IntelliSAW IRM-48 User manual

IntelliSAW IRM-48 Reader

INSTALLATION MANUAL

Document:

910.00371.0001

Revision:

1.1

Date:

14 July 2016

Page 1 of 28

IntelliSAW IRM-48 Reader

Installation Manual Page 2 of 28

IRM-48 Reader 910.00371.0001

Copyright © 2016, IntelliSAW

IntelliSAW reserves the right to make technical changes or modify the contents of this document without

prior notice. IntelliSAW is not responsible for errors or possible lack of information in this document.

IntelliSAW reserves all rights in this document and in the subject matter and illustrations contained

therein. Any reproduction, disclosure to third parties or utilization of its contents, in whole or in part,

without prior written consent of IntelliSAW is forbidden.

IntelliSAW

Rosemount Measurement

100 Burtt Rd.

Andover, MA 01810

+1-978-409-1534

WARRANTY

These products are warranted to be free from functional defects in material and workmanship at time of

manufacture and to conform at that time to the specifications set forth in the relevant instruction manuals

or data sheets, for such products for a period of one year.

Reference IntelliSAW terms and conditions provided at time of purchase for complete warranty details.

IntelliSAW IRM-48 Reader

Installation Manual Page 3 of 28

IRM-48 Reader 910.00371.0001

IMPORTANT INFORMATION

This symbol identifies messages in this document related to safety.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or

serious injury.

Failure to follow the instructions given will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

Failure to follow the instructions given can result in death or serious injury

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury.

Failure to follow these instructions can result in personal injury.

NOTICE

NOTICE alerts you to practices unrelated to personal injury, such as those that can cause property

damage.

Failure to follow these instructions can result in property damage.

IMPORTANT

IMPORTANT indicates additional information about making effective use of this product.

IntelliSAW IRM-48 Reader

Installation Manual Page 4 of 28

IRM-48 Reader 910.00371.0001

TABLE OF CONTENTS

1 Introducing the IRM-48 Reader........................................................................................... 6

1.1 Models......................................................................................................................... 6

1.2 Instructions for Use...................................................................................................... 6

2 Product Overview................................................................................................................ 7

2.1 System Inputs and Outputs.......................................................................................... 7

2.2 Labeling....................................................................................................................... 7

2.2.1 Serial ID Label...................................................................................................... 7

2.2.2 Compliance Label................................................................................................. 7

2.2.3 Product Label........................................................................................................ 8

2.3 Connectors.................................................................................................................. 8

2.3.1 USB Cable Connector........................................................................................... 9

2.3.2 Power and Modbus RTU Connector ..................................................................... 9

2.3.3 SMA (RF) Connectors........................................................................................... 9

2.3.4 Humidity Sensor Connector.................................................................................10

2.4 Power / Feedback LED...............................................................................................10

3 Installation..........................................................................................................................11

3.1 Unpacking...................................................................................................................11

3.2 Dimensions.................................................................................................................12

3.3 Din Rail Mounting .......................................................................................................12

3.3.1 Installation Location.............................................................................................13

3.3.2 Recommended Spacing.......................................................................................13

4 Wiring ................................................................................................................................14

4.1 Power and Modbus RTU Connections........................................................................15

4.1.1 Power ..................................................................................................................15

4.2 Communication Connections......................................................................................17

4.3 Humidity Sensor Connections.....................................................................................19

4.4 Air Interface Connections............................................................................................19

5 Sensor Installation & System Configuration .......................................................................20

5.1 Sensor Installation ......................................................................................................20

5.2 System Configuration..................................................................................................20

6 System Integration.............................................................................................................21

6.1 Modbus Commands....................................................................................................21

6.2 Modbus Registers.......................................................................................................22

7 Specifications.....................................................................................................................24

IntelliSAW IRM-48 Reader

Installation Manual Page 5 of 28

IRM-48 Reader 910.00371.0001

8 Product Certifications.........................................................................................................25

8.1 Compliance.................................................................................................................25

8.2 Wireless Certifications ................................................................................................26

8.2.1 Telecommunication Compliance..........................................................................26

8.2.2 Approved Antennas .............................................................................................26

8.2.3 Federal Communications Commission (FCC)......................................................26

8.2.4 Industry Canada (IC)............................................................................................27

9 Contact..............................................................................................................................28

IntelliSAW IRM-48 Reader

Installation Manual Page 6 of 28

IRM-48 Reader 910.00371.0001

1INTRODUCING THE IRM-48 READER

The IntelliSAW IRM-48 Reader is a remote monitoring unit that provides temperature, partial

discharge (PD), and humidity sensing for predictive condition-based monitoring of electrical

power critical assets such as switchgear, circuit breakers, and bus ducts. Multiple IRM Readers

can be bussed to a CAM-4 system or existing SCADA system providing immediate data display

and alarming.

1.1 MODELS

This manual covers the following models:

•IRM-48-T00: Temperature only monitoring

•IRM-48-TP0: Temperature and PD monitoring

•IRM-48-T0H: Temperature and Humidity monitoring

•IRM-48-TPH: Temperature, PD, and Humidity monitoring

1.2 INSTRUCTIONS FOR USE

The IRM-48 Reader is intended for use in the measurement of Temperature, Humidity, Ambient

Temperature, Partial Discharge and Surface Discharge of Low to Medium Voltage air insulated

Electrical Equipment. Readers connect Air Interfaces through RF cables for wireless

interrogation of SAW temperature sensors and Partial Discharge monitoring, while humidity and

ambient temperature sensors are wired to the readers. Interfacing to the IntelliSAW CAM-4 or

an existing SCADA, DCS, or historian is easily accomplished with industry standard Modbus

RTU (RS485 serial).

