Intelligent UFM-B User manual

A Higher Level of Precision…

A Higher Level of Performance

UFM-B UFM-F UFM-L NTEP Bench Scales

Maintenance Manual

1

MAINTENANCE MANUAL

UFM SERIES

NTEP & MEASUREMENTCANADA

CONTENTS

1.INTRODUCTION

2.SPECIFICATIONS

2.1 SYSTEM BLOCKDIAGRAM

2.2 PHYSICAL LAYOUT OF ELECTRICAL CONNECTION

2.3 GENERALSPECIFICATIONS

2.4 INTERNAL SETTINGSAND CALIBRATION METHODS

3.TROUBLE SHOOTING

3.1 TROUBLESHOOTING LOOP

3.2 PARTS AND COMPONENTS TROUBLE SHOOTING

4.ELECTRICAL CIRCUITRY

4.1 SCHEMATICS

4.2 PCB LAYOUT

5.BILLOF MATERIAL

6.APPENDIX

JANUARY 2005 REV 2

Specifications andFunction Subject toChange withoutNotice

2

1. INTRODUCTION

TheUFM seriesis designedand programmed according toNTEP and

Measurement Canada requirements.

These indicatorsare sealedto preventunauthorizedaccesstointernal

parts. Endusers should be advisednot toundertake anytroubleshooting

except thoselisted inthe operation manual.

This maintenancemanualcontains of certain information thatmay result

infraudulent use. Donotreleaseanypartof thismanual to anyend

users or un-authorizedpersons.

Theinternalminijumper shouldbe so setto prevent un-authorized

settings or alterations.

Ifaloadcell has been replaced, makesurethat the protection devices

are correctly set.

After servicing,itis necessary togothrough alltestsand procedures

to ensure theindicator meetsall the meteorological and approval

requirements.

Features of the UFM series

1.Designed to meet NTEP & MEASUREMENT CANADA requirements.

2.ZeroIndicator.

3.TareIndicator.

4.FullTareFunction (Subtractive)

5.Negative ValueIndicator.

6.AutoTareFunction.

7.Power on Zero Function.

8.Manual Zero Function.

9.Average Function.

10.AutoPower Saving Function.

11.Metric/AvoirdupoisConversionFunction(whereitislegalforuse).

12.Large Size WTNLCD display, 5 x 51mm.

13.Low Battery WarningSignal.

14.2 Point Calibration.

15.MiniJumper toPrevent End-user Calibration.

16.Optional EL Backlight.

17.Optional Printer and RS232C Interface.

18.Accumulation Function Available.

19.Built-in Rechargeable BatteryOperated.

20.Battery Operating time: 200 Hours Plus with Full Charge.

21.Gravity Compensation Software

3

2. SPECIFICATION

2.1 SYSTEM BLOCK DIAGRAM

Description:

When amass isplacedonthe platform, the load of thearticle is

transferred to the load cell inside.

Theresistance to the excitation currentinthe straingauge willthen

bechanged and the analogoutput signalvaries in proportion tothe

load applied.

Itis amplifiedanddigitizedcontinuouslyby the A/D converterinto

adigital signal. Subsequently, the resulting countisprocessedand

managedbythe CPU.TheCPU refers to theinstructionsfrom thekeyboard,

andthen conveys the outputdata toLCD driver, whichformatsthedata

into a readout onthe display panel.

