Intellinox ecoAzur V4 Series User manual

User’s

manual

V4 SERIES DEMAND CONTROL

KITCHEN VENTILATION SYSTEM

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 2 / 17

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 3 / 17

SAFETY INSTRUCTIONS AND NOTES

Warnings caution you about conditions which can result in serious injury or death and/or damage to the equip-

ment. They also tell you how to avoid the danger. The warning symbols are used as follows:

Electricity warning warns of hazards from electricity which can cause serious

injury and/or damage to the equipment.

General warning warns about conditions, other than those caused by electricity,

which can result in physical injury and/or damage to the equipment.

WARNING! The ECOAZUR® system and related equipment should ONLY be installed

by qualified personnel. Electrical wiring and connections should be done by a qualified

electrician.

WARNING! The ECOAZUR® system and related equipment should be properly

grounded to provide protection against electric shocks.

WARNING! More than one circuit disconnect switch may be required to de-energize

the equipment before servicing. Dangerous voltage is present when input power is

connected to the ECOAZUR® processor panel.

WARNING! Lockout electrical power to all equipment (ECOAZUR® processor panel,

hood lights, VFDs, motors, etc.) before hood and duct cleaning procedure.

Do not expose control panels to any water.

WARNING! Dangerous voltage is present when input power is connected to VFDs.

After disconnecting the supply, wait at least 5 minutes (to let the intermediate circuit

capacitors discharge) before removing the cover.

WARNING! Legal regulations and regulations issued by authorities must be observed

during installation.

WARNING! Never pressure wash the ECOAZUR® components, including the optic sen-

sors.

WARNING! Ensure that all electrical switches and system components (including ac-

cess doors) are returned to an operable state after the cleaning procedure.

WARNING! The ECOAZUR® system will start up automatically after an input voltage

interruption. Dampers and exhaust fans may automatically be energized.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 4 / 17

WARNING! The device may only be opened at the manufacturer's site. It does not

contain any parts that can be replaced or repaired by the user. Never attempt to re-

pair a malfunctioning ECOAZUR® part, including any other related equipment such as

VFDs (Variable Frequency Drives), dampers, motors, fans, etc.; contact your local Au-

thorized Service Center for repair or replacement.

WARNING! Do not stare at the ECOAZUR® optic sensor light.

WARNING! In case of occurrence of any problem please call your authorized service

center.

For more information, concerning your ECOAZUR® DCKV control system, contact your authorized service

center.

Read and understand instructions provided with any other equipment related to the ECOAZUR® DCKV

control system.

Product disposal (W.E.E.E . Directive)

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn. All locally valid regulations and requirements

must be observed.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 5 / 17

TABLE OF CONTENTS

SAFETY INSTRUCTIONS AND NOTES ............................................................................................................................... 3

1 OVERVIEW .............................................................................................................................................................. 6

2 SEQUENCE OF OPERATIONS.................................................................................................................................... 7

2.1 NORMAL OPERATING MODES ................................................................................................................. 8

2.2 TYPICAL OPERATION SCENARIO ............................................................................................................. 10

2.3 ECOAZUR OVERRIDE MODES ................................................................................................................. 11

3 USER INTERFACE ................................................................................................................................................... 13

3.1 ECOAZUR DISPLAY ................................................................................................................................. 13

3.2 KEYPAD COMMANDS ............................................................................................................................ 13

4 KITCHEN PERSONNEL OPERATION INSTRUCTIONS ............................................................................................... 15

5 MAINTENANCE ..................................................................................................................................................... 16

5.1 TEMPERATURE SENSORS ....................................................................................................................... 16

5.2 OPTIC SENSORS .................................................................................................................................... 16

5.3 KEYPAD DISPLAY ................................................................................................................................... 16

5.4 EXHAUST DAMPERS AND PRESSURE TRANSMITTERS .............................................................................. 16

6 TROUBLESHOOTING .............................................................................................................................................. 17

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 6 / 17

1 OVERVIEW

The purpose of this User’s Manual is to provide the basic knowledge required for operating the

ECOAZUR® DCKV (Demand Control Kitchen Ventilation) system in the context of a commercial or

institutional kitchen. This document also provides instruction for the end user concerning

maintenance and troubleshooting of the ECOAZUR® control system. Should additional information be

required, the following documents may be referenced:

- ECOAZUR® Product Specifications (E4PS-EN) – Product design characteristics

- ECOAZUR® Installation Manual (E4IM-EN) – Mechanical installation

- ECOAZUR® Programming Manual (E4PM-EN) – Parameter setup, advanced troubleshooting

- ECOAZUR® Electrical Diagrams - Project specific wiring instruction

The ECOAZUR® control system interfaces with third-party devices such as VFDs, fans and other

equipment. Refer to manufacturer specific documentation and instructions for your safety and for

proper operation and maintenance of these equipment.