WARNING

The Reader is not intended for use in monitoring assets above 40KV

The reader is intended to be installed in Low Voltage compartments of switchgear or in similar

types of assets; a unit can also be installed in a weather proof environmental enclosure. The

unit is intended for use at a maximum altitude of 5km, between -40°C to +70°C and between 10

- 95% non-condensing relative humidity. The reader has been recognized for meeting UL

61010-1 safety requirements for electrical equipment. Please refer to Specifications and

Compliance for complete ratings.

WARNING

The Reader is not intended for installation in asset Medium Voltage or High Voltage

Compartments. Only sensors and antennas are intended for installation in medium

voltage Compartments.

IntelliSAW IRM-48 Reader

Installation Manual Page 7 of 28

IRM-48 Reader 910.00371.0001

2PRODUCT OVERVIEW

2.1 SYSTEM INPUTS AND OUTPUTS

The maximum system inputs and outputs are as follows:

Inputs

Outputs

12 temp sensors

Communications: Modbus RTU

4 air interfaces (PD / temp)

8 humidity sensors

Power: 24V to 60V DC (3.5W)

2.2 LABELING

The Reader has two labels on the bottom of the unit, a Serial ID label and a compliance label,

and one main product label on the top.

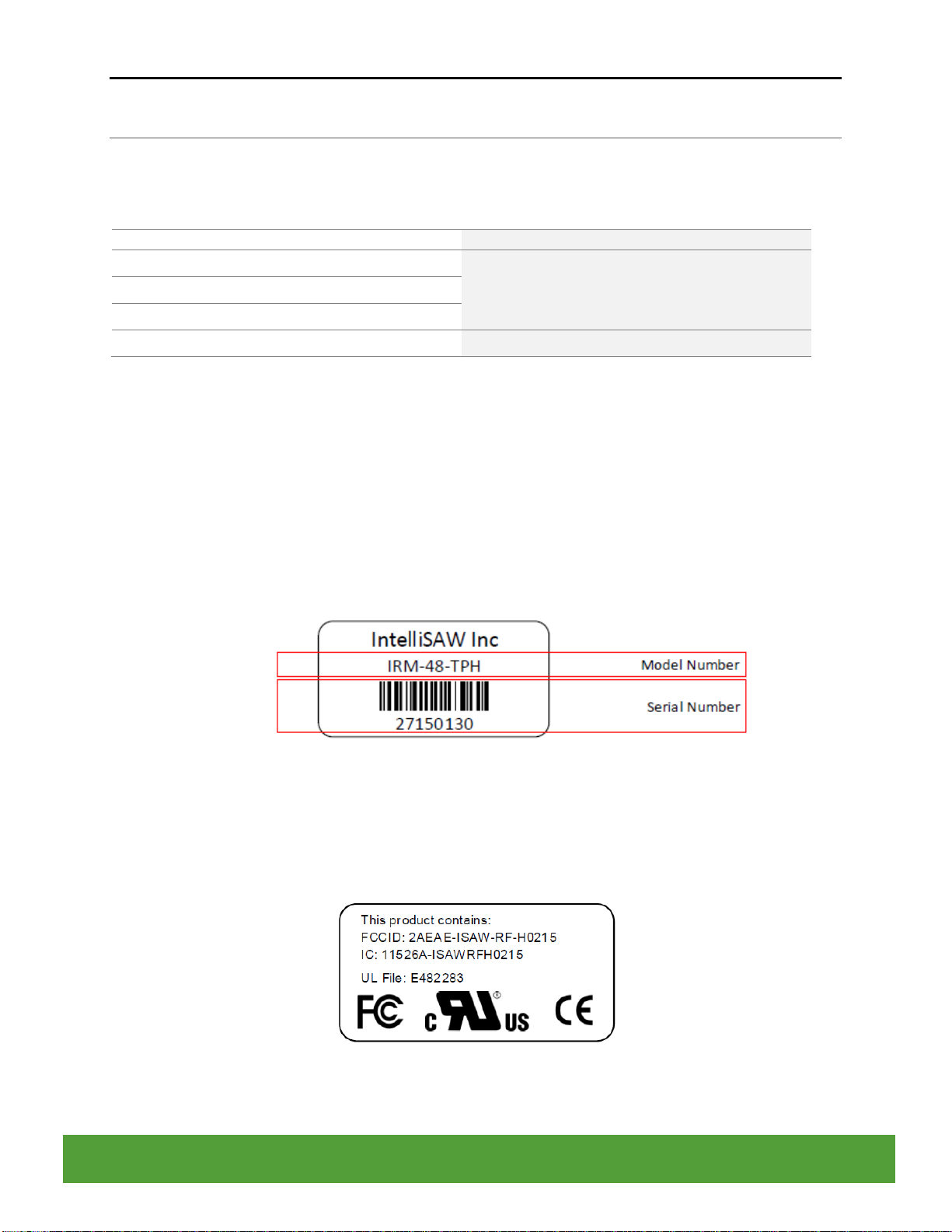

2.2.1 Serial ID Label

The IRM-48 Serial ID label provides a model number and serial number for the reader.

Figure 1: IRM-48 Model Number and Serial ID Label

2.2.2 Compliance Label

The compliance label provides product certification information.