LCD DRIVER

CPU

with ROM

E+

LOAD E-

CELL S+

S- POWER SUPPLY:

AC ADAPTOR

(9V/500mA)

RECHARGEABLE

BATTERY (6V 4Ah)

A/D UNIT

KEYBOARD

(6 KEYS)

LCD

INTERFACE

4

2.2 PHYSICALLAYOUT OFELECTRICAL CONNECTION

RECHARGEABLE

BATTERY

6V 4Ah

LOADCELL

5

PIN

CONNECOTR

MAIN BOARD

F

M

-

1

2

-

X

J4

J3

PLATFORM

INDICATOR

E+E

-

S+S

-

- +

BAT

+

-

DCIN

J6

PRINTER

D-SUB 25

(FEMALE)

J2

RS232

RS232C

-

1B1

RS-232 BOARD

D-SUB25

(FEMALE)

5

2.2.1 CONNECTIONBETWEEN INDICATOR ANDPLATFORM(5 PINROUND CONNECTOR)

PIN ASSIGNMENT

INDICATORPLATFORM

PIN #1E+

PIN #2E-

PIN #3S+

PIN #4S-

PIN #5GND

2.2.2 CONNECTION OF RS-232 BETWEEN INDICATOR AND PC(25PIND-SUB)

PIN ASSIGNMENT

INDICATOR(25PIN D-SUB,FEMALE)PC(25PIND-SUB,MALE)

** RTS & CTS have been shorted internally.

BAUDRATE 4800,9600(DEFAULT), 19200

Protocol:N81 (DEFAULT),E71

Code ASCII

Dataoutput: Continuous (DEFAULT) or, *M+/MC key

* Press M+ to output a reading of individualtransaction.

* Press MC to output thetotal of readings.

EXC+

SIG+

SIG

-

LOADCELL

SHIELD

RED

GREEN

BLACK

WHITE

EXC

-

PIN #1SHIELD

PIN #2RXD

PIN #3TXD

PIN #4RTS

PIN #5CTS

PIN #6DSR

PIN #7 GND

PIN #8 DCD

PIN #20

DTR

PIN #1SHIELD

PIN #2TXD

PIN #3RXD

PIN #4RTS

PIN #5CTS

PIN #6DSR

PIN #7 GND

PIN #8 DCD

PIN #20

DTR

6

2.2.3 Parallel PrinterInterface(D-SUB 25pin)

PIN ASSIGNMENT

PIN NUMBER

ASSIGNMENTPINNUMBER

ASSIGNMENT

1 STROBE 7 D5

2 D0 8 D6

3 D1 9 D7

4 D2 11 BUSY

5 D3 25 GND

6 D4

7

2.3 GENERAL SPECIFICATION

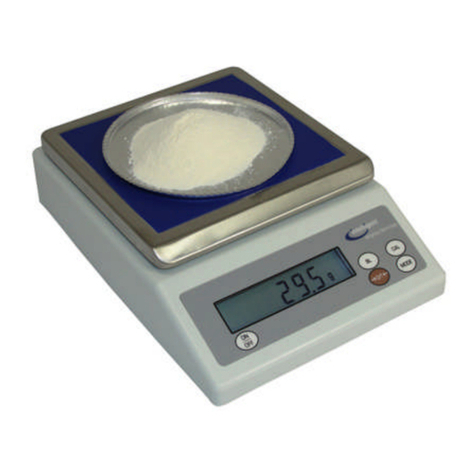

2.3.1 Overall View

UFM SERIES

Indicator Dimension

UFM-B = 250(W) x 80 (D)mm x150(H)

UFM-F/L= 250(W) x 130(D)mm x 150(H)

OverallDimension

UFM-B = 330(W) x 450(D) x 750(H)mm

UFM-F = 420(W) x 520(D) x 880(H)mm

UFM-L = 500(W) x600(D) x 880(H)mm

8

2.3.2 Model Specifications

Model No.

