17

Installation and set up10

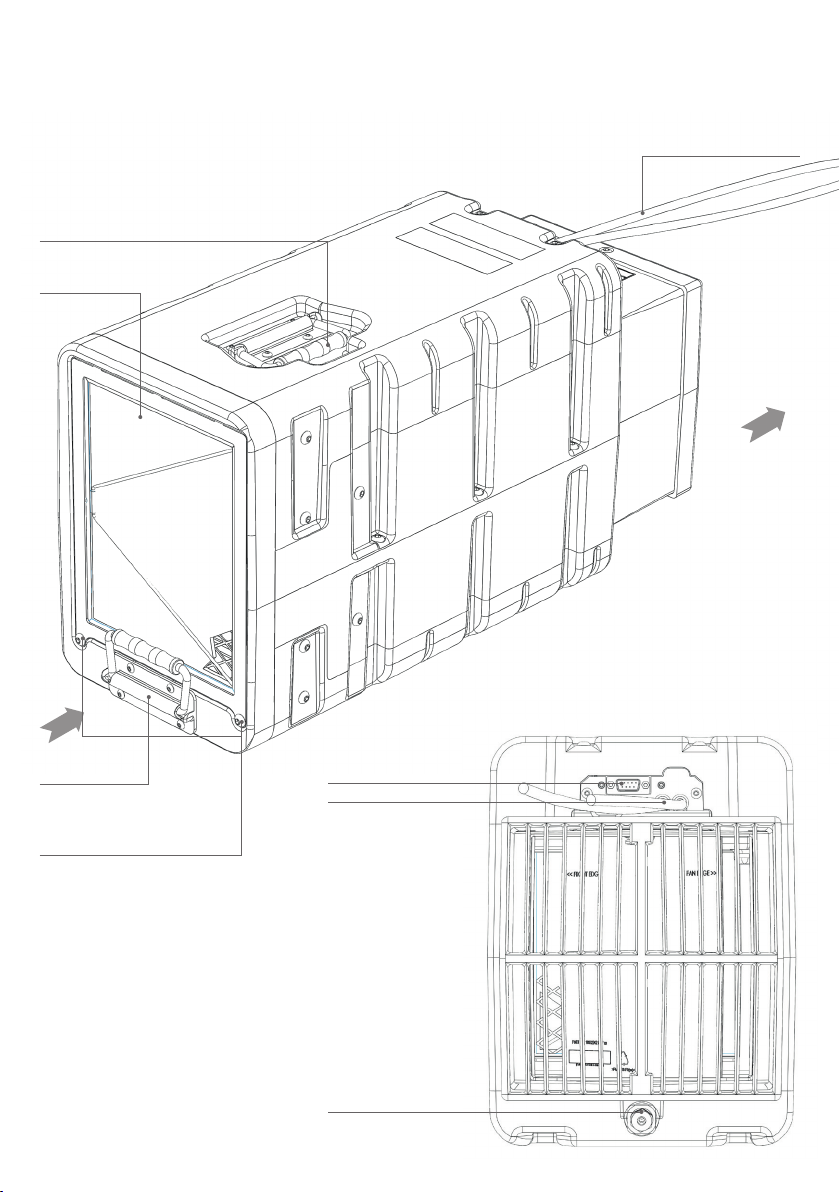

Air supply and ventilation

The FCM-801 should be setup in a well ventilated environment with consideration given

to the precautions of hydrogen control. The FCM-801 requires an unrestricted supply of

clean air to deliver power output. The unit will require up to 6,500 slpm of unrestricted

air flow. The application should consider the air flow required for the environmental

conditions expected, the enclosure should not unduly restrict the air flow. The covers

should be designed to enable the exhaust gas to leave the enclosure directly and so that

it cannot be recirculated into the air inlet.