Figure 2: IRM-48 Compliance Label

IntelliSAW IRM-48 Reader

Installation Manual Page 8 of 28

IRM-48 Reader 910.00371.0001

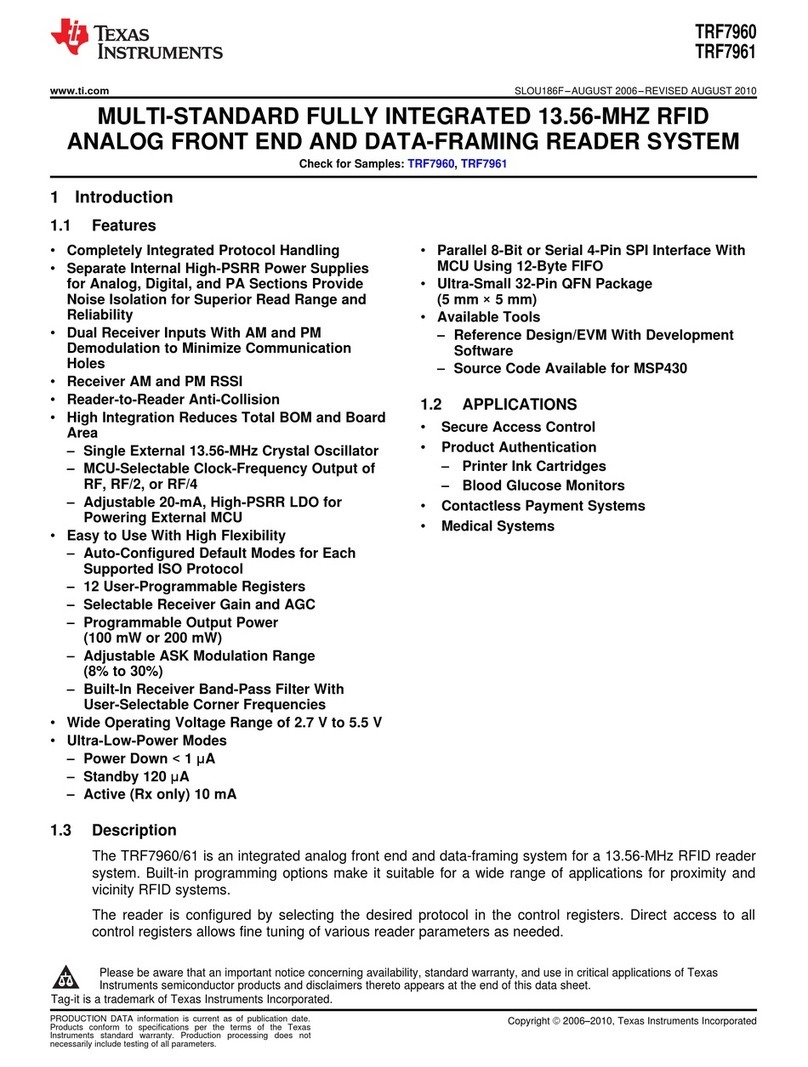

2.2.3 Product Label

The top product label provides guidance to the model type, product voltage and power ratings,

and connector interfaces.

Figure 3: Product top label

Model identification boxes will be red if the option is available in the reader.

2.3 CONNECTORS

The product has up to seven connectors (depending on model):

•(1) USB connector –used for configuration

•(1) Power and Modbus RTU (RS485) connector

•(4) SMA (RF) connectors –used for air interface connections

•(1) Ground lug –chassis Function Earth (FE)

•(1) Humidity connector –available with humidity option

Figure 4: Front and side views of IRM-485 Reader

Power &

Modbus

RTU

USB

Humidity

SMA (RF)

Model Identification

Voltage and

power ratings

Ground Lug

IntelliSAW IRM-48 Reader

Installation Manual Page 9 of 28

IRM-48 Reader 910.00371.0001

2.3.1 USB Cable Connector

Interface

Name

Description

USB

USB

USB mini used for unit configuration

2.3.2 Power and Modbus RTU Connector

Pin

Name

Description

V+

Power In +

Input power range from 24 to 60V DC.

V-

Power In -

Input power range from 24 to 60V DC.

FE

Functional Earth

This pin is used for ground and shield connectivity.

Should use separate wire from Case Ground.

D-COM

DATA Common

Common input for Modbus RTU (RS485)

DATA-

DATA Negative

Negative Input for Modbus RTU (RS485)

DATA+

DATA Positive

Positive Input for Modbus RTU (RS485)

2.3.3 SMA (RF) Connectors

Pin

Name

Description

P1

RF Port 1

Air Interface Radio Frequency Port 1

P2

RF Port 2

Air Interface Radio Frequency Port 2

P3

RF Port 3

Air Interface Radio Frequency Port 3

P4

RF Port 4

Air Interface Radio Frequency Port 4

Ground

Case Ground

Chassis ground lug connection, required for safety when air

interfaces are near energized conductors.

IntelliSAW IRM-48 Reader

Installation Manual Page 10 of 28

IRM-48 Reader 910.00371.0001

2.3.4 Humidity Sensor Connector

Pin

Name

Description

H-PWR

Humidity Power

Humidity Cable Power Input from Humidity Sensor

H-DAT

Humidity Data

Humidity Cable DATA Input from Humidity Sensor

H-CLK

Humidity Clock

Humidity Cable Clock Input from Humidity Sensor

H-COM

Humidity

Common

Humidity Cable Common Input from Humidity Sensor

2.4 POWER /FEEDBACK LED

The product has one power / feedback LED.