Capacity

(Max) Readability

(e) Platform

UFM-B30 30kg/60lb0.01kg/0.02lb

UFM-B60 60kg/120lb 0.02kg/0.05lb

UFM-B150 150kg/300lb 0.05kg/0.1lb

330 x450mm

UFM-F60 60kg/120lb 0.01kg/0.02lb

UFM-F120 120kg/250lb 0.02kg/0.05lb

UFM-F300 300kg/600lb 0.05kg/0.1lb

420 x520mm

UFM-L60 60kg/120lb 0.01kg/0.02lb

UFM-L120 120kg/250lb 0.02kg/0.05lb

UFM-L300 300kg/600lb 0.05kg/0.1lb

UFM-L600 600kg/1200lb

0.1kg/0.2lb

500 x600mm

Class III

MaximumTare

Range Full Tare Range (Subtractive)

Power on Zero

Range ±10%Max

Manual Zero

Range ±2% Max

MinimumLoad 20e

Operation

Environment 0o~40oC (32o~104oF),

Non-condensed. R.H.≦85%

Power

Consumption 0.1W

2.3.3 Main Components Used

Microprocessors: SM8958A

Crystal Oscillator:11.0592MHz

Display Device: WTNLiquid CrystalDisplay

2.3.4 AnalogSpecification

- Electronic, self-indicating device, with single [-or multi]-

intervalindication. Themaximum number ofverification scale

intervals will be:

n ≤6000 forclass III instrumentsor

n ≤1000 forclass IIII instruments.

9

- Power supplyof 5V DC;

- Minimumsignal voltage per verificationscale interval is 1.5 µV;

- 16bitsserial digitaloutput;

- Excitation power supply forthe load cell is 5 V DC;

- Minimuminput impedance of the load cell is 85 Ω;

- Maximumcable lengthforthe connection betweentheindicator and

the junctionboxor loadcells (when more thenone loadcell is

connected) is 1 m/mm2.

- Theanalog data processingunit isbuilt inaclosedmetalbox.

2.4 INTERNALSETTINGS AND CALIBRATIONMETHODS

12internal settings are available asbelow table.

Function Symbol Description

1 F1 Offset value reading

2 F2 Full LCD display segment checking

3 F3 Span valuereading/Configuration Setup

4 F4 Auto poweroff setting

5 F5 RS-232 transmission setting

6 F6 Average function setting

7 F7 Data output setting

8 F8 Printout formatsetting

9 F9 Auto tare function setting

10 F19 1/30000 verificationmode

11 F20 C.G.-gravity of calibration location

12 F21 U.G.-gravityoflocation of installation

2.4.1 How toEnter theFunctionsRequired

a. Press andhold TARE and turn scaleon by pressing ON/OFF

b. The scaleshows F1

c. Press TARE until the desired function numberappears

d. Press MODE to enterselection

e. Press TARE to save and continue selection

f. Press ZERO to quit to restartthe scale

2.4.2 OffsetValue Reading (F1)

a.Remove all loads from platform

b.Enter F1 throughprocedures as described in 2.4.1

c. The displayshows theoffset value

10

2.4.3 Full Segment Display (F2)

a.Refer to the 2.4.1 on how to enter F2

b.All displaysegments will lightup

c.Check all digitsandarrow indicationsto verifyanydefects or

errors

d.Press TARE to quit

2.4.4 Span Value Reading/Configuration Setup (F3)

TheUFMseries is designedaccording toNTEP andMeasurement Canada

requirementswithmaximum resolutionlegalfortrade at 1/6000. It

isalso approved for1/3000 so users canchoose thepreferred resolution

depending onthe working environment.

When type NTEP (legal for trademode) is selected, the ratedcapacity

will belimitedto maximum of1/6000. When type normal (not legalfor

trade mode)is selected,therated capacitywill be allowedfor amaximum

of1/30000.The indicator alsoprovidesoptionfordual intervalswhen

set.

TOENTER FUNCTION

a.Refer to the 2.4.1 onhow to enter F3

b.Press MODE to select tYPE (NTEPor normal), unit (metric onlyor

metric/imperial conversionsupport), dP (decimalpoint), CAP2

(capacity andreadability), CAP1? (for dual interval, only allowed

when type isset in normal mode).

