14

8.1

8.2

8.3

8.4

8.5

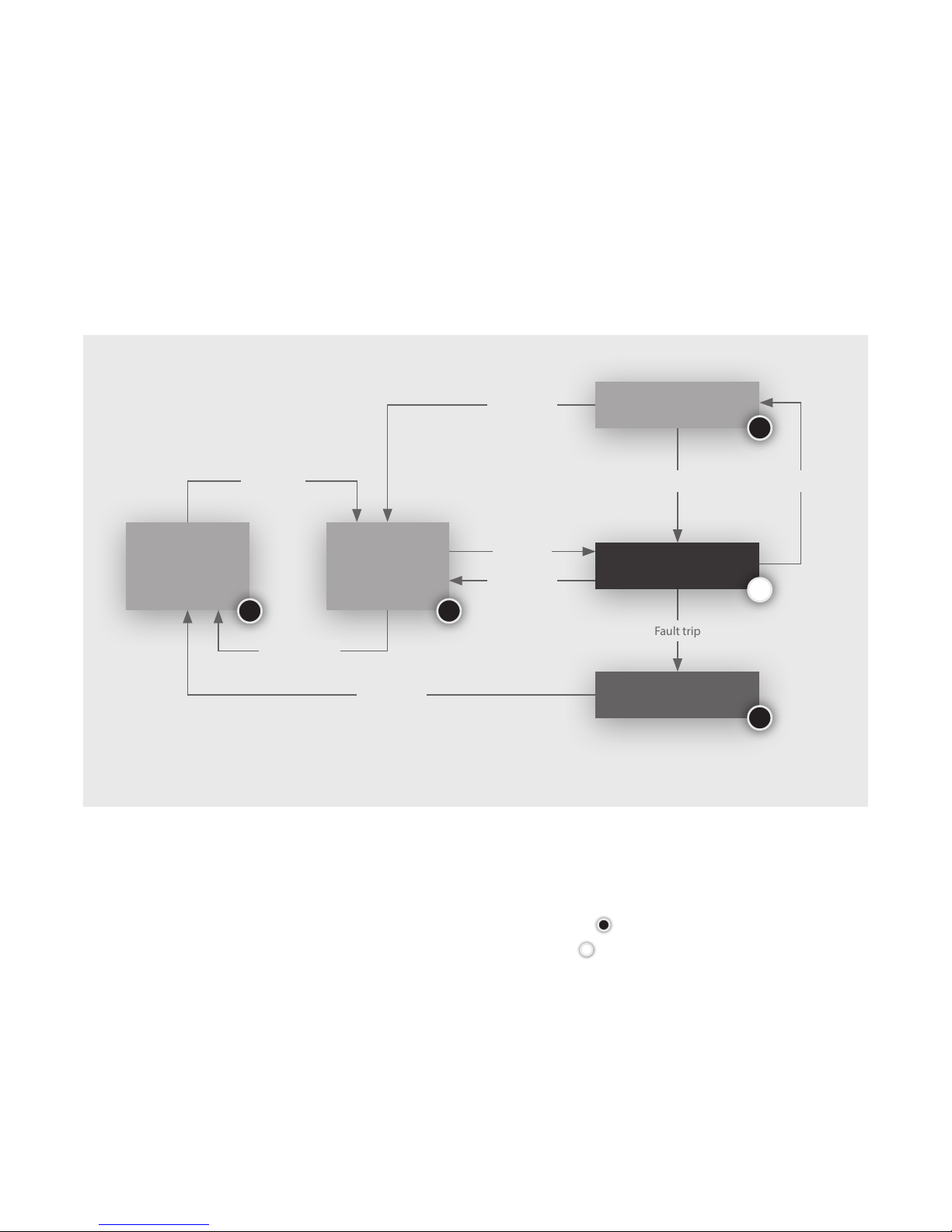

Overview FCM 802/804

The FCM-802/804 provides regulated DC at nominal 24V or 48V output to a battery

bus. The DC bus will be held at nominal voltage by a battery or external supply to act

as a hybrid system. In the hybrid system, the battery is used to provide power whilst

the fuel cell starts. It supports the load during the fuel cell performance optimisation

cycle and while the system is in the standby mode. The nominal operating voltage is

factory settable upon request.

The hydrogen pressure must be provided in a regulated state to the module inlet.

The FCM-802/804 will generate power when it is given both ‘Enable’and ‘Run’ signals

and detects DC bus and fuel pressure are present.

Anode purge

As the fuel cell operates, it is necessary to remove water and any impurities from the

anode (the hydrogen side of the fuel cell). This is done by exhausting a small amount

of hydrogen to the coolant air stream. The hydrogen is mixed with the air stream so

that, as the mixture exhausts the module, the concentration is low enough that it will

not sustain a ame. There is no impact on power production during anode purge.

Performance Optimisation Cycle (POC)

During normal operation, the FCM-802 / 804 will periodically conduct an optimisation

cycle which improves the performance of the fuel cell. Multiple cycles are triggered in

rapid succession at start-up. Cycles occur less than 15 times an hour during running.

Power production is reduced or suspended for up to 12 seconds during the cycle so an

external power source may be needed to briey provide power to the load.

Standby state

As a fuel saving measure the FCM-802/804 will stop producing power if the load

drops below 6A, default for FCM-804, for example (see Delay Stop Under Current,

13 Control Parameters) for more than a minute; below this point, the ancillary

equipment compromises the fuel cell eciency. The load will then be provided by

the battery.

The FCM-802/804 will continue to monitor the battery and, if its voltage drops below

the nominal voltage, it will restart (See Delay Start Under-Voltage in Section 12).

When the fuel cell is running, it will power the load (if present) and oat the battery

voltage to the nominal set-point. This feature is designed to achieve the maximum

useful energy from the fuel available.

Fault state

If the parameters of the FCM-802/804 leave the normal operational range then a fault

is triggered. When a fault has been triggered the controller will latch. Toclear the

fault, the controller needs to be turned o via the Enable signal. For reset instructions

see Section 9.

Operation of FCM-802/8048