LED States:

•No Illumination: No Power

•Solid Green: Power, no measurements

•Green / Amber toggle: Automated measurements

•Fast flashing Amber: Rebooting

LED

IntelliSAW IRM-48 Reader

Installation Manual Page 11 of 28

IRM-48 Reader 910.00371.0001

3INSTALLATION

IMPORTANT

•The installation instructions are only for the IRM-48 Reader.

•It is assumed an Air Interface Antenna, and Sensors have been installed and configured.

WARNING

INSTALLATION AND CONFIGURATION SHOULD BE PERFORMED ONLY BY

PERSONNEL WHO ARE TECHNICALLY COMPETENT AND AUTHORIZED TO DO SO.

LOCAL REGULATIONS REGARDING ELECTRICAL INSTALLATION AND SAFETY MUST

BE OBSERVED.

Failure to follow the instructions given can result in death or serious injury

WARNING

THE USE OF THIS EQUIPMENT IN A MANNER NOT SPECIFIED IN THIS MANUAL OR BY

THE MANUFACTURER MAY IMPAIR PROTECTION OF THE USER AND EQUIPMENT.

Failure to follow the instructions given can result in death or serious injury

CAUTION

THIS EQUIPMENT IS DESIGNED FOR INSTALLATION IN AN ENCLOSURE THAT

PROVIDES ADEQUATE PROTECTION AGAINST ELECTRIC SHOCK.

Failure to follow these instructions can result in personal injury.

3.1 UNPACKING

1. Remove the product from its packing. Retain the packing for future use, to transport the

instrument to a different site or to return it to the supplier for repair/testing.

2. Examine the delivered items for damage or defects. If any are found, contact the courier

immediately.

3. In the Box:

a. Reader with a pre-installed din rail mounting clip

b. Power and Modbus RTU terminal block (6 position 5.08mm Plug)

IntelliSAW IRM-48 Reader

Installation Manual Page 12 of 28

IRM-48 Reader 910.00371.0001

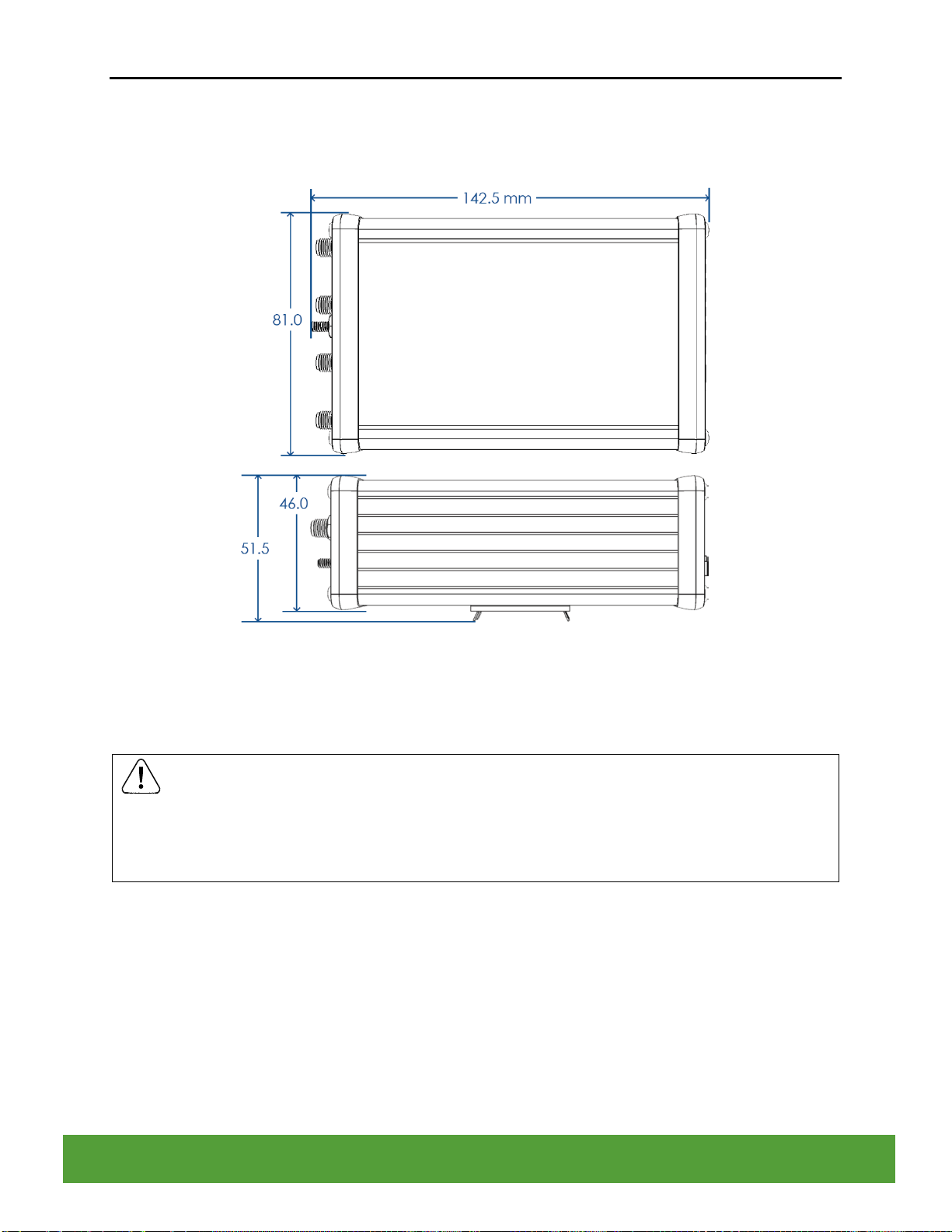

3.2 DIMENSIONS

The IRM-48 instrument has dimensions of 81 H × 142.5 W x 51.5 mm D (3.19 H × 5.61 W ×

2.03 in D).

Figure 5: IRM-48 Dimensions (in mm)

3.3 DIN RAIL MOUNTING

CAUTION

ENSURE THE INSIDE OF THE PANEL IS WITHIN THE READER’S OPERATING

TEMPERATURE AND THAT THERE IS ADEQUATE AIR FLOW TO PREVENT

OVERHEATING.

The IRM-48 Reader is mounted on standard 35 mm din rail. It can be mounted either vertically

or horizontal by changing the orientation of the mounting clip.

The din rail mounting clip is located on the back of the IRM-48 Reader and is screwed on to the

frame. The clip is normally oriented for vertical installation of the reader on to a din rail. To

change the installation mounting orientation, remove the 2 screws holding the mounting clip to

the frame of the reader. Once removed, turn the mounting clip 90 degrees in the desired

direction and screw on the mounting clip to the two additional tapped holes on the frame of the

reader.

IntelliSAW IRM-48 Reader

Installation Manual Page 13 of 28

IRM-48 Reader 910.00371.0001

Figure 6: Horizontally Installed Din Rail Mounted Reader

Figure 7: Vertically Installed Din Rail Mounted Reader

3.3.1 Installation Location

The IRM-485 Reader is intended for installation in LV compartments of switchgear, other

electrical assets, or in weather protected enclosed locations. The Reader is required to be

installed within 7m of the Air Interface, the maximum length of the Air Interface Antenna RF

cable.

3.3.2 Recommended Spacing

It is recommended to allow up to 5 cm (2 in.) for the IRM-48 Reader connectors. It is best to

have the USB connector easily accessible.

IntelliSAW IRM-48 Reader

Installation Manual Page 14 of 28

IRM-48 Reader 910.00371.0001

4WIRING

WARNING

SYSTEM WIRING SHOULD BE PERFORMED ONLY BY PERSONNEL WHO ARE

TECHNICALLY COMPETENT AND AUTHORIZED TO DO SO. LOCAL REGULATIONS

REGARDING ELECTRICAL INSTALLATION AND SAFETY MUST BE OBSERVED.

Failure to follow the instructions given can result in death or serious injury

WARNING

TO AVOID ELECTRICAL SHOCK. AC POWER WIRING MUST NOT BE CONNECTED TO

THE SOURCE UNTIL ALL WIRING CONNECTIONS PROCEDURES ARE COMPLETED.

Failure to follow the instructions given can result in death or serious injury

WARNING

CHECK THE INFORMATION LABEL ON THE CASE TO DETERMINE THE CORRECT

VOLTAGE BEFORE CONNECTING TO A LIVE SUPPLY.

Failure to follow the instructions given can result in death or serious injury

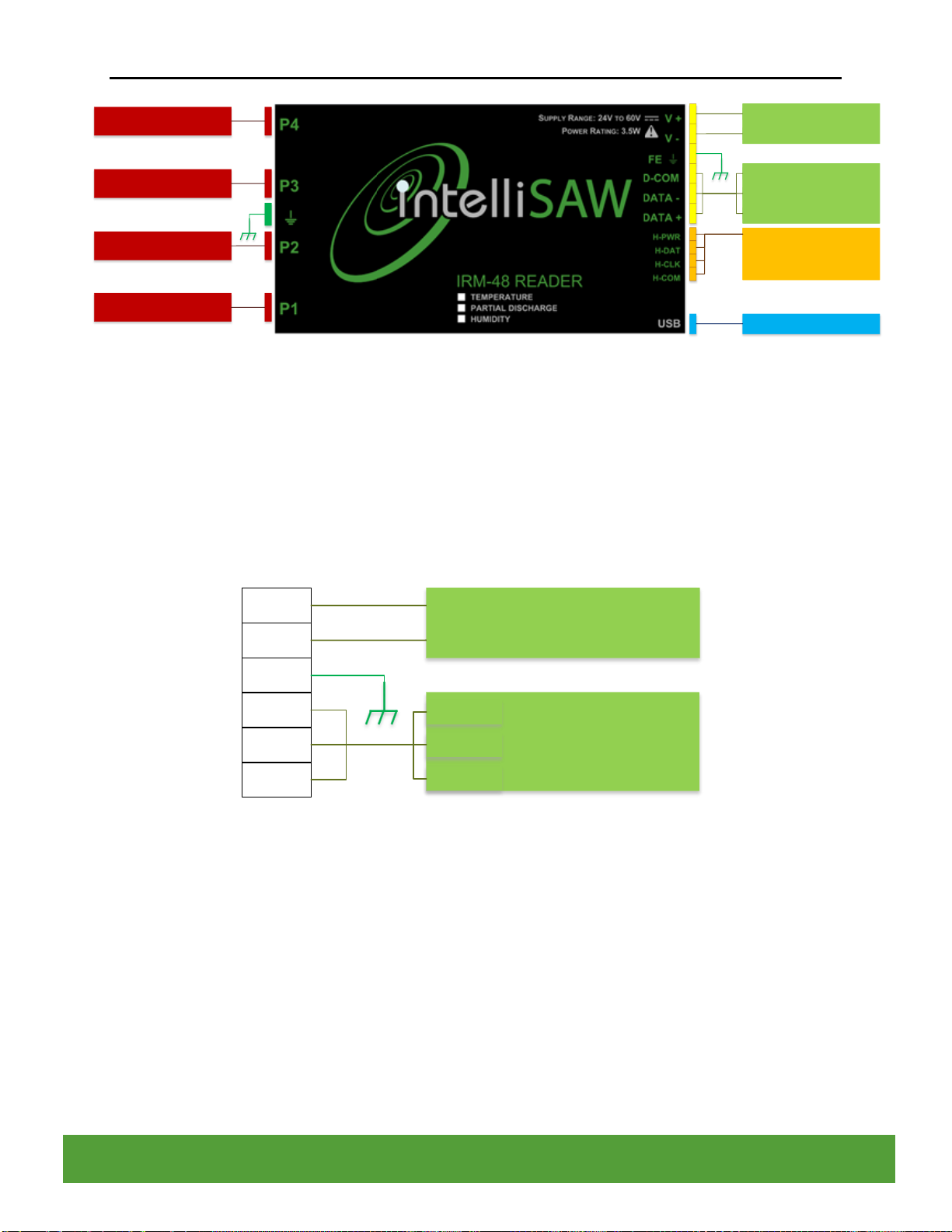

IMPORTANT

The wiring diagram below shows all possible combinations. The actual connections required

depend upon your system installation.

The Reader terminal connections are illustrated in the figure below. In general, all wiring

connections are made to the instrument after it is installed.

IntelliSAW IRM-48 Reader

Installation Manual Page 15 of 28

IRM-48 Reader 910.00371.0001

Power Supply

V+

V-

Modbus RTU

D-COM

DATA -

DATA +

Humidity Sensor

M12 Connector

Laptop

AIR INTERFACE ANTENNA

AIR INTERFACE ANTENNA

AIR INTERFACE ANTENNA

AIR INTERFACE ANTENNA

Figure 8: IRM-48 Connections and Common Wiring

4.1 POWER AND MODBUS RTU CONNECTIONS

The IRM-48 Reader uses a single connector for power and Modbus RTU communication. The

Connector is a 6 position Male connector. The connector accepts 16-26 AWG wire.

It is recommended that Ferrules be used for all terminating wires.

V+

V-

FE

D-COM

DATA -

DATA +

24V - 60V DC

Power Supply

V+

V-

Modbus RTU

D-COM

DATA -

DATA +

Figure 9: Power and Modbus RTU Connections

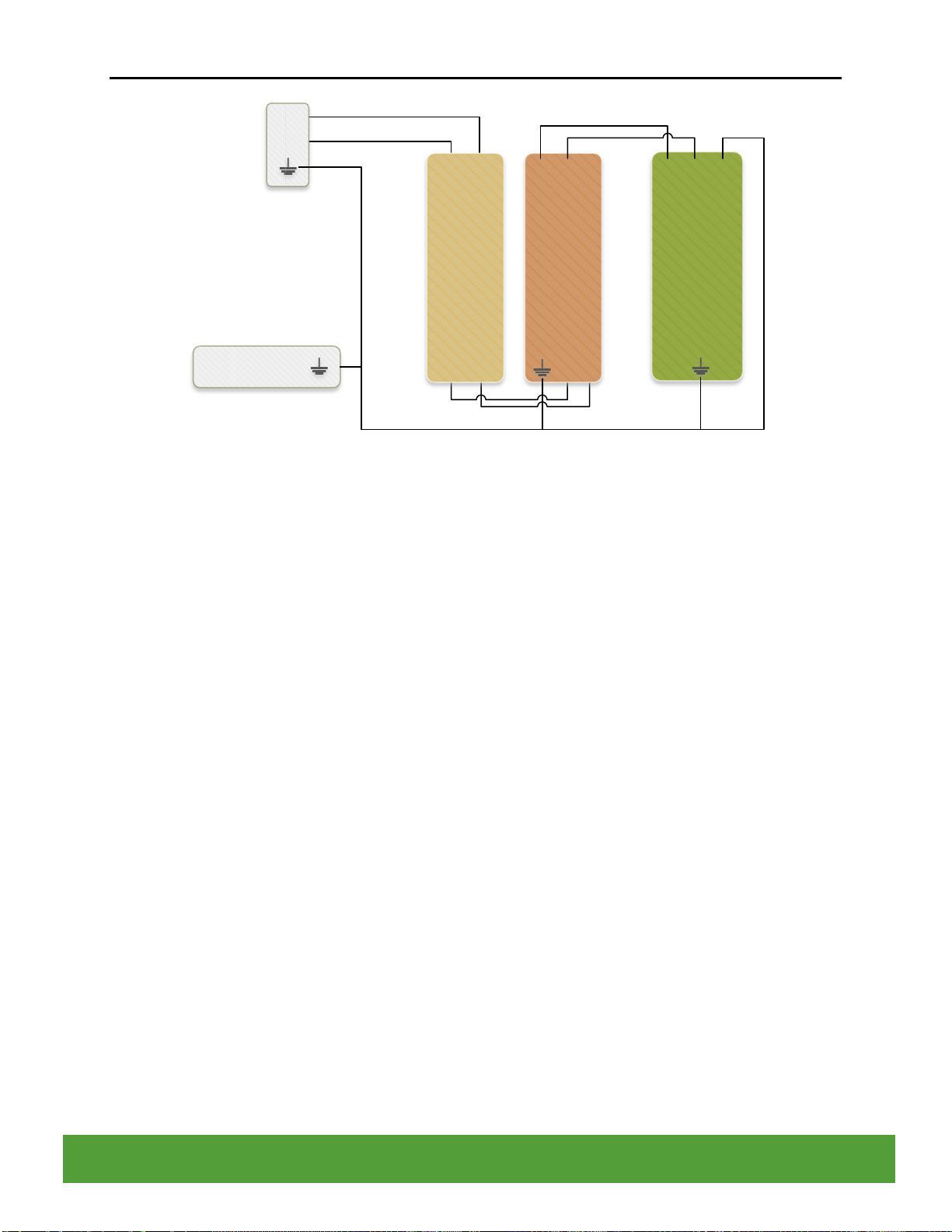

4.1.1 Power

The IRM-48 Reader operates at 48VDC nominal power, but can operate between 24 to 60V DC

with a total power consumption of 3.5 W. The following block diagram outlines the

recommended power wiring for the IRM-48 Reader with a 2-pole circuit breaker and AC/DC

power supply. Surge suppression devices can also be installed on the input line and neutral if

higher safety rating is required.

IntelliSAW IRM-48 Reader

Installation Manual Page 16 of 28

IRM-48 Reader 910.00371.0001

AC/DC

Power

Supply

N L

V+ V-

N

L

Input Power

2-pole

Circuit

Breaker

1 3

2 4

IntelliSAW

Reader

V+ V- FE

Low-voltage

Compartment FE

Figure 10: IntelliSAW Reader Recommended Power Wiring

4.1.1.1 Local versus bussed DC power

IntelliSAW recommends the use of a DC power supply in the same low-voltage compartment as

the reader. This is the simplest and most flexible option. It is possible to run a DC power bus

alongside the RS485 bus, however, this option requires careful consideration of the wire

diameter. This method also increases the likelihood of EFT or surge voltages along the DC bus.

4.1.1.2 DC power wire diameter considerations

Power connections are recommended to be a minimum 18 AWG, tin-coated, soft drawn copper

per ASTM B8, Class B stranding, 300V rated. Insulation shall be EP (ethylene propylene) or

EPCP (ethylene propylene chlorosulfonated polyethylene compound).

If bussed power is being considered, the wire gauge must be selected to prevent excessive

voltage drop between the DC power source and the reader that is electrically farthest from the

source. The larger wire diameter required could force the use of a custom cable for DC power

as the power bus wire cannot be the same gauge as the communications bus (RS485). Most

standard RS485 bus installations use wire diameters of about 0.5mm or 24 AWG; this wire size

may be too small to properly support DC power to all the readers if there are many readers a

bus.

4.1.1.3 Functional Earth wiring

Functional earth (FE) connection should always be installed between the reader’s FE terminal,

FE post, and the FE connection in the low-voltage compartment. FE at the cable connection

shunts transients at the cables, while case ground provides both RF shielding and safety

against induced voltages on air interface cables.

IntelliSAW IRM-48 Reader

Installation Manual Page 17 of 28

IRM-48 Reader 910.00371.0001

IMPORTANT

There are two INDEPENDENT connections that shall be individually wired to the

Protective Earth of the installation site such that there is an extremely low impedance

between the enclosures; this is best achieved using the shortest possible ground

cable.

4.2 COMMUNICATION CONNECTIONS

The IntelliSAW readers are connected in a network using a standard, half-duplex RS485 bus.

This is a 3-wire bus, differential signals for data +/- and a common signal return. The common

signal is clamped to PE for safety and connects to the line driver through a high resistance to

prevent ground loops. The figure below shows the various elements of a network in a

switchgear substation.

Figure 11: RS485 Data Communication Bus Topology

4.2.1.1 Recommended Cabling

IntelliSAW recommends the use of shielded cable for the RS485 wiring, providing at least one

twisted pair, one single line, and a drain wire, although typical cable has two twisted pair. The

twisted pair provides DATA+/- signals to each reader while the single line would be for D-COM,

providing a low-impedance return for each reader.

4.2.1.2 Bus cable shielding

The drain wire associated with the RS485 bus shielding foil should be connected to the

protective earth at the source end (the end of the line segment closest to the bus master) with

the destination end left unconnected. This prevents ground loops and induced noise. Each

IntelliSAW IRM-48 Reader

Installation Manual Page 18 of 28

IRM-48 Reader 910.00371.0001

segment of the bus should be shield-terminated to the protective earth in the cabinet from which

it originates.

4.2.1.3 Bus resistive termination

The RS485 bus needs to be terminated at each end with 120 Ω resistors when long stretches of

cable are used. This ensures that the bus has the correct impedance. In general, RS485

adapters and bus masters provide the source impedance internally and should be located at

one end of the bus.

If the bus length is less than 2% of the maximum (20 meters at 9600 baud), the termination

resistor may be omitted, as long as the bus master has termination and failsafe resistors.

4.2.1.4 Bus data rate (baud rate) considerations

The RS485 bus data rate is dependent on the bus cable length and the number of readers on

the bus. In industrial environments, slower data communication rates are generally more

reliable; IntelliSAW recommends either 19200 baud or 9600 baud for the data rate.

Bus length

Bus cable length has an impact on the overall data rates which can be achieved. A

conservative rule for RS485 uses the equation: (baud rate * cable length (m)) < 10 x 106. A

9600 baud network would require a bus less of (10 x 106÷ 9600), or 1042 meters (about 3400

feet). This is perfectly adequate for most substation installations.

Number of Readers

As the number of readers increase on the RS485 bus, the baud rate must be adjusted to

accommodate the electrical characteristics of the communication protection circuits. The

following table is a guide for number of readers versus system baud rate:

Readers

Baud Rate

1

115,200

1 –8

38,400

1 –16

19,200

1 –32

9,600

IntelliSAW IRM-48 Reader

Installation Manual Page 19 of 28

IRM-48 Reader 910.00371.0001

4.3 HUMIDITY SENSOR CONNECTIONS

The Humidity Sensor Connector is a 4 position male connector. The connector accepts 16-26

AWG wire. It is recommended that Ferrules be used for all terminating wires. The IntelliSAW

Humidity sensor is shipped with a cable assembly.

H-PWR

H-DAT

H-CLK

H-COM

M12 Connector HUMIDITY

SENSOR

Figure 12: Humidity Connector

4.4 AIR INTERFACE CONNECTIONS

The IRM-48 Reader supports up to 4 Air Interface Antenna connections (P1-P4). The Air

Interface Antenna connections on the Reader are female SMA connections. The Air Interface

Antenna’s connect to the Reader through RF cables with Male SMA Connectors on each end.

RF Cables are provided by IntelliSAW when purchasing air interfaces. Only IntelliSAW provided

antennas are suitable for the desired performance and for compliance with transmitter

authorizations.

IntelliSAW IRM-48 Reader

Installation Manual Page 20 of 28

IRM-48 Reader 910.00371.0001

5SENSOR INSTALLATION &SYSTEM CONFIGURATION

5.1 SENSOR INSTALLATION

This manual does not cover specific sensor installation. Please reference the IntelliSAW

Sensor Installation Manual for more detail.

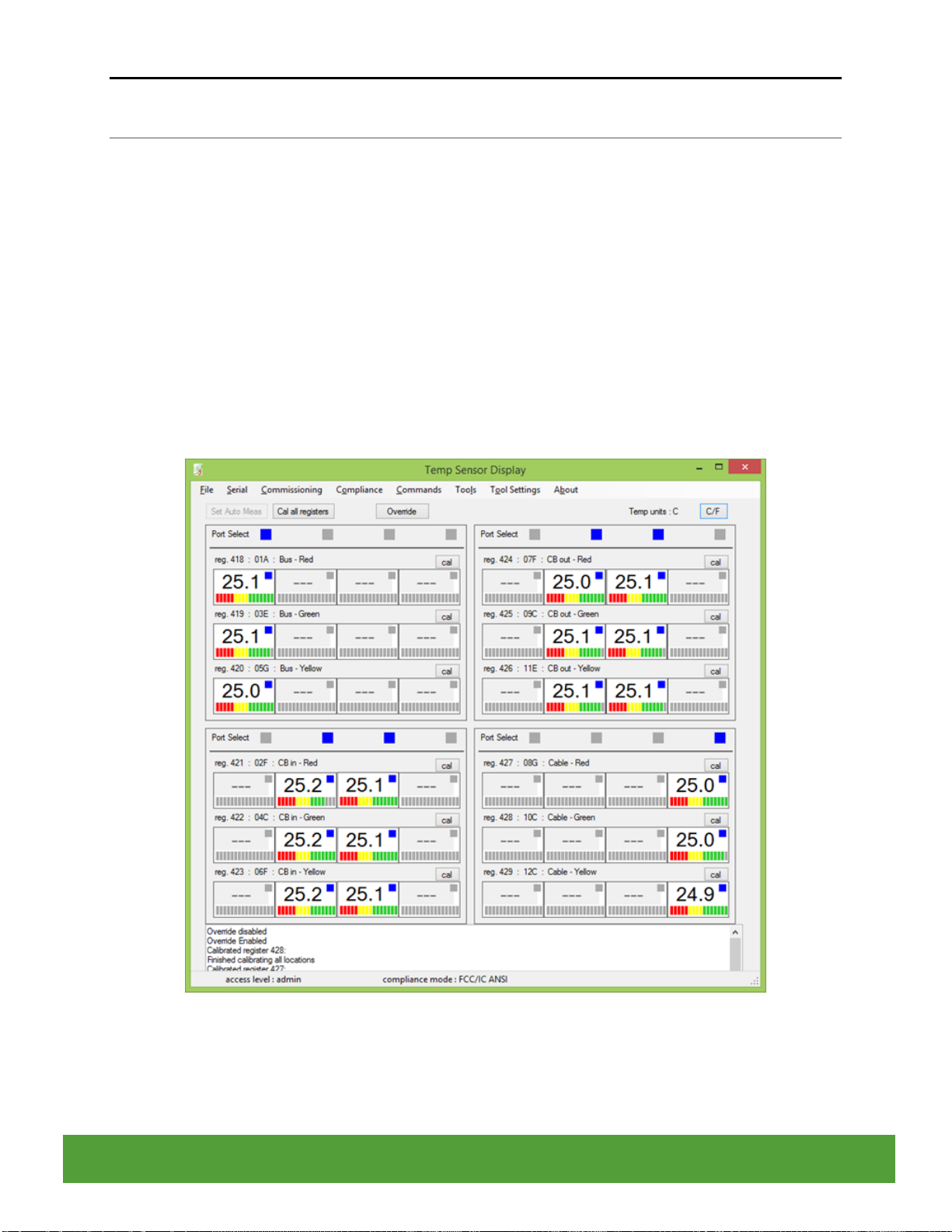

5.2 SYSTEM CONFIGURATION

The Reader requires system configuration for the associated installed temperature sensors, air

interfaces, and humidity sensors. Configuration is performed through the USB port and uses

the IntelliSAW Measurement Configuration Software. Details will not be discussed here, please

refer to the Configuration Software User Manual for detailed instructions.

Figure 13: IntelliSAW System Configuration Software

Table of contents