TOSET TYPE (Select betweenNTEP andnon NTEPapplication)

a.Press M+ when displayshows tYPE and select the operating type

of ntEP or norm for normal

b.Press MODE to save and continuesetup

TOSET WEIGHING UNIT

a.Press M+ when display shows unit and select the weighingunit of

kg, g, lbkg or lb g.When itisset kg or gonly, scalewillonly

displayresultin metric form,butwhen set to lb kg or lbg ,scale

will allow metric/imperialconversion

b.Press MODE to save and continuesetup

11

TOSET DECIMAL POINT

a.Press M+ when display shows dP and selectthedecimal place from

NIL to3 decimalplace

b.Press MODE to save and continuesetup

TOSET CAPACITY AND GRADUATION

(For Singleinterval, it means Max x e; for Dual Interval, it means Max2x e2)

a.Press

M+

whendisplayshows

CAP2

and utilize

M+ to increase value,

MR tomovecursor to the next digit

b.The graduation is limitedtomaximumof 1/6000when type NTEP is

selected. It must be set to validatethe change

c.Press MODE to save and continuesetup

TOSET DUAL INTERVAL (Max1x e1)

When type NORMAL is set, displaywill now show CAP1? to allow setup

for dual interval.

a.Press

M+

whendisplayshows

CAP1?

andutilize

M+ to increase value,

MR tomovecursor tothe next digit. Thedefault valueis 50%of

the capacity setin CAP2.

b.The graduation also must be setto validate the change

c.Press MODE to save and completethe setup

NOTE 1: Youmust resetcapacityevery time whenyouchangethetype

betweenNTEPand NORMAL.

NOTE 2: When NTEP type isselected,indicator will automatically

limit userstoprogramtheconfiguration under1/6000.When

NORMAL typeisselected, indicatorwill automatically allow

users to program the configuration under 1/30000.

NOTE 3: When settingup capacities,users mustprogram all digits

including division before pressing MODE to completesetup.

2.4.5 Auto Power Off Setting (F4)

This unit isequippedwith AUTO POWER OFF function. Default setting

=auto off after4minutesofidletime.Follow the steps below to

disable/enable the AUTO POWER OFF function.

a.Refer to the 2.4.1 onhow to enter F4

b.Press MODE to shift between 0_OFF and 4_OFF

12

-To disablethe AUTOPOWER OFF function select “0-OFF”

-To employthe AUTO POWER OFF function select “4-OFF”

c.Press TARE to save andreturn toother function

2.4.6 RS-232Transmission Setting (F5)

a.Refer to the 2.4.1 onhow to enter F5

b.Press M+ toselect baud rate of 4800, 9600 and 19200

c.Press MODE to entertransmissionprotocolselectionandpress M+

to select P=n81 or P=E71

d.Press TARE to save and return to other function

Note: The defaultvalue is:

Baud Rate :9600

DATA BIT:8

PARITY BIT :N(NONE)

STOP BIT:1

CODE :ASCII

2.4.7 AVERAGE FUNCTION(F6)

a.Refer to the 2.4.1 onhow to enter F6

b.Press MODE to select FiLt.0 or FiLt.1

-To disablethe AVERAGE FUNCTION select “FiLt.0”

-To employthe AVERAGE FUNCTION select “FiLt.1”

c.Press TARE to save and return to other function

2.4.8 Data OutputSetting (F7)

a.Refer to the 2.4.1 onhow to enter F7

b.Press MODE to select dataoutput format of SEr.1 or SEr.2

-Whenselects SEr.1,scalewilltransmitdatacontinuously via

RS-232whenreading is stable

-When selects SEr.2,data will transmit single data viaRS-232

when pressing M+

c.Press TARE to save and return to other function

2.4.9 DATA PRINTOUT FORMAT (F8)

a.Refer to the 2.4.1 onhow to enter F8

b.Press MODE to select dataoutput format of Prnt.1 or Prnt.2

-When Prnt.1 is selected, scalewill print data in atableformat

with numberof entries andtotal weight

-When Prnt.2 is selected, scalewill printsingledata whenpressing

M+

c.Press TARE to save and return to other functions

13

2.4.10 Auto Tare Function Setting (F9)

a.Refer to the 2.4.1 onhow to enter F9

b.Press MODE to select Troff or Tr_on

-Troff will disable the auto tare off function

-Tr_on willenable theautotarefunctionandtareoffthefirst

weightthatis placedon the scale

c.Press TARE to save and returnto other functions

2.4.11 High ResolutionVerification Mode (F19)

This function is intendedtobeused only by the manufacturer forinitial

verificationpurpose.

2.4.12 Gravity CompensationDevice C.G. (F20)

This function stores thegravityvalueofwherethescaleismanufactured.

Scale was calibrated according to thevalue stored.

a.Refer to the 2.4.1 onhow to enter F20

b.Use MODE toshifttonextdigitanduse ON/ZERO toincrease the

value

c.Press and hold MODE to save or TARE to quit

-When thechange is saved, scale willenter calibration

automatically toreflect thechange ingravity. Pleaserefer to

2.4.14 forhow to calibrate the scale

2.4.13 Gravity CompensationDevice U.G. (F21)

This function stores the gravity valueofwhere the scale willbe used.

Thevalue stored in F.21will be usedtocompare with thevalue in

F.20 tocompensate thedifference in gravity value.

a.Refer to the 2.4.1 onhow to enter F21

b.Use MODE toshifttonextdigitanduse ON/ZERO toincrease the

value

c.Press and hold MODE to save andreturn toother functions

14

2.4.14 CALIBRATION METHODS

DEALER CALIBRATION

a.Turn indicator off

b.Press and hold TARE,then press ON/OFF

c.Indicator displays F1

d.Press MODE to enter dealer calibration

e.Pressandhold MODE for YES and indicatorwill self calibratezero

point before proceeding tothe firstpoint calibration

f.Load the mass accordingto the display, normally the firstpoint

is 1/3of the full capacity

g.Press MODE whendisplay is flashing

h.Indicator displays CAL._2

i.Press MODE for YES or ZERO to exit

j.Load the massaccordingtothedisplay,normallythesecond point

is the2/3 capacity

k.Press MODE whendisplayis flashingtocompletethecalibration

procedure

AUTO CALIBRATION

a.Turn indicator off

b.Press and hold MODE,then press ON/OFF

c.Indicator displays CAL._1

d.Press MODE for YES and indicator will self calibratezeropoint

beforeproceeding to the first pointcalibration

e.Load the mass accordingto the display, normally the firstpoint

is 1/3of the full capacity

f.Press MODE whendisplay is flashing

g.Indicator displays CAL._2

h.Press MODE for YES or ZERO to exit

i.Load the massaccordingtothedisplay,normallythesecond point

is the2/3 capacity

j.Press MODE whendisplayis flashingtocompletethecalibration

procedure

Note

Auto calibration can only beperformedwhenthe span value

Is within+/-10% tolerance ofdealer calibration.

15

NOTE: CALIBRATIONIN LB

When calibratingthescale in lb,please refertothefollowing steps:

a.Enablethe metric/imperial weighingunitconversion in F3

b.Press MODE to change the weighing unit tolb when scale is on

c.Repeatthe proceduresin Auto Calibration

16

CHECK LOAD CELL,

A/D UNIT,OFFSET

VALUE

CHECK POWER

SUPPLY,LCD,LCD

DRIVER IC,R37,38

CHECKPLATFORM

STOPS,LOAD

CELL,A/D UNIT,

BAD SOLDERING

RE-CALIBRATE

THE SCALE

CHECKPLATFORM

STOPS,LOAD

CELL,OFFSET

VALUE

3. TROUBLE SHOOTING

3.1 TROUBLE SHOOTING LOOP

POWER ON

COUNT DOWN

?

NODISPLAY

DISPLAY RANDOM

FIGURE

CHECK POWER SUPPLY,

CPU,LCD,KEYBOARD CHECKCPU,LCD,

LCD DRIVERIC

OK

COUNTS AND

THEN ZERO?

OK

PROPER READOUT

?

CORRECT READOUT

?

NORMALOPERATION

SHOW

“

00

000

”

UNSTABLE

GHOST

OK

OK

INCORRECT

CAN’TREACHFULL

CAPACITY

17

3.2 PARTS AND COMPONENTS TROUBLESHOOTING

3.2.1 Power Supply Checks

3.2.1.1Relevant parts:

Main Board (FM-12-X)

Q1 (A1515)

Q2 (A733)

U5 (IC4027)

U11(AIC 1722-5.0)

Q5 (C1061)

Q4 (C945)

ZD1(ZENER 8.2V)

R51(1.2R 1/2W)

DC JACK

BATTERY(6V 4Ah)

Description:

1) Power source: Rechargeable Battery6V/4Ah orAC adaptor(9V,

500mA)

2)+5V powerdrives digitalcircuit system.

U11 (AIC 1722-5.0) is a 5volts Voltage Regulator.

3)+5V powerdrives analog circuit system.

U4 (AS2950A) is a 5 volts Voltage Regulator.

4)Auto-off:

Ifthe indicator is set to 4_oFFofpower-saving functionor under

LO-BATsituation, after afixedtime interval (normally4minutes),

the CPU will release alowtohighpulse signal to toggleU5, then

Q1 cuts off, indicator will beshutdownimmediately.

18

5)Low PowerDetection:

The Q2(A733) isdesignedtodetect the power level. When battery

powerislessthan5.5V,thecollectorpolewillbecomelowpotential,

then CPU will instruct LCDdisplay to show LO-BAT symbol.

3.2.1.2Input voltage:5.5Vor higher

Check andrecharge battery ifvoltage is less than 5.5V.

3.2.1.3System voltage(Vcc): 5V+/- 10%

Check that thesystem voltageis within5V +/- 10%

a) less than 4.5V, the CPU may notworkproperly.

b) more than 6V, ghosting will appear on LCD.

3.2.2 Platform Overload Stop

Make surethattheplatformdoes notinterfere withanythingwhen

weighing. Check that the platform does not touch the upper (no

load) and/or lower (full load) overload stops.

3.2.3 LCD DisplayChecking

3.2.3.1 Check that it issolderedand connected properly between LCD

and driver IC (PCF8576), driver IC (PCF8576) and CPU.

3.2.3.2 Check whether LCD is broken.

3.2.4 CPU Checking

3.2.4.1 Check that allpinsare seated properlyintothe socket.

3.2.4.2 Check that theCrystal Oscillator works.

3.2.4.3 Check theRESET is normally low.

3.2.5 A/D Unit Checking

3.2.5.1Check that the A/D unit iscorrectly fed with +5VDC power.

3.2.5.2 Check that the signal output of loadcell is normal.

3.2.5.3 Check OP. Amplifiers &A/D Converter (AD7705).

19

When no error is found with the abovechecking procedures,the trouble

canbe caused bytheloadcell or the PCB itself.Replace withanew

one will help to identify the defective part.

Following the replacementofany parts,itisimportant that the scale

berecalibrated again.

This manual suits for next models

2

Table of contents

Other Intelligent Scale manuals

Intelligent

Intelligent PM User manual

Intelligent

Intelligent AXM-1500 User manual

Intelligent

Intelligent PH Series Mounting instructions

Intelligent

Intelligent W10 User manual

Intelligent

Intelligent Intelligent-Lab PBW User manual

Intelligent

Intelligent PM SERIES User manual

Intelligent

Intelligent Intell-Lab PD-3000 Series User manual

Intelligent

Intelligent QHD Series Mounting instructions