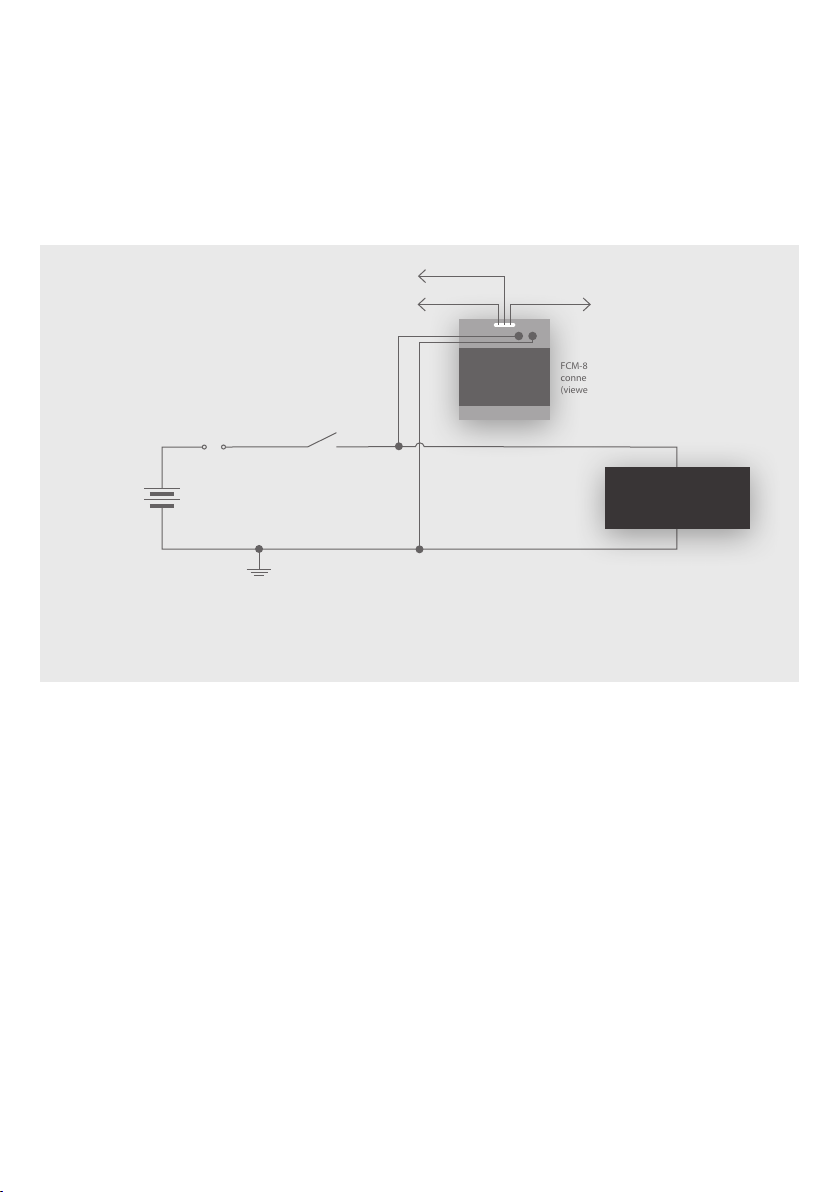

As part of the design, the main air flow is also used to manage the risk of a hydrogen

build-up. The hydrogen purge gas is routed into the air flow so that it is diluted to

below the lower flammability limit at the point of exit from the unit; therefore, the

installer should take care not to restrict the exhaust stream. This gas stream will contain

hydrogen, this is at a concentration where it is not flammable. The design of the

integration should consider the use of a hydrogen sensor as part of the integrated safety

case. This should also consider the hydrogen storage and supply system.

The FCM-801 should be provided with air in the temperature range of +5°C to +40°C,

it should not be operated outside this range. The installation of the FCM-801 must be

considerate of other equipment near the FCM which may elevate the local ambient

temperature. A local increase of ambient temperature may affect the performance of the

fuel cell. Do not use if the air has smoke or corrosive gas present.

Hot air that is generated by other equipment within 0.6m of the inlet of the FCM-801 is

of concern and should be limited to 5% of expected operating power of the FCM-801 in

order to limit the ingestion of hot air.

The FCM-801 should not be located in an area where sleeping may occur.

The FCM-801 consumes oxygen as it operates it is therefore minimum air ventilation

requirement must be observed at all time to ensure safety of personnel in the room, if

being used in an enclosed space:

· Rooms of less than 5m3must have a permanent vent area of 100cm2

· Rooms greater than 5m3 must have a permanent vent area of 50cm2

· If multiple FCMs are being used additional ventilation maybe required, especially if the

load is more than 10kW. Contact Intelligent Energy Product Support for further advice.

The above is applicable only if openable windows (or equivalents such as grilles or louvre

panels) are also present. Extraction must be provided in cases where the above does

not apply. This covers case such as internal rooms without windows. If the extraction is

adjacent to the fuel cell system the rate must be at least 30l/s. If the extraction is elsewhere

in the room the rate must be at least 60l/s. The above ventilation requirements are what

is needed for the FCM-801, however the hydrogen storage and supply may impose

additional requirements. The Install may also need to consider the effect of the fuel cell

operation on oxygen depletion, additional mitigation should be considered for this. This is

the responsibility of the integrator to manage safely. These may be more onerous.

10.5

Warning:

Warning: