviations/Acronyms & Terms Used In This Manual

CAF Compressed Air Foam. Foam created by injecting air into a

surfactant-carrying liquid solution such as the many fire fighting

foam concentrates/solutions commercially available.

CAFS Compressed Air Foam System. A foam generating system that

uses compressed air as a primary energy source.

CFM/SCFM Cubic Feet per Minute/Standard Cubic Feet Per Minute –

Alternate unit of measure for volume throughput.

Concentrate A highly concentrated foam solution intended to be combined with

water in the Merlin’s liquid storage tanks.

Dry Foam

‘Dry’ foam is a term used for highly expanded foam. The more air

injected into the surfactant solution the greater the foam

expansion. Dry foam contains more air and requires less liquid to

create.

Expansion Ratio

The ratio of foam volume created after expansion to the liquid

volume present before expansion. A 1:1 ratio means the liquid

has not been expanded. A 15:1 ratio means the liquid has been

expanded to 15 times its original volume.

High-Pressure

Air

The Merlin can accept air from one of two sources – a high-

pressure air source or an air compressor. The high pressure air

cylinder, rated at 4350/4500-PSI is the source of the Merlin’s

high-pressure air supply.

Low-Pressure Air The Merlin can accept air from one of two sources – a high-

pressure air source or an air compressor. Air compressors are

the source for low-pressure air.

Solution As used in this manual "solution" refers to a either a water + foam

concentrate mixture or an undiluted foam solution.

PSI Pounds per Square Inch – Unit of measure for pressure.

Wet Foam ‘Wet’ foam is a term used for unexpanded or minimally expanded

foam. Wet foam contains less air and requires more liquid to

create.

MR012013.4

12

2.4 Purpose of Equipment

The Merlin Handcart CAFS is a multiple use, self-contained foam delivery apparatus

specifically designed for rapid, mobile response to fire emergencies and hazmat response

missions. The Merlin is capable of creating and applying foam solutions as an independent

system, using only on-board resources (liquid and air). The Merlin also has the ability to

connect to an external air source (air compressor) in lieu of a high-pressure air cylinder.

Utilizing an external air source eliminates the operational limitations imposed by using a

limited on-board containerized air supply.

The Merlin is capable of applying numerous foam solutions, including but not limited to Class

A & B firefighting foams (including long duration proteins, AFFF and AR-AFFF),

decontaminating foams such as EasyDECON® DF200, moldicides and many new wetting

agents and combination A/B firefighting agents.

If you are unsure of the suitability of a foam concentrate or it’s compatibility with the Merlin

system, contact Intelagard before using the concentrate in the unit.

For additional information on capabilities and employment modes see Sections 3 (Equipment

Data and Description) and 4 (Inspection, Preparation & Use of the Merlin) of this manual.

2.5 Safety, Care, and Handling

WARNING! The Merlin Handcart uses high-pressure, containerized air as an

energy source to create and propel foam onto a target. Before operation,

ALWAYS verify that all hoses and accessories are properly connected.

Further, ALWAYS inspect the unit to ensure the integrity of the air cylinder is

not compromised and all lines are serviceable.

2.5.1 High Pressure Air. The Merlin system uses a high-pressure air cylinder as the

container for air energy that creates and propels foam onto targets. Users MUST ALWAYS

exercise appropriate cautions when filling, transporting and using high-pressure air cylinders.

The cylinders provided by Intelagard are carbon-fiber wrapped for added safety, and the

installed air cylinder valve includes a burst disk. In the event a cylinder is overcharged, the

burst disk will rupture at ~6750 psi, venting the air into the atmosphere. Intelagard’s air

cylinders are manufactured to Department of Transportation (DOT) standards, which require

a cylinder be capable of withstanding 3.33 times operating pressure without incident (3.33 x

4500 psi). The DOT special permit number is provided on the cylinder label. Always use

cylinders that meet DOT standards in the Merlin. The Merlin also has a low pressure port for

utilizing power from a compressor.

SAFETY must always be foremost in the operators mind to prevent accidents or incidents

that could lead to system damage and/or personal injury. Read and observe all safety

warnings in this manual and NEVER attempt to operate a Merlin CAF system with an air leak.

If escaping air is heard once the system is pressurized, turn off the air supply, activate the

handset to release trapped air and fluid and then thoroughly inspect the system to identify

the source of the air leak – do not use a Merlin with an air leak!

MR012013.4

13

2.5.2 Hazardous Materials. The Merlin ships with the air cylinder (if purchased)

empty; therefore there are no hazardous material restrictions on transport or storage of the

Merlin Handcart. Fire foam concentrates are also free of restrictions on transport and

storage. Intelagard provides concentrate MSDS’s on request, and a MSDS is enclosed in all

foam concentrate cases.

The Merlin is suitable for use with a multitude of foam concentrates therefore it is not possible

to address all possible contingencies within this manual. If purchasing Class A or B fire foam

concentrates or EasyDECON® DF200 through Intelagard these materials are

environmentally safe and also impose no restrictions on transport or storage beyond standard

temperature considerations for long-term storage.

In the interest of personnel safety and system integrity users must take the time to familiarize

themselves with the qualities of the solutions they will apply with the Merlin Handcart by

thoroughly reviewing the MSDS provided with the foam concentrates.

2.6 Commercial Warranty Information

Intelagard provides a limited commercial warranty included in the purchase agreement and/or

contract. Contact your contracts or procurement manager for a copy of the warranty.

Intelagard’s commercial warranties are available on our webpage, www.intelagard.com.

MR012013.4

14

SECTION 3- EQUIPMENT DATA AND DESCRIPTION

Section 3 Contents:

3.0 Merlin Characteristics, Capabilities and Features

3.1 Merlin Physical Parameters

3.2 Merlin Operational Parameters

3.3 Location of Major Components

3.4 Description of Major Components

3.5 Description of Merlin Controls and Indicators

3.6 Merlin Modes of Operation

3.7 Nozzle Options

3.8 Foam Mixing and Nozzle Guide

3.0 Merlin Characteristics, Capabilities and Features

3.0.1 The Merlin is a self-contained, independently functioning and transportable

Compressed Air Foam (CAF) generation apparatus, highly suited for fire and hazardous

vapor suppression, liquid spill response, and military and civil decontamination operations.

The Merlin is designed to apply foaming solutions for fire suppression (Class A & B),

decontamination, hazardous material remediation, biohazard control, toxic material spill

remediation, cleaning and mold control, as well as many other applications

3.0.2 The Merlin is capable of applying most commercially available foam concentrates,

including Class-A, long-duration protein, AFFF, AR-AFFF, decontaminating foams, and many

new wetting agents and combination A/B agents. The Merlin has many additional

applications, including application of non-foaming liquid solutions and air-aspirated foam with

simple nozzle changes and control adjustments. Contact Intelagard for recommended

foaming agents or with any questions regarding system capabilities.

3.0.3 The Merlin is powered by means of air energy, provided by an approved air

cylinder or external air compressor2. Filtered, breathing quality air is injected into an approved

surfactant solution to create foam, which is propelled onto a target via the air energy that also

drives the internal pump subsystem. Intelagard offers DOT-approved 66 cu. ft., 4350/4500-

psi, carbon-fiber wrapped air cylinders with the Merlin. If other air cylinders are used in the

Merlin, they must meet Intelagard’s criteria to avoid voiding the system's warranty. See

Section 7.3 for air cylinder compatibility information.

WARNING! NEVER use high and low pressure sources to power the system at

the same time! Doing so will result in severe damage to system!

2To operate the Merlin without performance degradation an air compressor must be capable of providing 12-

CFM of filtered air at 100-110 psi. See Section 7. Paragraph 7.1 for additional information

MR012013.4

15

3.1 Merlin Physical Parameters

System Specifications.

COMPLETE SYSTEM:

Dry Weight: System: ~80.7 lbs3(without fluid or air cylinder)

Full Weight: ~224 lbs (with 14 gal fluid and 1 full air cylinder)

Dimensions: ~49.25” H x 19.25” W x 23.75” D (height measurement will change

with tire inflation and tire choice)

TANK:

Liquid Capacity: (2) 7 gallon tanks (measured to top of sight tube)

Material: Molded Polypropylene

Closure (Cap): Lanyard retained, vented, poly construction, 3” diameter

PUMP:

Combined Flow: ~10 gallons per minute4(gpm) liquid flow rating

Pressure: 100 psi Optimum, 110 psi Maximum

Construction: Glass reinforced poly housing with Santoprene internals

AIR INJECTION (Foam Expansion Control):

Adjustable by mechanical valve, 90 degrees rotation, wet/dry setting

COMPRESSED AIR FOAM (CAF) MANIFOLD:

Expansion: 1:1 (liquid application) to ~35:15

Air Consumption: ~9.5 scfm Max6

Resupply Ratio: ~1:1 MAX (14-gal tank load emptied per full air cylinder)7

Output Stream: ~105 gallons per minute finished foam

Output Throw Distance: ~40 ft MAX8

3Intelagard cylinder adds ~13 lbs.

4The Merlin pumps are individually rated to dispense ~5-gallons of liquid per minute. When working in

conjunction with the CAF components pump flow is reduced by as much as 35%.

5Achievable expansion ratio depends on foam solution composition. Concentration and concentrate quality will

affect finished foam expansion.

6Air consumption varies according to foam solution make-up and wet dry setting. Re-supply ratio based on 66

cu. ft, 4500psi cylinder.

7The tank to cylinder resupply ratio will vary according to foam solution, nozzle selection and system settings

(wet/dry).

8Wet/Dry settings, foam product, nozzle used, wind and other factors will significantly affect foam throw

distance.

MR012013.4

16

3.2 Merlin Operational Parameters

OPERATIONS PARAMETERS

Structure,

Woodland Fire

Fighting

Class-A Foam. Foam expansion ratio should be adjusted via the Air Control Valve to

determine the best setting for the situation. See Foam Mixing and Nozzle Guidelines,

Section 3.8 for more recommendations.

Vehicle, Tire and

Fuel Fires

Class B (AFFF or AR-FFF) foam. Foam expansion ratio should be adjusted via the Air

Control Valve to determine the best setting for the situation. See Foam Mixing and

Nozzle Guidelines, Section 3.8 for more recommendations,

Decontaminant

Solution,

EasyDECON®

DF200

EasyDECON DF200 is available in a three-part formulation that ships in 5 gal, 100 gal

and 500 gal configurations. Add Part 1 to Tank A, Part 2 to Tank B, and finally, Part 3 to

Tank A when ready to deploy. (Shelf life of the EasyDECON DF200 is significantly

degraded once Part 3 is added to Part 1.) Do not dilute with water. Apply at

expansion ratio best suited for the target area and agent challenge. Use the fan spray

nozzle to apply foam to vertical surfaces.

Flow / Capacity /

Throughput

14 gal (total) fluid tanks can yield up to ~490 gal of finished foam with the Air Control

Valve adjustment set fully to the ‘dry’ setting using a smooth bore nozzle (~35:1

expansion9). Foam expansion is a function of the amount of air injected into a liquid

solution. A higher “wet” setting will use more liquid and less air. A higher “dry” setting

will use more air, and less liquid. Optimum settings must be determined by the operator

based upon the environment, mission and specific challenges presented. As air

consumption varies based upon the wet/dry setting, operators can expect to empty the

fluid tanks approximately one time on a fully charged air cylinder. If ‘wetter’ foam is

being applied the air supply will last comparatively longer than when applying ‘dry’ foam.

Set-up Times

Tank Refill Time: ~1-2 minutes

Pumping time: Subject to system settings

System PMCS: < 10 minutes

System Start-Up: < 1-2 minutes

System Shutdown: < 1 minute

Configure for external air: < 2 minutes

Foam Projection

Distance Projection distance is a function of wet/dry settings, foaming agent, air source, nozzle

used and weather. With standard equipment, projection distance is up to ~40 feet10

Operating Pressure 100 psi optimal, 110 psi maximum

Low Pressure Air

(Air Compressor)

Requirements

Compressor must provide a minimum of 12-scfm at 100 psi optimum, 110 psi maximum.

Owner/operators should test their compressor to determine suitability for use with the

Merlin

Foam Expansion System: 1:1 (unexpanded) up to ~35:1 (35 times original liquid volume). With Mid-X

Nozzle: up to ~ 70:1 is achievable

Accessories See section 9 of this manual

Table 3.2.1 - List of Merlin Operational Parameters

9Achievable expansion varies based upon concentrate and nozzle used and operator chosen system settings.

10 Throw distance can vary significantly based upon foam concentrate, water quality, wet/dry settings, air quality,

nozzle used and weather.

MR012013.4

17

3.3 Location of Major Components

Figure 3.3.1 - Location of Major Components

ITEM COMPONENT FUNCTION

1AirCylinderand

NozzlePouch

MoldandmildewresistantCordura®fabricpouchforcylinderstorageandnozzle

storage

2AirCylinder

RetentionStrapsRetentionstrapstoholdcylindersinplaceforsafestorageandtransport

3AirCylinder(s)and

Valve(s)

4350/4500psicarbonfiberwrapped,66cu.ft.aircylinder;StandardUScylindersare

equippedwithCGAvalveswithburstdisk(DINfittingsavailableonrequest)

4PortableHandcartAluminumhandcarton10"pneumatic*tireswithextendedhandleforeasier

movement.(*solidrubbertiresavailableuponrequest)

5

ControlPanel/

Removable

EquipmentCase

Controlpanelincludes aircontrolvalve,flowbalancingvalvesforfluidtanksand

cylinderpressuregauge.EquipmentcasehousesfunctionalcomponentsoftheMerlin,

andcanberemovedforremoteoperations.

6LowPressureAir

ConnectionConnectionforlowpressureauxiliaryairsource

7HighPressureAir

Connection

Connectionforhighpressureaircylinder.Connectstocylinderwith"highpressurewhip

line"

8Handset/Hose

Assembly

20'x3/4"IDhose,shipswithfullporthighperformancehandsetattached.Nozzle

attachestohandsetviaquickconnectfitting

MR012013.4

18

ITEM COMPONENT FUNCTION

9Nozzle

Nozzlesareinterchangeable,andusedtotailorfoamapplicationtothemission–see

Section3paragraph3.7foradditionalinformationMerlinshipsstandardwith12mm

SmoothBoreNozzle.

10DischargePortPortwherefoamexits Merlin totheattachedhose/hosehandsetassemblyconnected

viaquickconnectfitting

11FluidTanks(2)

Twin7gal(measuredtotopofsighttube)tanksaremoldedfromhighgrade

polypropyleneresins.Configuredwithsighttubesforfluidlevelmonitoring.Includes

drainplugforeasycleaning.

12FluidPortsandCaps3"capscoveringtheMerlin'stankfillingports.Capsareventedandlanyardretained

13FlowBalancing

ValvesValvesadjustfluidflowforindividualMerlinfluidtanks

14AirControlValveAnadjustabledial,labeledWetterFoamandDryerFoam.Usedtoselecttheamountof

airinjectedintothefoamthuscontrollingthefoamexpansionratio.

Table 3.3.1 – Merlin Major Components.

3.4 Description of Major Components

#1. Air Cylinder and Nozzle Pouch: The air cylinder(s) are held in the Merlin cart unit in an

attached, padded ballistic cloth pouch and polyethylene sheet. Two standard cylinders can be

accommodated at the same time. This allows for efficient recharging of the air supply if the

Merlin is being used for extended deployment. The cylinders are placed in the pouch, valve

end up, and one cylinder is connected to the system.

#2. Air Cylinder Retention Straps: There are two cylinder retention straps on the handcart

cross member directly above the pouch. These straps must be buckled and tightened around

the cylinder(s) to ensure secure transport of the cylinders and operator safety.

#3. Air Cylinder(s) and Valve(s) - Intelagard air

cylinders are 4350/4500 psi carbon fiber wrapped

high pressure air cylinders. Our air cylinders ship

with the valve installed (CGA or DIN) and are ready

to be filled upon receipt by customer. Our standard

cylinders have a DOT or CE label around the cylinder

body and are certified for use only with Intelagard CAF systems. These carbon composite

cylinders have a 15-year service life, and must be hydro-statically tested every five years per

DOT test criteria. The date of manufacture and the service pressure rating can be found on

the DOT label. The valves incorporate a burst disk, designed to rupture at approximately

6750 psi in the event of over-filling. Per DOT regulations high-pressure cylinders are

manufactured to withstand overfilling to 3.33 times operating pressure. 4350 cylinders have

been manufacturer-approved for filling to 4500psi. Always inspect cylinders for damage prior

to re-charging. Cylinders incorporate a serial number on the data plate.

WARNING! To maintain the integrity of the system Intelagard recommends

using only quality, filtered air to charge our cylinders. Never use a Merlin air

cylinder as a breathing air cylinder! Only persons trained in the proper use of

air compressors and cascade systems should refill air cylinders!

Figure 3.4.1 – Air Cylinder

MR012013.4

19

#4. Portable Handcart: The Merlin is mounted to a rugged aluminum handcart that allows

the user to comfortably transport the unit, whether full or empty. The standard 10” pneumatic

tires are mounted on alloy wheels for movement over uneven terrain. The tire pressure

should be maintained at a minimum pressure of 30 psi, with a maximum pressure of 50 psi.

The extended aluminum handle allows for proper balancing of the system while transporting.

Custom bracketing has been designed to allow for secure connection of the tanks, cylinder

pouches and equipment modules. Optional semi-pneumatic and hard rubber tires, as well as

larger tires and wheels are available from Intelagard.

#5. Control Panel / Removable Equipment Case: The control panel located on the front of

the removable equipment case is configured for effective use by personnel in Personal

Protective Equipment (PPE). The controls on the panel include the air control valve (for

wetter and drier foam expansion consistency), the flow balancing valves for Tank A and Tank

B, and the cylinder pressure gauge.

The equipment case can be easily and quickly removed from the Merlin by detaching the four

quick connect fittings located on the back of the case, and removing the pins holding the case

and bracket to the handcart. Once removed, the case can be carried to remote locations and

connected to a high or low pressure air source, and to bulk fluid storage (via optional fluid

drafting hoses) for large scale operations. The case houses the functional components of the

Merlin system including various calibrations and adjustments that require special equipment

and procedures to change. These settings are factory preset.

WARNING! Opening this enclosure improperly may lead to injury, death or

equipment damage!

The equipment case may only be opened and serviced by factory authorized

personnel. Breakage of the factory seal by unauthorized personnel will void equipment

warranty!

#6. Low Pressure Air Connection: Merlin users with an

available compressed gas supply (nitrogen or

compressed air) can operate the Merlin system by

bypassing the internal regulation system and supplying

regulated low pressure directly to the Merlin via the

equipment case low pressure air connector. A

compressed gas supply regulated to 110psi MAX can be

connected via the quick-disconnect fitting. An external

compressor must provide a minimum of 12-scfm at 100

psi optimum, 110 psi maximum. Owner/operators should

test their compressor to determine suitability for use with

the Merlin.

#7. High Pressure Air Connection: Below the low pressure connection is a male quick-

disconnect for high pressure connection to the equipment case. Cascade cylinder systems

Fig.3.4.2 High and Low Pressure

Air Connections

MR012013.4

20

Fig 3.4.3 High performance handset

Fig 3.4.4 Trigger Handset

and SCBA type cylinders can be connected here by using the high pressure whip line

included with the Merlin system. The high and low pressure connections are gender-

alternated and different in connection shape. They are not interchangeable. One end of the

high pressure whip line connects to the equipment case and the other connects to the

cylinder valve.

#8. Handset and Hose Assembly: The Merlin ships with a standard 20’ long x 3/4” diameter

hose and high performance handset assembly. The handset comes pre-installed on the hose.

The system connection end of the hose is equipped with a quick-connect coupling to make

connection to the discharge port quick and easy. The tip of the handset incorporates a quick-

connect coupling for multiple available nozzles.

The discharge hose has a high degree of chemical compatibility. The discharge hose is rated

for up to 300 psi (20.7 bar) of pressure. The hose also has a flame resistant outer jacket.

Owners/operators should adhere to the guidelines set forth in NFPA 1962 “Standard for the

Inspection, Care and Use of Fire Hose, Couplings, Nozzles and the Service Testing of Fire

Hose”. 8.1 High performance handset Configuration -

Standard): The high performance handset ships

standard with the Merlin, and is connected to the 20’

hose with a stainless steel quick-connect fitting. Once

the unit is filled with foam solution and the air cylinder

is secured in place and opened, all that is required to

operate the system is to safely aim the handset and

open the valve by turning clockwise to stop. This

handset requires two hands to operate. One hand firmly grasps the pistol grip handle at the

base of the valve, while the other hand rotates the valve handle counterclockwise (forward) to

turn on and clockwise (upward) to turn off. The system will dispense foam as long as the

valve is open, and will cease when the valve is closed, or when components are exhausted.

8.2 Trigger Handset (Optional): The trigger

handset is a rapid-action valve that is operable by

one hand. It consists of a handset trigger valve that

is operated by squeezing the trigger with the index

finger. This handset trigger has a locking tab

(dependent upon order specifications) that allows the

user to lock the handset in the open position by

pressing the top portion of the trigger. To disengage the lock, squeeze in and down on the

top section of the trigger, allowing the lock tab to release. Use of this handset with the Merlin

will result in reduced throw distance, but is recommended for use with decontaminent

solutions such as EasyDECON DF200. Call Intelagard or your local distributor for more

information.

The handset hose attaches to the discharge port on the Merlin with a stainless steel quick-

connect fitting. When not in use, the hose should be stored by coiling it around the metal

hose bracket located on the front of the fluid tanks.

NEVER pull the Merlin using the hose!

Table of contents

Popular Firefighting Equipment manuals by other brands

Unifire

Unifire FORCE 80 Generic system manual

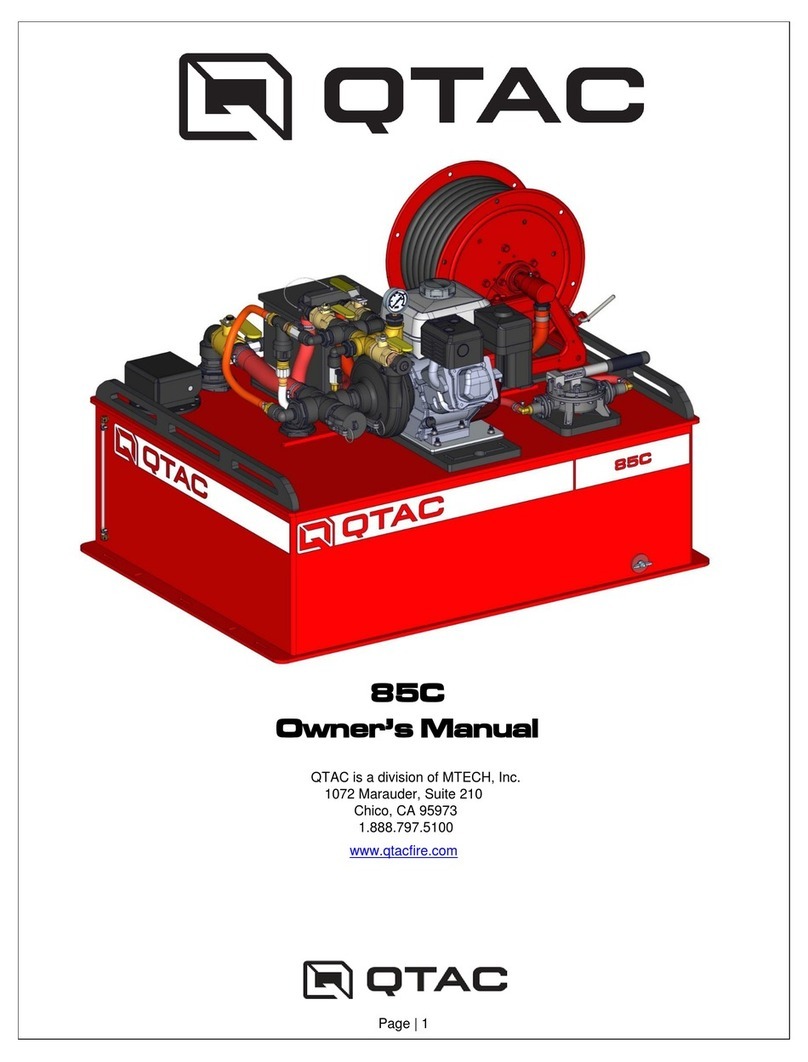

QTAC

QTAC 85C owner's manual

Amerex

Amerex HALOTRON BRX 337 Owner's maintenance manual

Waterous

Waterous Pressure Governor Installation and operation

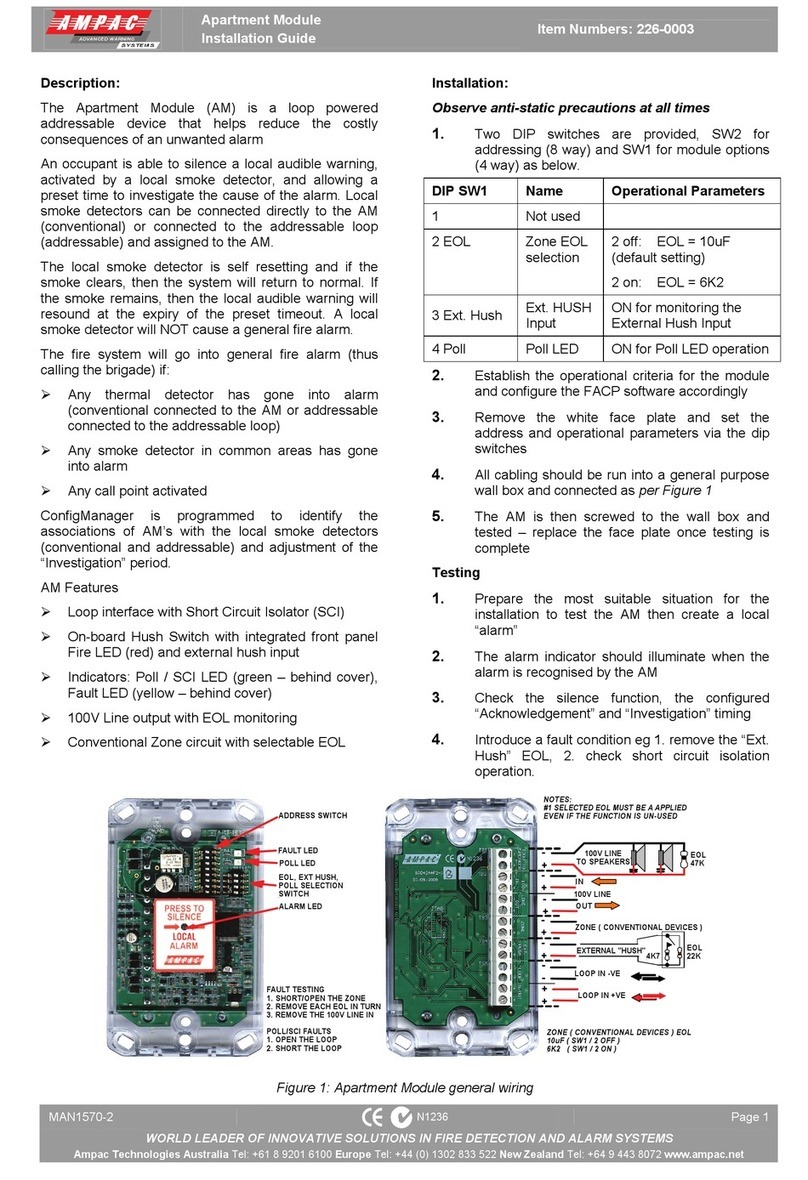

Ampac

Ampac 226-0003 installation guide

TFT

TFT ULTIMATIC Instructions for installation, operation and maintenance