Only qualified professionals should install, program and service the ECOAZUR® system. Legal

regulations and regulations issued by authorities must be observed, notably in the USA:

- NFPA 96 - Standard for Ventilation Control and Fire Protection of Commercial Cooking

Operations

- NFPA 70 - National Electric Code (NEC)

The ECOAZUR® DCKV system usage is limited to the following application:

- Commercial cooking ventilation, including Type 1 and Type 2 hoods (grease hoods /

condensate hoods), with or without modulating dampers.

- ECOAZUR® modulating dampers are not fire dampers and should solely be used as an airflow

control device with an ECOAZUR® system.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 7 / 17

2 SEQUENCE OF OPERATIONS

The ECOAZUR® system is designed to control kitchen hood ventilation based on detected cooking

activity. Airflows are adjusted using ECMs (Electrically Commutated Motor) or VFDs (Variable

Frequency Drive), and, in some cases, exhaust dampers are added to increase potential savings.

A combination of temperature and optic sensors allow for a wider range of airflow modulation

(typically 30-100% or 50-100%), thus increasing potential savings. During non-cooking periods,

exhaust fans automatically reduce their speed to the COOL DOWN preset speed and will ultimately

come to a stop in IDLE mode, after the preset time has elapsed. In IDLE, the system continues to detect

any cooking activity and, if necessary, will automatically switch to PREPARATION and COOKING modes,

thus fulfilling the requirements of the NFPA 961 and of the International Mechanical Code2. The

following is a graphical representation of the ECOAZUR® sequence of operations:

When exhaust dampers are used in combination with an exhaust fan, they are forced to operate

according to their corresponding exhaust fan operating mode. This ensures that the exhaust duct air

velocity, under cooking conditions, is above 500 ft/min as prescribed by NFPA 963.

1 NFPA 96-2017, 8.2.3.3

2 IMC-2018, 507.1.1

3 NFPA 96 2017, 8.2.1.1

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 8 / 17

PREPARATION and COOL DOWN modes may be disabled when not required, leading to a simplified

sequence of operations:

2.1 NORMAL OPERATING MODES

2.1.1 PREPARATION

Typically, an exhaust fan in PREPARATION mode operates at 20% airflow (approximately), while its

related make-up air unit remains off. The intent is to prevent a make-up air unit from starting until an

actual cooking load is detected.

When in IDLE mode, the following conditions will start an exhaust fan in PREPARATION mode:

• A related hood temperature sensor reads a temperature rise above PREP/COOL TEMP

threshold (typically 27degC / 80.6degF).

• The BAS (Building Automation System) sends a request to the ECOAZUR® processor to operate

the exhaust fan at least at PREPARATION preset speed.

Note: PREPARATION / COOL DOWN modes are disabled in the default parameter setup.

2.1.2 COOKING

Typically, an exhaust fan in COOKING mode may be set to modulate 30-100% (18-60 Hz or 15-50Hz)

or 50-100% (30-60 Hz or 25-50Hz) depending on the cooking equipment as well as the hood and duct

design. When no exhaust dampers are used, the exhaust fan speed corresponds to the highest

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 9 / 17

demand among all related hood sensors (temperature, optics, etc.).

When exhaust dampers are used, each exhaust damper airflow setpoint is determined by the highest

demand among all its related hood sensors. The ECOAZUR® system will control the exhaust fan speed

to maintain the proper exhaust static pressure in the main exhaust duct. In order to maintain sufficient

air velocity in the exhaust duct system during cooking operations, all dampers linked to the same

exhaust fan will be forced to enter COOKING mode simultaneously as soon as a cooking condition is

detected. This provides means for ensuring that the exhaust duct air velocity remains above 500

ft/min as prescribed by NFPA 964.

In all cases, make-up air units are controlled as a function of their related exhaust fans. A desired

exhaust to make-up air ratio may be programed in the ECOAZUR® system.

The following conditions will switch an exhaust fan to COOKING mode:

• Pressing the AUTO key on the ECOAZUR® keypad. All the exhaust fans controlled by the keypad

display will run in COOKING mode.

• A related hood temperature sensor reads a temperature above the

“COOKING TEMP” threshold (typically 30degC / 86degF).

• A related optic sensor detects cooking activity, such as the presence of smoke or vapor

generated by the cooking equipment.

• The BAS sends a request to the ECOAZUR® processor to force the exhaust fan to operate in

COOKING mode.

2.1.3 COOL DOWN

An exhaust fan in COOL DOWN mode will run at 20% airflow (approximately). The make-up air unit

will be turned off and the cooking appliances will cool down before the exhaust fan reaches IDLE

mode.

The following conditions will switch an exhaust fan to COOL DOWN mode:

• When sensors have stopped reading cooking activity (COOKING state) for longer than 30

minutes (typical COOKING OFF DELAY setting), the exhaust fan speed will automatically

decrease to the COOL DOWN preset speed. Note that temperature sensors are required to

read below PREP/COOL TEMP in order to leave COOKING mode (typically 27degC / 80.6degF).

• Pressing the STOP key on the ECOAZUR® keypad will bypass the COOKING OFF DELAY and COOL

DOWN OFF DELAY of all exhaust fans linked to the keypad. All exhaust fans sensing no cooking

activity will switch to COOL DOWN mode, and if possible, to IDLE mode immediately.

4 NFPA 96-2017, 8.2.1.1

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 10 / 17

Note: PREPARATION / COOL DOWN modes are disabled in the default parameter setup.

2.1.4 IDLE

An exhaust fan in IDLE mode is typically programmed to stop. Related sensors remain ready to detect

any cooking activity and trigger PREPARATION or COOKING mode. The following conditions will switch

a given exhaust fan to IDLE mode:

• When all sensors have stopped reading PREPARATION / COOL DOWN conditions for longer

than 30 mins (typical PREP OFF DELAY, COOL DOWN OFF DELAY settings). Note that

temperature sensors must read below the IDLE TEMP threshold for the exhaust fan to switch

to IDLE (typically 25degC / 77 degF).

• Pressing the STOP key on the ECOAZUR® keypad will bypass the COOL DOWN OFF DELAY of all

exhaust fans linked to the keypad. All exhaust fans sensing no activity will switch to IDLE mode

immediately.

2.2 TYPICAL OPERATION SCENARIO

Given the sequence of operations previously described, the following is an example of how ECOAZUR®

would operate the kitchen ventilation based on the fluctuation of a hood temperature sensor:

*Prep off-delay parameter

**Cooking off-delay parameter

***Cooldown off-delay parameter

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 11 / 17

In a similar manner, optic sensors also provide hood modulation based on smoke and vapor density. When

an optic pair detects any cooking activity, the related exhaust damper or exhaust fan is immediately forced

to COOKING mode and their airflow setpoint increases according to the sensor demand.

The ECOAZUR® processor continuously retains the highest sensor demand among all related sensors for a

given exhaust damper or exhaust fan.

2.3 ECOAZUR OVERRIDE MODES

2.3.1 MAX OVERRIDE

If the hood ventilation appears to be insufficient at any moment, ventilation may be overridden to full

speed for a predetermined amount of time. The make-up air units will adjust automatically to the

required make-up airflow. The following conditions will switch the kitchen ventilation to MAX

OVERRIDE:

Pressing the MAX key on the ECOAZUR® keypad will switch the related exhaust fans to MAX

OVERRIDE. The exhaust fan will automatically return to normal operations after a

predetermined amount of time (15 min, 60 min, 6 hr, 24 hr or an unlimited time duration).

An ECOAZUR® processor digital input programmed to MAX is activated by the BAS or another

third-party system.

When an ECOAZUR® V4CC3 series processor panel is used, a “MAX – OFF – AUTO” selector is

available on the processor panel and allows the user to force the kitchen ventilation system to

100% speed (“MAX” position), while forcing all exhaust dampers to a fully open fail-safe

position.

2.3.2 OFF OVERRIDE

OFF OVERRIDE forces the kitchen ventilation to stop, regardless of any ECOAZUR® sensor detection,

and keeps the ventilation system from starting when cooking conditions occur. Local/national codes

and regulations may prohibit overriding the system in OFF OVERRIDE as a means of operation (OFF

OVERRIDE is disabled by default). In locations where regulations do not require the ventilation to start

automatically upon cooking condition, the STOP OVERRIDE may be used:

The STOP key on ECOAZUR® keypad may be customized to STOP OVERRIDE. All ventilation

appliances related to the given keypad will be switched to STOP OVERRIDE when STOP key is

pressed. The user must press AUTO or MAX in order to leave the OFF OVERRIDE mode.

• An ECOAZUR® processor digital input programmed to OFF is activated by the BAS or another

third-party system.

• An ECOAZUR® processor digital input programmed to SCHEDULE 1 to 4 is deactivated by the

BAS or another third-party system.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 12 / 17

• When an ECOAZUR® V4CC3 series processor panel is used, a “MAX – OFF – AUTO” selector is

available on the processor panel and allows the user to force the kitchen ventilation system to

stop (“OFF” position) disregarding any cooking activity.

2.3.3 FIRE OVERRIDE

FIRE OVERRIDE has the highest priority among all other operation modes. The ECOAZUR® control

system continuously monitors the hood fire suppression system (dedicated normally closed micro-

switch). In the event of a fire, the ECOAZUR® keypad displays FIRE ALARM, the make-up air units are

turned off and the exhaust fans are forced to a 100% speed. Electrical circuits powering the exhaust

dampers are also de-energized, thus forcing all dampers to a fully open position within 4 seconds.

When hood lights are controlled by the ECOAZUR® processor, the installer may customize light

operations during FIRE OVERRIDE (force on, force off, automatic).

2.3.4 VFD BYPASS OVERRIDE

An ECOAZUR® processor digital input may be programmed to VFD BYPASS OVERRIDE in order to force

the entire kitchen ventilation to 100% when a VFD is operating in bypass mode. The intent of this

override is to maintain a neutral static pressure for the kitchen while a VFD is on bypass. Additionally,

VFD BYPASS OVERRIDE ensures that all exhaust dampers are fully open when an exhaust fan is

bypassed to 100%. VFD BYPASS OVERRIDE has the second-highest operation priority, after FIRE

OVERRIDE.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 13 / 17

3 USER INTERFACE

3.1 ECOAZUR DISPLAY

The ECOAZUR® keypad displays a customizable set of ventilation appliances such as exhaust fans,

make-up air units, and dampers. If a keypad has more than 4 appliances to display, the screen will

cycle through all appliances, displaying them 4 by 4. Here is an example of a typical display:

Each line represents an appliance, with the following information:

• Appliance ID (left): Unique combination comprising 1 letter and 1 number.

◦ Dampers start with letter D

◦ Exhaust fans with letter E

◦ Make-up air units with M

• Custom name (center): Custom user defined name. When applicable, WARNING! blinks on

top of the custom name to indicate that maintenance may be required to keep the system

operating at maximum efficiency.

• Fan/damper modulation (right): Airflow setpoint in % is indicated when in normal operation

(IDLE-PREP-COOK-COOL modes).

◦ When STOP OVERRIDE is active, STOP is indicated on the interface and the ventilation

appliance is overridden to stop, disregarding any sensor demand. Local/national codes

and regulations may prohibit overriding system in STOP as a means of operation. The

installer should not enable the STOP OVERRIDE function if not permissible.

◦ When MAX OVERRIDE is active, the ventilation appliances are overridden to 100%, the

messages MAX and 100% will alternate on the interface.

3.2 KEYPAD COMMANDS

MAX, AUTO and STOP buttons on a keypad will only control ventilation appliances linked to a given

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 14 / 17

keypad. By default, keys are configured to function as mentioned in the previously described

sequence of operations. The following is a summary of keypad commands (default settings):

Key Default Function

MAX

Forces the ventilation to MAX mode for a predetermined amount of

time (pressed once: 15 min, pressed twice: 60 min). The key may be

customized or disabled.

AUTO Sets the ventilation to COOKING mode.

STOP

Attempts to force the ventilation to IDLE mode. This key has no effect

when cooking conditions are detected. The key may be customized or

disabled.

FN/LIGHT Toggles the hood light (default function).

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 15 / 17

4 KITCHEN PERSONNEL OPERATION INSTRUCTIONS

At the beginning of the kitchen operation period:

• Press the AUTO key to start ventilation in COOKING mode. The hood lights will turn on

automatically.

• Turn on the cooking appliances. ECOAZUR® will automatically adjust the kitchen ventilation

according to the sensed cooking activity.

• Should the user forget to start the ventilation using the AUTO key, ECOAZUR® will automatically

start the ventilation as soon as cooking activity is sensed. Lights will also turn on automatically.

During the kitchen operation period:

• The hood exhaust systems will automatically adjust to the sensed cooking load (temperature,

vapor and smoke) by varying fan speeds and damper positions (if applicable).

• The make-up air units will adjust the supply airflow to the kitchen based on their related exhaust

fan airflow.

• The user may press the MAX key at any moment to override the hood ventilation to 100% (MAX

OVERRIDE). The system will automatically return to normal operations after a preset amount of

time.

When kitchen operation is over:

• The kitchen ventilation will automatically switch from COOKING to COOL DOWN, and ultimately

to IDLE when sensor activity and timers allow.

• The user may bypass off-delays by pressing the STOP key when sensed cooking activity allows.

• Lights will automatically turn off when all exhaust fans have reached IDLE mode.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 16 / 17

5 MAINTENANCE

5.1 TEMPERATURE SENSORS

Temperature sensors may be located in the hood collar as well as in the hood canopy. Temperature probes

rarely require cleaning. Should grease or other contaminants build up, clean the temperature probes using

cloth and soap. A good practice is to ensure that the hood cleaning procedures include cleaning the

temperature probes.

5.2 OPTIC SENSORS

Optic sensors are typically at both ends of a hood. An optic sensor rarely requires cleaning since it can

accommodate an accumulation of grease on its lenses. A good practice is to clean the optic lenses using

light duty soap and a cloth once a month.

No deterioration of system performance will occur due to dirty optic sensors unless an optic sensor is

blinking (warning indication on the keypad). Refer to the Troubleshooting section for more information on

the procedure to follow when an optic sensor is blinking.

5.3 KEYPAD DISPLAY

The ECOAZUR® keypad display may be cleaned using cloth and light duty soap when necessary.

5.4 EXHAUST DAMPERS AND PRESSURE TRANSMITTERS

Proper maintenance includes cleaning the damper blades and the exhaust duct pressure transmitter ports

as part of the hood and exhaust duct cleaning procedure. Prior to this cleaning operation, make sure to lock

out power to the ECOAZUR® processor panel as well as to the exhaust and supply fans. This will ensure the

dampers remain in the open fail-safe position during cleaning. In the event a damper does not fully open

during cleaning procedures, call a qualified professional to verify the V4MD damper actuator.

User’s Manual

© 2019 Intellinox. All Rights Reserved. E4UM_EN20190506

www.intellinox.com 17 / 17

6 TROUBLESHOOTING

Should the ECOAZUR® processor detect any problematic condition, a WARNING message will be

issued on the keypad display. Depending on the nature of the error, ECOAZUR® may force ventilation

to 100% speed in order to ensure proper ventilation. The ECOAZUR® processor may also be

programmed to trigger a digital output based on the ECOAZUR® error status to notify the BAS (Building

Automation System).

In most cases, WARNING messages require contacting a qualified professional to service the

ECOAZUR® system. Systems connected to the ECOAZUR® Cloud service benefit from a fast diagnostic

through an internet remote access (not available in all countries). However, some warnings are related

to end-user maintenance and may be addressed by the kitchen personnel. This is the case of the IB

MISALIGNED warning message. In such an event, the corresponding optic sensor’s blue lights will blink

as an indication that little or no light is received from its paired emitter. This occurs when:

Problem Solution

A very large amount of vapor is produced,

blocking the light beam of the optic pair. The

system will issue a momentary WARNING

message.

The WARNING message will disappear

automatically as soon as the cooking conditions

return to normal.

An object is blocking the optic sensor’s light

beam and is preventing the pair from seeing one

another.

Remove the object. If a component of the fire

suppression system is blocking the optic light

beam, call a qualified professional to ensure the

fire suppression system is correctly fastened to

hood. Relocate optic sensors if necessary.

Optic sensors are misaligned Ensure the blinking optic sensor pair is aligned

and the compression seal is correctly tightened.

Optic sensors are very dirty Use a soft moist cloth to clean optic sensor

lenses.

If none of the previous situations apply Call a qualified professional to service the

ECOAZUR® system.

Table of contents

Popular Fan manuals by other brands

UFO

UFO ATWFI-01 user manual

ExBrite

ExBrite ZPFL5215DCFMLED installation guide

Kichler Lighting

Kichler Lighting Lucian II 330241 instruction manual

Fantech

Fantech Jetstream JCE202-3 CONTENTS & INSTALLATION INSTRUCTIONS

Carrier

Carrier EconoMiser X Installation, Setup and Troubleshooting Manual

Hunter

Hunter 23488 Manual de Installatión y Operatión

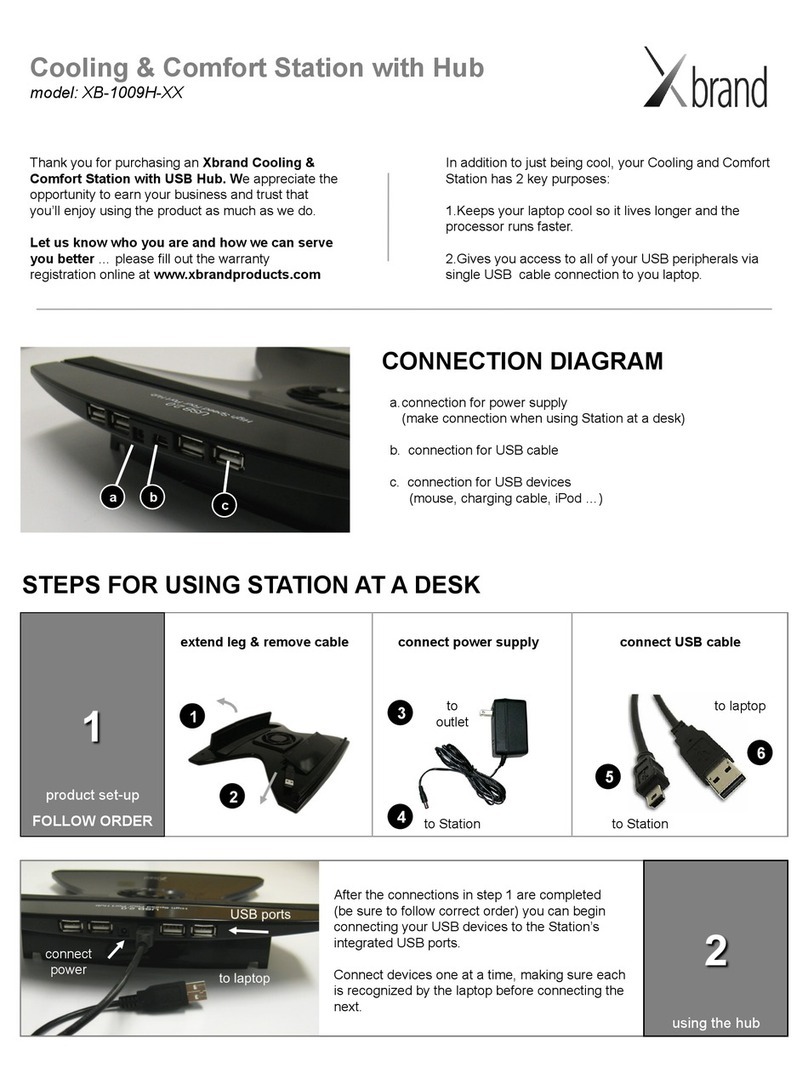

Xbrand

Xbrand Cooling & Comfort Station with Hub... user guide

Kichler Lighting

Kichler Lighting VASSAR instruction manual

Korona

Korona 81002 instruction manual

Weinmann

Weinmann MEDUMAT Easy CPR Service and repair instructions

Wirata

Wirata TF-160A instruction manual

Sunbeam

Sunbeam FA7500 Instruction booklet